Каковы общие дефекты и решения для экструзии пластмасс?

Plastic extrusion is used a lot to make pipes, profiles, films, sheets, and other stuff. But when you’re extruding, you can get defects that mess up how the product looks and works. And that makes your costs go up and slows down your production. The plastic extrusion process faces issues like air bubbles, cracks, uneven […]

В чем разница между экструзией и литьем под давлением?

Экструзия и литье под давлением - два распространенных производственных процесса, используемых при переработке пластмасс. Они используют разные технологии и оборудование в своих производственных процессах, поэтому существуют значительные различия в их применении и экономической эффективности. В этой статье мы сравним эти два процесса, чтобы помочь вам лучше понять их различия и сценарии применения. Экструзия пластмасс - идеальный [...].

Почему противодавление важно для контроля качества экструзии?

Back pressure in extrusion is a critical parameter that significantly influences the quality of the final product. It refers to the resistance the molten plastic exerts on the extruder screw, ensuring the material is properly melted, mixed, and homogenized before being extruded through the die. Understanding and controlling back pressure1 is vital for achieving consistent […]

Как настроить температурные профили для оптимальной экструзии?

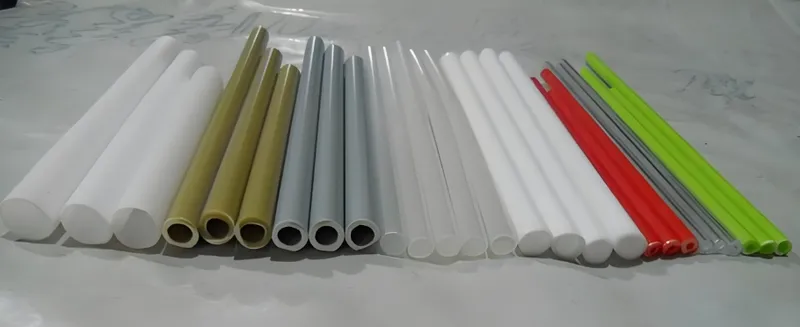

Extrusion is a widely used manufacturing process that shapes materials like plastics and metals into continuous profiles, such as pipes, sheets, or rods, by forcing them through a die. A key factor in achieving high-quality extrusion is the careful adjustment of temperature profiles1—the specific temperature settings across different zones of the extruder. Properly tuned temperature […]

Какие новые технологии определят будущее экструзии пластмасс?

The plastic extrusion industry is undergoing a transformative shift, driven by innovations that enhance sustainability, efficiency, and versatility. As global demand grows for eco-friendly materials, high-performance products, and smarter manufacturing processes, emerging technologies are redefining what’s possible in plastic extrusion. From bioplastics1 to digitalization, these advancements promise a future where plastic extrusion meets modern challenges […]

В чем ключевые отличия экструзии пластмасс от других методов?

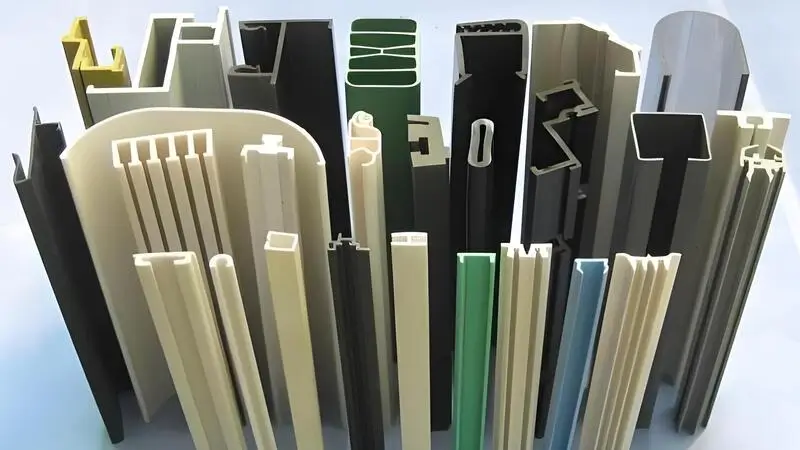

Plastic manufacturing encompasses a variety of techniques, each tailored to specific product types and production needs. Among these, plastic extrusion1 stands out for its ability to produce long, continuous shapes with uniform cross-sections—think pipes, tubing, and window frames. However, other methods like injection molding, blow molding, compression molding, rotational molding, and 3D printing offer distinct […]