Choosing the right manufacturing process is paramount to your product's success, impacting everything from cost and durability to production speed and aesthetic appeal. Within the world of plastics manufacturing, thermoforming stands out for its versatility. But dive a little deeper, and you'll find a critical distinction: heavy gauge (or thick gauge) versus thin gauge thermoforming1.

- 1. I. Basic Cognitive Level: Establishing Conceptual Framework

- 2. II. Application Analysis Level: Solving User Decision-Making Problems

- 3. III. Technical Deep Dive Level: Meeting Professional Reader Needs

- 4. IV. Practical Tools Level: Enhancing Content Operability

- 5. V. Extension Level: Building a Knowledge Network

I. Basic Cognitive Level: Establishing Conceptual Framework

Before we explore the "why," let's define our terms.

What is Thermoforming?

-

Full Technical Name: Termoform

-

Common Aliases: Vacuum forming (though this is a specific type of thermoforming), pressure forming, drape forming.

-

Core Principle: Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and then trimmed to create a usable product. The force used to form the sheet can be vacuum, air pressure, mechanical force, or a combination.

Defining the Gauges:

The primary differentiator is the thickness of the plastic sheet used:

- Heavy Gauge Thermoforming (Thick Gauge Thermoforming):

-

Definition: This process uses plastic sheets typically thicker than 0.120 inches (3mm). Sheets are loaded individually into the thermoforming machine.

-

Core Principles: Focuses on creating durable, structural parts, often with complex three-dimensional shapes. Tooling is generally more robust than thin gauge but less expensive than injection molding tooling.

- Thin Gauge Thermoforming:

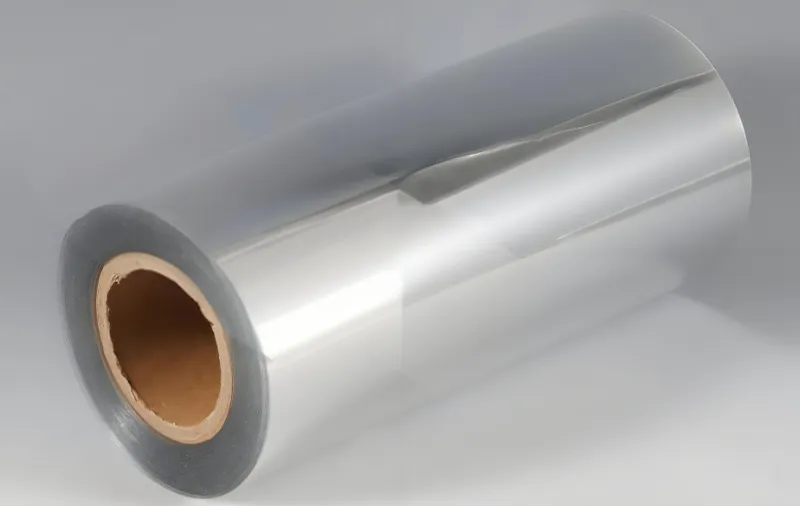

- Definition: This process uses plastic sheets or films typically thinner than 0.060 inches (1.5mm), often fed from a continuous roll.

- Core Principles: Geared towards high-volume production of disposable or semi-disposable items, often for packaging. Speed and cost-efficiency per part are key.

(Note: There's a "medium gauge" range between 0.060" and 0.120", which can sometimes blur the lines, but the core distinctions generally hold.)

Preliminary Classification:

-

Sürece göre:

-

Heavy Gauge: Often utilizes vacuum forming, pressure forming, twin-sheet forming (fusing two sheets for hollow parts).

-

Thin Gauge: Predominantly roll-fed, utilizing vacuum forming, and sometimes pressure forming for finer detail.

-

Malzemelerle:

-

Heavy Gauge: ABS, HIPS, HDPE, LDPE, PP, PVC, PETG, Acrylic, Polycarbonate. Material choice is driven by structural needs, UV resistance, chemical resistance, etc.

-

Thin Gauge: PET, RPET, PS, HIPS, PVC, PP, OPS. Material choice often prioritizes clarity, food safety, and cost.

-

Uygulamalara göre: (More on this in the next section)

-

Heavy Gauge: Permanent, structural components.

- Thin Gauge: Packaging, disposable items.

II. Application Analysis Level: Solving User Decision-Making Problems

The "why it matters" truly shines when we look at where each type is used.

Typical Application Scenarios:

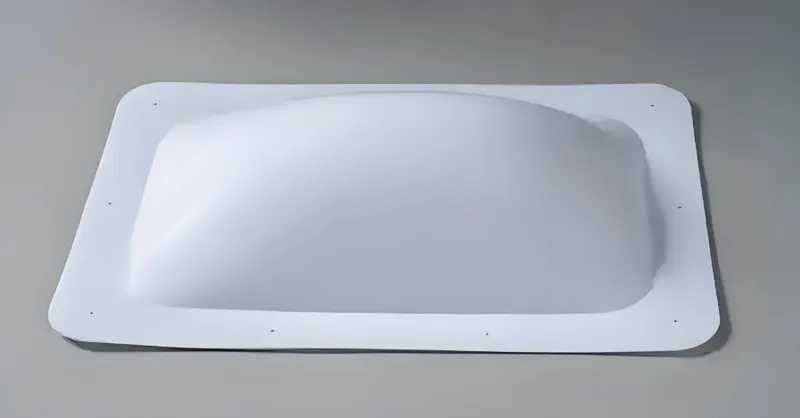

A. Heavy Gauge Thermoforming: Think durable, long-lasting parts, often replacing metal or fiberglass.

- Automotive & Transportation: Vehicle dashboards, door panels, truck bed liners, dunnage trays, tractor components, ATV fenders.

-

Industrial Equipment: Machine housings, enclosures, guards, trays.

-

Tıbbi: Medical device enclosures, hospital bed components, trays for instruments.

-

Retail & Signage: Point-of-purchase displays, kiosks, large signage.

-

Tüketim Malları: Kayak hulls, luggage exteriors, spa pools.

B. Thin Gauge Thermoforming: Think high-volume, often single-use or short-term use items.

-

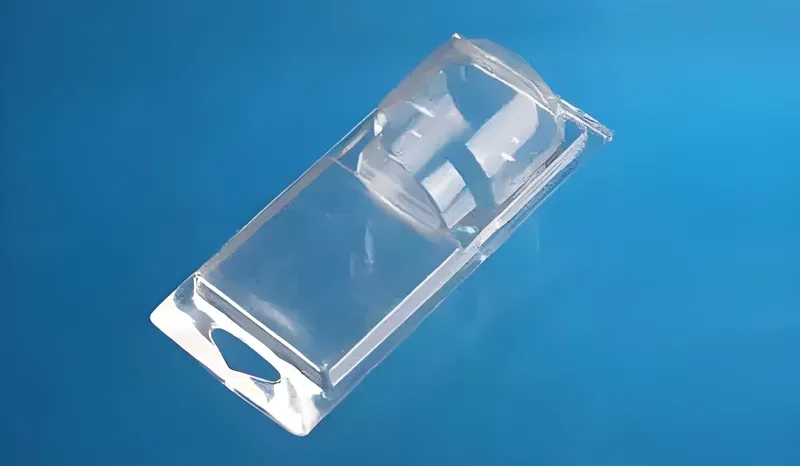

Gıda Ambalajı: Clamshells, blister packs, trays for meats and produce, take-out containers, yogurt cups.

-

Consumer Goods Packaging: Blister packs for electronics or toys, cosmetic trays.

-

Tıbbi Ambalaj: Sterile packaging for medical devices, pharmaceutical blister packs.

-

Horticulture: Seedling trays, flower pots.

-

Disposable Goods: Disposable cups, plates, lids.

Pros and Cons Comparison:

| Özellik | Ağır Ölçülü Termoform | Thin Gauge Thermoforming | Notes (vs. Injection Molding - ZetarMold's expertise) |

|---|---|---|---|

| Kalıp Maliyeti | Moderate (lower than IM) | Düşük | IM: High tooling cost |

| Parça Boyutu | Can produce very large parts | Generally smaller parts | IM: Can be large, but tooling is massive |

| Dayanıklılık | High, structural integrity | Low to moderate, often flexible | IM: High durability, solid parts |

| Detail/Complexity | Good, but less intricate than IM; undercuts possible | Simpler forms, limited detail | IM: Excellent for complex, intricate details |

| Duvar Kalınlığı | Thicker, more uniform (but can thin at corners) | Thinner, can have significant thinning | IM: Very consistent wall thickness possible |

| Üretim Hızı | Slower cycle times (sheet-fed) | Very fast cycle times (roll-fed) | IM: Fast cycle times once mold is ready |

| Malzeme Atıkları | Higher (trimming of individual sheets) | Lower (trimming from roll, often recyclable in-line) | IM: Relatively low, regrind often reused |

| Unit Cost | Higher for small parts, competitive for large parts | Very low for high volumes | IM: Low unit cost at very high volumes |

| Minimum Volume | Lower runs viable | Best for high-volume production | IM: Typically requires high volumes to justify tooling |

Why this comparison matters: If you need a large, durable housing for equipment and expect moderate volumes, heavy gauge thermoforming might be a good fit due to lower tooling costs than injection molding. However, if you need millions of small, intricate parts with tight tolerances, injection molding is likely superior. For disposable packaging, thin gauge thermoforming is king.

III. Technical Deep Dive Level: Meeting Professional Reader Needs

Process Full Workflow Breakdown (Key Differences Highlighted):

- Material Loading:

-

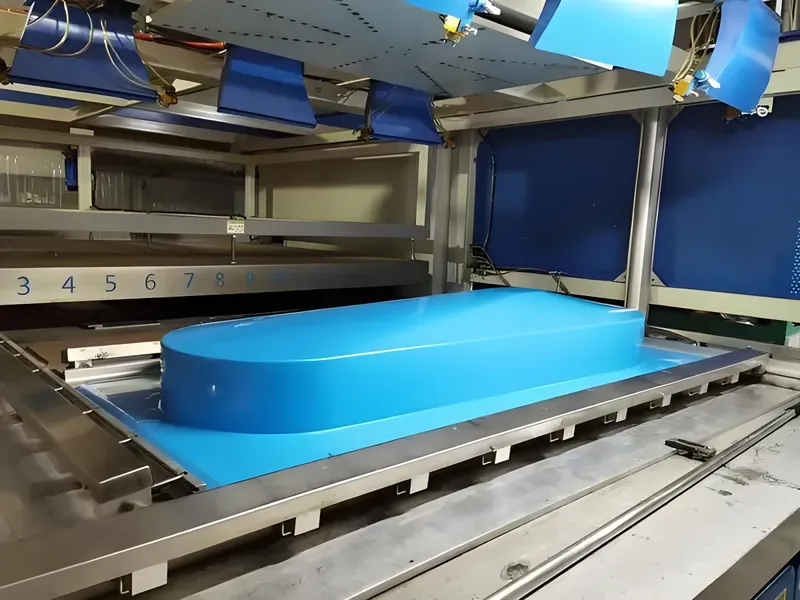

Heavy Gauge: Individual pre-cut plastic sheets are clamped into a frame.

-

Thin Gauge: Plastic film/sheet is fed continuously from a roll.

- Isıtma:

-

The plastic sheet is heated (e.g., by radiant, infrared, or convection heaters) until it becomes soft and pliable (its glass transition temperature).

-

Heavy Gauge: Longer heating times due to thickness. Even heating is critical to prevent cold spots.

-

Thin Gauge: Faster heating due to thinner material.

- Şekillendirme:

- The softened sheet is stretched over or into a temperature-controlled mold.

-

Vakum Şekillendirme3: Air is evacuated between the sheet and mold, atmospheric pressure forces the sheet against the mold. Common for both.

-

Pressure Forming: Air pressure is applied to the non-mold side of the sheet, pushing it onto the mold. Used for sharper detail, common in heavy gauge for defined features, and sometimes in thin gauge for better replication.

-

Mechanical Forming (Matched Molds): Two mold halves press the sheet into shape. More common for heavy gauge.

-

Twin-Sheet Forming (Heavy Gauge Specific): Two heated sheets are formed and fused simultaneously to create hollow or double-walled parts.

- Soğutma:

-

The formed part is cooled (often with fans, sometimes chilled molds) to solidify its shape.

-

Heavy Gauge: Longer cooling times.

- Thin Gauge: Faster cooling.

- De-molding & Trimming:

-

The part is removed from the mold.

-

Excess plastic (the "web" or "skeleton") is trimmed off.

-

Heavy Gauge: Often trimmed using CNC routers or robotic trimming stations. More material to trim.

-

Thin Gauge: Often die-cut in-line or near-line. Less material to trim per part.

Anahtar Parametreler: Heating temperature, heating time, vacuum/pressure levels, cooling time, mold temperature.

Material Compatibility Explanation:

- General Suitability: Most thermoplastics can be thermoformed. The choice depends on the application's requirements (e.g., strength, clarity, cost, chemical resistance, temperature resistance).

-

Impact of Gauge:

-

Heavy Gauge: Allows for materials like Polycarbonate (PC) for high impact, ABS for good all-around properties, or HDPE for chemical resistance in thicker sections. The sheet's inherent strength is critical.

-

Thin Gauge: Often uses PET for clarity and food safety, PS for low cost and ease of forming, or PP for living hinges and toughness. Material flow and stretchability at thin gauges are key.

-

Moisture Absorption: Some materials (e.g., ABS, PC, PETG) are hygroscopic4 and must be dried before thermoforming to prevent bubbles or surface defects, especially critical for heavy gauge where imperfections are more noticeable and structural integrity is key.

IV. Practical Tools Level: Enhancing Content Operability

Design Checklist (Reminders of Process Limitations):

When considering thermoforming, ask these questions:

-

Part Size & Geometry: Is it very large? (Favors Heavy Gauge) Is it relatively flat with pockets or more box-like?

-

Wall Thickness Requirements: Can you tolerate some wall thinning, especially in corners and deep draws? (Thinning is inherent to thermoforming).

-

Taslak Açıları: Are sufficient draft angles (typically 3-5 degrees, more for textured surfaces) incorporated for easy de-molding?

-

Detail & Tolerances: How sharp do corners and edges need to be? Are tolerances very tight? (Pressure forming helps; IM excels here).

-

Undercuts: Are undercuts necessary? (Possible with thermoforming using moving mold sections, but adds complexity and cost).

-

Malzeme Seçimi: What are the structural, aesthetic, chemical, and temperature requirements?

-

Üretim Hacmi: Low, medium, or high volume? (Influences tooling investment and per-part cost).

-

Secondary Operations: Will it require extensive trimming, painting, assembly?

-

Bütçe: What is the tooling budget vs. per-part cost target?

-

Appearance: Are both sides of the part visible? (Thermoforming typically only controls one surface well; twin-sheet can address this for heavy gauge).

Process Selection Decision-Making (Basic Ideas):

Is Thermoforming Right? If so, Heavy or Thin Gauge?

-

Start with the End Use:

-

Durable, structural, long-life part? -> Consider Ağır Ölçülü Termoform or alternatives like Enjeksiyon Kalıplama5, Rotational Molding.

-

Disposable, packaging, high volume? -> Likely Thin Gauge Thermoforming.

-

If considering Heavy Gauge Thermoforming vs. Injection Molding:

-

Tooling Budget: Lower for thermoforming.

-

Part Size: Very large parts often favor thermoforming.

-

Complexity/Precision: Higher for injection molding.

-

Hacim: Lower volumes (hundreds to low thousands) can be economical for heavy gauge. Higher volumes can justify IM.

-

Wall Thickness Consistency: Better with IM.

-

Decision Tree Prompts:

- Is the primary function structural integrity and long-term use?

-

YES -> Consider Heavy Gauge. Then ask:

-

Is the part very large (e.g., > 2x2 feet)? (Favors Heavy Gauge)

-

Are annual volumes < 5,000-10,000 units? (Favors Heavy Gauge tooling cost)

-

Are extremely tight tolerances and complex internal features NOT critical? (Favors Heavy Gauge)

-

If answers trend opposite, Injection Molding might be better.

-

NO (e.g., it's for packaging, disposable use) -> Consider Thin Gauge. Then ask:

-

Are volumes very high (tens of thousands to millions)? (Favors Thin Gauge)

-

Is low unit cost critical? (Favors Thin Gauge)

-

Is the part relatively simple in form and thin-walled? (Favors Thin Gauge)

V. Extension Level: Building a Knowledge Network

Understanding how thermoforming fits into the broader manufacturing landscape is key.

Related Technology Navigation:

-

Yukarı Akım Teknolojileri:

-

Plastic Resin Manufacturing: The source of raw materials.

-

Sheet Extrusion: The process that creates the plastic sheets or rolls used in thermoforming. Many thermoformers have in-house extrusion.

-

Downstream Technologies (Post-Forming):

-

Kırpma: CNC routing, robotic trimming, die-cutting.

-

Montaj: Joining thermoformed parts with other components (fasteners, adhesives).

-

Bitiriyorum: Painting, silk-screening, coating, EMI/RFI shielding.

-

Alternative/Complementary Technologies:

-

Injection Molding (ZetarMold's Specialty): Best for complex, high-precision, high-volume solid parts. Higher tooling costs, but lower part costs at scale.

-

Rotasyonel Kalıplama: For very large, hollow, low-stress parts (e.g., tanks, playground equipment). Low tooling cost, slow cycle times.

-

Şişirme Kalıplama: For hollow parts like bottles and containers.

-

3D Printing (Additive Manufacturing): Excellent for prototyping, custom low-volume parts, complex geometries not possible with molding.

-

Fabrication (from sheet stock): Cutting, bending, and assembling plastic sheets without heat forming; for simpler, often angular designs.

Understanding the difference between heavy and thin gauge thermoforming is not just academic; it's a practical necessity for anyone involved in product development and manufacturing. It directly impacts cost, performance, and suitability for your intended application.

-

Discover the advantages of thin gauge thermoforming for high-volume production and its role in packaging. ↩

-

Explore this link to understand the thermoforming process, its applications, and benefits in various industries. ↩

-

Learn about vacuum forming, a key technique in thermoforming, and its advantages for creating detailed shapes. ↩

-

Learn about hygroscopic materials to ensure quality in your thermoforming projects, preventing defects and ensuring structural integrity. ↩

-

Discover the advantages of Injection Molding to see how it compares with Thermoforming for complex parts. ↩