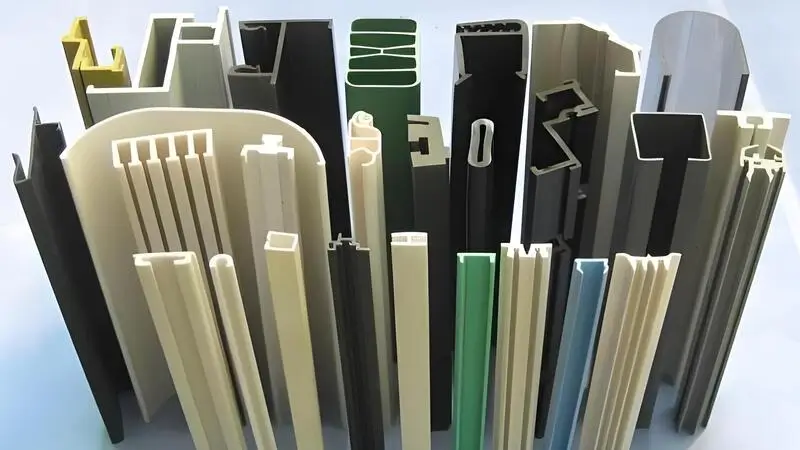

Many industries widely use plastic products because they offer lightweight, corrosion-resistant, and inexpensive options. The quality of plastic extrusion molds is crucial to the accuracy and productivity of plastic products. Whether it’s a simple pipe or a complex industrial fitting, the mold is key.

This article explains how to make plastic extrusion molds. It covers design, choosing materials, machining, surface treatment, and assembly testing.

Plastic extrusion molds are designed for specific shapes and profiles.True

The molds are custom-made to shape the extruded plastic into the desired form, ensuring consistent results.

Plastic extrusion molds can only be used for one type of material.False

Molds can be used for various thermoplastics, provided they are compatible with the material's properties and temperature requirements.

- 1. How to design the plastic extrusion mold in the early stage?

- 2. What kind of material should we choose for plastic extrusion molds?

- 3. Which machining techniques2 will we use for plastic extrusion molds?

- 4. What is Electrical Discharge Machining( EDM)?

- 5. What are the surface treatment methods for plastic extrusion molds?

- 6. What are the steps of plastic extrusion mold assembly?

- 7. What are the steps of plastic extrusion mold debugging?

- 8. Conclusion

How to design the plastic extrusion mold in the early stage?

Pre-design is the basis for making plastic extrusion molds1. This step is critical, just like building a house before drawing blueprints, to provide precise guidance for subsequent work.

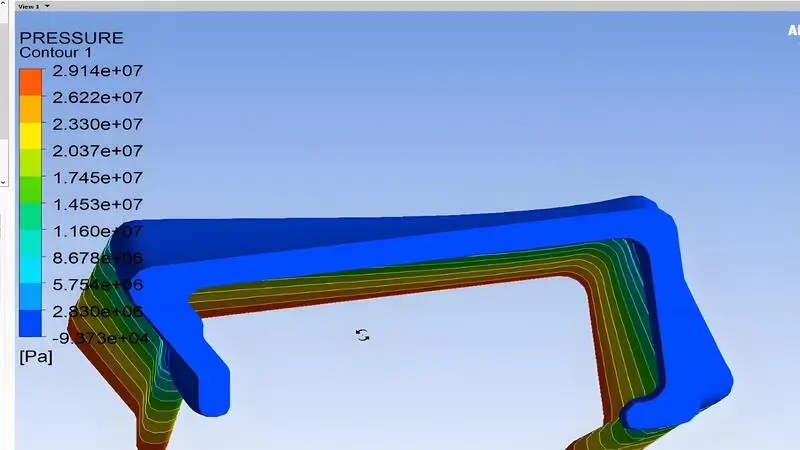

Engineers must simulate and analyze the mold structure, flow channel, and cooling system. They do this based on the product's shape, size, and precision. This helps them optimize the design.

Plastic product evaluation

After we receive the design drawings, we need to analyze how we will use them. We must check the performance requirements and find key details. These include shape complexity, dimensional accuracy, and wall thickness uniformity.

Mold Structure Design

Mold structure design is the core of the preliminary design. Based on analyzing plastic products, identify the mold parting surface. Also, note the number of cavities, core structure, and mold release method.

Runner system design

The engineer should design a suitable main flow channel, manifold, and gate based on the product's shape, size, and cavity. The main flow channel helps the melt flow. The manifold spreads the melt evenly. The gate's location and size impact the flow rate and filling order.

Cooling system design

According to the shape and wall thickness of the product, reasonably arrange the cooling channels. The cooling channels should be near the surface of the cavity. This helps create a steady cooling effect. It also shortens the molding cycle and boosts production efficiency.

The design of a plastic extrusion mold is crucial for determining the shape and size of the final product.True

A well-designed mold ensures consistent production quality, minimizing defects and achieving the desired specifications.

Plastic extrusion molds can only be designed by experienced engineers.False

While experience is important, molds can also be designed using advanced software tools and simulations.

What kind of material should we choose for plastic extrusion molds?

Steel is strong, durable, and resistant to wear, perfect for precise, long-lasting molds. Aluminum alloy is lightweight, has excellent thermal conductivity, and is easy to work with, making it ideal for fast, lightweight mold production.

When choosing materials, we should consider the mold conditions, product production batch and cost and other factors.

Types and characteristics of steel

Commonly used mold steel are carbon steel, alloy steel and high-speed steel.

Carbon steel is hard and resistant to wear. However, it can deform a lot during heat treatment. Simple molds or those with low precision needs are best.

Alloy steel gains hardness, wear resistance, and toughness when alloying elements are added. It has low deformation during heat treatment. This makes it widely used in many types

of plastic extrusion molds.

High-speed steel is hard and resistant to wear. It also has high thermal hardness. This steel performs well when cutting at high temperatures. People often use it to make complex molding parts and cutting tools.

Advantages of aluminum alloy

Aluminum alloy is light and has a good density. It also conducts heat well, which helps cool molds faster. This improves production efficiency.

It is often used for plastic molds in the aerospace industry. It is also used for everyday items that do not need high mold life.

Selection of mold materials

When you choose mold materials, first consider how you will use the mold. Consider factors like working temperature, pressure, and wear. For high temperature, high pressure, and heavy wear, select strong, hard, and wear-resistant steel. If the working temperature is low and weight is not a concern, aluminum alloy may be a good choice.

Common materials used for extrusion molds include steel, aluminum, and copper alloys.True

These materials are preferred for their strength, heat resistance, and durability, making them ideal for extrusion mold construction.

Extrusion molds can only be made from steel.False

While steel is a common material, other metals like aluminum and copper alloys are also used for molds.

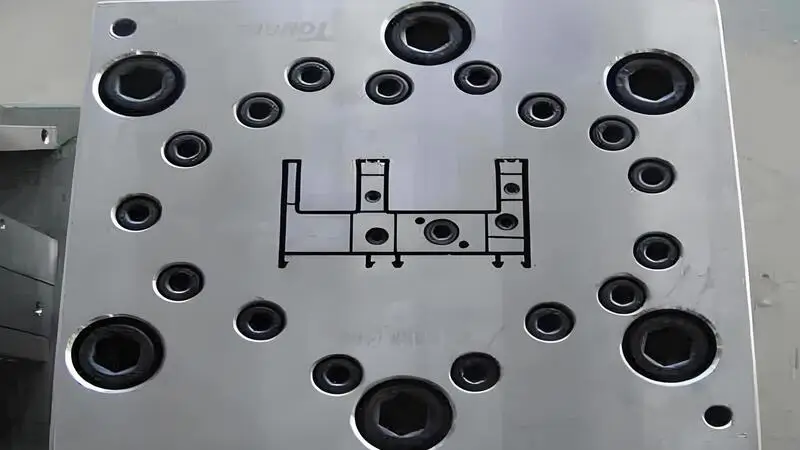

Which machining techniques2 will we use for plastic extrusion molds?

Based on the design drawings, the mold material will be processed into a specific shape and dimensional accuracy of the parts. The processing accuracy and quality directly affect the mold assembly and performance.

Extrusion molds usually use turning, milling, drilling, grinding and other machining methods.

Turning

On the lathe, the tool spins while the workpiece moves back and forth. This helps shape the outer circle, bore, threads, and other surfaces. You can achieve high dimensional accuracy and surface roughness.

Milling

In the milling machine, the milling cutter rotates and the workpiece moves to achieve multi-face processing. Milling can process a variety of flat surfaces, step surfaces, grooves, cavities and other complex shapes.

Drilling

On the drilling machine, the drill rotates and the axial feed is used to drill holes. The drilling accuracy is relatively low. Generally, reaming, boring and other processes are needed to improve the accuracy and surface quality.

Grinding

Grinding is done by rotating the grinding wheel at high speed and feeding the workpiece. The surface of the mold parts is ground. It can process a variety of flat surfaces, cylindrical, internal holes and other surfaces. Very high precision and roughness can be obtained.

CNC machining is commonly used for plastic extrusion molds.True

CNC machining offers high precision and the ability to create complex designs, which are essential for accurate and efficient mold production.

Plastic extrusion molds can only be machined using manual methods.False

Plastic extrusion molds are typically machined using automated methods like CNC, which provide higher precision and efficiency compared to manual techniques.

What is Electrical Discharge Machining( EDM)?

EDM can work with complex shapes on mold materials. This is hard to do with traditional machining. It can create fine holes, narrow slots, and complex cavity surfaces.

EDM uses high temperatures from the discharge to etch mold material. This method is not limited by material hardness. It can process materials that are very hard and strong.

Working Principle

In discharge corrosion, the tool electrode is made of copper or graphite. It connects to a pulse power supply along with the workpiece. When they are a certain distance apart, the pulse voltage creates a discharge channel in the medium.

This medium can be kerosene or deionized water. This creates high temperatures that melt, vaporize, and erode the metal on the workpiece's surface.

Application

In plastic extrusion mold production, we often use it to create complex shapes. This includes the core, cavity, and inserts.

Parts with shaped holes, narrow slots, or complex curved surfaces are hard to process with traditional methods. This is why EDM is needed for high precision. For high hardness mold materials, the use of EDM can avoid processing difficulties and tool wear.

Process Parameters

The parameters of the process significantly impact the quality and efficiency of machining. Key parameters include pulse width3, pulse interval, discharge current4, and discharge voltage. Pulse width dictates the duration of discharge, while pulse interval manages the time gap between consecutive discharges. Discharge current and voltage influence the discharge energy, thereby affecting machining speed and surface finish.

Cautions

Make sure the processing medium is clean and flowing. Regularly inspect and maintain the equipment. Pay attention to the processing state. Look for signs like spark color and sound. Address any abnormalities quickly.

EDM is used to machine hard metals that are difficult to machine with traditional methods.True

EDM is particularly effective for machining hard metals, alloys, and intricate shapes .

EDM can only be used on metals.False

Although EDM is commonly used on metals, it can also be used on other conductive materials such as graphite and certain ceramics.

What are the surface treatment methods for plastic extrusion molds?

To improve the performance and life of the mold, surface treatment is required. Commonly used surface treatment methods include nitriding, hard chrome plating5, and TD treatment

Surface treatment can improve the surface hardness, wear resistance, corrosion resistance, and mold release performance of mold parts.

Nitriding treatment

Nitrogen atoms infiltrate the surface of the mold parts to form a nitrided layer. This can improve the surface hardness to HV900 - 1200, significantly improve wear resistance and anti-seize performance, and provide a certain degree of corrosion resistance, extending the life of the mold.

Hard chrome plating

The hard chrome layer has high hardness, good wear resistance, and high surface finish. This can increase the surface hardness to HV800 - 1000, improve demolding performance, and make products easy to come out. Manufacturers commonly use it in molds that have high requirements for surface finish and demolding performance.

TD treatment

TD treatment6 is a thermal diffusion method of carbide cladding treatment technology. It spreads metal carbides to the surface of the mold parts at high temperatures. This creates a very hard carbide layer. The surface hardness of the treated parts can reach HV2800 to HV3200. They have great wear resistance, corrosion resistance, and anti-adhesion properties.

Other surface treatment methods

Carburizing can increase the carbon content of the surface, enhance hardness and wear resistance. Boron forms a boride layer on the surface, which has high hardness and good wear resistance. Chemical nickel plating forms a uniform nickel layer on the surface, improving corrosion resistance and wear resistance.

Extrusion mold surface treatment can improve the lifespan of molds.True

Surface treatments such as coating, polishing, or hardening can enhance the durability of molds by reducing wear and preventing corrosion.

Extrusion mold surface treatment is only necessary for high-volume production.False

Mold surface treatments can benefit all types of production runs, by improving the quality of the final product and reducing maintenance costs.

What are the steps of plastic extrusion mold assembly?

Mold assembly is the process of putting together each part to make a complete mold. It is similar to assembling car parts. Each part must fit perfectly to ensure the mold works properly.

The accuracy and quality of mold assembly are important. They affect how well the mold functions. They also influence the quality of plastic products.

Parts Cleaning

Before assembly, clean the mold parts. Remove surface oil, iron filings, dust, and other impurities. You can use chemical cleaning or ultrasonic cleaning using cavitation vibration off small impurities.

Positioning installation

Positioning installation is to use positioning pins, positioning blocks and other parts to ensure positioning accuracy. The design drawings show where to install the mold parts. Use bolts and nuts to secure them in place. Be careful to control the tightening torque. This will help prevent deformation or loosening of the parts.

Gap adjustment

Assembly must adjust the gap between the parts. The core and cavity gap should match the product size and molding process. If the gap is too large, it can cause flying edges. If it is too small, it will be hard to open and close. You can adjust the gap using a gasket or by grinding to reach the ideal size.

Assembly quality check

After you finish the assembly, check the mold's quality carefully. Look at the appearance and size accuracy. Also, check the condition of the parts and how well the moving parts work.

Mold assembly should be inspected for defects before extrusion begins.True

Inspecting the mold assembly before starting the extrusion process helps identify and fix potential issues .

Lubrication is not needed during the extrusion mold assembly.False

Lubrication is often used during mold assembly to reduce friction and ensure smooth operation of the extrusion process.

What are the steps of plastic extrusion mold debugging?

Extrusion mold debugging7 tests how well the mold works and the quality of the product. It uses a trial mold to find problems. When issues arise, we make adjustments and improvements quickly. This ensures the mold can produce good products steadily and efficiently.

Mold debugging mainly includes the preparation before mold trial, mold trial, problem analysis and optimization.

Prepare the equipment and materials for the mold test, such as extruder, plastic raw materials, cooling equipment. Choose the right raw materials and drying methods based on product needs. Adjust the extruder's temperature, pressure, and speed according to the mold structure and molding process.

Test mold

Observe closely the extruder operation, mold work and product molding quality. Watch how the plastic melt flows in the mold. Check for issues like underfilling, flow marks, and bubbles. Also, look at the size accuracy and surface quality of the products.

Problem analyzing and optimizing

If the filling is not full during the mold trial, it may be because of poor runner design or wrong process settings. In this case, you can adjust the runner or the process parameters. Dimensional issues may come from a mold gap problem, so you can readjust the gap. Through continuous analyzing and optimizing, the mold can reach the best working condition.

Extrusion mold debugging is a crucial step to ensure the quality of the final product.True

Debugging the mold helps identify and correct issues such as material flow inconsistencies and dimensional inaccuracies.

Extrusion mold debugging can only be done after the extrusion process is complete.False

Mold debugging can occur during the extrusion process as well, preventing defects and improve efficiency.

Conclusion

Making plastic extrusion molds is a complicated and delicate process. From pre-design to debugging and optimization, each step is closely connected and necessary. We can only make high-quality molds by carefully controlling every detail. This ensures a strong guarantee for producing plastic products.

-

Explore this link to gain insights into effective strategies and techniques for plastic extrusion mold debugging, ensuring high-quality production. ↩

-

Learn about TD treatment's role in creating ultra-hard surfaces for molds, ensuring exceptional wear and corrosion resistance. ↩

-

This resource will explain the critical role of pulse width in EDM, affecting machining speed and surface finish, essential for precision manufacturing. ↩

-

Understanding the impact of discharge current on EDM can help optimize machining efficiency and quality, crucial for high-precision applications. ↩

-

Learn why aluminum alloy is preferred for its lightweight and thermal conductivity, improving mold cooling and production speed. ↩

-

Explore the essential machining techniques that ensure high precision and quality in plastic extrusion mold production. ↩

-

Exploring this link will provide in-depth insights into optimizing the design of plastic extrusion molds, enhancing product quality and manufacturing efficiency. ↩