TPE wire extrusion faces challenges with adhesion and surface smoothness, impacting product quality and performance across various electrical applications.

TPE wire extrusion issues like poor adhesion and surface roughness can be resolved by optimizing extrusion parameters, material selection, and cooling methods to maintain consistent quality and performance.

While understanding the core challenges of TPE wire extrusion is essential, exploring strategies for parameter optimization can significantly enhance surface properties and adhesion. Learn more about improving your extrusion process for superior wire quality.

TPE in wire extrusion ensures flexibility and weather resistance.True

TPE materials are known for their flexibility and durability, making them ideal for applications requiring resilient and adaptable wire properties.

Adhesion issues in TPE extrusion are inevitable.False

Although challenging, adhesion problems can be mitigated through proper material selection and process optimization, minimizing defects in TPE wire extrusion.

- 1. What Specific Factors Contribute to Poor Adhesion of TPE Wire Extrusion?

- 2. What are the Methods to Improve the Adhesion of TPE Wire Extrusion?

- 3. What are the Reasons for the Non-Smooth Surface of TPE Wire Extrusion?

- 4. What are the Methods to Improve the Surface Smoothness of TPE Wire Extrusion?

- 5. How Does Bonding Quality and Surface Smoothness Affect the Performance of TPE Wire?

- 6. Conclusion

What Specific Factors Contribute to Poor Adhesion of TPE Wire Extrusion?

Poor adhesion in TPE wire extrusion can lead to significant manufacturing issues, affecting quality and performance in various applications.

Poor adhesion in TPE wire extrusion arises from surface contamination, improper temperatures, and incompatible materials. To improve adhesion, ensure cleanliness, optimize processing conditions, and use compatible materials.

Material Compatibility

The compatibility of the cover layer and the conductor is a big deal when it comes to extruding TPE wire. If they don’t get along, the adhesion will be affected.

Extrusion Temperature

The temperature of extrusion is very important for the fluidity, cross-linking and other properties of TPE materials. If the temperature is too high or too low, it will affect the adhesion.

Extrusion Speed

The extrusion speed is too fast, so the material doesn't stay in the nozzle for long enough to crosslink properly, which reduces adhesion. If the speed is too slow, the material can crosslink too much, which also affects adhesion.

Contaminated surfaces always lead to poor adhesion in TPE wire extrusion.True

Contaminants act as barriers, preventing proper bonding between layers and resulting in adhesion failure.

Extreme temperature settings have no impact on TPE wire adhesion.False

Improper temperatures can affect material flow and bonding, leading to insufficient adhesion.

What are the Methods to Improve the Adhesion of TPE Wire Extrusion?

Improving adhesion in TPE wire extrusion is critical for enhancing product durability and performance across various applications.

Improving TPE wire extrusion adhesion involves surface treatments, adhesive primers, and optimizing extrusion parameters to enhance material compatibility and surface energy for stronger bonds.

Optimize Material Formulation

Choose TPE materials that work well with the conductor materials to make them stick better. You can also make them stick better by changing the recipe, like adding sticky stuff and crosslinking agents.

Adjustment of Extrusion Temperature

Based on the performance of TPE, choose the right extrusion temperature1. Make sure the material flows well, but try to lower the temperature to keep the material in the head for less time and prevent it from cross-linking too much.

Control the Extrusion Speed

To make the material stay in the machine head for a moderate time to ensure adequate cross-linking, adjust the extrusion speed2. At the same time, avoid insufficient fluidity of the material due to too fast speed or excessive cross-linking of the material due to too slow speed.

Surface treatments can significantly improve TPE wire adhesion.True

Techniques like corona and plasma treatment increase surface energy, promoting better bond formation with adhesives and other materials.

All TPEs are naturally compatible with adhesives and require no additional treatment.False

Not all TPEs bond well without treatment; specific surface modifications are often necessary to enhance adhesion with adhesives.

What are the Reasons for the Non-Smooth Surface of TPE Wire Extrusion?

TPE wire extrusion can occasionally result in non-smooth surfaces, affecting product quality and consistency. Understanding the root causes is essential for ensuring optimal production outcomes.

Non-smooth TPE wire surfaces result from improper die design, material flow inconsistency, or temperature fluctuations. Resolving these issues enhances surface quality and product performance.

Extrusion Temperature

-

If the extrusion temperature is too high or too low: the surface of the TPE wire will not be smooth. When the temperature is too high, the material is too fluid, and the surface is prone to bubbles, burrs, and other defects. When the temperature is too low, the material is not fluid enough, and the surface is prone to unevenness.

-

Extrusion temperature is not enough: let me give you an example. We make tension tube products. We modify them with SEBS substrate. Many manufacturers use SBS substrate. We all know that SEBS-modified TPE extrusion will be higher than SBS-modified TPR extrusion. We have encountered many customers who used to use TPR extrusion pipe. They use our TPE extrusion temperature according to the TPR extrusion problem.

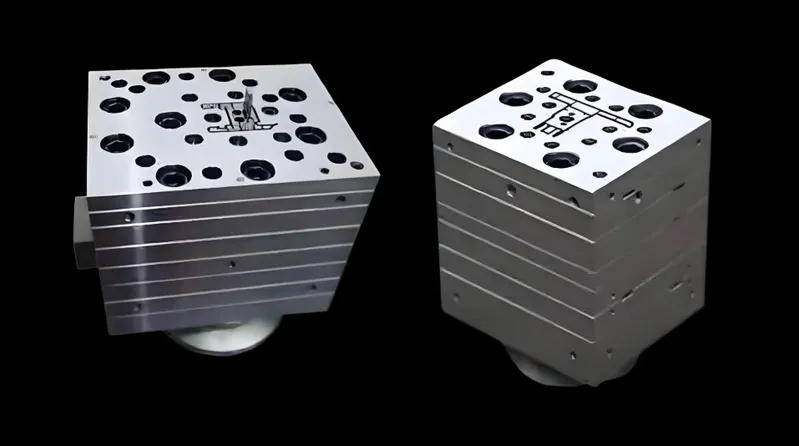

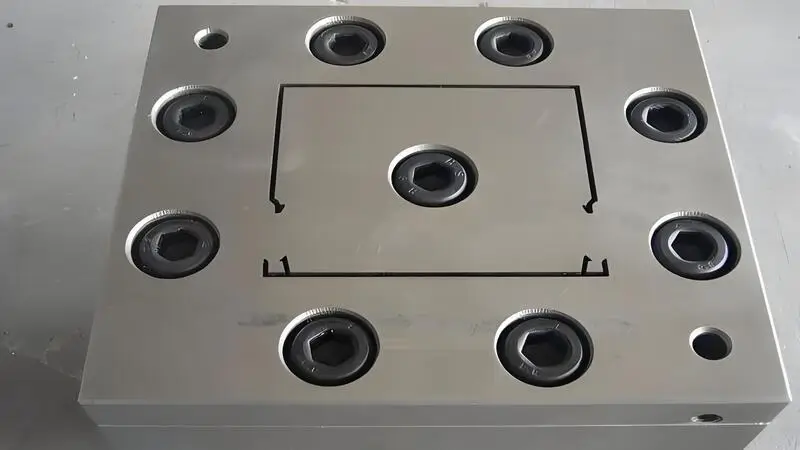

Mold Problems

- Mold design is not reasonable or the mold wall is not smooth: mold design3 is not reasonable or the mold wall is not smooth may lead to TPE wire surface is not smooth. Unreasonable mold design may lead to uneven extrusion and stretching of the material in the extrusion process; unsmooth mold walls may lead to material scratches or burrs on the mold walls.

-

The use of too much mold release agent: using too much mold release agent can cause defects on the surface of the products. Small runner and gate sizes, as well as poor exhaust, can also result in poor surface gloss.

-

Mold surface treatment: the smoothness of the mold surface affects the surface gloss of TPE products. If the mold surface is rough or not polished, then the products will copy the defects of the mold surface, resulting in the finished product surface luster. Dirt and oxides left on the mold surface will also affect the surface quality of the products.

Material Issues

-

Material Formulation4: the formulation of the TPE material is also an important factor that affects the surface smoothness. For example, the addition of flame retardants, fillers, and other additives may affect the fluidity, viscosity, and other properties of the material, which in turn affects the surface smoothness.

-

Material problems: if there are impurities mixed in the material, the product surface will not be glossy when it is not dry. The material has poor thermal stability and will decompose when heated.

-

Glossiness of TPE materials: the glossiness of TPE materials depends a lot on what you put in them. Some TPEs have a lower gloss level, which is usually related to what’s inside them, like fillers and plasticizers. Fillers like talc and calcium carbonate can make the material less see-through and smooth, which makes the surface gloss of the product lower. If you use too much plasticizer, the material can look sticky and not have any surface gloss.

-

Material moisture: this can also lead to the phenomenon of surface roughness, the focus here, not only the TPE material moisture, but also the color masterbatch moisture will also appear in this situation. If the TPE raw material plasticization caused by poor apparent roughness, cut cross-section, can not be found in the air holes (microporous), and this elasticity will not change, but the water-absorbing TPE extrusion, because a little bit of microfoam, elasticity deterioration, hardness decline. Once the water is excessive, the gas produced because it is more difficult to discharge at the root of the single screw, so it causes plasticization problems between the material and produces air holes in the material.

-

TPE raw materials: TPE raw materials cause TPE extrusion surface is not smooth, mainly the fluidity of the material, the molecular weight of the base material is too high, the melt finger is too low resulting. This kind of situation is only to replace the material. There is also the TPE material formula in the filler proportion is too large.

- Thermoplastic elastomer (TPE) raw materials: the reason for using TPE raw materials5 is that the extruded surface is not smooth. This is mainly due to the material’s fluidity, the high molecular weight of the base material, and the low melt index. In this case, the only solution is to replace the material. Additionally, the filler content in the TPE formulation is too high. The extrusion equipment is usually the cause, as the extruder is too small and the die is clean. Generally, as the pressure increases, the surface becomes smoother.

Molding Process Parameter Problems

- Temperature, pressure, and cooling time in the injection molding process6: the parameters of temperature, pressure, and cooling time in the injection molding process have a direct impact on the glossiness of TPE products. If the temperature during injection molding is too low or the cooling time is too short, the surface of TPE material fails to melt and cool sufficiently, which will easily lead to surface roughness and reduced gloss. Too high injection pressure may lead to excessive compression of the product surface, which in turn affects the surface gloss.

- Injection speed: if the injection speed is too fast, the material will stay in the barrel for too long, which will cause the surface gloss of the product to decrease. If the temperature of the barrel is too low, the temperature of the nozzle is too low, it will also cause the surface gloss of the product to decrease. If the mold temperature is too low, the cooling speed is too fast, when the melt is still filling the mold, the cavity wall formed on the crust, the shell layer is subjected to a variety of forces, making it white and muddy, reducing the surface gloss of the product. If the plasticizing back pressure is too small, the material will not be plasticized uniformly, and the mixing of the material and the colorant will not be good, resulting in uneven color of the surface of the product.

Application of Surface Treatment Technology

Sometimes, just adjusting the material and process parameters isn’t enough to get the gloss you want. You can make TPE products even glossier by using surface treatment technology. Spraying, coating, plating, and other surface treatment processes can make TPE products look even better.

Influence of Pduction Environment

The surface gloss of TPE products7 can also be affected by the production environment. If the humidity in the production environment is too high or the temperature fluctuates greatly, the TPE material may absorb water or surface crystallization may occur during processing, which may lead to a decrease in the surface gloss of the products. Dust, oil and other pollutants in the production plant may also be attached to the surface of the product during the injection molding process, affecting the gloss.

Improper die design leads to non-smooth TPE wire surfaces.True

Inaccurate die design can cause uneven material distribution, resulting in surface imperfections.

All surface inconsistencies in TPE wires are due to material defects.False

While material defects can contribute, temperature control and extrusion speed also significantly impact surface quality.

What are the Methods to Improve the Surface Smoothness of TPE Wire Extrusion?

Enhancing the surface smoothness of TPE wire extrusion is crucial for improving product quality and performance across various applications, from consumer electronics to medical devices.

Optimizing extrusion temperature, ensuring consistent material feed, and using advanced die design improve TPE wire extrusion's surface smoothness, enhancing aesthetic and functional properties.

Optimize Extrusion Temperature

Based on the performance of TPE materials, select the right extrusion temperature. While making sure the material flows well, try to lower the extrusion temperature to reduce how long the material stays in the nozzle. This will help prevent surface defects like bubbles and flash.

Improvement of Mold

- Optimize the die structure: to make sure the material is evenly squeezed and stretched when it’s being squeezed out, you need to optimize the die. At the same time, you need to improve the finish of the inside of the die so that the material doesn’t leave any scratches or burrs on the inside of the die.

- Fine polishing of the mold surface: to make TPE products8 shinier, you need to polish the mold. You can use mechanical or chemical methods to make the mold surface as smooth as a mirror. This will make the product surface smooth and shiny. You also need to clean and maintain the mold regularly to prevent dirt and oxide buildup, which will also help make the products shinier. For some complex molds, you can also consider using coating technology to make the mold surface smoother.Don’t use or use less mold release and apply it evenly. Make runners and gates bigger, and add vent slots.

Adjust the Material Formula

To make TPE products shiny, you need to start with the formulation design. First, choose raw materials with high gloss. Second, control the amount of filler you use. You can also use special fillers, like superfine talcum powder or light calcium carbonate with surface treatment. These materials will keep the physical properties of the TPE while reducing the impact on the gloss.

To improve the gloss level, you can reduce the amount of plasticizer or choose the right kind of plasticizer. You can also adjust the formulation of TPE materials. For example, you can reduce the amount of flame retardants, fillers, and other additives. You can also add lubricants, antioxidants, and other additives to improve the fluidity, viscosity, and other properties of the material and improve the surface smoothness.

Selection of Suitable Surface Treatment Technology

Depending on the product’s use requirements, you can choose the appropriate surface treatment technology to enhance the gloss. Spraying clear glossy coatings is a common practice to enhance surface gloss without changing the color of the product. Electroplating technology can also be used for certain TPE products that require a metallic texture to further enhance their appearance. The use of UV curing coating technology not only increases the gloss, but also enhances the abrasion resistance and aging resistance of the product.

Optimization of Molding Process Parameters

To make TPE products look shinier, you can adjust the injection molding process. Raise the injection temperature a bit so the TPE material melts completely when it flows. That way, the surface will look smooth. Extend the cooling time so you don’t take the products out too early. That way, the surface will cool enough to look shiny all over.

To avoid the impact of high or low pressure on the gloss, adjust the injection pressure. Through repeated tests and adjustments, you can find the best combination of process parameters.

Slow down the injection speed to reduce the time the material stays in the barrel. Increase the nozzle temperature to increase the melt temperature. Increase the mold surface temperature, slow down the cooling rate, or use techniques such as local heating at the gate. Increase the back pressure as needed.

Improve the Production Environment

Another way to make TPE products look better is to improve the production environment. Keep the temperature and humidity in the production workshop constant, reduce the moisture and impurities in the air, and effectively prevent the TPE material from getting wet during processing.

Make sure the production equipment is clean. If there are impurities or oil in the equipment, it can mess up the surface of the products. For some special TPE materials, you might want to store and handle the raw materials in a dry place to keep them from getting wet.

Optimized extrusion temperature improves TPE wire surface smoothness.True

Proper temperature management reduces surface defects, ensuring a smoother finish.

Consistent material feed during extrusion negatively impacts surface quality.False

Consistent material feed helps maintain uniformity, improving surface smoothness in TPE wire extrusion.

How Does Bonding Quality and Surface Smoothness Affect the Performance of TPE Wire?

Bonding quality and surface smoothness significantly impact TPE wire performance, influencing durability, conductivity, and aesthetic appeal across various applications.

High-quality bonding enhances TPE wire durability and electrical performance, while surface smoothness reduces friction and improves aesthetics, essential for consumer electronics and automotive applications.

Influence of Bonding Quality on TPE Wire Properties

-

Adhesion and service life: the bonding quality is directly related to the adhesion of the TPE wire. A wire with good adhesion is less likely to fall off or separate during use, which can extend the service life of the wire.

-

Stability during processing: TPE wire with good bonding quality is more stable during processing, and is less likely to fall off or separate, which ensures the smoothness of the production process.

The Effect of Surface Smoothness on the Performance of TPE Wire

- Appearance and feel: TPE wire with smooth surface is more beautiful in appearance and more comfortable to the touch, especially in applications that require frequent contact, such as headphone cables and data cables.

-

Electrical performance: when used as an insulating layer for wires and cables, the smooth surface TPE wire can better maintain the integrity and stability of the insulation layer, ensuring safe and reliable electrical performance.

-

Processing performance: smooth surface TPE wire is easier to mold and plasticize during processing, which helps to reduce production costs and improve production efficiency.

Specific Methods to Improve Bonding Quality and Surface Smoothness

- Conductor preheating: if the adhesive doesn’t change color, try increasing the preheat temperature or voltage to improve adhesion.

-

Pressurized mold: squeeze the mold or adjust the distance inside the head to make sure the wire bridge distance, outer diameter and insulation thickness of the wire, and at the same time make sure there is no eccentricity.

-

Adjustment of adhesive hardness: use a softer adhesive to make it stick better and adjust the hardness of the adhesive according to the weather.

-

Irregular stranding: when you can’t make the bond better any other way, you can increase the contact area between the adhesive and the conductor by using a stranded conductor with irregular stranding.

-

Screw temperature and extrusion pressure: to make the surface of the TPE wire smooth, adjust the screw temperature and extrusion pressure. In general, increasing the pressure will make the surface smoother.

High bonding quality boosts TPE wire durability and performance.True

Strong layer adhesion minimizes defects, leading to enhanced reliability and electrical properties.

Surface smoothness has no impact on TPE wire applications.False

Smooth surfaces reduce friction and enhance appearance, crucial for usability and visual appeal in consumer products.

Conclusion

This paper is about the factors that affect the adhesion and surface smoothness9 of TPE wire during extrusion. Poor adhesion is mainly caused by material compatibility, inappropriate extrusion temperature and speed. To improve adhesion, we can optimize the material formula and adjust the extrusion temperature and speed.

The surface is not smooth, mainly related to temperature, mold design, material formula, environment and other factors. We can effectively improve the surface smoothness of TPE wire and improve its performance by optimizing process parameters, adjusting material formula and adopting appropriate surface treatment technology.

-

Understanding the right extrusion temperature is crucial for achieving the best adhesion and surface quality in TPE products. ↩

-

Exploring the impact of extrusion speed can help optimize the production process and improve product quality. ↩

-

Exploring mold design principles can significantly improve the surface quality of TPE products, leading to better manufacturing outcomes. ↩

-

Learning about material formulation can help you optimize TPE properties for better surface finish and product quality. ↩

-

Understanding the impact of TPE raw materials can help improve product quality and surface finish. ↩

-

Learn about critical factors in injection molding that influence TPE product quality and performance. ↩

-

Explore techniques to enhance the glossiness of TPE products for better aesthetics and market appeal. ↩

-

Explore this resource to learn effective techniques for enhancing the quality and appearance of TPE products, ensuring better performance and aesthetics. ↩

-

This link will provide insights into methods and technologies that can enhance surface smoothness in TPE wire, crucial for product quality. ↩