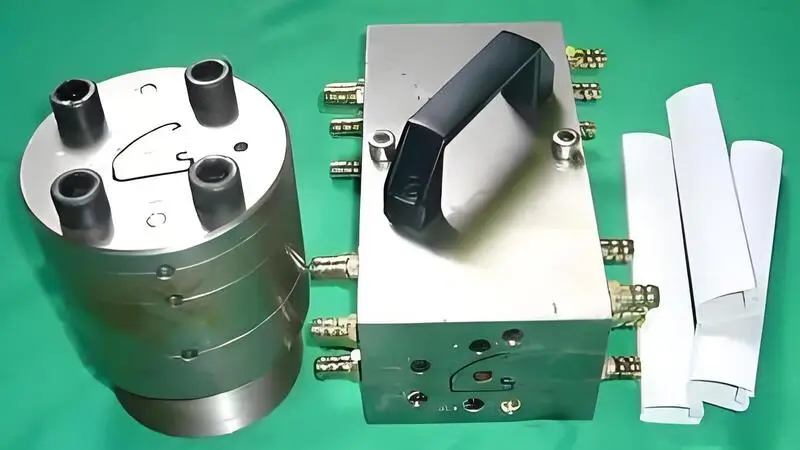

Plastic extrusion is a key manufacturing process that involves melting plastic and forcing it through a mold to create continuous shapes. The mold is crucial in defining the product's shape, size, and quality. Proper mold design directly impacts production efficiency, material flow, and cost-effectiveness, making it vital for high-quality extrusion results.

Molds in plastic extrusion shape molten plastic into desired forms, like pipes or profiles. Proper mold design ensures uniform flow, accurate dimensions, and reduces waste and energy use. Regular maintenance maintains consistent production quality..

Common materials for plastic extrusion include thermoplastics like PVC, PE, PP, and PS.True

These materials are widely used due to their versatility and unique properties in different applications.

Plastic extrusion can only be done with a single material.False

Different materials can be used in the extrusion process depending on the desired properties of the final product.

What are the Types of plastic extrusion molds?

Choosing the right type of mold is critical in the plastic extrusion process. Cold extrusion molds and hot extrusion molds are two common types of molds, each of which exhibits different advantages in different production scenarios, and understanding their differences can help optimize the production process.

Plastic extrusion molds are classified into cold and hot types. Cold molds are used for specific materials, while hot molds are versatile for various products. Selecting the appropriate mold based on needs enhances production efficiency and product quality.

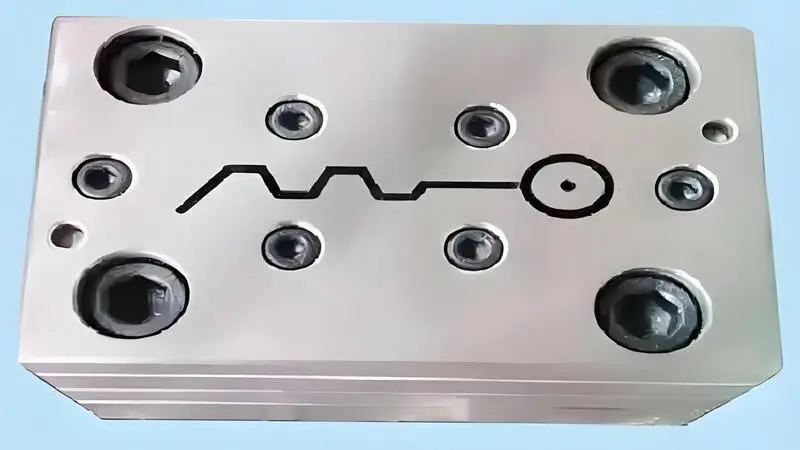

Cold extrusion molds

Cold extrusion molds are molds that the material enters from the top of the mold from the extrusion machine to be molded after being heated to a molten state. It is characterized by the fact that the plastic enters the mold directly after melting and the mold structure itself completes the molding. The plastic inside a cold extrusion mold is usually not reheated and the main function of the mold is to set the molten plastic.

Hot extrusion molds

Hot extrusion molds are molds that keep the plastic in a molten state and regulate the temperature of the plastic throughout the mold. The plastic is continuously heated by a heating system and extruded through the heated mold and the extrusion machine to complete the molding. Hot extrusion molds use technologies such as heating tapes, heating plates, or hot runner systems to ensure that the temperature of the plastic is uniform throughout the extrusion process and to avoid uneven cooling.

There are various types of plastic extrusion molds used for different applications.True

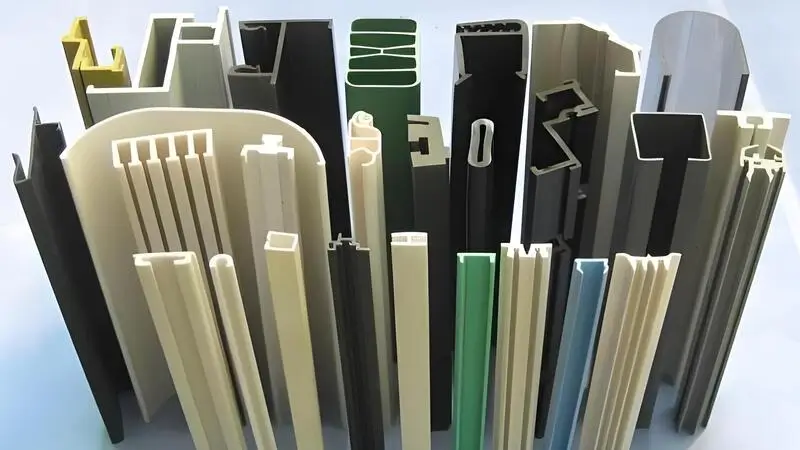

Plastic extrusion molds come in a variety of shapes and sizes to accommodate different products, such as dies for profiles, sheets, films, and pipes, each designed to produce specific shapes and meet performance requirements.

Plastic extrusion molds are all the same.False

Plastic extrusion molds vary greatly depending on the product being produced. For example, molds for pipes are different from those for films or profiles, with each requiring specific designs and materials to ensure efficient production and desired product properties.

What are the Applications of Plastic Extrusion Molds?

Plastic extrusion molds play a key role in the production process, affecting product quality, appearance and productivity. Different types of molds are used in a wide range of applications covering several industries, from basic pipes and profiles to complex industrial components, and the optimal design of plastic extrusion molds is essential to increase productivity and reduce costs.

Plastic extrusion molds, used in industries like construction, automotive, and packaging, optimize productivity and surface finishes. Cold and hot extrusion molds are designed for different materials and shapes, reducing costs in products such as pipes, frames, tubes, films, and cable jacketing.

Cold extrusion molds are widely used in the following areas:

PVC pipes and profiles: PVC material is easy to process in cold extrusion molds and has high production efficiency.

PE pipes: low and high density polyethylene pipes also often use cold extrusion molds.

Conventional profiles: for simple plastic profiles like window frames and door frames.

Hot extrusion molds are widely used in the following areas:

High-precision thin-walled profiles: such as electronic equipment housings, precision tubing, and automotive parts.

High melting point plastics: such as PA (nylon), POM, and certain polymer materials.

Specialty plastic products: such as sheathing materials for wires and cables, composite materials, etc.

Plastic extrusion molds are used in a variety of industries for producing custom profiles and products.True

Plastic extrusion molds are essential in producing a wide range of products, including pipes, profiles, sheets, films, and custom shapes, used in industries like construction, automotive, packaging, and consumer goods.

Plastic extrusion molds have limited applications.False

Plastic extrusion molds are versatile tools used across numerous industries, enabling the production of complex profiles, high-precision components, and continuous shapes, suitable for both high-volume and customized manufacturing.

What are the Advantages and disadvantages of cold extrusion molds and hot extrusion molds?

In the plastic extrusion molding process, the choice of mold affects the entire production process. Cold extrusion molds and hot extrusion molds each have different working principles and applications. Understanding their advantages and disadvantages will help you make a more appropriate choice in actual production.

Cold extrusion molds operate at room temperature, while hot extrusion molds heat materials to improve flow, making them suitable for high-strength materials. Cold extrusion excels in accuracy, while hot extrusion enhances material handling and flow

Cold extrusion molds

Advantages: The cost of making cold extrusion molds is relatively low because you don’t need a fancy heating system. The design and making of cold extrusion mold is pretty simple, and it’s easier to take care of. Cold extrusion molds are good for making a lot of stuff, and you can make it go really fast.

Disadvantages: Since the heating control of the cold extrusion mold is relatively simple, it may lead to uneven cooling of the plastic during the molding process, which affects the quality of the product. For some materials with high melting points or requiring fine temperature control (e.g., high-density polyethylene, some engineering plastics), cold extrusion molds may not be able to handle them effectively.

Hot extrusion molds

Advantages: Hot extrusion molds are able to keep the plastic in a molten state by using a precise temperature control system, which prevents temperature changes from affecting the quality of the product. They can process a wider range of plastics, especially those with high melting points and high viscosity. Because the temperature is consistent throughout the mold, the plastic products that are made have a smooth surface and are very accurate in size.

Disadvantages: Hot extrusion molds are more expensive to make and maintain because they have to have a heating system and a complicated temperature control design. It takes a long time to make hot extrusion molds because you have to get the temperature control system inside the mold just right. Heating systems use up a lot of energy, which means it costs more to run them.

Cold extrusion molds offer higher precision and better surface finishes compared to hot extrusion molds.True

Cold extrusion molds allow for greater control over the material, resulting in better dimensional accuracy and smoother surface finishes, making them ideal for applications requiring high precision.

Cold extrusion molds are better for processing high-strength materials than hot extrusion molds.False

Hot extrusion molds are more suitable for processing high-strength materials, as the elevated temperature reduces material hardness and facilitates easier flow during the extrusion process.

How to choose a cold extrusion mold or hot extrusion mold?

When selecting a cold or hot extrusion mold, it is important to understand the material properties and processing needs. Each has its own advantages, and choosing the right die can improve productivity and ensure product quality.

Cold extrusion suits room-temperature molding, while hot extrusion is for high-temperature processing. Mold choice depends on material properties, product needs, and production processes, optimizing efficiency and reducing costs.

Product requirements

If you need a product that’s really precise, especially if you need a good surface finish and tight tolerances, you should use a hot extrusion mold. But if you’re making a standard profile or tube that’s not super fancy, you might want to go with a cold extrusion mold.

Production scale

If you’re making a lot of parts, you might want to go with a cold extrusion mold because it’s faster. But if you’re making a small number of really precise parts, you might want to go with a hot extrusion mold.

Material selection

If you’re using a material with a high melting point or a high viscosity (like a high-performance plastic or an engineering plastic), you’ll see more benefits from using a hot extrusion mold.

Budget

If you don’t have a lot of money, you can go with a cold extrusion mold. It’ll save you money and still get the job done.

Choosing a cold extrusion mold or hot extrusion mold depends on the material and desired properties.True

Cold extrusion molds are used for materials that do not require heat for shaping, while hot extrusion molds are used for materials that need to be softened or melted to form complex shapes. Both methods are essential depending on the type of plastic and final product specifications.

Choosing a cold extrusion mold or hot extrusion mold is irrelevant to the material properties.False

The choice between cold and hot extrusion molds is directly related to the material being used. For instance, materials like metals or high-temperature plastics may require hot extrusion, whereas thermoplastics with lower melting points may be processed with cold extrusion, impacting the final product's strength, texture, and appearance.

Conclusion

Whether it’s cold extrusion or hot extrusion, their respective characteristics and applicable scenarios make them play an important role in plastic extrusion molding Understanding their working principles, advantages and disadvantages, as well as the scope of application, can help manufacturers make more accurate decisions when designing production lines.