The top 5 plastic vacuum forming1 factories in the Philippines are Formplas Services, SG Eco Industries, INFIDEAL, Fompac Plastics, and Alcami Global (Philippines facility), renowned for their specialized services in packaging, automotive, and medical applications.

This guide explores these leading factories, the materials and processes involved in vacuum forming, and key considerations for businesses seeking reliable manufacturing partners in the Philippines.

Vacuum forming is only suitable for small-scale production.Falso

While often used for low to medium volumes, vacuum forming can be scaled for larger runs with automation and advanced trimming techniques.

A moldagem a vácuo pode produzir peças altamente detalhadas.Verdadeiro

With precise mold design and process control, vacuum forming achieves intricate details and tight tolerances suitable for various applications.

What are the Top 5 Plastic Vacuum Forming Factories in the Philippines?

The Philippines hosts several top-tier factories excelling in plastic vacuum forming, offering specialized services tailored to industries like packaging, automotive, and medical manufacturing.

The leading factories—Formplas Services, SG Eco Industries, INFIDEAL, Fompac Plastics, and Alcami Global (Philippines facility)—are recognized for their expertise, innovative solutions, and extensive client reach.

| Rank | Factory Name | Location | Key Services |

|---|---|---|---|

| 1 | Formplas Services Corporation | Metro Manila, Philippines | Vacuum forming, blister packaging2, custom packaging |

| 2 | SG Eco Industries Inc. | Philippines | Custom thermoforming, vacuum forming |

| 3 | INFIDEAL | Philippines (operations since 2022) | Custom thermoformed trays, packaging solutions |

| 4 | Fompac Plastics Corporation | Multiple branches (e.g., Manila, Cebu, Davao) | Blister packaging, plastic trays, food packaging |

| 5 | Alcami Global (Philippines Facility) | Batangas, Philippines | Thermoforming, vacuum forming, injection molding |

Formplas Services Corporation

- Location: Metro Manila, Philippines

-

Key Services: Specializes in vacuum forming for food trays, cosmetic trays, and blister packaging.

-

Notable: Founded in 2004, Formplas is celebrated for its high-quality packaging and strong local market presence.

SG Eco Industries Inc.

- Location: Philippines

-

Key Services: Offers custom thermoforming3, including vacuum forming, with a large machine capacity (2300mm x 1100mm).

-

Notable: Known for providing expert material and tooling advice to optimize client outcomes.

INFIDEAL

- Location: Philippines (operations since 2022)

-

Key Services: Produces custom thermoformed trays for laboratory, medical, cosmetic, and electronic packaging.

-

Notable: Quickly gained industry recognition for its innovative packaging solutions.

Fompac Plastics Corporation

- Location: Multiple branches across the Philippines (e.g., Manila, Cebu, Davao)

-

Key Services: Excels in blister packaging, plastic trays, and food packaging.

-

Notable: Its extensive network supports a broad client base nationwide.

Alcami Global (Philippines Facility)

- Location: Batangas, Philippines

-

Key Services: Focuses on thermoforming, including vacuum forming, and injection molding.

-

Notable: A US-based company with a facility producing 20 million thermoformed trays annually.

For more information, visit their websites: Formplas Services, SG Eco Industries, INFIDEAL, Fompac Plastics, Alcami Global.

Formplas Services is the oldest vacuum forming factory in the Philippines.Verdadeiro

Established in 2004, it boasts a long-standing reputation in the industry.

All top factories are located in Metro Manila.Falso

While Formplas is in Metro Manila, Alcami Global operates in Batangas, and Fompac has branches nationwide.

What Materials are Commonly Used in Vacuum Forming?

The choice of material in vacuum forming significantly affects the product's performance, durability, and suitability for specific uses.

Common materials include polystyrene (PS), PETG, PVC, ABS, and acrylic, selected for their clarity, resistência ao impacto4, or resistência química5 properties.

Poliestireno (PS)

-

Properties: Clear, cost-effective.

-

Aplicações: Widely used in food packaging for its transparency and affordability.

PETG (Politereftalato de etileno glicol)

-

Properties: High impact resistance, FDA-approved for food contact.

-

Aplicações: Ideal for medical trays and durable packaging.

PVC (cloreto de polivinilo)

-

Properties: Chemical resistance, flame retardant.

-

Aplicações: Commonly used in pharmaceutical blister packaging.

ABS (Acrilonitrilo Butadieno Estireno)

-

Properties: High impact strength, heat resistance.

-

Aplicações: Suitable for automotive parts and robust products.

Acrylic

-

Properties: Optical clarity, weather resistance.

-

Aplicações: Used in signs, displays, and decorative items.

These materials provide flexibility, allowing manufacturers to tailor products to specific industry needs.

Polystyrene is the most commonly used material in vacuum forming.Verdadeiro

Its clarity and low cost make it a top choice for packaging applications.

All vacuum forming materials are suitable for high-temperature applications.Falso

Materials like PS have limited heat resistance, whereas ABS performs better under higher temperatures.

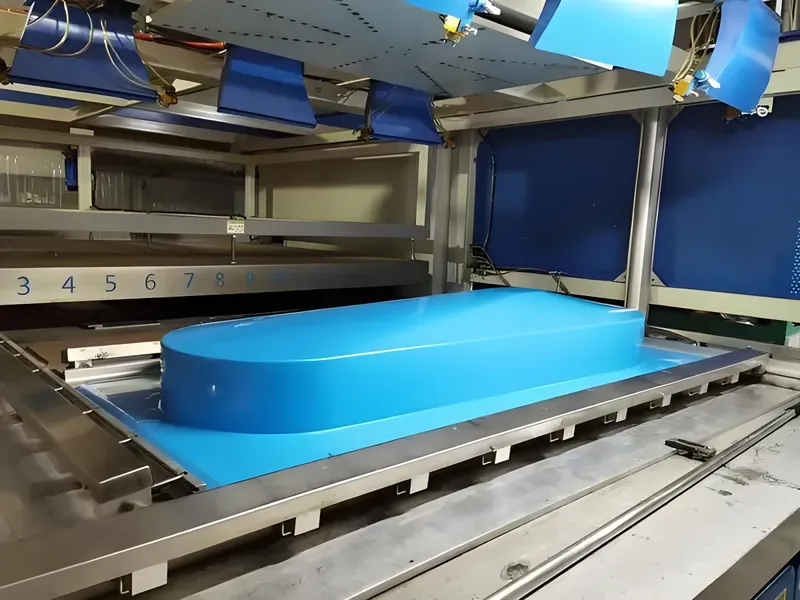

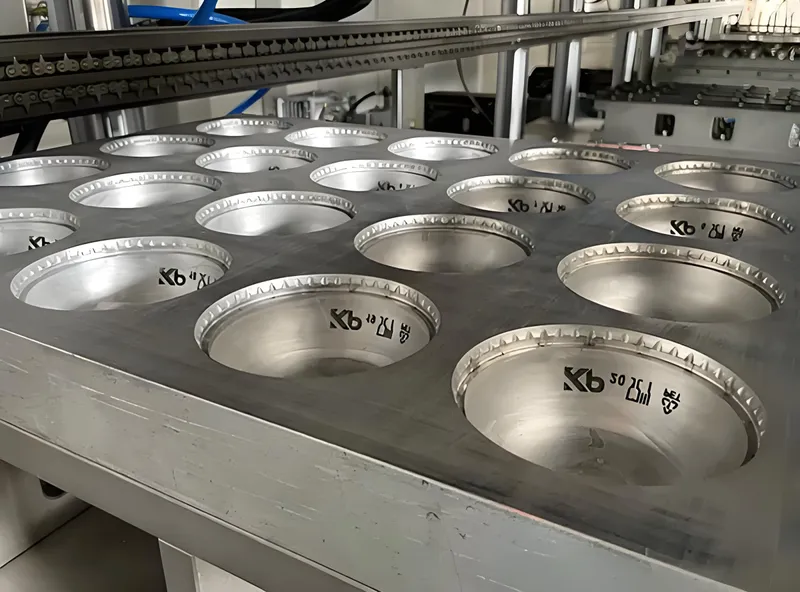

Quais são as etapas do processo de formação de vácuo?

Vacuum forming transforms plastic sheets into precise shapes through a series of controlled steps, ensuring quality and consistency.

O processo inclui seleção de materiais6, heating, forming, cooling, trimming, and finishing, each vital for producing high-quality products.

Seleção de materiais

Select a plastic sheet based on the product’s requirements, such as durability or clarity.

Aquecimento

Heat the plastic sheet in an oven (typically 120°C to 200°C) until pliable, ensuring uniform temperature distribution.

Formação

Position the heated sheet over a mold and apply vacuum pressure (-14.7 psi) to shape it, with mold design influencing precision.

Arrefecimento

Cool the formed plastic with air or water to solidify its shape, with timing dependent on material thickness.

Aparar

Remove excess plastic using tools or Máquinas CNC7 for a finished product, ensuring accurate cuts.

Acabamento

Add optional processes like printing or assembly to enhance functionality or aesthetics.

Precision in each step—temperature, vacuum strength, and cooling—ensures the final product meets specifications.

Vacuum forming always produces uniform thickness in the final product.Falso

Stretching can cause thinning, particularly in deep or complex molds.

Proper cooling is essential for maintaining the shape of vacuum-formed parts.Verdadeiro

Effective cooling ensures dimensional stability and shape retention.

What are the Key Factors Affecting the Vacuum Forming Process?

Several variables impact the quality and efficiency of vacuum forming, requiring careful optimization.

Os principais factores incluem material thickness8, conceção do molde9, temperatura de aquecimento10, and vacuum strength, each influencing the final product’s quality.

Material Thickness

- Thicker sheets need more heat and time, while thinner sheets risk tearing during forming.

Conceção de moldes

- Complex molds with undercuts or poor draft angles can complicate forming and affect quality.

Temperatura de aquecimento

- Incorrect temperatures may cause uneven forming or material breakdown.

Vacuum Strength

- Too little pressure leaves incomplete shapes; too much can thin the material excessively.

Mastering these factors is critical for consistent, high-quality results.

Mold design has no impact on the vacuum forming process.Falso

Mold complexity, including draft angles, directly affects forming success and product quality.

Heating temperature is a critical factor in vacuum forming.Verdadeiro

Proper heating ensures the plastic forms accurately without degrading.

Conclusão

Plastic vacuum forming is a dynamic and economical process driving innovation in the Philippines across industries like packaging, automotive, and medical manufacturing. The top factories—Formplas Services, SG Eco Industries, INFIDEAL, Fompac Plastics, and Alcami Global—offer specialized expertise and scalable solutions. By understanding the materials, process steps, and influencing factors, businesses can confidently partner with these leaders for high-quality, tailored products. Whether you need custom trays or large-scale production, these factories are equipped to deliver exceptional results.

-

Explore this link to understand the plastic vacuum forming process and its applications in various industries. ↩

-

Learn about blister packaging's versatility and its role in protecting products across various sectors. ↩

-

Discover the advantages of custom thermoforming and how it can tailor packaging to specific needs. ↩

-

Exploring materials with high impact resistance can enhance your knowledge of durable packaging solutions. ↩

-

Learning about chemical resistance materials is crucial for selecting the right packaging for sensitive products. ↩

-

Learn about the critical factors in material selection that can impact the quality and durability of vacuum-formed products. ↩

-

Discover how CNC machines improve precision and efficiency in the trimming stage of vacuum forming, ensuring high-quality finishes. ↩

-

Understanding how material thickness affects vacuum forming can help you optimize your processes for better results. ↩

-

Exploring mold design's role in vacuum forming can lead to improved product quality and efficiency in your projects. ↩

-

Learning about heating temperature's effects can help you avoid common pitfalls and enhance your vacuum forming outcomes. ↩