Plastic extrusion transforms raw plastic into continuous shapes using heat and pressure, a technique vital for creating various products like pipes, sheets, and films.

Plastic extrusion melts polymers and pushes them through a die for continuous shapes, efficiently making items like pipes, sheets, and films.

Understanding plastic extrusion is key to optimizing manufacturing processes. This method allows for the creation of diverse plastic profiles. Dive deeper to explore how different extrusion techniques can benefit your production line.

Plastic extrusion is used to create custom shapes from raw plastic material.True

Plastic extrusion allows manufacturers to design dies that produce specific cross-sectional profiles, making it versatile for custom shapes.

Plastic extrusion can only be used for thermoplastics.False

While commonly used for thermoplastics, plastic extrusion can also be applied to some thermosetting materials under controlled conditions.

What are the Basic Principles of Plastic Extrusion?

Plastic extrusion is a fundamental manufacturing process that shapes and forms materials into products used in various industries. Through controlled heating and extrusion, raw plastic is transformed into versatile items such as tubing, films, and sheets.

Plastic extrusion melts and shapes plastic through a die, producing continuous products like pipes. Key components include the extruder, die, and cooling system, crucial for efficient manufacturing in automotive and construction industries.

Mechanical Principles

Extrusion is simple. A screw turns in a barrel and pushes the plastic forward. The screw is actually an inclined plane or ramp, wrapped around a center layer. Its purpose is to increase pressure to overcome greater resistance.

When you’re extruding, you have three things to fight against: the friction of the solid particles (feed) against the barrel wall and the friction between them during the first few turns of the screw (feed zone); the adhesion of the melt to the barrel wall; and the flow resistance inside the melt as it is pushed forward.

Thermal Principles

Thermoplastics are plastics that can be melted when they get hot and solidify when they cool down. Where does the heat come from to melt the plastic? The heaters on the feed throat and barrel/die may help and are important when you start up, but the motor input energy, the heat generated by the friction in the barrel as the motor turns the screw against the resistance of the thick melted plastic, is the most important heat source for all plastics, except for small systems, slow screw speed1s, high melt temperature plastics and extrusion coating applications.

Gearing Principles

In most extruders, the change in screw speed is achieved by adjusting the motor speed. The motor usually runs at a full speed of about 1750rpm, but this is too fast for an extruder screw.

If it runs that fast, too much frictional heat is generated and the residence time of the plastic is too short to prepare a uniform, well-mixed melt. Typical reduction ratios are between 10:1 and 20:1. The first stage can use either gears or pulleys, but the second stage uses gears and the screw is located in the center of the last large gear.

In some slow-running machines (such as twin screws for UPVC), there may be three reduction stages and the maximum speed may be as low as 30 rpm or less (ratios up to 60:1). At the other extreme, some very long twin screws used for mixing can run at 600 rpm or faster, so a very low deceleration rate and a lot of deep cooling are required.

Plastic extrusion always produces finished products ready for use.False

Many extrusion products require additional processing, such as cutting or cooling, before they are considered complete.

Consistent die temperature is crucial in ensuring uniform product quality in plastic extrusion.True

Maintaining uniform die temperature helps avoid inconsistencies and defects in the extruded products, leading to better quality and reliability.

What are the Process Parameters for Extrusion Molding?

Extrusion molding parameters define product quality and efficiency, playing a vital role in various manufacturing sectors.

Extrusion molding parameters include barrel temperature, screw speed, and die design, affecting flow, shape, and accuracy, essential for optimal production in packaging and construction.

Temperature

Temperature is one of the important conditions for the smooth progress of extrusion molding. Starting from solid materials in powder or granular form, high-temperature products are extruded from the die head and undergo a complex temperature change process.

Strictly speaking, the extrusion molding temperature should refer to the temperature of the plastic melt, but this temperature depends to a large extent on the temperature of the barrel and the screw, and a small part comes from the friction heat generated during mixing in the barrel, so the barrel temperature is often used to approximate the molding temperature.

To smoothly transport, melt, homogenize, and extrude the plastic in the barrel, and to efficiently produce high-quality parts, the key is to control the temperature of each section of the barrel. The barrel temperature is adjusted by the heating and cooling system and the temperature control2 system of the extruder.

The head temperature must be controlled below the thermal decomposition temperature of the plastic, and the temperature at the die can be slightly lower than the head temperature, but the plastic melt should be guaranteed to have good fluidity.

Also, the temperature fluctuation and temperature difference during the molding process will cause defects such as residual stress, uneven strength at each point, and dull surface on the plastic parts. There are many factors that cause such fluctuations and temperature differences, such as unstable heating and cooling systems, changes in screw speed, etc., but the screw design and selection have the greatest impact.

Pressure

When you extrude, the plastic has to push through the die. It’s like trying to squeeze toothpaste out of a tube. You have to push hard to get it to come out. The pressure inside the plastic as it goes through the barrel is what makes it melt and become a solid part.

If you increase the die pressure, you can make the melt mix better and make the product denser. But if you increase the die pressure too much, you’ll make less product.

Just like temperature, pressure changes over time will also produce periodic fluctuations, which also have an adverse effect on the quality of plastic parts.

Changes in screw speed and instability in the heating and cooling systems are all causes of pressure fluctuations. In order to reduce pressure fluctuations, the screw speed should be reasonably controlled to ensure the temperature control accuracy of the heating and cooling devices.

Extrusion Rate

The extrusion rate (also known as extrusion speed) is the amount of plastic that comes out of the die of the extruder in a certain amount of time. It is usually measured in kilograms per hour or meters per minute. The size of the extrusion speed tells you how much the extruder can make.

There are many factors that affect the extrusion speed, such as the structure of the die, screw and barrel, screw speed, heating and cooling system structure, and plastic characteristics.

Both theory and practice have shown that the extrusion rate3 increases with the increase of screw diameter, spiral groove depth, homogenization section length, and screw speed, and increases with the increase of melt pressure at the end of the screw and the gap between the screw and the barrel.

When the structure of the extruder, the type of plastic, and the type of plastic parts have been determined, the extrusion rate is only related to the screw speed. Therefore, adjusting the screw speed is the main measure to control the extrusion rate.

The extrusion rate also changes during production, which affects the shape and size of the plastic parts. So, besides getting the screw design and dimensions right, you have to control the screw speed and extrusion temperature. That way, you can keep the extrusion pressure and melt viscosity from changing because of temperature changes. That way, you can keep the extrusion rate from changing.

Traction Speed

When you extrude plastic, you get a long, continuous part. You need something to pull it out. The plastic gets stretched as it comes out of the die and gets pulled. The more you stretch it, the stronger it gets in the direction you stretch it, but it also shrinks more when it cools.

Usually, you pull it out at the same speed you extrude it. The ratio of how fast you pull it to how fast you extrude it is called the pull ratio4. It has to be more than 1.

Barrel temperature uniformity is vital for efficient extrusion molding.True

Consistent barrel temperature ensures even material flow, reducing defects and enhancing product quality.

Extrusion molding requires complex machinery maintenance.False

Although maintenance is essential, advancements in technology have streamlined machinery upkeep, making it more straightforward than traditionally perceived.

What are the Steps of Plastic Extrusion?

Plastic extrusion transforms raw plastic material into continuous shapes like pipes and sheets, crucial for numerous manufacturing applications.

Plastic extrusion involves feeding, melting, shaping raw plastic through a die, and cooling to create continuous profiles like pipes and sheets.

Feeding and Preheating

The feeding device of the plastic extruder usually uses a funnel design to add the plastic raw material into the barrel. During the feeding process, the raw material needs to be preheated to improve its fluidity and melting effect. Preheating can be achieved through a heater outside the barrel, or the raw material can be preheated by a preheater.

Melting and Conveying

When the raw material goes into the barrel, the screw keeps pushing it forward. Meanwhile, the heater outside the barrel heats the raw material, making it melt and become a sticky liquid. The screw and the heater work together to make the liquid form layers in the barrel.

The screw is a key part of the plastic extruder, and its shape and structure have a big effect on how well it melts and moves the plastic. The screw is usually made in sections, with different parts of the screw having different thread depths and widths to work with different kinds of plastic.

How fast the screw turns is also important for how well it melts and moves the plastic, and you have to change the speed depending on what kind of plastic you’re using, how hot it is, and what you want to make.

Extrusion and Molding

After the plastic is melted and conveyed, the plastic melt reaches the die (mold) part. The die extrudes the melt into the desired shape according to the shape and requirements of the product. The structure and design of the die have an important influence on the molding effect of the product, and need to be designed and manufactured according to the requirements of the product.

When the melt is extruded, it is subjected to pressure and shear forces inside the die, and gradually forms the shape of the product. At the same time, the cooling system outside the die cools the product to keep it in a certain shape and size. The cooling speed and cooling method need to be adjusted according to the material and requirements of the product.

Traction and Cutting

After extrusion and molding, the product needs to be pulled out of the die and cut. The traction device usually uses a crawler or roller design to pull the product out of the die by friction. The cutting device cuts according to the length and requirements of the product to ensure the specifications and quality of the product.

Plastic extrusion reduces production costs by minimizing waste material.True

Extrusion produces continuous shapes with minimal waste, optimizing material usage and reducing costs in large-scale production.

Extrusion can only be used for producing hollow products like pipes.False

Extrusion is versatile and can produce various solid and hollow products, including sheets, films, and profiles.

What are the Characteristics of Plastic Extrusion Process?

The plastic extrusion process is a versatile manufacturing method used extensively to produce continuous profiles with consistent cross-sections, critical for industries like construction and packaging.

Plastic extrusion involves melting pellets and shaping them through a die, offering versatility, efficiency, and cost-effectiveness for large-scale production.

Precision Plastic Molding

The precision of extruded products is relatively high, and products with diameter, thickness, and length relative to the specified precision can be produced. High-precision products have very important applications in all walks of life because they can better meet customer needs or freely develop more complex products.

Plastic extrusion is a process that can make plastic molding more precise and produce all kinds of complex plastic products, such as pipes, profiles, sheets, etc. By adjusting the parameters of the extruder and the mold structure, the size and shape of the products produced can be accurately controlled to meet the needs of different customers.

High Production Efficiency

Compared with other plastic processing methods, the plastic extrusion process5 has higher production efficiency. The production process of plastic extrusion molding is simple and easy, and can be automated. The production efficiency is relatively high, and you can make a lot of products in a short time.

An extruder can continuously produce plastic products up to hundreds of meters long, with fast production speed, automatic production, reduced labor costs, and improved production efficiency. In addition, extrusion molding6 can also be continuously produced without stopping for mold change operations, greatly reducing the time cost of product production. Suitable for mass production.

Strong Controllability

You can control the plastic extrusion7 process to make different products. You can change the temperature, pressure, speed, and other things on the extruder to make the material and process work for different products. You can also change the mold whenever you want to make different products.

Smooth Product Surface

Plastic products made by plastic extrusion have a smooth surface and stable quality. When the plastic is extruded and cooled by the mold, it is not easy to produce bubbles and defects on the surface. It looks good and feels good, and is suitable for occasions with high requirements on the product surface.

Excellent Mechanical Properties

Extrusion molding products have excellent mechanical properties, such as wear resistance, high temperature resistance, corrosion resistance, high strength, and good toughness. These excellent mechanical properties8 make extruded products widely used in various fields, such as chemical fiber, building materials, electronics, automobiles, packaging and other industries.

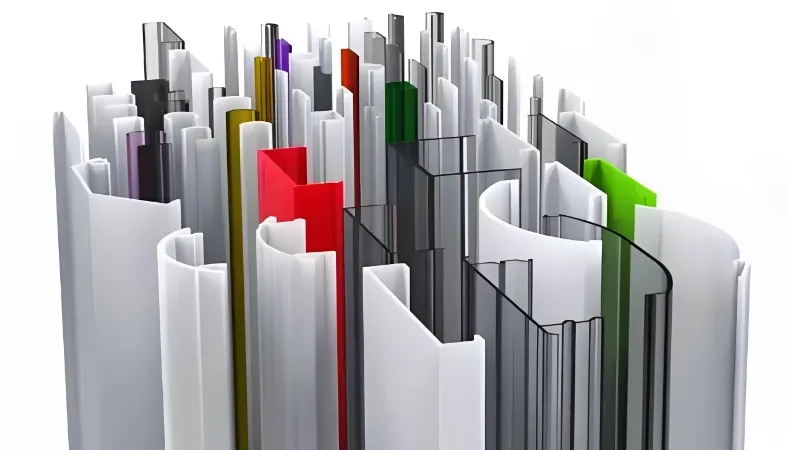

Various Shapes

Extrusion molding technology can make all kinds of products, like pipes, plates, films, profiles, and so on. You can also customize them. The products are very flexible.

Low Production Cost

Extrusion molding is cheap to produce because the equipment and process for this technology are simple, and the scrap rate is low. When you make products, cost is important. So, extrusion molding is a good choice for making products.

In the process of plastic extrusion, plastic particles are heated and softened before being extruded, which reduces waste and saves raw materials to the maximum extent. Moreover, the extruder can accurately control the amount of extrusion, avoiding waste of raw materials, improving the utilization rate of raw materials, and reducing production costs.

Plastic extrusion is primarily used for creating complex 3D shapes.False

While plastic extrusion excels at forming continuous 2D profiles, not 3D shapes, it is more suited for uniform cross-sectional products like pipes and sheets.

Extrusion processes can handle multiple types of plastic materials.True

The versatility of extrusion allows it to process a wide range of plastics, accommodating different product requirements and applications.

What are the Application Areas of Plastic Extrusion?

Plastic extrusion is integral in manufacturing, empowering diverse industries with tailored plastic products, from automotive parts to packaging.

Plastic extrusion is used in automotive components, construction materials, consumer products, and packaging, offering versatility, enhanced properties, cost-effectiveness, and design flexibility.

Home Decoration Materials

In the home decoration field, plastic extrusion technology is also widely used. Extrusion technology can make decorative materials such as floors, wall panels, and skirtings. These materials are not only beautiful and easy to install, but also have good wear resistance, water resistance, and corrosion resistance. The plastic extrusion process provides a more diverse and environmentally friendly choice for home decoration.

Door and Window Profiles

In the construction industry, plastic door and window profiles have gradually replaced traditional wooden and metal door and window profiles because they are light, don’t rust, and are easy to make.

PVC is one of the main materials for making door and window profiles. You can make door and window frames, sashes, and other parts with different shapes by squeezing the PVC out of a machine. These parts look good, keep the heat in, keep the noise out, and are part of modern buildings.

Pipes

Pipes are one of the most common things made with plastic extrusion. You can make water pipes, gas pipes, or wire insulation pipes with extrusion. PVC, PE, and PP are the most popular plastics for making pipes because they have good physical properties and are easy to process. You can make pipes with different diameters, wall thicknesses, and lengths with extrusion to fit different uses.

Automotive Parts

Plastic extrusion is also important in the automotive industry. Extrusion can make car parts like dashboards, seals, and other parts. These parts need to look good and be the right size. They also need to be able to handle the weather and not wear out. Extrusion can make these parts. It can make good car parts that make the car better.

Electronic and Electrical Parts

In the electronic and electrical industry, plastic extrusion technology is widely used to make all kinds of housings, insulation materials, radiators and other parts. These parts need to have good insulation, heat resistance and mechanical strength. By adjusting the structure and size of the extrusion die, we can make all kinds of complex shapes and colors of electronic and electrical parts to meet the needs of different products.

Other Special Profiles

Besides the common plastic profiles mentioned above, plastic extrusion technology can also produce various special profiles according to customer needs. For example, special profiles for safety railings and protective devices, precision profiles for medical equipment and lighting components, etc. The production of these special profiles requires high-precision mold design and advanced extrusion technology to meet the needs of specific fields.

Plastic extrusion is limited to simple shapes and profiles.False

Modern extrusion technologies allow for complex profiles and multi-material products, expanding the scope of design and application.

Plastic extrusion offers cost-effective solutions in high-volume manufacturing.True

The continuous production process and efficient use of materials result in significant cost savings for large-scale operations.

Conclusion

Plastic extrusion is a process that pushes plastic forward by rotating the screw in the barrel, involving mechanical, thermal and deceleration principles. Thermoplastics are preheated, melted, conveyed to the mold to form the desired shape, and are completed by traction cutting.

Extrusion molding is a great way to make stuff. It’s super precise, super fast, easy to control, and cheap. You can use it to make all kinds of things like home stuff, pipes, doors and windows, car parts, and electronics. You can make all kinds of shapes to fit whatever you need. It’s great for all kinds of stuff.

-

Learning about screw speed's effects can lead to better control over the extrusion process and improved product outcomes. ↩

-

Exploring temperature control methods can enhance the quality and consistency of extruded plastic products. ↩

-

Understanding the factors influencing extrusion rate can help optimize production efficiency and product quality. ↩

-

Exploring pull ratio helps in understanding its impact on the strength and dimensions of extruded plastic products. ↩

-

Learning about the plastic extrusion process reveals its efficiency and versatility in producing various plastic products. ↩

-

Learn about the extrusion molding process and its applications in various industries for better insights into manufacturing. ↩

-

Explore the advantages of plastic extrusion to understand its impact on production efficiency and product quality. ↩

-

Discover the mechanical properties of extruded products to appreciate their durability and versatility in different applications. ↩