The extrusion foaming process creates lightweight, thermally efficient materials by introducing gas into polymers during extrusion, forming a foam structure suitable for various applications.

Extrusion foaming injects gas into polymers during extrusion, creating lightweight, cellular materials for packaging, construction, and insulation, reducing material use and improving thermal properties.

Understanding the intricacies of the extrusion foaming process and its applications is key to leveraging its benefits for your industry. Delve deeper to explore how different gases and polymers affect the final foam properties and applications.

Extrusion foaming reduces material costs in manufacturing.True

By expanding the polymer with gas, foam products are created using less raw material, leading to cost savings.

Extrusion foaming is only used in packaging applications.False

While common in packaging, extrusion foaming also finds applications in construction, automotive, and insulation industries due to its versatile properties.

- 1. What are the Common Materials Used in Extrusion Foaming?

- 2. What are the Steps in the Extrusion Foaming Process?

- 3. What are the Three Factors of the Extrusion Foaming Process?

- 4. What are the Applications of Extrusion Foaming?

- 5. What are the Differences Between Extrusion Foam Process and Molded foam?

- 6. Conclusion

What are the Common Materials Used in Extrusion Foaming?

Extrusion foaming materials are pivotal in industries needing lightweight and insulated products, enhancing efficiency and reducing costs.

Extrusion foaming commonly uses polystyrene, polyethylene, polypropylene, and polyurethane for thermal insulation, weight reduction, and versatility in packaging, construction, and automotive industries.

Polylactic Acid (PLA)

PLA is a biodegradable material. The extrusion foaming process1 can make the product lighter, which can reduce costs and improve the heat resistance and flexibility of the material. PLA foam is widely used in food packaging and other fields. For example, companies like Coopbox in Italy and TAG Packaging in Korea have been researching this for many years and have achieved great results.

Polyethylene (PE)

Polyethylene is also one of the common extrusion foaming materials. Through the extrusion blow molding foaming2 process, tiny air bubbles can be formed in PE products, thus reducing the amount of plastic material used.

For example, a patent filed by LIBERTY mentions an extrusion blow molded foamed polyethylene product and a method for its preparation, which includes components such as a blowing agent masterbatch, a matrix resin, and a color masterbatch.

These materials have different properties and can be used for different things when you’re making foam with an extruder. You have to think about what you’re making and where it’s going to be used to pick the right material.

Ethylene Vinyl Acetate Copolymer (EVA)

EVA is a common foam material with good shock absorption, cushioning, waterproofing, and thermal insulation properties. The extrusion foam process can produce EVA foam3 sheets, plates, tubes, etc., which are widely used in shoe insoles, sports equipment, soundproofing materials, and toys.

Polystyrene is a key material used in extrusion foaming.True

Polystyrene is commonly used due to its excellent insulation properties and lightweight nature, suitable for packaging and construction.

Extrusion foaming materials are unsuitable for all industries despite their benefits.True

While they offer various advantages, some industries may require materials with different properties, such as rigidity or specific chemical resistances.

What are the Steps in the Extrusion Foaming Process?

The extrusion foaming process is pivotal in producing lightweight, durable materials across industries by introducing a foaming agent to plastic polymers during extrusion.

The extrusion foaming process involves melting polymer, adding a foaming agent, and cooling to form foam, used in packaging, automotive, and construction for its lightness and strength.

Mixing of Raw Materials

Mix the polymer resin with the blowing agent4 and other additives (like nucleating agents, flame retardants, etc.) to make sure the blowing agent is spread out evenly in the polymer.

Plasticization and Extrusion

The mixed raw material goes into an extruder where it gets melted and plasticized at high temperatures. During this process, the blowing agent gets evenly distributed in the polymer matrix.

Foaming Process

When the temperature goes up, the blowing agent starts to break down or evaporate, making gases that make bubbles in the melt. The foaming process is controlled by temperature, pressure, and the ratio of raw materials.

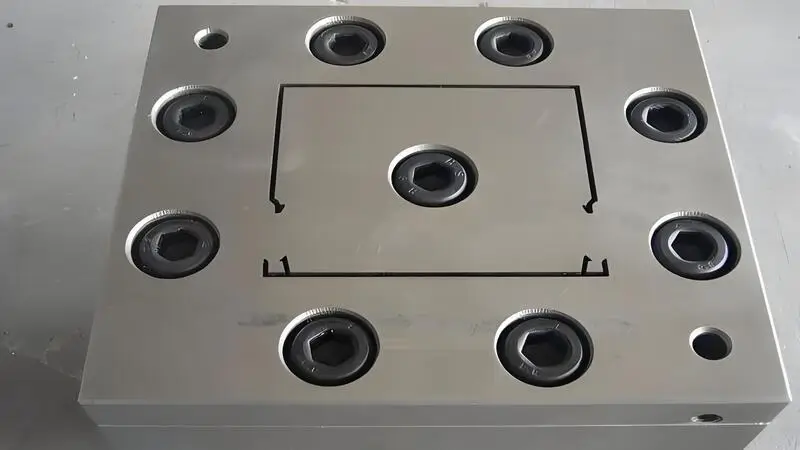

Mold Extrusion

As the melt is squeezed through the mold, pressure is suddenly let go, causing the gases to blow up and make a closed cell structure. This step decides the structure and properties of the final product.

Cooling and Shaping

The extruded stuff is cooled down fast in a cooling unit so it can harden and keep the shape and size we want. While it’s cooling, the blister structure gets even more stable.

Maturing Process

After molding, the material is allowed to sit for a while so that the gases in the blowing agent are gradually replaced by air, which helps to make the material stronger and more durable.

Cutting and Packaging

Finally, we cut the molded material to the specifications we want and package it up to send it out.

Extrusion foaming always results in a uniform cell structure.False

The uniformity of the cell structure depends on factors like the type of foaming agent and process conditions.

Extrusion foaming reduces material usage without compromising strength.True

By expanding polymers into foam, material use is minimized while maintaining structural integrity.

What are the Three Factors of the Extrusion Foaming Process?

The extrusion foaming process is critical in creating lightweight and efficient materials for various industries by incorporating gases into polymers during the extrusion process.

The extrusion foaming process relies on polymer type, foaming agent, and processing conditions, which determine the foam's structure, density, and performance.

Extrusion Temperature

The temperature of extrusion has a big effect on how well the foam sheet forms. If you start extruding at a lower temperature, the bubbles will be bigger. As you increase the temperature, the bubbles will get smaller. If you keep increasing the temperature, the bubbles will get bigger again.

This is because the temperature of the extrusion is low, and the gas in the melt is unevenly mixed, nucleated, and unevenly dispersed, resulting in the formation of large bubbles and a high density of the foam sheet; when the temperature rises to a certain value, the extruded melt cannot withstand the internal expansion force and quickly collapses.

You need to figure out the extrusion temperature5 by considering the crosslinking agent, AC, and how much the system gels.

If the temperature of the crosslinking agent is too high, the crosslinking temperature and the decomposition rate of the AC are too high, resulting in a difficult control of the molding time; if the temperature is too low, the decomposition rate of the AC and the crosslinking speed of the crosslinking agent6 are not compatible, so that the gel amount of the system is small and a good bubble cannot be obtained.

Also, the temperature of the head and mouth mold during the foaming process of the polyethylene sheet is very important. Generally, the temperature of the extruder body is between 140 and 190 degrees Celsius, and the temperature of the head is between 180 and 210 degrees Celsius. It is best to use a low-temperature extrusion process to achieve a fine and uniform bubble structure.

Melt Residence Time in the Extruder

The screw speed is low, the material stays in the barrel for a long time, the blowing agent decomposes a lot, it’s easy to foam and form bubbles, so the number of bubbles is small and the size of the bubbles is big, and the bubble structure7 is bad; also, because the material stays in the barrel for a long time, the melt crosslinks too much, and the material shrinks when it foams.

Moreover, the likelihood of the gas inside the melt diffusing to the external surface is also higher, leading to an increase in the density of the product.

The screw speed is higher, the material stays in the barrel for a shorter period of time, the decomposition process of the foaming agent is shorter, the gas generation is insufficient, which tends to result in a smaller number of bubbles, smaller sizes, and a faster process. When the process is carried out too quickly, at the exit of the extrusion die, the residual foaming agent cannot be completely decomposed, resulting in a higher density of the product.

Also, the material stays in the residence for a short time, definitely a short cross-linking time, low cross-linking degree, melt wall sticking, with the increase in the amount of AC decomposition gas, low cross-linking melt can’t withstand the gas pressure and cause melt rupture.

In general, when the speed is low, the density is high. As the speed increases, the density decreases. When it reaches a certain value, the density starts to increase. It can be seen that if the screw speed is too high or too low, the size of the bubbles will be different, and bubbles or broken bubbles will occur. If the speed is too fast, the material will not be well plasticized and the gas will escape.

Extrusion Pressure

The extrusion pressure is too low, the AC decomposition of the gas produced in the melt, the diffusion coefficient is too large, and the solubility is very small, resulting in a large amount of gas escaping; the extrusion pressure increases, the gas solubility of the melt increases, the number of nuclei increases, the bubble holes are smaller, and the density is also small.

The Role of Additives in Foaming

The general decomposition temperature of crosslinking agents is 120°C, which can meet the requirement of being higher than the melting temperature of PE and lower than the decomposition temperature of AC blowing agents8.

At this temperature, the crosslinking agent breaks down into free radicals that are more chemically active and can grab hydrogen atoms from the PE chains. This makes the carbon atoms in the polymer chains into active free radicals. The free radicals from two or more chains combine with each other to make C-C chemical bonds, which make a net-like structure.

After PE cross-linking, the degree of cross-linking can reach 80%. The melt viscosity increases, so as to obtain a fine and uniform porous structure of high expansion rate of foam sheet. However, when the amount of crosslinking agent is too large, the crosslinking rate is too large.

At this time, AC is too late to decompose. The viscosity of the melt is already very large. The bubbles are not fully expanded. So the bubble in vivo pressure is very large. When the external pressure is removed, the product appears cracked, wrinkles.

To get a great bubble structure, you need at least 60% gel when you use the right amount of crosslinker. Usually, the tensile strength of the product goes up and then goes down as you use more crosslinker.

The reason why the foam board sheet is formed with poor quality, large bubble hole size, and small quantity is that the blowing agent is basically completely decomposed in the extruder, and most of the gases in the supersaturated melt diffuse and escape to the outside of the melt, and there is a shortage of bubble cores.

So, the melt in the extruder should have a lot of gas or a little AC blowing agent in it. In fact, even if there’s a little blowing agent left in the melt, it can still act as a nucleus. Once it comes out of the mold, it can foam up.

The effect of AC blowing agent dosage on the structure of the bubble hole and the performance of the foamed sheet. Foaming process is a complex physicochemical process, foaming requires the outward expansion of the gas pressure and the bubble wall melt surface tension to achieve a dynamic balance.

According to the foaming “hot spot” nucleation mechanism, if the molding, in a certain period of time can not form a large number of bubble nuclei, you can not get the bubble hole uniformity and density of the foam body. Whether a large number of nuclei can be formed during the molding process, the amount of AC in the system is one of the important factors.

In theory, as the AC content of the gas increases, so does the power generation, but more AC content isn’t always better.

When the dosage exceeds a certain limit, the amount of gas increases, the decomposition rate of AC increases, greater than the rate of crosslinking crosslinking agent, so the amount of gas escaping from the melt gradually increases, resulting in a gradual increase in the total density of the surface of the product.

The elongation at break of the product decreases and then increases with the increase of AC dosage. This is because when the AC dosage is small, the AC decomposition rate is compatible with the crosslinking rate of the crosslinking agent, with the increase of AC dosage, its decomposition rate also increases, the gas in the melt can not be fully expanded, so the toughness of the product is reduced.

Polymer selection is vital for determining foam characteristics.True

Different polymers interact uniquely with foaming agents, directly influencing the foam's properties like strength and thermal insulation.

All extrusion foaming processes use the same foaming agent.False

Various foaming agents are utilized based on the desired foam properties, such as chemical and physical blowing agents.

What are the Applications of Extrusion Foaming?

Extrusion foaming offers versatile solutions in manufacturing, contributing to lightweight and insulated products across several sectors.

Extrusion foaming is used in packaging, automotive, and construction for lightweight, insulated materials, enhancing efficiency and reducing costs.

The extrusion foaming process is about heating, mixing and extruding polyurethane raw materials through an extruder to form a continuous foaming material. This process is about continuity and high efficiency and is good for mass production. Extruded foamed products usually have a flat surface and uniform bubble structure, and are good for applications that need large-area thermal or sound insulation.

Construction

You can use extruded foam to make all kinds of waterproof, heat insulation and sound insulation materials, like extruded foam insulation layer, extruded foam sound insulation boards, extruded foam rigid foam boards, etc. These materials are often used in building exterior walls, roofs, basements, walls, etc.

Packaging Industry

You can use extruded foam to make all kinds of packaging materials, like extruded foam plastic packaging film, extruded foam protective pads, extruded foam cushioning materials, and so on. These materials are used a lot in packaging for things like electronics, home appliances, toys, food, and more.

Automobile Industry

You can use extruded foam to make all kinds of car parts, like extruded foam door panels, extruded foam roof panels, extruded foam car seat cushions, and so on. These parts are light, strong, soundproof, heat-insulating, and impact-resistant.

Furniture Industry

Extrusion foaming can make all kinds of density board and board materials for furniture, such as extrusion foaming furniture panels, desktops, cabinets, sofas, etc. These materials are lightweight, beautiful, energy-saving, with good fire resistance and antimicrobial properties.

Extrusion foaming reduces material costs in manufacturing.True

By creating lightweight products, extrusion foaming reduces the amount of raw material required, thus lowering costs.

Extrusion foaming is only used in the packaging industry.False

Extrusion foaming is utilized in various sectors, including automotive and construction, for applications like thermal insulation and cushioning.

What are the Differences Between Extrusion Foam Process and Molded foam?

Understanding the distinctions between extrusion foam and molded foam is key for optimizing material properties and production efficiencies in various applications.

Extrusion foam involves continuous production, offering uniform density and flexibility, while molded foam is created in molds, providing precise shapes and greater structural integrity. Each process caters to different industrial needs such as packaging, automotive, and construction.

Process Flow

Extrusion foaming is when you heat, mix, and extrude polyurethane raw materials through an extruder to make a continuous foamed material. Injection foaming and molding foaming are different ways to foam.

Injection foaming is when you put the raw material into the injection molding machine, heat it up and make it soft, and then inject it into the mold to make it into shape. Molded foaming is when you pour the raw material into the mold, heat it up and make it foam, and fill up every corner of the mold.

Principle

Extrusion foaming is when you add the blowing agent to the plastic melt in the extruder, then you extrude the melt through the extruder head to mold it. When you get to the nozzle of the extruder head, there’s a sharp pressure drop, and that causes the blowing agent to decompose really fast and make gas, and the plastic expands and makes foam.

Molding foaming is when you mix the plastic pellets and the blowing agent together and put them in the mold, and then you heat it up and melt it and make it foam. The molded foam is when you take the plastic pellets and the blowing agent and put them in the mold, and then you heat it up and melt it, and the blowing agent decomposes and makes gas, and that makes the plastic expand and make foam.

Molding Characteristics

Extruded foam: The gas can expand in a longer time and a larger space, and the form is highly adjustable, so it can be produced in a variety of shapes such as tubes, rods, and plates. The surface skin is relatively rough, but the internal shrinkage is small, suitable for mass production.

Molded Foam: The gas can only expand to the limited position of the mold, the form is more fixed, the skin is smooth, and the internal shrinkage is not easy. Because molds are needed, the shape and size need to be customized, and it is difficult to carry out mass production.

Application Scenarios

Because of the difference in molding characteristics, molded foam and extruded foam have different applications.

Extruded foam is suitable for continuous production lines and is good for mass production with a flat surface and uniform bubble structure.

Extruded foam is good for making foam products with higher density and good toughness, like thermal insulation materials, air conditioning sound insulation materials, automotive interiors, and so on.

Molded foam is good for making custom and complicated things, and you can make different molds for different things. You can make all kinds of foam things with molded foam, like toys and 3D puzzles.

Advantages and Disadvantages

Extrusion foaming has many advantages. It’s efficient, stable, easy to control, and great for mass production.

The disadvantage is that the equipment investment is large, suitable for continuous production. The advantages of molded foam are customization, complex structure, suitable for small batch production and complex structure products. The disadvantage is that the production cycle is longer, suitable for intermittent production.

Extrusion foam is more cost-effective for mass production than molded foam.True

The continuous production process of extrusion foam reduces labor and material costs, making it suitable for large-scale operations.

Molded foam always has a higher density than extrusion foam.False

Molded foam can vary in density depending on the formulation and application, and it's not inherently higher than extrusion foam.

Conclusion

Extrusion foaming9 is a way to make foam continuously by melting and extruding at high temperatures. It is mainly used to make things lighter, keep heat in, and stop things from shaking. People use different materials for this, like polylactic acid (PLA), polyethylene (PE), and ethylene vinyl acetate copolymer (EVA). They use them for different things, like food packages, building stuff, and car parts.

The process steps include mixing raw materials, plasticizing and extruding, foaming, extruding through a die, cooling and shaping, aging, and cutting and packaging. Extruded foam10 is suitable for large-scale production with higher productivity and consistent quality compared to molded foam.

-

Understanding the extrusion foaming process can enhance your knowledge of material science and its applications in various industries. ↩

-

Learning about extrusion blow molding foaming can provide insights into innovative manufacturing techniques and material efficiency. ↩

-

Exploring EVA foam's properties can help you discover its versatility in applications like sports equipment and soundproofing materials. ↩

-

Understanding blowing agents is crucial for optimizing foam production and enhancing material properties. ↩

-

Learn how extrusion temperature influences bubble size and foam density for better product quality. ↩

-

Explore the importance of crosslinking agents in achieving desired foam characteristics and stability. ↩

-

Learning about bubble structure factors can lead to better foam quality and performance in manufacturing processes. ↩

-

Understanding the role of AC blowing agents can help optimize foam production and improve product quality. ↩

-

Explore this link to understand the process and applications of extrusion foaming in various industries. ↩

-

Learn about the benefits of extruded foam, especially in mass production and its applications in various sectors. ↩