Additives are essential in extrusion processes, enhancing material properties like flowability, stability, and strength to meet the demands of industries such as plastics manufacturing, automotive, and construction. Validating the performance of these additives through specific tests ensures they deliver the intended benefits during processing and in the final product. This blog post explores the key tests used to assess additive performance in extrusion, offering a detailed look at their purpose, methodology, and applications.

Tests such as melt flow index, rheological analysis, thermal stability, mechanical property, and degradation assessments validate additive performance in extrusion, ensuring improved process efficiency and product quality across diverse applications.

Understanding these tests is critical for manufacturers seeking to optimize extrusion outcomes. Let’s dive into the specifics of each test, how they’re conducted, and their significance in validating additive effectiveness.

Additives in extrusion only enhance material appearance.False

Additives improve multiple properties, including processability, thermal stability, and mechanical strength, beyond just aesthetics.

All additive performance tests are identical across industries.False

Tests vary by material and application, such as differing requirements for polymers versus metals or food extrusion.

- 1. What Are the Key Tests for Validating Additive Performance in Extrusion?

- 2. What Are the Steps in Testing Additive Performance in Extrusion?

- 3. What Factors Influence the Choice of Tests for Additive Performance?

- 4. What Are the Applications of Additive Performance Testing in Extrusion?

- 5. What Are the Differences Between Testing Additives in Extrusion vs. Other Processes?

- 6. Conclusion

What Are the Key Tests for Validating Additive Performance in Extrusion?

To ensure additives perform as expected in extrusion, a suite of tests evaluates their impact on both the process and the extruded product. These tests target specific properties influenced by additives, from flow behavior to long-term durability.

Key tests include Melt Flow Index (MFI)1, rheological tests, thermal stability tests, mechanical property tests, and degradation tests, each tailored to assess additive effects on extrusion performance.

| Test Type | Purpose | Standard Reference (if applicable) |

|---|---|---|

| Melt Flow Index (MFI) | Measures material flowability | ASTM D1238 |

| Rheological Tests2 | Evaluates viscosity and elasticity under shear | ASTM D4440 |

| Thermal Stability3 | Assesses resistance to heat during processing | TGA: ASTM E1131, DSC: ASTM D3418 |

| Mechanical Properties | Tests strength, flexibility, and impact resistance | Tensile: ASTM D638, Impact: ASTM D256 |

| Degradation Tests | Evaluates long-term stability and aging resistance | ASTM G154 |

Melt Flow Index (MFI)

The Melt Flow Index test quantifies how easily a polymer flows under heat and pressure, a critical factor in extrusion. Additives like lubricants or plasticizers can increase MFI, improving processability. This test, governed by ASTM D1238, involves extruding a polymer through a die under specified conditions and measuring the flow rate in grams per 10 minutes.

Rheological Tests

Rheological tests analyze a material’s viscosity and elasticity under shear forces, simulating extrusion conditions. Additives that modify flow behavior, such as flow enhancers, are assessed using tools like rheometers (ASTM D4440). These tests ensure the material maintains optimal flow without excessive resistance or degradation.

Thermal Stability Tests

Thermal stability tests4, including Thermogravimetric Analysis (TGA, ASTM E1131) and Differential Scanning Calorimetry (DSC, ASTM D3418), evaluate how additives like stabilizers protect materials from heat-induced breakdown during extrusion. These tests measure weight loss or phase transitions at elevated temperatures, ensuring process reliability.

Mechanical Property Tests

Mechanical tests5 assess the final product’s strength and durability, influenced by additives like fillers or reinforcing agents. Standards like ASTM D638 (tensile strength) and ASTM D256 (impact resistance) measure properties such as elongation, toughness, and flexibility, confirming that additives enhance performance without compromising integrity.

Degradation Tests

Degradation tests, such as UV exposure testing (ASTM G154)6, evaluate how additives like antioxidants or UV stabilizers maintain product stability over time. These tests simulate environmental conditions, ensuring extruded products resist aging, cracking, or loss of function in applications like outdoor construction materials.

Thermal stability tests are irrelevant for low-temperature extrusion.False

Even in lower-temperature processes, thermal stability ensures additives prevent unexpected degradation.

Mechanical property tests confirm additive contributions to product durability.True

Tests like tensile strength validate that additives enhance the extruded product’s physical performance.

What Are the Steps in Testing Additive Performance in Extrusion?

Testing additive performance follows a structured process to isolate and measure their effects, ensuring reliable results that translate to real-world extrusion success.

The process involves preparing samples with and without additives, conducting targeted tests, analyzing results, and validating against standards to confirm performance improvements.

Sample Preparation

Samples are prepared by blending additives into the base material (e.g., polycarbonate or polypropylene) and creating a control sample without additives. Uniform mixing ensures consistent test conditions.

Conducting Tests

Specific tests are selected based on the additive’s intended function:

-

Flow enhancers: MFI and rheological tests.

-

Stabilizers: Thermal stability tests (TGA, DSC).

-

Reinforcers: Mechanical tests (tensile, impact).

Analyzing Results

Results are compared between additive-enhanced and control samples. Metrics like increased MFI, improved thermal resistance, or higher tensile strength indicate additive efficacy.

Validation Against Standards

Results are benchmarked against industry standards (e.g., ASTM or ISO) to ensure they meet application-specific requirements, such as durability for medical devices or stability for automotive parts.

A single test can fully validate an additive’s performance.False

Comprehensive validation requires multiple tests to assess various properties like flow, stability, and strength.

Control samples are essential for meaningful test results.True

Comparing against a baseline without additives highlights the specific impact of the additive.

What Factors Influence the Choice of Tests for Additive Performance?

The choice of tests depends on several variables, ensuring they align with the extrusion process and end-use requirements.

Factors include the additive type, base material, and application needs, which dictate whether flow, stability, or strength is prioritized in testing.

Additive Type

-

Plasticizers: Require MFI and rheological tests for flow improvement.

-

Stabilizers: Need thermal stability tests to verify heat resistance.

-

Fillers: Demand mechanical tests to assess strength gains.

Base Material

- Polycarbonate: Focus on thermal and mechanical tests due to its use in durable applications.

- Polypropylene: Emphasize flow and degradation tests for packaging or automotive uses.

Application Requirements

-

Medical Devices: Prioritize mechanical strength and sterilization resistance (e.g., Trinseo’s CALIBRE™ Polycarbonate Resins).

-

Construction: Focus on thermal stability and weathering resistance.

All additives require the same testing approach.False

Testing varies by additive function, such as flow tests for lubricants versus stability tests for antioxidants.

Application needs drive test selection.True

Tests are chosen to match the performance demands of the final product, like durability in medical applications.

What Are the Applications of Additive Performance Testing in Extrusion?

Testing additive performance supports a wide range of industries, ensuring extruded products meet stringent quality and functionality standards.

Applications span plastics for packaging and medical devices, automotive components, and construction materials, where additives enhance efficiency, durability, and compliance.

Plastics Manufacturing

In plastics, additives improve processability and product properties. Testing validates their use in products like packaging films or durable medical enclosures (e.g., Trinseo’s PLEXIGLAS® Acrylic Resins).

Automotive

Additives enhance lightweighting and durability in extruded automotive parts. Tests ensure components like door panels meet mechanical and thermal standards.

Construction

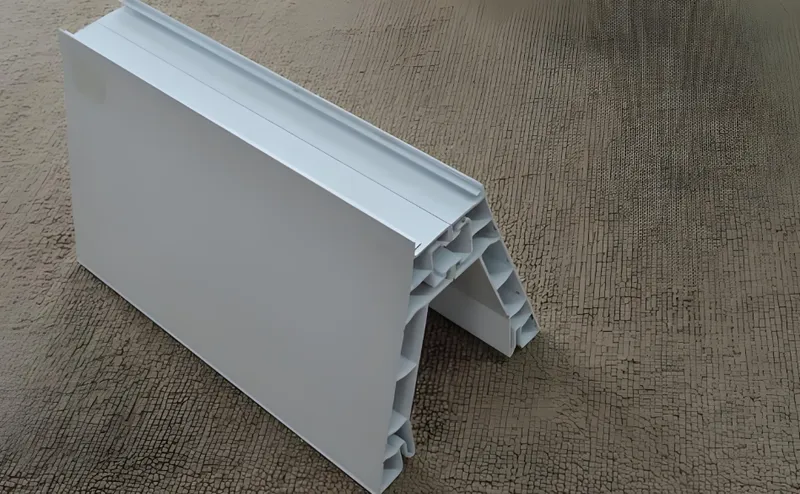

For construction, additives improve insulation and weather resistance in extruded foams. Testing confirms performance in applications like insulation boards.

Additive testing is exclusive to plastics extrusion.False

Testing applies to metals and other materials in extrusion, ensuring performance across industries.

Testing ensures compliance with industry-specific standards.True

Validated additives meet regulations, such as safety for medical devices or durability for construction.

What Are the Differences Between Testing Additives in Extrusion vs. Other Processes?

Testing additives in extrusion differs from other methods like injection molding due to unique process dynamics and material behaviors.

Extrusion testing emphasizes continuous flow, shear behavior, and thermal stability, contrasting with molding’s focus on mold filling and cooling.

Process Dynamics

Extrusion’s continuous nature requires tests like MFI and rheology to assess flow under sustained shear, unlike molding’s batch-based evaluations.

Material Behavior

Extruded materials face prolonged heat and pressure, necessitating thermal stability tests, while molding tests prioritize rapid cooling effects.

Product Outcomes

Extrusion produces continuous profiles (e.g., pipes), requiring uniformity tests, whereas molding focuses on discrete, complex shapes.

Extrusion and molding use identical additive tests.False

Extrusion’s continuous flow demands unique tests like rheology, unlike molding’s cooling-focused assessments.

Extrusion testing reflects its high-shear environment.True

Tests like rheological analysis capture additive performance under extrusion-specific conditions.

Conclusion

Validating additive performance in extrusion through tests like Melt Flow Index, rheological analysis, thermal stability, mechanical properties, and degradation assessments ensures that materials meet both processing and application demands. These tests, tailored to additive type, material, and industry needs, enable manufacturers to enhance efficiency, reduce costs, and produce high-quality products. As extrusion technology evolves, ongoing testing will remain vital to unlocking new additive potentials.

-

Explore this link to understand how MFI impacts polymer processing and the role of additives in enhancing flowability. ↩

-

Discover the importance of rheological tests in ensuring optimal material flow and performance during extrusion. ↩

-

Learn about thermal stability tests to see how they protect materials from heat breakdown during processing, ensuring quality. ↩

-

Exploring thermal stability tests helps in understanding how additives protect polymers from heat degradation, ensuring reliability in applications. ↩

-

Mechanical tests are vital for assessing the strength and durability of polymers, ensuring they meet industry standards and application needs. ↩

-

Understanding UV exposure testing is crucial for ensuring product longevity and performance in outdoor applications. ↩