Vakum şekillendirme ve enjeksiyon kalıplama1 are two widely used plastic manufacturing processes2. While both are employed to create plastic parts, they differ significantly in their methods, applications, and suitability for different projects. Understanding the differences between these two processes is crucial for making informed decisions about which one to use for your specific needs.

Vacuum forming heats a plastic sheet and uses a vacuum to shape it over a mold, ideal for larger, simpler parts. Injection molding injects molten plastic into a mold, best for small, detailed, high-volume parts.

Choosing between vacuum forming and injection molding depends on factors like part complexity, production volume, and budget. Delve deeper to explore how each process works and which one suits your project.

Vacuum forming is generally cheaper for low volumes.Doğru

Vacuum forming has lower tooling costs and faster setup times, making it more cost-effective for small production runs.

Injection molding is only suitable for small parts.Yanlış

While injection molding excels in producing small, intricate parts, it can also be used for larger components, though it may be less cost-effective.

What is Vacuum Forming and Injection Molding?

Net Tanımlar

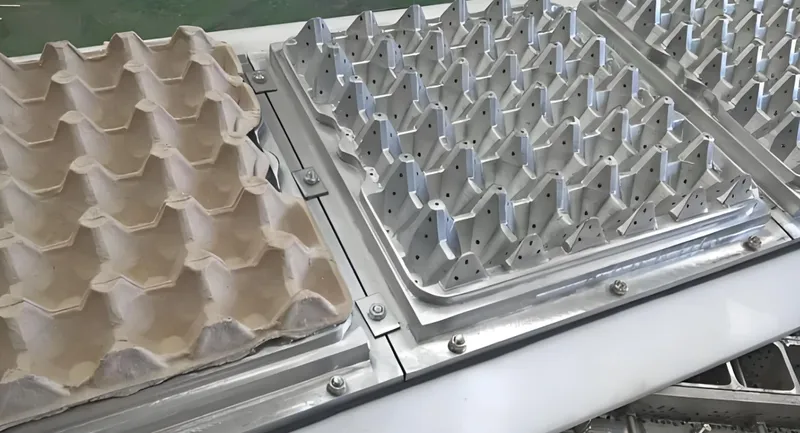

- Vakum Şekillendirme3 (Thermoforming): A manufacturing process where a thermoplastic sheet is heated to a pliable temperature, stretched over a single-surface mold (male or female), and shaped using vacuum pressure. The vacuum pulls the sheet against the mold, forming a hollow, thin-walled part. It is often referred to as thermoforming, a broader category that includes other forming techniques.

- Enjeksiyon Kalıplama: A process where plastic pellets are melted and injected under high pressure into a double-sided mold cavity. The material cools and solidifies, forming a precise, solid part that is ejected from the mold. It is widely used for producing complex, high-volume parts with tight tolerances.

Sınıflandırma

-

Sürece göre: Vacuum forming is a subset of thermoforming, relying on heat and vacuum pressure. Injection molding is a distinct process involving high-pressure injection of molten material.

-

Malzemelerle: Both primarily use termoplastikler4 (e.g., ABS, PVC). Injection molding also supports thermosets, rubber, liquid silicone rubber (LSR), and metal injection molding (MIM).

- Uygulamalara göre: Vacuum forming is suited for large, shallow parts with simpler geometries, such as packaging or automotive interiors. Injection molding excels in small, intricate parts like medical devices or consumer electronics components.

Vacuum forming is limited to thermoplastics.Doğru

Vacuum forming primarily uses thermoplastics due to their ability to be heated and reshaped.

Injection molding can only use plastics.Yanlış

Injection molding can also process thermosets, rubber, and even metals through metal injection molding (MIM).

When to Use Vacuum Forming vs. Injection Molding?

Tipik Uygulama Senaryoları

- Vakum Şekillendirme: Commonly used in industries requiring large, lightweight parts with moderate detail, including:

- Paketleme: Blister packs, clamshells, and trays.

- Otomotiv: Interior panels, dashboards, and trim.

- Tıbbi: Device housings and trays.

- Consumer Products: Appliance covers, display stands.

- Enjeksiyon Kalıplama: Preferred for high-precision, complex parts across various sectors, such as:

- Otomotiv: Gears, connectors, and engine components.

- Tıbbi: Syringes, surgical instruments, and diagnostic equipment.

- Tüketici Elektroniği: Phone cases, keyboard keys, and remote controls.

- Endüstriyel: Valves, fittings, and tool components.

Artılar ve Eksiler Karşılaştırması

The following table summarizes the advantages and disadvantages of each process:

| Aspect | Vakum Şekillendirme | Enjeksiyon Kalıplama |

|---|---|---|

| Artıları | - Lower tooling costs - Faster setup - Suitable for large parts - Ideal for prototyping and short runs |

- Yüksek üretim oranları - Excellent detail and finish - Consistent quality - Wide material range |

| Eksiler | - Limited to simpler geometries - Less detail - Variable wall thickness - Not for high volumes |

- High initial tooling costs - Longer setup times - Higher waste (with cold runners) - Not economical for low volumes |

Vacuum forming is better for prototyping.Doğru

Due to its lower tooling costs and faster setup, vacuum forming is often preferred for prototyping and short production runs.

Injection molding cannot produce large parts.Yanlış

While less common, injection molding can produce large parts, but it may require specialized equipment and higher costs.

How Do the Processes Work?

Süreç Tam İş Akışı Dökümü

-

Vakum Şekillendirme:

-

Isıtma: A thermoplastic sheet is placed in an oven and heated until soft and pliable.

-

Şekillendirme: The sheet is stretched over a mold (male for inner dimensions, female for outer dimensions) using mechanical or air pressure.

-

-

Vakum Uygulaması5: A vacuum is applied to pull the sheet tightly against the mold, forming the shape.

-

Soğutma: The sheet cools on the mold to set the shape.

- Bitiriyorum: The part is removed, trimmed (manually or via CNC), and may be sanded, painted, or stenciled.

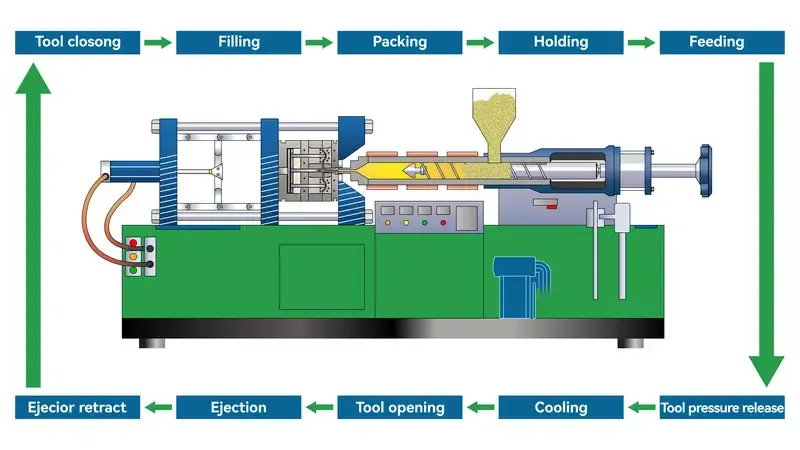

- Enjeksiyon Kalıplama:

-

Malzeme Hazırlama6: Plastic pellets are fed into a hopper and melted in a heated barrel.

- Injection: The molten plastic is injected into a closed mold under high pressure.

-

Soğutma: The mold is cooled to solidify the plastic.

-

Ejection: The mold opens, and the part is ejected using pins or other mechanisms.

-

Secondary Operations: Parts may be trimmed, assembled, or finished (e.g., painting, silk-screening).

Malzeme Uyumluluk Açıklaması

- Vakum Şekillendirme: Limited to thermoplastics that can be heated and stretched without degrading. Common materials include:

- ABS (Acrylonitrile Butadiene Styrene): Durable and versatile.

- Acrylic: Transparent and impact-resistant.

- Polycarbonate: Strong and heat-resistant.

- PVC (Polyvinyl Chloride): Flexible and chemical-resistant.

- PETG (Polyethylene Terephthalate Glycol): Clear and food-safe.

- Material choice affects part strength, clarity, and cost.

- Enjeksiyon Kalıplama: Supports a broader range of materials, offering greater flexibility:

- Termoplastikler: ABS, polypropylene, polyethylene, polystyrene, PVC.

- Thermosets: Epoxy, phenolic (for heat-resistant parts).

- Rubber and LSR: For flexible or medical-grade parts.

- Glass-Filled Polymers: For enhanced strength.

- Specialty Plastics: Fireproof, food-safe, or biocompatible grades.

- Metals (MIM): For high-strength, small components.

- Material selection depends on part requirements for strength, flexibility, or environmental resistance.

Vacuum forming can use the same materials as injection molding.Yanlış

While both processes use thermoplastics, injection molding supports a wider range of materials, including thermosets and metals.

Material choice impacts part properties in both processes.Doğru

The selected material directly influences the strength, flexibility, and other properties of the final part.

What are the Design Considerations for Each Process?

Tasarım Kontrol Listesi

- For Vacuum Forming:

- Include taslak açıları7 (typically 3–5°) to ease part removal.

- Avoid deep draws or complex undercuts due to single-direction shaping.

- Aim for uniform wall thickness to prevent thinning during stretching.

- Doğrulama malzeme uyumluluğu8 with heating and forming processes.

- Enjeksiyon Kalıplama için:

- Design for easy ejection using ejector pins or stripper plates.

- Incorporate proper gating (e.g., edge or pin gates) to minimize visible marks.

- Ensure uniform cooling to avoid warping or sink marks.

- Optimize the flow path to prevent air traps or incomplete filling.

Süreç Seçimi Karar Verme

The following table provides a decision-making framework for choosing between vacuum forming and injection molding:

| Criteria | Vakum Şekillendirme | Enjeksiyon Kalıplama |

|---|---|---|

| Parça Boyutu | Large, shallow parts | Small to medium, complex parts |

| Üretim Hacmi | Low to medium (250–2,500 units/year) | High (thousands to millions) |

| Tooling Budget | Lower cost, simpler molds | Higher cost, complex molds |

| Parça Karmaşıklığı | Simple geometries, no undercuts | Intricate designs, undercuts, threads |

| Malzeme İhtiyaçları | Thermoplastics only | Thermoplastics, thermosets, metals |

Decision Tree Prompt:

- What is your üretim hacmi9?

- Low to medium (choose vacuum forming).

- High (consider injection molding).

-

How complex is your part?

- Simple, shallow (vacuum forming).

- Detailed, intricate (injection molding).

-

What is your budget for tooling?

- Limited (vacuum forming).

- Higher (injection molding).

-

Do you need specific materials?

- Thermoplastics only (either process).

- Thermosets or metals (injection molding).

Vakumlu şekillendirme yüksek hacimli üretim için idealdir.Yanlış

Vacuum forming is better suited for low to medium production volumes due to its slower cycle times and simpler tooling.

Injection molding requires more design considerations than vacuum forming.Doğru

Injection molding involves more complex design requirements, such as gating, cooling, and ejection, to ensure part quality.

İlgili Teknolojiler Nelerdir?

İlgili Teknoloji Navigasyon

- Yukarı Akım Teknolojileri:

- Material Science: Development of advanced thermoplastics, thermosets, and specialty plastics.

- Mold Design Software: CAD/CAM tools for creating precise molds.

-

Alt Akım Teknolojileri:

- Assembly Techniques: Joining parts via adhesives, welding, or fasteners.

- Surface Finishing: Painting, silk-screening, or coating for aesthetics and durability.

- Integration: Combining with CNC machining or 3D printing for hybrid manufacturing.

-

İlgili Süreçler:

- Şişirme Kalıplama: For hollow parts like bottles and containers.

- Rotasyonel Kalıplama: For large, hollow parts like tanks and playground equipment.

- Compression Molding: For thermoset materials like automotive composites.

- 3D Printing (Additive Manufacturing): For prototyping or low-volume, complex parts.

Vacuum forming and injection molding are the only plastic manufacturing processes.Yanlış

There are several other processes, such as blow molding, rotational molding, and 3D printing, each with unique applications.

Sonuç

Vacuum forming and injection molding are both valuable plastic manufacturing processes, each with its own strengths and ideal use cases. Vacuum forming is cost-effective for large, simple parts and low to medium production volumes, while injection molding excels in producing small, complex parts with high precision and consistency for large-scale production.

When deciding between the two, consider factors such as part size, complexity, production volume, budget, and material requirements. By understanding the differences and applications of each process, you can make an informed choice that best suits your project's needs.

-

Discover the intricacies of injection molding, its benefits, and why it's ideal for detailed parts in high volumes. ↩

-

Learn about various plastic manufacturing processes to make informed decisions for your production needs. ↩

-

Explore this link to understand the intricacies of Vacuum Forming and its applications in various industries. ↩

-

Learn about thermoplastics, their properties, and how they are utilized in different manufacturing processes. ↩

-

Understanding Vacuum Application is crucial for mastering vacuum forming techniques and achieving high-quality results. ↩

-

Learning about Material Preparation is essential for optimizing the injection molding process and ensuring product quality. ↩

-

Understanding draft angles is crucial for successful part removal in vacuum forming, ensuring efficiency and quality in production. ↩

-

Learning about material compatibility ensures that the right materials are used for optimal results in both forming processes. ↩

-

Exploring production volume helps in selecting the right manufacturing process, optimizing costs and efficiency for your project. ↩