Explore the process, materials, applications, and benefits of plastic extrusion in modern manufacturing.

Plastic extrusion is a widely used manufacturing process Fictiv Plastic Extrusion Explained that transforms raw plastic materials into a variety of products with uniform cross-sections. From pipes and tubes to window frames and packaging films, extruded plastics are integral to industries such as construction, automotive, and consumer goods. This process is favored for its cost-effectiveness, efficiency, and ability to produce large quantities of continuous products. In this comprehensive guide, we’ll dive into the fundamentals of plastic extrusion, including its materials, processes, applications, and how it stacks up against other manufacturing techniques.

Plastic extrusion is the most cost-effective manufacturing process for all plastic products.False

While extrusion excels at producing continuous profiles economically, other methods like injection molding may be more cost-effective for complex, discrete parts.

- 1. What are the Common Materials Used in Plastic Extrusion?

- 2. What are the Steps in the Plastic Extrusion Process?

- 3. What are the Different Types of Plastic Extrusion Processes?

- 4. What are the Key Factors in the Plastic Extrusion Process?

- 5. What are the Applications of Plastic Extrusion?

- 6. How Does Plastic Extrusion Compare to Other Manufacturing Processes?

- 7. Conclusion

What are the Common Materials Used in Plastic Extrusion?

Plastic extrusion relies on thermoplastic materials1 that can be melted and reshaped. Below are some of the most commonly used plastics in this process:

-

Polyethylene (PE)2: Lightweight, impact-resistant, and chemically resistant, PE is a go-to for packaging, pipes, and agricultural films.

-

Polyvinyl Chloride (PVC)3: Known for durability and versatility, PVC is widely used in construction for pipes, window frames, and electrical insulation.

-

Polypropylene (PP)4: With a high melting point and excellent chemical resistance, PP suits automotive parts, packaging, and textiles.

-

Polystyrene (PS): Rigid and transparent, PS is ideal for consumer goods like disposable cutlery and packaging.

-

Acrylonitrile Butadiene Styrene (ABS)5: Strong and impact-resistant, ABS is popular in automotive components and electronics.

Choosing the right material is critical, as each offers unique properties tailored to specific applications.

| Material | Properties | Common Applications |

|---|---|---|

| Polyethylene (PE) | Lightweight, impact-resistant | Packaging, pipes, films |

| Polyvinyl Chloride (PVC) | Durable, chemical-resistant | Pipes, window frames, insulation |

| Polypropylene (PP) | High melting point, chemical-resistant | Automotive parts, packaging |

| Polystyrene (PS) | Rigid, transparent | Cutlery, packaging |

| ABS | Strong, impact-resistant | Automotive, electronics |

All thermoplastics can be used in plastic extrusion.False

While many thermoplastics work well, some lack the necessary melt flow or thermal stability for effective extrusion.

What are the Steps in the Plastic Extrusion Process?

The plastic extrusion process6 transforms raw plastic into finished products through a series of precise steps:

-

Feeding: Plastic pellets or powder are loaded into the extruder’s hopper.

-

Melting: Heaters and friction from a rotating screw melt the plastic inside the barrel.

-

Shaping: Molten plastic is forced through a die, forming the desired profile.

-

Cooling: The extruded plastic is solidified using water baths, air, or cooling rolls.

-

Cutting/Coiling: The final product is cut to length or coiled for storage and transport.

Each step requires careful control to ensure consistent quality in the extruded product.

The die design is crucial for determining the final shape of the extruded product.True

The die serves as a mold, shaping the molten plastic as it exits the extruder.

Cooling is an optional step in plastic extrusion.False

Cooling is mandatory to solidify the plastic and preserve its intended shape.

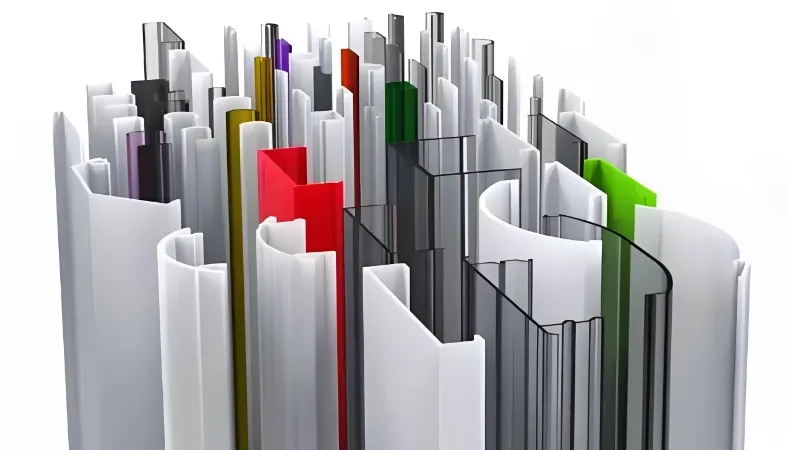

What are the Different Types of Plastic Extrusion Processes?

Plastic extrusion includes several specialized techniques, each tailored to specific products:

-

Tubing Extrusion: Produces hollow items like pipes and tubes using a mandrel or pin in the die.

-

Blow-Film Extrusion7: Creates thin films for packaging by extruding plastic into a bubble, cooled by an air ring.

-

Sheet Film Extrusion: Forms flat sheets for packaging and construction via pulling and rolling.

-

Over-Jacketing Extrusion: Applies plastic insulation to wires, ensuring protection and adhesion.

These variations highlight the adaptability of extrusion to diverse manufacturing needs.

All plastic extrusion processes use the same type of extruder.False

Different processes may employ single-screw or twin-screw extruders based on material and product requirements.

What are the Key Factors in the Plastic Extrusion Process?

Several factors influence the quality and properties of extruded products:

-

Temperature Control8: Ensures uniform melting, affecting flow and final characteristics.

-

Screw Speed: Impacts material mixing, conveyance, and production rate.

-

Die Design: Determines the precision and complexity of the extruded profile.

-

Cooling Rate: Affects strength, clarity, and flexibility as the plastic solidifies.

Optimizing these elements is vital for meeting product specifications.

Higher screw speeds always result in better product quality.False

Excessive speeds can lead to poor melting or mixing, reducing quality despite faster production.

What are the Applications of Plastic Extrusion?

Plastic extrusion serves a broad range of industries with versatile products:

-

Construction: Pipes, window frames, siding, and roofing materials.

-

Packaging: Films, sheets, and containers for food and industrial goods.

-

Automotive: Interior trim, seals, and structural components.

-

Electrical: Wire and cable insulation.

-

Medical: Tubing and catheters for healthcare.

Its flexibility makes extrusion a cornerstone of modern manufacturing.

Plastic extrusion is only used for industrial products.False

It also produces consumer items like toys, household goods, and packaging materials.

How Does Plastic Extrusion Compare to Other Manufacturing Processes?

Plastic extrusion differs from processes like injection molding and blow molding. Here’s a comparison:

-

Plastic Extrusion:

- Creates continuous profiles.

- Best for high-volume, uniform cross-section products.

- Low tooling costs, limited to simpler shapes.

-

Injection Molding:

- Forms discrete, complex 3D parts.

- Higher tooling costs but offers design flexibility.

- Ideal for intricate details and tight tolerances.

-

Blow Molding:

- Produces hollow objects like bottles.

- Involves inflating plastic in a mold.

- Suited for containers and packaging.

The right process depends on the product’s specific needs.

| Process | Product Type | Complexity | Tooling Cost | Production Volume |

|---|---|---|---|---|

| Extrusion | Continuous profiles | Simple | Low | High |

| Injection Molding | Discrete parts | Complex | High | Medium to High |

| Blow Molding | Hollow objects | Moderate | Medium | High |

Plastic extrusion is the best choice for all plastic manufacturing needs.False

It excels for continuous profiles, but injection molding is superior for complex, discrete parts.

Conclusion

Plastic extrusion is a vital manufacturing process, enabling the efficient production of diverse plastic products. By mastering its materials, steps, factors, and applications, manufacturers can harness its benefits for high-volume production. As technology advances, extrusion remains a cost-effective solution at the heart of modern industry.

-

Understanding thermoplastic materials is crucial for selecting the right type for specific applications in plastic extrusion. ↩

-

Exploring PE's properties and applications can help you understand its significance in various industries, especially in plastic extrusion. ↩

-

PVC's versatility makes it a key material in construction; learning more can enhance your knowledge of its applications and benefits. ↩

-

Explore the diverse applications of Polypropylene (PP) to understand its significance in various industries, from automotive to packaging. ↩

-

Learn about the unique properties of ABS that make it ideal for automotive and electronic applications, enhancing product durability. ↩

-

Discover the detailed steps of the plastic extrusion process to gain insights into how raw materials are transformed into finished products. ↩

-

Exploring blow-film extrusion will provide insights into its role in creating efficient packaging solutions. ↩

-

Learning about temperature control in extrusion can help you grasp its impact on product quality and performance. ↩