Melt fracture is a common challenge in polymer extrusion that can compromise the surface quality of extruded products, impacting both their appearance and performance. This blog post offers an in-depth guide to understanding and troubleshooting melt fracture1, covering its causes, effects across industries, and practical solutions. Whether you're involved in plastics manufacturing or seeking to enhance your extrusion process, this resource will equip you with the knowledge to address melt fracture effectively.

Melt fracture in extrusion is a flow instability that occurs when molten polymers are forced through a die at high rates, resulting in surface defects like sharkskinning or washboard patterns, commonly affecting industries such as packaging and medical devices.

By mastering the troubleshooting techniques outlined here, you can improve product quality and optimize your extrusion operations. Let’s dive into the details of melt fracture and how to tackle it.

Melt fracture only occurs in high-speed extrusion processes.False

While high extrusion rates increase the likelihood of melt fracture, it can also occur at lower speeds if die design or material properties are suboptimal.

Melt fracture is purely a cosmetic issue and does not affect product performance.False

In addition to aesthetic defects, melt fracture can compromise the mechanical properties and functionality of extruded products, especially in critical applications like medical devices.

- 1. What is Melt Fracture in Extrusion?

- 2. What Industries are Most Affected by Melt Fracture?

- 3. What are the Key Causes of Melt Fracture?

- 4. How Can You Troubleshoot Melt Fracture in Extrusion?

- 5. What are the Key Parameters in the Extrusion Process Affecting Melt Fracture?

- 6. What Materials are Most Prone to Melt Fracture?

- 7. Practical Tools for Preventing Melt Fracture

- 8. Related Technologies and Knowledge Network

- 9. Conclusion

What is Melt Fracture in Extrusion?

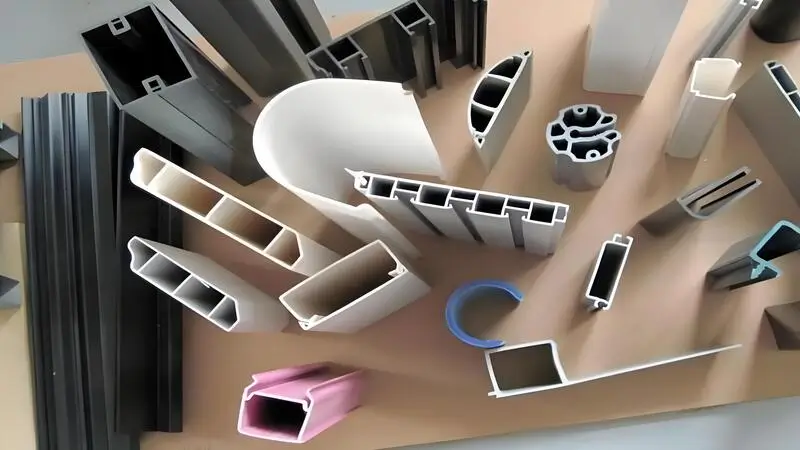

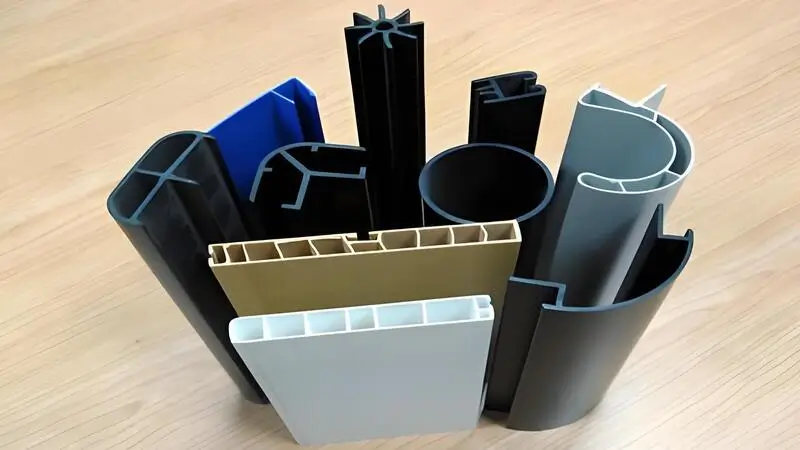

Melt fracture is a phenomenon in polymer extrusion where the surface of the extruded product becomes rough or distorted due to flow instabilities in the molten polymer as it exits the die. It’s often characterized by defects such as sharkskinning (fine ripples), washboard patterns (wavy distortions), or severe irregular distortions.

Melt fracture, also known as extrudate distortion2, is caused by high shear rates and extensional flows in the die, leading to viscoelastic instabilities in the polymer melt.

| Defect Type | Appearance | Common Causes |

|---|---|---|

| Sharkskinning | Fine, regular ripples | High extrusion rates, poor die design |

| Washboard | Wavy, periodic distortions | Excessive shear stress, material properties |

| Gross Distortion | Severe, irregular surface defects | Very high speeds, incompatible materials |

Core Principles of Melt Fracture

Melt fracture arises from the viscoelastic nature of polymers. When subjected to high shear rates in the die, the polymer melt can experience flow instabilities, disrupting the smooth surface of the extrudate. Key contributing factors include:

-

High Extrusion Speeds: Increased speed elevates shear stress.

-

Die Design Issues: Sharp transitions or rough surfaces in the die exacerbate instabilities.

-

Material Properties: High molecular weight polymers are more elastic, increasing the risk.

-

Temperature Control: Inadequate temperatures can hinder smooth flow.

Understanding these principles is the first step toward effective troubleshooting.

Polymers with high molecular weight are more prone to melt fracture.True

High molecular weight polymers have greater elasticity, increasing the likelihood of flow instabilities at high shear rates.

What Industries are Most Affected by Melt Fracture?

Melt fracture impacts industries where surface quality is critical, leading to production challenges and quality concerns.

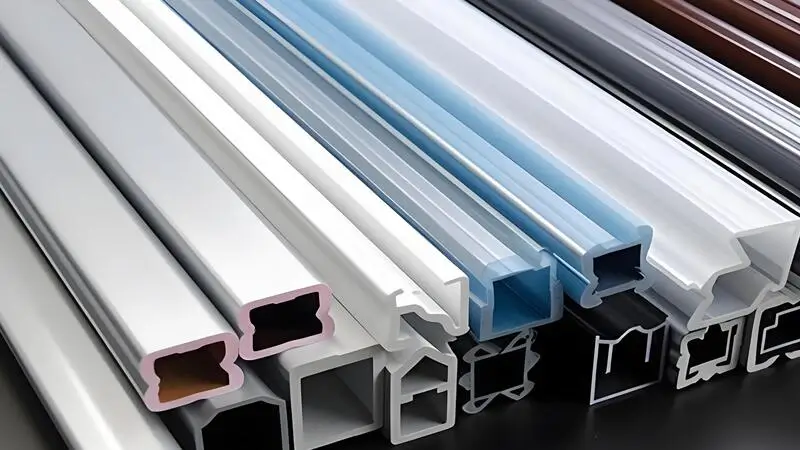

Melt fracture commonly affects the packaging, medical device, and automotive industries, where smooth surfaces are essential for product performance and aesthetics.

Packaging Industry

In packaging, melt fracture can create visual defects in films and sheets, reducing consumer appeal. For instance, sharkskinning3 in a food packaging film can fail clarity standards.

Medical Devices

For medical applications like tubing or catheters, surface defects from melt fracture can impair functionality and safety, where smoothness is vital to avoid irritation or damage.

Automotive Components

Extruded profiles and seals in automotive manufacturing require precise tolerances. Melt fracture can weaken mechanical properties or cause dimensional inaccuracies.

Melt fracture only impacts the visual appearance of extruded products.False

Beyond aesthetics, melt fracture can affect the mechanical properties and performance of extruded components, especially in precision applications.

What are the Key Causes of Melt Fracture?

Identifying the causes of melt fracture is crucial for effective troubleshooting. Multiple factors contribute to this issue.

The primary causes of melt fracture include high extrusion rates4, poor die design5, inadequate temperature control, and the use of high molecular weight polymers.

High Extrusion Rates

Pushing extrusion speeds to maximize output increases shear stress in the die, often triggering melt fracture.

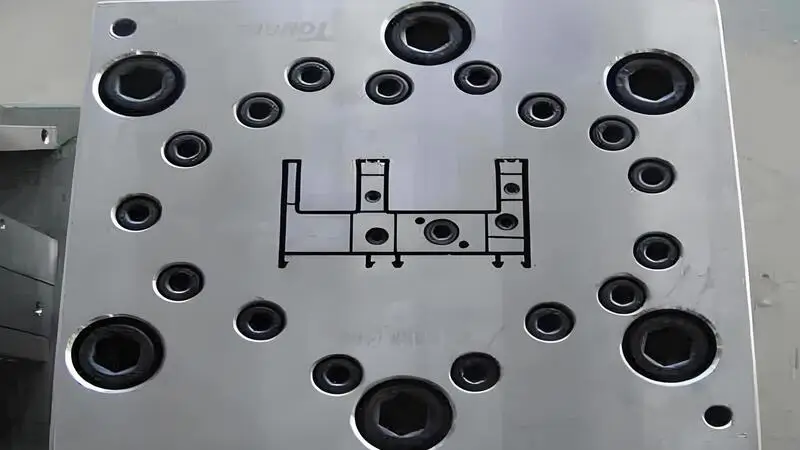

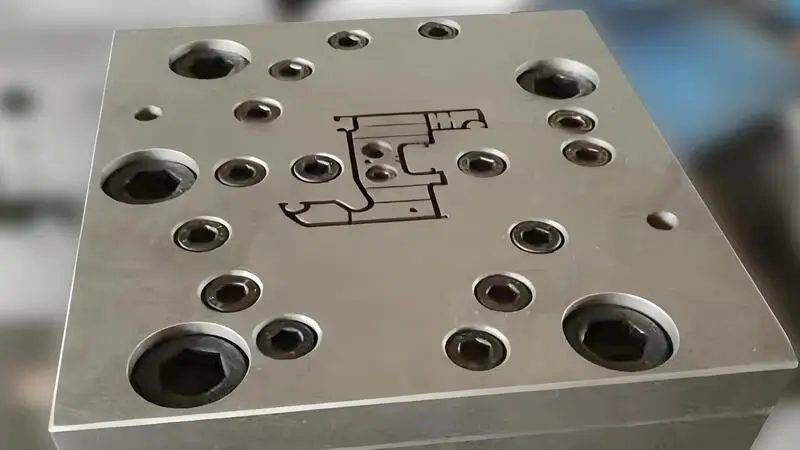

Poor Die Design

Dies with abrupt transitions, rough surfaces, or short land lengths disrupt polymer flow, leading to defects. Low die temperature6s increase polymer viscosity, hindering flow, while overly high temperatures may degrade the material.

Inadequate Temperature Control

Low die temperatures increase polymer viscosity, hindering flow, while overly high temperatures may degrade the material.

Material Properties

Polymers with high molecular weight or broad molecular weight distribution are more elastic, making them prone to flow instabilities.

Optimizing die design can completely eliminate melt fracture.False

While improved die design can reduce the risk, other factors like extrusion speed and material properties may still contribute to melt fracture.

How Can You Troubleshoot Melt Fracture in Extrusion?

Troubleshooting melt fracture involves a systematic approach to pinpoint and resolve the issue.

To troubleshoot melt fracture, reduce extrusion rates, optimize die temperature, improve die design, and consider material changes if necessary.

Step-by-Step Troubleshooting Guide

-

Identify the Defect Type

- Examine the extrudate for sharkskinning, washboard, or gross distortion to guide your approach.

-

Adjust Extrusion Rate

- Lower the speed incrementally to reduce shear stress and check for surface improvement.

-

Optimize Die Temperature

- Raise the temperature to lower viscosity, ensuring it stays below the polymer’s degradation point.

-

Inspect and Modify Die Design

- Look for sharp edges or inadequate land lengths; redesign for smoother flow if needed.

-

Evaluate Material Properties

- Switch to a lower molecular weight polymer or add processing aids if other adjustments fail.

Using processing aids can mitigate melt fracture without changing the polymer.True

Processing aids like fluoropolymer additives can reduce surface friction, helping to prevent melt fracture.

What are the Key Parameters in the Extrusion Process Affecting Melt Fracture?

Several process parameters influence the occurrence of melt fracture, requiring careful control.

Key parameters affecting melt fracture include extrusion rate, die temperature, die design, and pressure within the extruder.

Extrusion Rate

Higher rates increase shear stress, raising the risk of melt fracture.

Die Temperature

Optimal temperatures ensure smooth flow; deviations can destabilize the process.

Die Design

Smooth, gradual transitions and adequate land lengths stabilize polymer flow.

Pressure

Excessive pressure can amplify flow instabilities, necessitating monitoring and adjustment.

Die land length has no impact on melt fracture.False

Longer land lengths can help stabilize the flow, reducing the likelihood of melt fracture.

What Materials are Most Prone to Melt Fracture?

Material choice significantly affects melt fracture susceptibility.

Polymers like linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and some fluoropolymers are more prone to melt fracture due to their high molecular weight and elasticity.

| Polymer Type | Susceptibility to Melt Fracture | Notes |

|---|---|---|

| LLDPE | High | Common in film production |

| HDPE | High | Used in pipes and profiles |

| Polypropylene (PP) | Moderate | Varies with grade |

| Polystyrene (PS) | Low | Less elastic, smoother flow |

Using a polymer with a narrower molecular weight distribution can reduce melt fracture.True

Narrower distributions reduce elasticity, making the polymer less prone to flow instabilities.

Practical Tools for Preventing Melt Fracture

Proactive measures can minimize melt fracture risks.

Use a design checklist to ensure optimal die design, temperature control, and material selection, and follow a decision-making guide for troubleshooting melt fracture.

Design Checklist for Preventing Melt Fracture

| Aspect | Consideration |

|---|---|

| Die Design | Ensure smooth, gradual transitions; avoid sharp edges. |

| Temperature Control | Maintain optimal temperature profiles for the polymer. |

| Extrusion Rate | Operate within recommended rates for the material. |

| Material Selection | Choose grades with lower molecular weight if possible. |

| Processing Aids | Consider additives to improve flow characteristics. |

Decision-Making Guide for Troubleshooting

-

Is the extrusion rate too high?

- Yes: Reduce speed.

- No: Check temperature.

-

Is the die temperature optimized?

- No: Adjust temperature.

- Yes: Inspect die design.

-

Are there design flaws in the die?

- Yes: Redesign die.

- No: Assess material.

-

Is the polymer suitable?

- No: Switch grade or add aids.

Processing aids are always necessary to prevent melt fracture.False

Processing aids can help but are not always required if other parameters are well-controlled.

Related Technologies and Knowledge Network

Melt fracture connects to broader technologies that can enhance prevention efforts.

Upstream technologies like polymer synthesis7 and rheology testing can help tailor materials to reduce melt fracture risk, while downstream quality control and surface treatments can mitigate its effects.

- Upstream: Polymer synthesis and rheology testing8 for material optimization.

- Downstream: Quality control systems and surface treatments for defect management.

Explore polymer rheology and die design optimization9 for deeper insights.

Rheology testing is essential for preventing melt fracture.True

Rheology testing helps predict how a polymer will behave under extrusion conditions, allowing for better material selection and process design.

Conclusion

Addressing melt fracture in extrusion involves understanding its causes—high speeds, poor die design, and material properties—and applying targeted solutions like speed reduction, temperature optimization, and die improvements. By leveraging practical tools and related technologies, you can enhance product quality and efficiency in your extrusion processes.

For further learning, check out resources on polymer rheology and die design optimization.

-

Understanding melt fracture is crucial for improving product quality in extrusion processes. Explore this link to learn more about its impact and solutions. ↩

-

Extrudate distortion is a key issue in polymer processing. Learn more about its causes and solutions to improve your manufacturing processes. ↩

-

Sharkskinning can severely affect the appearance of extruded products. Discover effective prevention methods to enhance your extrusion quality. ↩

-

Learn how extrusion rates impact the quality of polymer products and how to optimize them for better results. ↩

-

Effective die design is crucial for preventing defects like melt fracture. Discover best practices to enhance your extrusion processes. ↩

-

Die temperature plays a vital role in polymer flow and quality. Learn more about its impact on extrusion processes. ↩

-

Understanding polymer synthesis is crucial for optimizing materials to prevent melt fracture, enhancing product quality. ↩

-

Rheology testing provides insights into material behavior, essential for minimizing melt fracture risks in extrusion. ↩

-

Exploring die design optimization can lead to significant improvements in extrusion processes, reducing defects and enhancing efficiency. ↩