Plastic extrusion is a cornerstone of modern manufacturing, enabling the production of a vast array of products from pipes and tubing to window frames and packaging materials. As the North American market evolves, several key trends are shaping the future of the plastic extrusion industry. From sustainability1 initiatives to technological breakthroughs, these trends are driving innovation and redefining what’s possible in plastic manufacturing.

In this blog, we’ll explore the trends influencing the North American plastic extrusion industry, delving into the technical aspects, applications, and decision-making tools that professionals need to stay ahead. Whether you’re an engineer, manufacturer, or business owner, understanding these trends will help you navigate the dynamic landscape of plastic extrusion.

- 1. Key Trends Shaping the North American Plastic Extrusion Industry

- 2. Basic Cognitive Level: Establishing the Conceptual Framework

- 3. Application Analysis Level: Solving User Decision-Making Problems

- 4. Technical Deep Dive Level: Meeting Professional Reader Needs

- 5. Practical Tools Level: Enhancing Content Operability

- 6. Extension Level: Building a Knowledge Network

- 7. Conclusion

Key Trends Shaping the North American Plastic Extrusion Industry

The North American plastic extrusion industry is undergoing significant transformation, driven by four major trends: sustainability, technological advancements, shifting market demands, and regulatory changes2. These trends are not only reshaping how plastic extrusion is approached but also creating new opportunities and challenges for manufacturers.

Sustainability: A Push for Eco-Friendly Practices

Sustainability is at the forefront of industry trends, with increasing pressure to reduce environmental impact. Companies are investing in technologies to incorporate recycled plastics into their extrusion processes, addressing both regulatory requirements and consumer demand for greener products. For example, the use of post-consumer recycled (PCR) plastics3 in extruded products like packaging films and construction materials is on the rise. According to a 2023 report by Grand View Research, the demand for recycled plastics in extrusion is expected to grow by 7.2% annually through 2030.

Additionally, energy-efficient extrusion processes are being developed to minimize carbon footprints, aligning with global sustainability goals.

Technological Advancements: Precision and Efficiency

Technological innovation is revolutionizing plastic extrusion. The adoption of twin-screw extruders4, which offer superior mixing and processing capabilities, is becoming more widespread. These extruders allow for better control over material properties, leading to higher-quality products. Automation and digital control systems are also enhancing precision, reducing waste, and improving overall efficiency. For instance, real-time monitoring systems can now adjust temperature and pressure dynamically, ensuring optimal processing conditions.

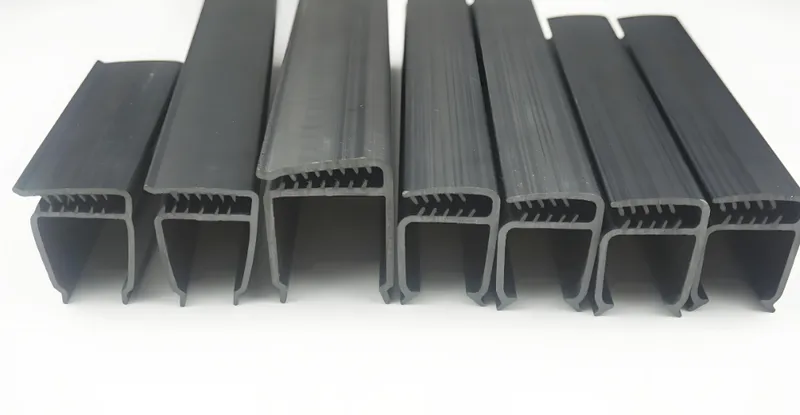

Advancements in die design are enabling the production of more complex profiles, expanding the range of applications for extruded plastics.

Market Demands: Customization and High-Performance Materials

Customers are increasingly seeking customized solutions, whether it’s unique profiles or specific material properties. This trend is driving manufacturers to adopt more flexible production lines capable of quick changeovers and small batch sizes. High-performance materials, such as engineering plastics like polycarbonate (PC) and acrylonitrile butadiene styrene (ABS), are also in demand for applications in industries like automotive and aerospace, where durability and precision are critical.

Emerging sectors, such as renewable energy, are creating new opportunities. For example, extruded plastic components are being used in solar panel frames and wind turbine parts.

Regulatory Changes: Stricter Standards and Compliance

Regulatory bodies are imposing stricter environmental and safety standards, pushing manufacturers to adopt greener practices and ensure product quality. Compliance with EPA regulations and industry-specific certifications, such as ISO 9001, is becoming essential. These changes are driving innovation in material selection and process optimization to meet both environmental and performance criteria.

Table: Impact of Trends on the Plastic Extrusion Industry

| Trend | Impact on Industry |

|---|---|

| Sustainability | Increased use of recycled materials, energy-efficient processes |

| Technological Advancements | Improved precision, efficiency, and product complexity |

| Market Demands | Demand for customization and high-performance materials |

| Regulatory Changes | Adoption of greener practices, compliance with standards |

Basic Cognitive Level: Establishing the Conceptual Framework

To fully grasp the trends shaping the industry, it’s essential to understand what plastic extrusion is and how it works.

Clear Definitions

Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. This process involves feeding plastic material (pellets, granules, flakes, or powders) into a heated barrel, where it is melted and then forced through a die to create the desired shape. Common aliases include profile extrusion or plastic profile manufacturing. The core principle is the transformation of solid plastic into a molten state, shaping it through a die, and then cooling it to solidify the shape.

Classification

Plastic extrusion can be classified based on several factors:

| Classification Type | Examples |

|---|---|

| Extruder Type | Single-screw, Twin-screw, Multi-screw |

| Plastic Material | PVC, PE, PP, PS, ABS, PC |

| Application | Pipes, Tubes, Sheets, Films, Profiles |

- By Extruder Type: Single-screw extruders are common for simple profiles, while twin-screw extruders are used for more complex materials or when better mixing is required.

- By Plastic Material: Thermoplastics like polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP) are widely used, each offering unique properties.

- By Application: Extrusion is used to produce a variety of products, from construction pipes to packaging films.

Plastic extrusion is a low-volume process.False

Plastic extrusion is designed for high-volume production, making it ideal for continuous profiles like pipes and tubing.

Application Analysis Level: Solving User Decision-Making Problems

Understanding where and how plastic extrusion is applied is crucial for making informed decisions about its use.

Typical Application Scenarios

Plastic extrusion is employed across multiple industries:

- Construction: Producing pipes for plumbing, window frames, and insulation materials.

- Packaging: Creating films, bags, and containers for food and consumer goods.

- Automotive: Manufacturing weather stripping, trim components, and fuel lines.

- Electronics: Producing cable insulation and protective casings.

These applications leverage extrusion’s ability to create continuous, uniform profiles at high volumes.

Pros and Cons Comparison

Compared to other manufacturing technologies, plastic extrusion offers distinct advantages and limitations:

- Pros:

- High production rates for continuous profiles.

- Ability to create complex cross-sections.

- Cost-effective for large-volume production.

- Cons:

- Limited to constant cross-section profiles.

- High initial setup costs for dies.

- Less flexible for small batch sizes compared to methods like injection molding.

Comparison with Injection Molding:

- Extrusion is ideal for long, continuous shapes (e.g., pipes), while injection molding is better for discrete, complex parts (e.g., gears).

Plastic extrusion is only suitable for simple shapes.False

Advancements in die design allow for the creation of complex profiles, expanding extrusion’s applicability beyond simple shapes.

Extrusion is more cost-effective than injection molding for high-volume production.True

Extrusion’s continuous process reduces material waste and labor costs, making it more economical for large runs.

Technical Deep Dive Level: Meeting Professional Reader Needs

For professionals, understanding the technical intricacies of the extrusion process is essential.

Process Full Workflow Breakdown

The plastic extrusion process consists of several key steps:

- Material Preparation: Raw plastic pellets are dried and blended with additives (e.g., colorants, stabilizers).

- Feeding: The material is fed into the extruder hopper.

- Melting: Inside the barrel, the plastic is heated and mixed by a rotating screw.

- Extrusion: The molten plastic is forced through a die to form the desired shape.

- Cooling: The extruded profile is cooled using water baths or air cooling systems.

- Cutting and Finishing: The profile is cut to length and undergoes post-processing (e.g., printing, punching).

Key Parameters:

- Barrel Temperature: Must be precisely controlled to avoid material degradation.

- Screw Speed: Affects residence time and mixing quality.

- Die Design: Determines the final shape and dimensional accuracy.

Material Compatibility Explanation

Different plastics require specific processing conditions due to their unique properties:

| Plastic Material | Processing Temperature (°C) | Notes |

|---|---|---|

| PVC | 160-190 | Requires careful control to prevent decomposition |

| PE | 180-240 | Widely used for films and pipes, more forgiving |

| PP | 200-250 | Higher strength for durable applications |

| PS | 180-260 | Common in packaging, lightweight |

Material selection impacts not only the extrusion process but also the final product’s performance, such as durability, flexibility, and chemical resistance.

Using recycled plastics in extrusion reduces product quality.False

With proper processing and additives, recycled plastics can achieve comparable quality to virgin materials.

Practical Tools Level: Enhancing Content Operability

To aid in decision-making, here are practical tools for designing and selecting the extrusion process.

Design Checklist

When designing extruded parts, consider the following:

- Uniform Wall Thickness: Ensures consistent cooling and reduces defects.

- Avoid Sharp Corners: Prevents stress concentrations and improves flow.

- Material Shrinkage: Account for the plastic’s shrinkage rate in dimensioning.

- Additives: Use UV stabilizers or flame retardants as needed for the application.

Process Selection Decision-Making

Use this simple decision tree to choose between extrusion and other methods:

- Is the part a continuous profile? If yes, consider extrusion.

- Does the part require complex, three-dimensional features? If yes, consider injection molding.

- What is the production volume? High volumes favor extrusion due to lower per-unit costs.

Extension Level: Building a Knowledge Network

Plastic extrusion is part of a broader ecosystem of manufacturing technologies.

Related Technology Navigation

- Co-Extrusion: Combines multiple materials in a single profile, useful for creating multi-layered products5 like food packaging.

- Blown Film Extrusion: A variant for producing plastic films, widely used in packaging.

- Sheet Extrusion: For flat plastic sheets used in thermoforming or construction.

- Downstream Processes: Cutting, punching, or laminating to finish extruded products.

Emerging technologies, such as 3D printing with extruded plastics6, are also gaining traction, offering new possibilities for customization and rapid prototyping.

Conclusion

The North American plastic extrusion industry7 is at a pivotal moment, shaped by sustainability, technological innovation, market demands, and regulatory pressures. By understanding these trends and the underlying technical processes, manufacturers can make informed decisions that enhance efficiency, reduce costs, and meet evolving customer needs. As the industry continues to evolve, embracing these changes will be key to staying competitive in a dynamic market.

-

Explore how sustainability is reshaping the plastic extrusion industry and driving innovation in manufacturing practices. ↩

-

Learn about the regulatory landscape and how it influences practices in the plastic extrusion sector, ensuring compliance and sustainability. ↩

-

Explore the advantages of PCR plastics in manufacturing, including sustainability and regulatory compliance, to enhance your understanding of eco-friendly practices. ↩

-

Learn how twin-screw extruders enhance mixing and processing capabilities, leading to higher quality products and efficiency in production. ↩

-

Learn about the process of creating multi-layered products in plastic extrusion for insights into advanced manufacturing techniques. ↩

-

Explore the advantages of 3D printing with extruded plastics to understand its impact on customization and rapid prototyping. ↩

-

Discover the latest trends in the North American plastic extrusion industry to stay informed about sustainability and innovation. ↩