Plastic extrusion, a cornerstone of modern manufacturing, transforms raw plastic into continuous profiles like pipes, sheets, and films, serving industries from construction to packaging. But did you know that how this process unfolds varies dramatically around the world? As of March 2025, regional trends in plastic extrusion1 are driven by unique economic conditions, regulatory frameworks, and industrial demands, making it a fascinating lens through which to view global manufacturing.

Why does this matter? For industry professionals, understanding these trends unlocks opportunities to optimize production, meet market needs, and stay ahead of the curve. In this blog post, we’ll dive into the essentials of plastic extrusion and explore its regional dynamics across North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, backed by data, examples, and insights.

What Is Plastic Extrusion?

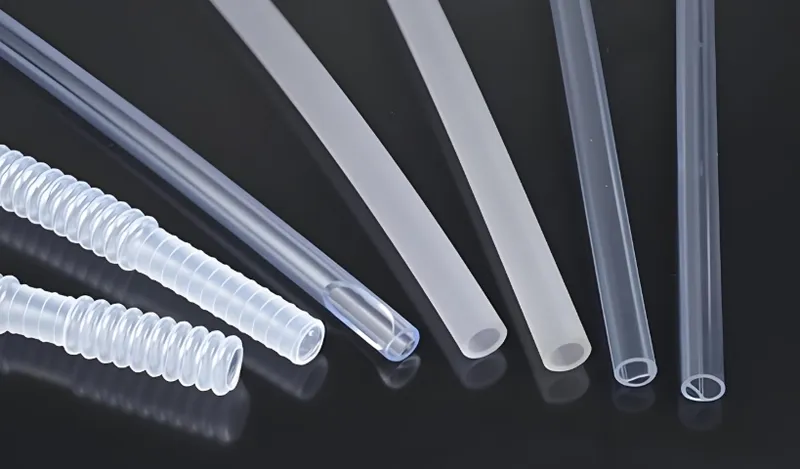

Plastic extrusion is a high-volume process where thermoplastic materials are melted and pushed through a die to create continuous shapes. It’s the backbone of products like PVC pipes, window frames, and packaging films, prized for its efficiency and versatility.

Plastic extrusion melts thermoplastics like PE, PP, and PVC, shaping them into continuous profiles for construction, packaging, and automotive use.

| Aspect | Description |

|---|---|

| Process | Thermoplastics are melted and extruded through a die into continuous forms. |

| Common Materials | Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), and more. |

| Applications | Pipes, sheets, films, wire insulation, and profiles for various industries. |

The process begins with plastic pellets fed into an extruder, melted by heat and a rotating screw, then forced through a die to form the desired shape. After cooling, the product solidifies, ready for use. Learn more at Plastic Extrusion Explained.

Plastic extrusion works with all plastics.False

Only thermoplastics, which can be melted and reshaped, are suitable; thermosets, which harden permanently, cannot be extruded.

Regional Trends in Plastic Extrusion

Plastic extrusion adapts to regional needs, from sustainability mandates2 in Europe to rapid industrialization in Asia. Here’s a closer look at the key trends shaping this industry worldwide.

North America: Sustainability and Innovation

In North America, particularly the U.S. and Canada, plastic extrusion thrives on advanced technology and a push for sustainability. The market is expected to hit USD 43.89 billion by 2031, with a CAGR of 6.12% North America Plastic Extrusion Market.

-

Key Industries: Construction (window frames), automotive (trim), and packaging.

-

Trend: Emphasis on biodegradable polymers3 and recycling targets.

-

Example: Companies like Trex leverage extrusion for sustainable decking materials.

North America leads in eco-friendly extrusion.True

Its focus on recycling and advanced tech aligns with global sustainability goals.

Europe: Eco-Friendly Practices

Europe sets the pace for eco-conscious extrusion, spurred by strict EU regulations on plastic waste. Germany alone produced 20.7% of fossil-based plastics in 2023 Europe’s Plastics Industry in 2023.

-

Trend: Emphasis on biodegradable polymers and recycling targets.

-

Insight: “The shift to circularity is non-negotiable,” says a German industry expert, highlighting Europe’s direction.

Europe’s market is shrinking due to regulations.False

Regulations fuel innovation in sustainable extrusion, sustaining growth.

Asia Pacific: Rapid Growth

Asia Pacific, led by China and India, dominates with a 41.1% share of the global extrusion machine market Plastic Extrusion Machine Market.

-

Key Industries: Electronics (insulation), packaging, and consumer goods.

-

Trend: Urbanization and low-cost production drive expansion, though sustainability is gaining traction.

-

Stat: China’s extrusion output surged with urban projects in 2024.

Asia’s growth harms the environment.False

While rapid, growth is tempered by investments in recycling and green tech.

Latin America: Emerging Opportunities

Latin America is an up-and-coming player, with potential in agriculture, packaging, and construction, despite political hurdles Latin America’s Plastics Industry.

-

Key Industries: Agriculture (irrigation tubing) and packaging.

-

Trend: Growth tied to industrialization, with a focus on cost-effective recycling.

-

Challenge: Infrastructure lags behind more developed regions.

Latin America’s market is insignificant.False

It’s small but growing, with untapped potential in key sectors.

Middle East and Africa: Petrochemical Power

The Middle East and Africa leverage petrochemical riches, with the plastic compounding market growing at a 5.6% CAGR by 2030 Middle East and Africa Plastic Compounding Market.

-

Key Industries: Packaging (bottles) and construction (infrastructure projects).

-

Trend: Investments in Saudi Arabia and the UAE boost production, with bio-based materials on the rise.

-

Example: Saudi Vision 2030 fuels extrusion demand.

The region relies only on fossil plastics.False

Bio-based plastics are emerging alongside traditional production.

How Regional Trends Shape Applications

Each region tailors plastic extrusion to its strengths, as shown below:

| Region | Top Applications | Focus Area |

|---|---|---|

| North America | Window frames, car trim | Sustainability, automation |

| Europe | Packaging films, building profiles | Eco-friendliness, regulations |

| Asia Pacific | Insulation, consumer packaging | Growth, cost efficiency |

| Latin America | Irrigation tubing, packaging | Cost-effective recycling |

| Middle East & Africa | Bottles, construction profiles | Petrochemicals, diversification |

Visualize this with a chart of market growth rates—Asia Pacific’s steep curve contrasts with Europe’s steady climb Plastic Extrusion Machine Market.

Challenges and Opportunities

-

Challenges: Environmental concerns, especially in Asia and Latin America, where recycling lags, and high initial costs for advanced systems.

-

Opportunities: Innovations like hybrid extrusion in North America and biodegradable polymers4 in Europe offer growth potential.

Plastic extrusion faces no challenges.False

Waste management and costs pose ongoing issues, though solutions are emerging.

Conclusion

Plastic extrusion is more than a manufacturing process—it’s a global story of adaptation and innovation. North America and Europe pioneer sustainability, Asia Pacific fuels growth, and emerging regions like Latin America and the Middle East and Africa promise future expansion. As recycling and efficiency shape the industry, staying informed on these trends is key for professionals aiming to thrive.

-

Explore this link to understand the cutting-edge advancements in plastic extrusion that are shaping the industry. ↩

-

This resource will provide insights into how sustainability is transforming plastic extrusion practices globally. ↩

-

Learn about biodegradable polymers and their significance in creating eco-friendly products through extrusion. ↩

-

Explore the latest advancements in biodegradable polymers to understand how they are shaping the future of sustainable plastic extrusion. ↩