Plastic extrusion is a vital manufacturing process that melts and shapes plastic into continuous profiles such as pipes, sheets, and films, serving industries worldwide due to its efficiency and versatility. As environmental concerns mount, the industry is pivoting towards sustainable practices to lessen its ecological impact. This blog post explores the sustainable practices gaining momentum in plastic extrusion—recycled materials, energy efficiency1, bio-based plastics2, and sustainable cooling methods—detailing their applications, benefits, and challenges to offer a comprehensive guide for industry professionals and enthusiasts.

Plastic extrusion shapes melted plastic into continuous profiles like pipes and sheets, and sustainable practices are reducing its environmental footprint across industries.

Sustainable practices in plastic extrusion reduce environmental impact.True

By integrating recycled materials, energy-efficient processes, and bio-based plastics, the industry significantly lowers waste and emissions.

Sustainable practices are always more expensive than traditional methods.False

While initial costs may be higher, long-term savings from reduced material and energy use often offset these expenses.

What are the Sustainable Practices in Plastic Extrusion?

Sustainable practices in plastic extrusion aim to minimize environmental harm while preserving efficiency and product quality. Below are the key practices transforming the industry:

Recycled Materials

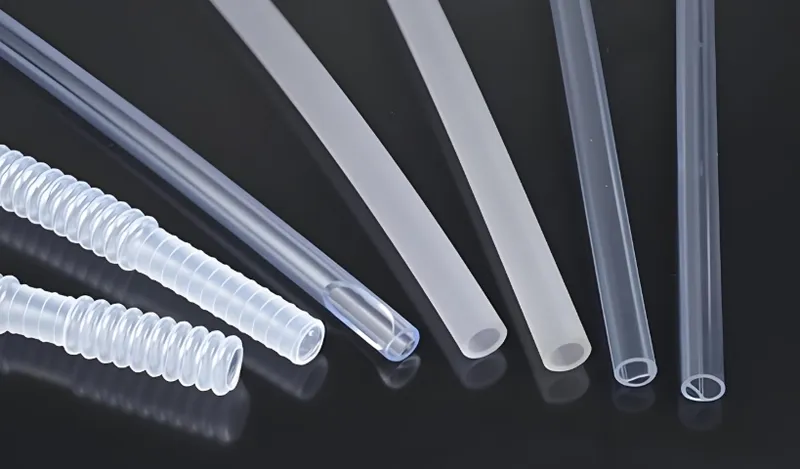

Using recycled plastics3—sourced from post-consumer and post-industrial waste—is a cornerstone of sustainable extrusion. These materials are processed into pellets or flakes via regrinding and advanced sorting, ensuring quality for extrusion into products like pipes, profiles, and packaging.

Benefits:

-

Reduces landfill waste.

-

Conserves resources by decreasing reliance on virgin plastics.

-

Lowers energy use compared to producing new plastics.

Challenges:

-

Maintaining consistent quality and purity.

-

Risk of contamination or degraded properties.

-

Higher processing costs for sorting and cleaning.

Despite these hurdles, recycled materials are increasingly adopted, fueled by regulations and consumer demand for eco-friendly products.

Energy Efficiency

Energy efficiency is critical for cutting the carbon footprint of plastic extrusion. Key strategies include:

-

High-efficiency motors and drives.

-

Temperature control systems to reduce heat loss.

-

Optimized screw designs for improved melting and mixing.

-

Variable-speed drives to align energy use with production needs.

These practices slash energy consumption, reducing operational costs and emissions. However, high initial investment costs and process adjustments pose challenges.

Bio-Based Plastics

Bio-based plastics, derived from renewable sources like corn or sugarcane (e.g., PLA—Polylactic Acid), provide a sustainable alternative to petroleum-based plastics. They offer biodegradability and a reduced carbon footprint, ideal for packaging films, disposable items, and agricultural films.

Benefits:

-

Decreases dependence on fossil fuels.

-

Compostable under specific conditions.

-

Aligns with sustainability goals.

Challenges:

-

Higher production costs.

-

Potential competition with food production for resources.

-

Limited composting infrastructure.

Bio-based plastics are gaining ground as companies prioritize greener options.

Sustainable Cooling Methods

Cooling, traditionally water-intensive in extrusion, is evolving with sustainable methods like air-based cooling systems, which minimize water use and environmental impact.

Benefits:

-

Conserves water, vital in water-scarce regions.

-

Enhances energy efficiency.

-

Speeds up production rates.

Challenges:

-

Ensuring uniform cooling for quality.

-

Higher upfront costs for new systems.

-

Potential energy increases if not optimized.

Sustainable cooling is increasingly essential for reducing ecological footprints.

Sustainable cooling methods can reduce water usage in plastic extrusion.True

Air-based cooling systems significantly cut water use, preserving this critical resource.

Bio-based plastics are always more cost-effective than traditional plastics.False

Though environmentally beneficial, bio-based plastics often incur higher production costs due to agricultural inputs and processing.

Applications of Sustainable Plastic Extrusion

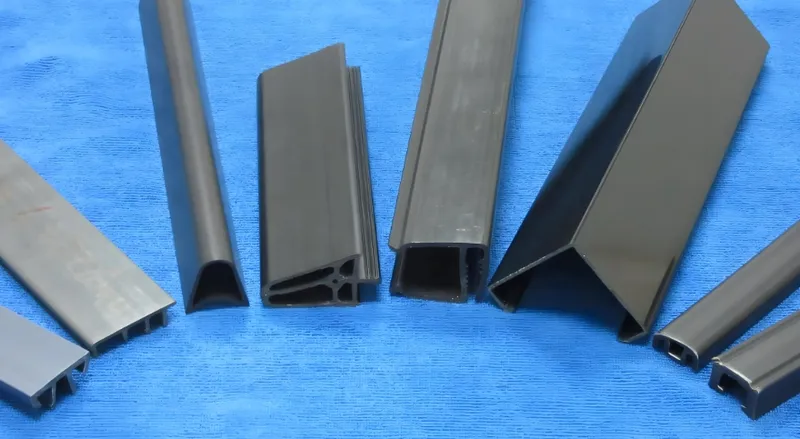

Sustainable extrusion practices are revolutionizing multiple sectors:

-

Construction: Recycled PVC pipes and window frames offer durability and cost-effectiveness.

-

Automotive: Lightweight bio-based profiles enhance fuel efficiency.

-

Packaging: Recycled or bio-based films and sheets create eco-friendly containers.

-

Electrical: Sustainable wire insulation ensures safety and durability.

-

Healthcare: Bio-based or recycled medical tubing meets biocompatibility standards.

These applications highlight the versatility and transformative potential of sustainable extrusion.

Comparison with Traditional Practices

| Aspect | Sustainable Practices | Traditional Practices |

|---|---|---|

| Material Usage | Recycled or bio-based plastics4 | Virgin petroleum-based plastics |

| Energy Consumption | Optimized for efficiency | Higher due to less efficient equipment |

| Environmental Impact | Reduced waste and emissions | Higher ecological footprint |

| Cost | Higher initial, lower long-term | Lower initial, higher operational |

| Product Quality | Comparable with proper processing | Consistent with established methods |

This table underscores the trade-offs, aiding stakeholders in decision-making.

Challenges and Future Trends

Sustainable practices face obstacles but promise a bright future:

Challenges

-

Material Compatibility: Ensuring recycled or bio-based materials meet performance needs.

-

Cost: Higher initial investments for equipment and materials.

-

Quality Control: Consistency with variable recycled inputs.

-

Regulatory Compliance5: Adapting to evolving standards.

Future Trends

-

Circular Economy6: Focus on closed-loop systems and recycling.

-

Material Innovation7: New bio-based and biodegradable plastics.

-

Technological Advancements: Improved energy efficiency and cooling.

-

Regulatory Drivers: Stricter environmental mandates.

As these trends progress, sustainable extrusion will shape a greener industry.

Conclusion

Sustainable practices in plastic extrusion—recycled materials, energy efficiency, bio-based plastics, and sustainable cooling—are more than trends; they’re imperatives for the industry’s future. By adopting these methods, manufacturers can reduce environmental impact while meeting market demands. As challenges are overcome and innovations emerge, sustainable plastic extrusion will continue to gain traction, paving the way for an efficient, eco-conscious manufacturing landscape.

-

Learn about innovative strategies to enhance energy efficiency in plastic extrusion, reducing costs and emissions while promoting sustainability. ↩

-

Discover the benefits and challenges of bio-based plastics, a sustainable alternative that aligns with eco-friendly goals and reduces fossil fuel dependence. ↩

-

Explore the advantages of recycled plastics, including resource conservation and reduced landfill waste, to understand their impact on sustainability. ↩

-

Explore this link to understand how bio-based plastics can revolutionize sustainability in packaging and reduce reliance on fossil fuels. ↩

-

Learn about the importance of Regulatory Compliance in ensuring sustainable manufacturing and how it shapes industry standards. ↩

-

Explore the concept of Circular Economy to understand its role in promoting sustainability and reducing waste in manufacturing. ↩

-

Discover the latest advancements in Material Innovation that are crucial for developing sustainable materials and practices in various industries. ↩