Twin Sheet Thermoforming is a specialized manufacturing process that heats two plastic sheets, forms them into molds, and fuses them together to create a hollow, double-walled part. This technique is widely adopted in industries like automotive, medical, consumer goods, and commercial displays to produce lightweight, strong, and insulated components. Unlike single-sheet thermoforming, Twin Sheet Thermoforming1 allows for features on both sides of the part, offering unique design flexibility and functionality that make it a standout choice for many applications.

Twin Sheet Thermoforming is more cost-effective than injection molding for moderate production volumes.True

With lower tooling costs and faster lead times, Twin Sheet Thermoforming is often more economical for moderate production runs compared to injection molding.

Twin Sheet Thermoforming can only produce simple geometries.False

While it has limitations, Twin Sheet Thermoforming can create complex parts with features on both sides, making it suitable for a wide range of applications.

- 1. What are the Common Materials Used in Twin Sheet Thermoforming?

- 2. What are the Steps in the Twin Sheet Thermoforming Process?

- 3. What are the Key Factors in the Twin Sheet Thermoforming Process?

- 4. What are the Applications of Twin Sheet Thermoforming?

- 5. What are the Differences Between Twin Sheet Thermoforming and Other Methods?

- 6. Conclusion

What are the Common Materials Used in Twin Sheet Thermoforming?

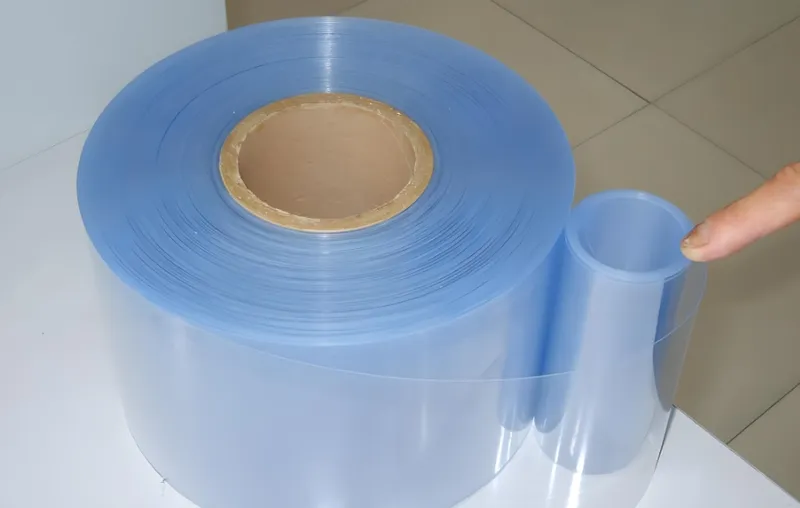

Twin Sheet Thermoforming works with a variety of thermoplastic materials2, each selected for specific properties that cater to diverse applications. The choice of material significantly impacts the strength, durability, and functionality of the final part.

Common materials include ABS, HIPS, PC, HDPE, and PETG, chosen for their strength, durability, and ease of forming.

| Material | Properties | Applications |

|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene)3 | Strong, durable, impact-resistant | Automotive parts, consumer goods |

| HIPS (High Impact Polystyrene) | Lightweight, inexpensive | Food packaging, housings |

| PC (Polycarbonate) | High impact resistance, clarity | Safety equipment, medical devices |

| HDPE (High-Density Polyethylene) | High strength, chemical resistance | Industrial products, containers |

| PETG (Polyethylene Terephthalate Glycol) | Clear, impact-resistant, easy to form | Displays, medical devices |

These materials are selected based on the needs of the application—ABS for its durability in automotive parts, PETG for its clarity in medical devices, or HDPE for its chemical resistance in industrial uses. This versatility makes Twin Sheet Thermoforming adaptable to a broad range of industries.

ABS is the most commonly used material in Twin Sheet Thermoforming.True

ABS is widely used due to its strength, durability, and ease of processing, making it ideal for a broad range of applications.

Twin Sheet Thermoforming is limited to thin-gauge materials.False

The process can handle material thicknesses from 0.060 to 0.500 inches, allowing for parts of varying sizes and strengths.

What are the Steps in the Twin Sheet Thermoforming Process?

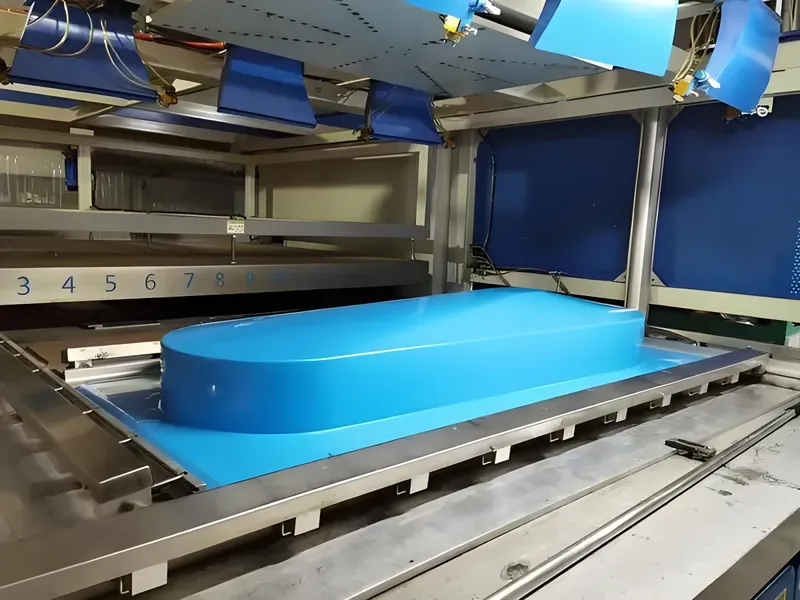

The Twin Sheet Thermoforming process involves a series of precise steps to transform two plastic sheets into a single, hollow part. Each step plays a critical role in ensuring the quality and performance of the final product.

The process includes material preparation, heating, forming, fusion, cooling, and trimming, each essential for achieving the desired part characteristics.

-

Material Preparation: Two thermoplastic sheets are selected and prepared, typically ranging from 0.060 to 0.500 inches in thickness, based on the application requirements.

-

Heating: The sheets are clamped into frames and heated uniformly to their forming temperature (e.g., 200-250°C for ABS) until pliable.

-

Forming: Vacuum or pressure is applied to shape each sheet into its respective mold, creating the desired geometry.

-

Fusion: The molds are brought together under high pressure (at least 10,000 pounds) to fuse the sheets at predetermined points, forming a strong bond.

-

Cooling: The part cools within the molds to set its shape and stabilize its structure.

-

Trimming: Excess material is trimmed off after removal from the molds to achieve the final dimensions.

The fusion step is the most critical in Twin Sheet Thermoforming.True

Proper fusion ensures a strong, seamless bond between the two sheets, which is essential for the part's structural integrity.

Twin Sheet Thermoforming requires specialized equipment.True

The process demands machinery capable of handling two sheets simultaneously and applying the necessary pressure for fusion.

What are the Key Factors in the Twin Sheet Thermoforming Process?

Several factors influence the success of Twin Sheet Thermoforming, affecting the quality, strength, and appearance of the final part. Precise control of these elements is vital for consistent results.

Key factors include material selection4, temperature control5, pressure application, and mold design, each requiring careful management.

-

Material Selection: The right thermoplastic ensures the desired properties, such as strength or clarity, are achieved.

-

Temperature Control: Uniform heating prevents material degradation and ensures proper forming.

-

Pressure Application: Adequate pressure (minimum 10,000 pounds) during fusion creates a robust bond between sheets.

- Mold Design6: Well-designed molds accommodate forming and fusion, influencing part geometry and material flow.

| Factor | Impact on Process |

|---|---|

| Material Selection | Determines strength, durability, and process compatibility |

| Temperature Control | Affects formability and prevents defects like warping |

| Pressure Application | Ensures strong fusion and bond integrity |

| Mold Design | Influences shape, detail, and ease of mold release |

Temperature control is the most challenging aspect of Twin Sheet Thermoforming.True

Maintaining uniform heating across both sheets is critical to prevent defects and ensure consistent part quality.

Mold design has little impact on the final part quality.False

Mold design significantly affects the forming and fusion processes, influencing the part's shape, strength, and appearance.

What are the Applications of Twin Sheet Thermoforming?

Twin Sheet Thermoforming is employed across multiple industries to create parts that combine strength, lightness, and insulation. Its hollow, double-walled structure makes it ideal for applications requiring these attributes.

Applications include automotive interior panels, medical device enclosures, appliance housings, and commercial display stands, among others.

-

Автомобили: Interior panels, dashboards, and trim components benefit from strength and weight reduction.

-

Медицина: Enclosures, trays, and covers for devices require precision and cleanliness.

-

Consumer Goods: Appliance housings and fitness equipment demand durability and aesthetics.

-

Commercial: Display stands and signage leverage the hollow structure for insulation.

Twin Sheet Thermoforming is primarily used in the automotive industry.False

While automotive is a major application, the process is also widely used in medical, consumer goods, and commercial industries.

Twin Sheet Thermoforming can produce parts with excellent thermal and acoustic insulation.True

The hollow structure inherently provides thermal and acoustic insulation, ideal for specific applications.

What are the Differences Between Twin Sheet Thermoforming and Other Methods?

Twin Sheet Thermoforming stands out from processes like single-sheet thermoforming and injection molding due to its unique advantages and limitations, making it a strategic choice depending on project needs.

Compared to single-sheet thermoforming, Twin Sheet Thermoforming produces double-walled parts with enhanced strength and insulation. Compared to injection molding7, it offers lower tooling costs and faster lead times for moderate production volumes.

| Aspect | Twin Sheet Thermoforming | Single-Sheet Thermoforming8 | Injection Molding |

|---|---|---|---|

| Part Structure | Double-walled, hollow | Single-walled | Solid or hollow |

| Strength | High, due to double walls | Moderate | High |

| Tooling Cost | Moderate | Low | High |

| Lead Time | 6-10 weeks | 4-8 weeks | 3-6 months |

| Production Volume | Moderate to high | Low to moderate | High |

| Design Flexibility | Features on both sides, insulation | Limited to one side | Complex geometries |

-

Single-Sheet Thermoforming: Suited for simpler, single-walled parts with lower strength needs.

-

Injection Molding: Best for high-volume, complex solid parts, though costlier and slower to tool.

- Twin Sheet Thermoforming: Balances strength, flexibility, and cost for moderate runs.

Twin Sheet Thermoforming is always the best choice for producing hollow parts.False

While excellent for many hollow parts, other methods like blow molding or rotational molding may be more suitable for certain geometries or volumes.

Twin Sheet Thermoforming offers faster lead times than injection molding.True

With lead times of 6-10 weeks compared to 3-6 months for injection molding, it accelerates market entry.

Conclusion

Twin Sheet Thermoforming is a versatile, cost-effective process9 that delivers strong, lightweight, and insulated parts for industries ranging from automotive to medical. Its advantages—lower tooling costs, faster lead times, and design flexibility10—position it as a valuable alternative to other manufacturing methods. By mastering its materials, steps, and key factors, manufacturers can harness Twin Sheet Thermoforming to produce high-quality products efficiently.

-

Explore the benefits of Twin Sheet Thermoforming to understand why it's a preferred choice in various industries, enhancing design and functionality. ↩

-

Discover the top thermoplastic materials used in manufacturing to make informed choices for your projects, ensuring strength and durability. ↩

-

Learn about ABS plastic's unique properties and its wide range of applications, making it a popular choice in various industries. ↩

-

Learn about the importance of material selection in Twin Sheet Thermoforming and how it affects product quality. ↩

-

Discover why maintaining proper temperature is essential for successful Twin Sheet Thermoforming and preventing defects. ↩

-

Discover best practices in Mold Design to optimize the thermoforming process and improve product quality. ↩

-

Discover the pros and cons of injection molding to see how it stacks up against other manufacturing processes. ↩

-

Explore this link to understand how Single-Sheet Thermoforming can optimize production for simpler parts. ↩

-

Learn how Twin Sheet Thermoforming can save costs while maintaining quality, making it a smart choice for manufacturers. ↩

-

Discover the design possibilities with Twin Sheet Thermoforming that can help you innovate and meet diverse market needs. ↩