Die build-up in die casting is a critical challenge that can compromise the quality of cast parts and shorten the lifespan of dies. This accumulation of residues—such as carbon deposits, lubricant residues1, and environmental contaminants—on die surfaces can lead to surface defects, dimensional inaccuracies, and increased production costs. Understanding and implementing effective die build-up removal strategies is essential for maintaining production efficiency and ensuring high-quality outcomes. This blog post explores the definition, classification, removal strategies, process workflows, material compatibility, practical tools, and related technologies for managing die build-up in die casting.

Die build-up in die casting refers to residue accumulation on die surfaces, including carbon deposits, lubricants, and contaminants, which impacts casting quality and die longevity.

By delving into these aspects, manufacturers can optimize their maintenance practices and enhance operational performance.

Die build-up only occurs due to lubricant residues.False

While lubricant residues contribute significantly, die build-up also arises from carbon deposits during casting and environmental contaminants like dust.

Effective removal strategies can extend die life and improve casting quality.True

Regular and appropriate cleaning prevents residue accumulation, reducing defects and prolonging die usability.

- 1. What is Die Build-Up in Die Casting?

- 2. How is Die Build-Up Classified?

- 3. What are the Common Strategies for Die Build-Up Removal?

- 4. What are the Steps in the Die Build-Up Removal Process?

- 5. What Factors Influence the Choice of Cleaning Method?

- 6. How Does Material Compatibility Affect Die Cleaning?

- 7. What Practical Tools Enhance Die Build-Up Removal?

- 8. What are the Related Technologies for Die Cleaning?

- 9. Conclusion

What is Die Build-Up in Die Casting?

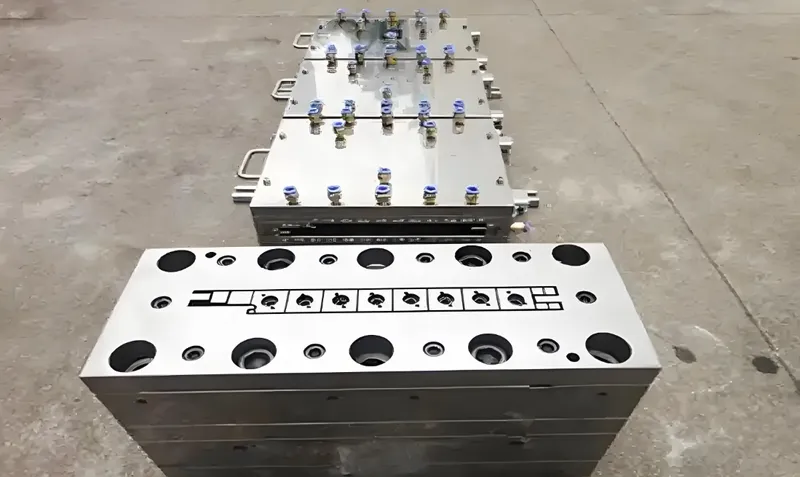

Die build-up is the unwanted accumulation of residues on the surfaces of die casting molds. These residues originate from multiple sources, including lubricants applied to aid part release, carbon deposits formed during the high-temperature casting process, and external contaminants like dirt or dust. If left unaddressed, die build-up2 can cause defects such as surface imperfections or sticking parts, ultimately reducing die lifespan and increasing maintenance costs.

Die build-up consists of lubricant residues, carbon deposits, and environmental contaminants that accumulate on die surfaces, necessitating effective removal strategies.

Recognizing the sources and effects of die build-up is the first step toward selecting the right cleaning approach, minimizing downtime, and maintaining consistent production quality.

How is Die Build-Up Classified?

Die build-up can be classified based on its origin, which guides the selection of appropriate removal techniques. The three main categories are:

-

Lubricant-Related Build-Up: Residues from oil-based or water-based lubricants used during casting to facilitate part release and cooling.

-

Metal-Related Build-Up: Carbon deposits resulting from incomplete combustion or metal solidification during the casting process.

-

Contaminant-Related Build-Up: Deposits from external sources, such as dust or airborne impurities, that settle on die surfaces.

Die build-up is categorized into lubricant-related, metal-related, and contaminant-related types, each requiring tailored cleaning methods.

This classification enables targeted maintenance, ensuring that the chosen strategy effectively addresses the specific residue type.

What are the Common Strategies for Die Build-Up Removal?

Several methods are available for removing die build-up, each with distinct advantages and drawbacks. The choice depends on factors like residue type, die material, and production requirements.

Common die build-up removal strategies3 include solvent cleaning, mechanical cleaning, and ultrasonic cleaning, each suited to specific residue types and die conditions.

| Method | Pros | Cons |

|---|---|---|

| Solvent Cleaning | Effective for organic residues, easy to apply | Requires ventilation, potential chemical hazards |

| Mechanical Cleaning | Removes tough deposits, no chemical use | Time-intensive, risk of surface damage |

| Ultrasonic Cleaning | Non-abrasive, reaches intricate areas | Requires specialized equipment, higher cost |

-

Solvent Cleaning4: Uses chemicals like acetone or water-based cleaners to dissolve lubricant residues. Ideal for light organic build-up but less effective against carbon deposits.

-

Mechanical Cleaning: Employs tools like brushes or sandblasting to physically remove stubborn residues. Best for heavy build-up but requires caution to avoid damaging the die.

- Ultrasonic Cleaning5: Utilizes high-frequency sound waves in a liquid medium to dislodge residues, perfect for complex die geometries without abrasion.

These strategies can be combined for comprehensive cleaning, depending on the severity and type of build-up.

Solvent cleaning works for all die build-up types.False

Solvent cleaning excels with organic residues but struggles with carbon deposits or heavy contaminants, often requiring mechanical or ultrasonic methods.

Ultrasonic cleaning is ideal for intricate die designs.True

Its non-abrasive nature and ability to penetrate complex geometries make it highly effective for detailed dies.

What are the Steps in the Die Build-Up Removal Process?

Removing die build-up involves a structured process to ensure thorough cleaning while preserving die integrity. Here’s a typical workflow:

-

Identify the Build-Up Type: Inspect the die visually or analytically to determine if the residue is lubricant-related, metal-related, or contaminant-related.

-

Select the Cleaning Agent: Choose an appropriate solvent (e.g., acetone for oils, carbon removers for metal deposits) or method based on the residue type.

-

Apply the Cleaning Agent: Use the selected solvent or tool, adhering to safety guidelines, especially with hazardous chemicals.

-

Mechanical Cleaning6 (If Needed): Employ brushes, scrapers, or blasting for persistent residues, ensuring minimal surface damage.

-

Inspect the Die: Verify cleanliness using magnification or testing, ensuring the die is ready for reuse.

The die build-up removal process includes identifying the residue, selecting and applying a cleaning method, mechanically cleaning if necessary, and inspecting the die.

This systematic approach restores the die to optimal condition, preventing defects in future castings.

What Factors Influence the Choice of Cleaning Method?

Selecting the right cleaning method requires evaluating several key factors:

- Build-Up Type: Organic residues favor solvents, while carbon deposits may need mechanical methods.

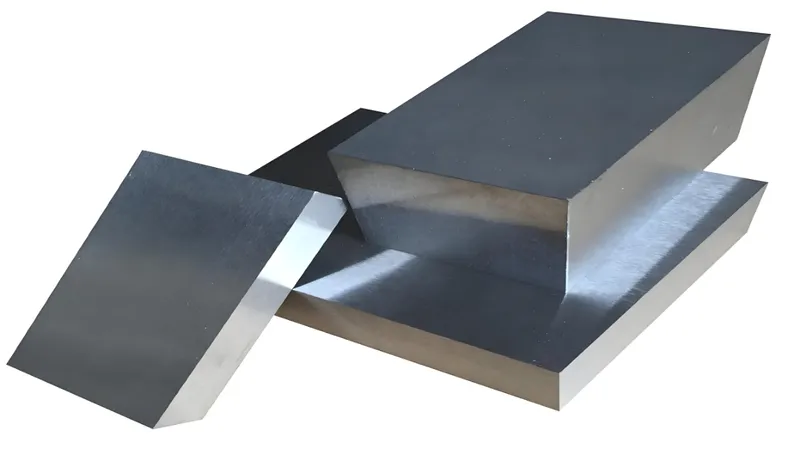

- Die Material: Steel dies, common in die casting, must be cleaned with compatible agents to avoid corrosion.

-

Build-Up Severity: Light residues may require only solvent cleaning, whereas heavy accumulations might need ultrasonic or mechanical intervention.

-

Safety and Environmental Concerns: Opt for methods that reduce operator risk and use eco-friendly materials when possible.

Factors influencing cleaning method choice include build-up type, die material, severity, and safety considerations.

Careful assessment ensures an efficient, safe, and effective cleaning strategy tailored to specific needs.

How Does Material Compatibility Affect Die Cleaning?

Most die casting dies are made of steel, requiring cleaning agents7 that won’t corrode or damage the material. Compatibility considerations include:

-

Solvent Selection: Strong alkaline cleaners may harm aluminum castings but are typically safe for steel if properly managed.

-

Protective Coatings: Cleaning agents must not degrade anti-corrosive coatings or surface treatments on the die.

Material compatibility ensures cleaning agents preserve steel dies and their coatings, preventing corrosion or damage.

Always refer to manufacturer guidelines or test new agents to safeguard die longevity.

What Practical Tools Enhance Die Build-Up Removal?

Effective die maintenance relies on practical tools and practices, such as:

-

Maintenance Schedule: Clean dies regularly (e.g., every 20,000–30,000 shots) based on production volume to prevent excessive build-up.

-

Storage and Handling: Store cleaning agents per safety data sheets (SDS) and use personal protective equipment (PPE) during application.

- Operator Training: Educate staff on cleaning techniques, safety protocols, and the importance of proactive maintenance.

Practical tools for die build-up removal include regular maintenance schedule8s, safe storage practices, and operator training.

These measures promote consistency and reduce production disruptions.

What are the Related Technologies for Die Cleaning?

Advanced technologies can enhance traditional cleaning methods, offering greater efficiency and precision:

-

Ultrasonic Cleaning: Uses sound waves to clean intricate die surfaces without abrasion (Learn More About Ultrasonic Cleaning).

-

Plasma Cleaning: Employs ionized gas to remove residues, ideal for sensitive materials without chemicals.

-

Steam Cleaning: Applies high-temperature steam to dissolve build-up, providing a solvent-free alternative.

Related technologies like ultrasonic, plasma, and steam cleaning offer advanced solutions for die maintenance.

Integrating these into routines can improve cleaning outcomes and support complex die designs.

Conclusion

Managing die build-up in die casting is essential for maintaining high-quality production and extending die life. By understanding its sources, classifying residues, and applying tailored removal strategies—such as solvent, mechanical, or ultrasonic cleaning9—manufacturers can optimize their processes. Material compatibility, structured workflows, practical tools, and advanced technologies further enhance effectiveness. Regular maintenance and trained operators are key to preventing build-up, reducing costs, and ensuring consistent casting quality.

-

Learn about the impact of lubricant residues on die casting and effective methods for their removal to ensure high-quality outcomes. ↩

-

Explore effective strategies and insights on managing die build-up to enhance casting quality and die longevity. ↩

-

Discover various removal strategies that can optimize maintenance practices and improve production efficiency. ↩

-

Discover the best solvents for cleaning die castings and how they can improve the cleaning process. ↩

-

Explore how ultrasonic cleaning can enhance die maintenance by effectively removing residues without causing damage. ↩

-

Learn about mechanical cleaning techniques and their effectiveness in tackling stubborn die residues. ↩

-

Explore this link to discover effective cleaning agents that ensure the longevity and performance of die casting dies. ↩

-

Understanding the significance of a maintenance schedule can help prevent excessive build-up and extend die life. ↩

-

Learn about ultrasonic cleaning's efficiency and precision in maintaining die surfaces without abrasion. ↩