Thermoforming, a versatile manufacturing process where heated plastic sheets are shaped using molds, is evolving rapidly. Its future will be shaped by sustainability, technological advancements1, and expanding applications, making it a key player in modern manufacturing.

Thermoforming’s future lies in sustainable materials2, automation, and new applications like electric vehicles3 and medical devices, driven by eco-friendly plastics and digital tools.

Understanding the future of thermoforming4 is crucial for industries seeking cost-effective, flexible, and environmentally conscious manufacturing solutions. Explore how advancements in materials, technology, and applications are shaping this process.

Thermoforming will become obsolete due to new manufacturing technologies.False

Thermoforming is evolving with sustainable materials and automation, ensuring its relevance in modern manufacturing.

Thermoforming is only used in packaging.False

While packaging is a major application, thermoforming is also vital in automotive, medical, and consumer goods industries.

- 1. What is Thermoforming and How Does It Work?

- 2. What are the Typical Applications of Thermoforming?

- 3. How Does Thermoforming Compare to Other Manufacturing Processes?

- 4. What is the Full Workflow of the Thermoforming Process?

- 5. What are the Key Design Considerations for Thermoforming?

- 6. What Technologies are Related to Thermoforming?

- 7. What are the Future Trends in Thermoforming?

- 8. Conclusion

What is Thermoforming and How Does It Work?

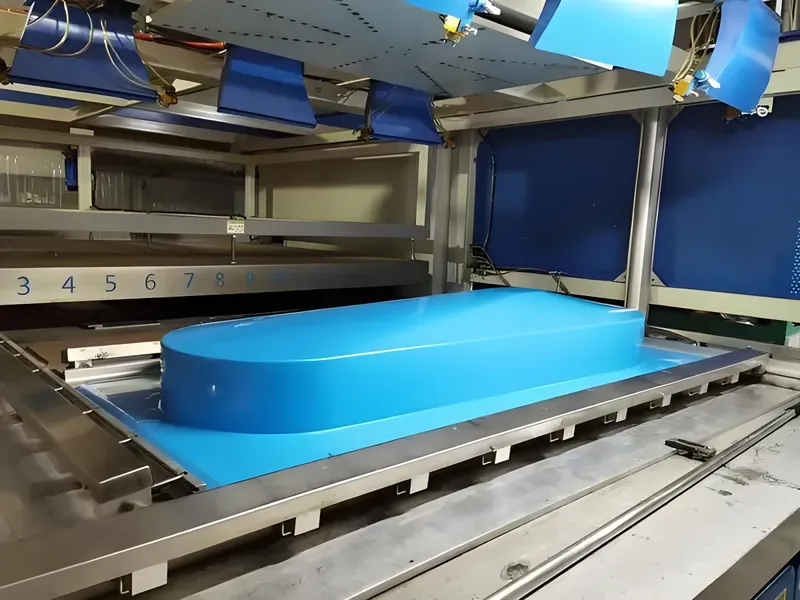

Thermoforming is a manufacturing process that heats plastic sheets and forms them into specific shapes using molds, offering flexibility and cost-effectiveness across industries.

Thermoforming heats thermoplastic sheets5 to a pliable state, shapes them using molds, and cools them to create products for packaging, automotive, and medical applications.

| Process Type | Typical Applications | Notes |

|---|---|---|

| Vacuum Forming | Packaging, trays | Uses vacuum pressure |

| Pressure Forming | Complex shapes, automotive | Uses compressed air |

| Twin-Sheet Forming | Hollow parts, pallets | Forms two sheets simultaneously |

Definition and Core Principles

Thermoforming, also known as plastic thermoforming or vacuum forming6, involves heating a thermoplastic sheet to a temperature where it becomes pliable (typically 150°C to 250°C). The sheet is then shaped using a mold through vacuum, pressure, or mechanical force. Once cooled, the plastic retains the mold’s shape. This process is widely used due to its ability to produce lightweight, cost-effective parts with complex geometries.

Classification of Thermoforming

Thermoforming can be classified based on several factors:

-

By Process: Includes vacuum forming (for simple shapes), pressure forming (for detailed parts), mechanical forming (using physical force), and twin-sheet forming (for hollow structures).

-

By Material: Common thermoplastics include PET (for clarity), PVC (for flexibility), ABS (for impact strength), and PC (for heat resistance).

-

By Application: Used in packaging7 (blister packs), automotive8(dashboards), medical (sterile trays), and consumer goods (appliance housings).

These classifications highlight thermoforming’s adaptability to various industry needs.

Thermoforming is limited to simple shapes.False

Advanced techniques like pressure forming allow for complex, detailed parts with undercuts.

Thermoforming uses only a few types of plastics.False

A wide range of thermoplastics, including PET, PVC, ABS, and PC, are used based on application requirements.

What are the Typical Applications of Thermoforming?

Thermoforming’s flexibility makes it suitable for a wide range of industries, from packaging to automotive, offering cost-effective solutions for complex designs.

Thermoforming is used in packaging, automotive, medical, and consumer goods for its ability to create lightweight, cost-effective parts with design flexibility.

Packaging Industry

Thermoforming is ideal for producing blister packs, trays, and clamshells due to its low tooling costs and quick production setups. It’s particularly suited for medium to large production runs where customization is needed.

Automotive Industry

In automotive manufacturing, thermoforming is used for interior components like dashboards, door panels, and seat backs. Its ability to produce large, lightweight parts makes it valuable for electric vehicles (EVs), where weight reduction is critical for efficiency.

Medical Industry

Thermoforming is essential for creating sterile packaging, disposable devices, and custom trays. Its ability to form complex shapes that meet strict regulatory standards makes it a go-to process in medical manufacturing.

Consumer Goods

From electronics housings to toys, thermoforming allows for intricate designs and quick prototyping, meeting the demands of fast-paced consumer markets.

Thermoforming is only cost-effective for small production runs.False

Thermoforming is economical for medium to large runs due to lower tooling costs compared to other processes.

Thermoforming offers high design flexibility for complex parts.True

Techniques like pressure forming enable the creation of detailed, intricate shapes with undercuts.

How Does Thermoforming Compare to Other Manufacturing Processes?

Thermoforming offers distinct advantages and limitations compared to other plastic manufacturing methods, making it suitable for specific applications.

Thermoforming provides lower tooling costs and faster turnaround than injection molding but may have higher per-unit costs for very large volumes.

Pros and Cons Comparison

| Aspect | Pros | Cons |

|---|---|---|

| Cost | Lower initial tooling costs, cost-effective for medium to large runs. | Higher per-unit cost for very high volumes compared to injection molding. |

| Design | High flexibility, suitable for complex shapes with undercuts. | Part thickness can vary, affecting structural integrity. |

| Speed | Quick turnaround for prototyping and production. | Less suitable for extremely high-volume production. |

| Material | Wide range of thermoplastics available, including recyclable options. | Limited to thermoplastics, not suitable for thermosets. |

| Finish | Lightweight parts with good impact resistance, potential for high gloss. | Surface finish may require secondary operations for high-quality aesthetics. |

This comparison highlights thermoforming’s strengths in flexibility and cost for medium-volume production, while injection molding excels in high-volume, precision parts.

Thermoforming is always cheaper than injection molding.False

While tooling costs are lower, per-unit costs can be higher for very large production runs.

Thermoforming allows for quick prototyping and design changes.True

Its lower tooling costs and faster setup make it ideal for rapid prototyping.

What is the Full Workflow of the Thermoforming Process?

The thermoforming process9 involves several key steps, each critical for producing high-quality parts efficiently.

The thermoforming workflow includes material selection10, heating, forming, cooling, trimming, and inspection, with precise control over temperature and pressure.

Step-by-Step Breakdown

-

Material Selection: Choose a thermoplastic sheet (e.g., PET, ABS) based on part requirements.

-

Sheet Preparation: Cut the sheet to size for the mold.

-

Heating: Heat the sheet uniformly to its forming temperature (e.g., 150°C for PET).

-

Forming: Use vacuum, pressure (80-100 psi for pressure forming), or mechanical force to shape the sheet over the mold.

-

Cooling: Allow the part to cool and solidify on the mold.

-

Trimming: Remove excess material (flash) using cutting tools or robots.

-

Inspection and Packaging: Inspect for defects and package for shipping.

Material Compatibility

Different materials affect the process and final product:

-

PET: High clarity, used in packaging, requires careful heating to avoid crystallization.

-

ABS: Impact-resistant, used in automotive, but challenging to recycle.

-

PC: Heat-resistant, used in electronics, but brittle if mishandled.

Thermoforming requires precise temperature control for each material.True

Different thermoplastics have unique forming temperatures, critical for achieving desired properties.

All thermoforming processes use the same forming pressure.False

Pressure varies based on the process; pressure forming uses higher pressures for detailed parts.

What are the Key Design Considerations for Thermoforming?

Designing for thermoforming requires attention to specific factors to ensure part quality and process efficiency.

Key design considerations11 include draft angles, wall thickness, undercuts, material shrinkage, and trim lines to optimize part quality and manufacturability.

Design Checklist

-

Draft Angles: Include 1°-5° on vertical surfaces for easy part removal.

-

Wall Thickness: Aim for uniformity to avoid thinning in deep draws.

-

Undercuts: Minimize or use removable mold sections to prevent forming issues.

-

Material Shrinkage: Account for shrinkage (e.g., 1-2% for PET) in design.

-

Trim Lines: Plan for easy trimming to reduce waste and finishing time.

Process Selection Decision-Making

-

Use Thermoforming When:

-

Production volumes are medium to large.

-

Parts have complex geometries or large sizes.

-

Quick prototyping or low tooling costs are needed.

-

-

Consider Injection Molding When:

-

Production volumes are very high.

-

Parts require tight tolerances.

-

Material waste must be minimized.

-

Uniform wall thickness is crucial in thermoforming.True

It ensures consistent strength and avoids material thinning in deep draws.

Thermoforming cannot handle parts with undercuts.False

With proper mold design, thermoforming can accommodate undercuts using techniques like removable inserts.

What Technologies are Related to Thermoforming?

Thermoforming is part of a broader manufacturing ecosystem, with upstream and downstream technologies enhancing its capabilities.

Related technologies include plastic extrusion, material science, secondary finishing, and emerging tools like 3D printing12 and smart manufacturing.

Upstream Technologies

-

Plastic Extrusion: Produces thermoplastic sheets used in thermoforming.

-

Material Science: Develops new thermoplastics with enhanced properties like recyclability and heat resistance.

Downstream Processes

-

Secondary Finishing: Includes printing, decorating, or assembling to enhance aesthetics and functionality.

-

Quality Control: Uses inspection systems to detect defects and ensure compliance.

Complementary and Emerging Technologies

-

Injection Molding: Suitable for high-volume, precision parts.

-

3D Printing: Used for prototyping or creating complex molds.

-

Smart Manufacturing: Integrates IoT and AI for real-time process optimization, reducing waste and improving efficiency.

Thermoforming is isolated from other manufacturing technologies.False

It integrates with upstream and downstream processes, as well as emerging technologies like smart manufacturing.

3D printing is replacing thermoforming.False

3D printing complements thermoforming by aiding in prototyping and mold creation, but thermoforming remains essential for mass production.

What are the Future Trends in Thermoforming?

The future of thermoforming is shaped by sustainability, technological advancements, and new applications, ensuring its continued relevance in manufacturing.

Key trends include sustainable materials, automation, digital tools, and growth in electric vehicles and medical devices, driving innovation and efficiency.

Sustainability and Eco-Friendly Materials

-

Increased use of recyclable materials like rPET and biodegradable plastics to meet environmental regulations.

-

Innovations in materials offering durable finishes, reducing the need for secondary operations.

Technological Advancements

-

Automation: Robotics and 6-axis trimming enhance precision and eliminate post-molding finishes.

-

Digitalization: CAD and simulation software optimize mold designs and predict outcomes, reducing prototyping needs.

- Real-Time Monitoring: Systems like ToolVu reduce downtime by monitoring air pressure, temperature, and tool strain.

Material Innovation

- Development of advanced thermoplastics with properties like flame resistance, UV stability, and high impact strength for demanding applications.

New Applications

-

Electric Vehicles (EVs): Thermoformed parts contribute to lightweighting, improving fuel efficiency and integrating with sleek designs.

-

Medical Devices: Growth in sterile packaging and disposable devices, leveraging thermoforming’s ability to create complex, precise parts.

Energy Efficiency

- Innovations in heating and forming processes, such as quartz heaters, reduce energy consumption and operational costs.

Customization

- Thermoforming’s ability to produce customized parts at scale meets the growing demand for personalized products in consumer electronics and medical devices.

Thermoforming will focus more on sustainability in the future.True

The industry is shifting toward recyclable and biodegradable materials to meet environmental goals.

Automation in thermoforming reduces precision.False

Automation enhances precision and efficiency, reducing human error and waste.

Conclusion

The future of thermoforming is bright, driven by sustainability, technological innovation, and expanding applications. As industries seek cost-effective, flexible, and eco-friendly manufacturing solutions, thermoforming will continue to evolve, offering new possibilities for lightweight, durable, and customized products.

-

Explore the cutting-edge technologies that are enhancing thermoforming processes, improving efficiency and product quality. ↩

-

Discover how sustainable materials are revolutionizing thermoforming, making it more eco-friendly and efficient for various applications. ↩

-

Learn about the innovative applications of thermoforming in electric vehicles, contributing to lightweight and efficient designs. ↩

-

Understanding thermoforming can enhance your knowledge of modern manufacturing techniques and their applications across various industries. ↩

-

Exploring thermoplastic sheets will provide insights into the materials that drive innovation in manufacturing processes. ↩

-

Learning about vacuum forming can help you grasp the nuances of different thermoforming techniques and their specific uses. ↩

-

Discover how thermoforming revolutionizes packaging with cost-effective and customizable solutions. ↩

-

Learn how thermoforming enhances automotive design and efficiency, especially for electric vehicles. ↩

-

Understanding the thermoforming process is essential for anyone involved in manufacturing, as it outlines the critical steps for producing high-quality parts efficiently. ↩

-

Choosing the right material is crucial for the success of the thermoforming process, impacting both quality and efficiency. ↩

-

Exploring design considerations can significantly enhance the manufacturability and quality of thermoformed parts, making it a valuable resource for designers. ↩

-

Explore this link to discover how 3D printing is revolutionizing manufacturing processes and enabling innovative designs. ↩