In the plastic extrusion industry, minimizing waste is important for both productivity and the environment. In this blog, we will explore how plastic extrusion can reduce material waste. We will also share tips and tricks to improve your production process.

You can reduce waste by improving processes, controlling extrusion speed, and proper mold design.

Optimizing process parameters like temperature, pressure, and screw speed can significantly reduce material waste in plastic extrusion.True

Proper control of these parameters ensures efficient material usage and minimizes defects.

Recycling and reusing scrap materials in plastic extrusion is not effective for maintaining product quality.False

Recycled materials can be effectively reused in production, especially when mixed with virgin materials.

- 1. How to optimize process parameters to reduce material waste?

- 2. How to optimize mold design to reduce material waste?

- 3. How to recycle and reuse scrap to reduce material waste?

- 4. How to optimize the production process to reduce material waste?

- 5. How to train employees awareness to reduce material waste?

- 6. Conclusion

How to optimize process parameters to reduce material waste?

To reduce plastic extrusion waste1, start by accurately controlling the extruder parameters. This ensures that the extrusion process uses the plastic material optimally, effectively reducing waste.

Reasonable control of extruder parameters2 such as temperature, pressure, screw speed, etc. can reduce material waste.

Temperature control

Keeping the extruder temperature in the right range stops the material from sticking or flowing badly. This happens when it gets too hot or too cold.

Pressure control

Proper pressure adjustment helps ensure that the extruded plastic flows evenly, avoiding over or under material.

Screw speed

Screw speed affects how fast plastic flows and mixes. Adjusting the speed carefully can help reduce waste.

Automated control systems

Modern extruders have automated control systems. These systems can monitor and adjust settings in real time. This helps reduce waste from human error.

Accurate temperature control in plastic extrusion can significantly reduce material waste.True

Maintaining the correct temperature range prevents material degradation, sticking, or poor flow, which can lead to waste.

Pressure control has no impact on reducing material waste in plastic extrusion.False

Proper pressure adjustment ensures even material flow, preventing over- or under-extrusion, which reduces waste.

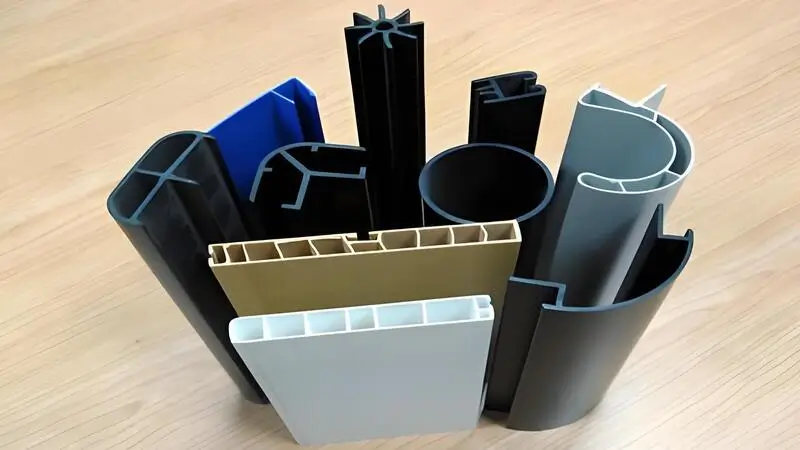

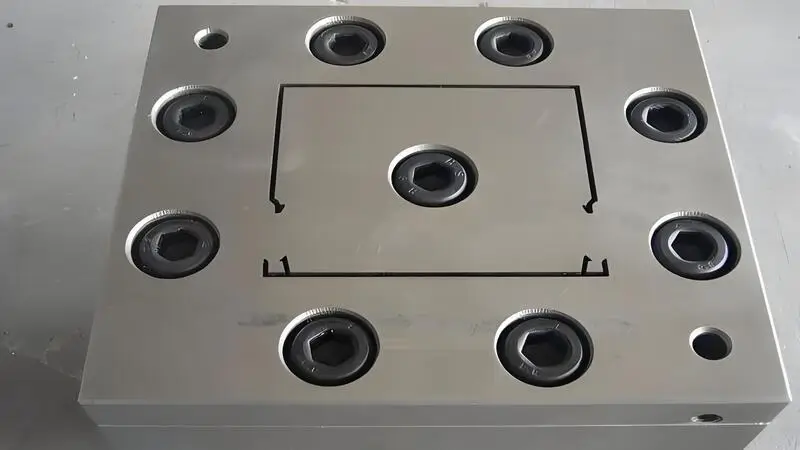

How to optimize mold design to reduce material waste?

The design of the mold has a direct impact on how much material you use when you’re extruding. By improving the mold design3, you can reduce waste. This also helps make your production more stable and efficient.

Improving the mold structure and the flow path of the material boosts your production efficiency. It also helps you waste less material.

Suitable Mold Material

The material you use for your mold determines how long it lasts and how accurately it processes your material. A good mold can help you avoid wasting material you don’t need to waste.

Runner design

Improving the design of your mold’s runners ensures that molten plastic flows evenly into the mold cavity. This helps you avoid wasting material.

Mold Maintenance

Taking care of your mold regularly helps you avoid wasting materials. This way, you will not damage your mold or wear it out.

Optimizing the runner design in molds can significantly reduce material waste in plastic extrusion.True

Efficient runner designs ensure even material flow and minimize excess material, reducing waste during the extrusion process.

Using high-quality mold materials has no impact on reducing material waste in plastic extrusion.False

High-quality mold materials improve durability and precision, reducing defects and material waste during production.

How to recycle and reuse scrap to reduce material waste?

Another way to reduce material waste is by recycling and reusing waste materials4. You can reduce waste generated during the plastic extrusion process by recycling and using less new raw materials.

By managing waste effectively, you can reduce waste and production costs.

Sorting and recycling waste materials

By sorting and recycling waste materials, you can use more renewable materials and avoid wasting resources.

Reusing waste materials

You can recycle waste materials and use them again in production. This works best for products made from the same materials. This reduces the amount of resources you use.

Controlling the size of waste materials

You control the size of recycled waste. This allows it to mix with new raw materials. It does not affect the overall quality of the product.

Recycling and reusing scrap materials in plastic extrusion can significantly reduce material waste and production costs.True

Reusing scrap materials reduces the need for virgin raw materials, minimizes waste, and lowers overall production expenses.

Recycled scrap materials cannot be reused in plastic extrusion without compromising product quality.False

When properly processed and blended with virgin materials, recycled scrap can maintain product quality while reducing waste.

How to optimize the production process to reduce material waste?

To reduce material waste, it is important to have an accurate production process. By improving the production process, you can cut out extra steps and waste. This will also make the product more efficient.

A well-designed production process ensures efficient use of materials and reduces material waste.

Reduce raw material waste

Calculate and control the amount of raw material input accurately to reduce unnecessary waste.

Optimize production cycle

Improving the production cycle helps each batch of products use raw materials better. This reduces idle time and waste.

Quality control and process adjustment

Careful quality control and quick process changes can keep each part of production running well. This helps reduce waste from mistakes in the process.

Data monitoring system

Using a real-time monitoring system to gather data from production can help track material use. This can reduce waste.

Optimizing the production process can significantly reduce material waste.True

By implementing process improvements such as better material handling, precision cutting, and recycling of scrap, manufacturers can minimize waste .

Optimizing the production process has no impact on reducing material waste.False

Process optimization, including lean manufacturing techniques and advanced technologies, directly contributes to waste reduction .

How to train employees awareness to reduce material waste?

Employees are the ones who actually reduce material waste. Strengthening employee training and raising their environmental awareness can significantly improve the efficiency of material utilization in the production process.

Cultivating employees' attention to material conservation and enhancing their sense of responsibility can effectively reduce material waste.

Skill Enhancement

Regularly provide employees with relevant skills training to help them master the latest production processes and minimize operational errors.

Environmental Awareness

We organize activities and lectures on environmental protection. This helps employees understand the importance of reducing material waste. We encourage them to focus more on saving resources in their work.

Incentive mechanism

Set up an incentive mechanism related to material waste reduction to motivate employees to take the initiative to participate in the action of saving materials.

Training employees on proper material handling techniques can significantly reduce material waste.True

Educating employees on efficient material usage, proper storage, and waste minimization strategies can lead to a noticeable reduction in material waste.

Employee training has no impact on reducing material waste in manufacturing processes.False

Well-trained employees are more aware of waste reduction practices, leading to better resource management and less material waste in production.

Conclusion

Cutting down on material waste in plastic extrusion helps save money and protect the planet. By adjusting your production settings, improving your die design, and recycling scrap, you can cut waste. You can also boost productivity and lessen your impact on the environment. Training your staff and using new technology will help too. As technology continues to evolve, the plastics extrusion industry is poised to realize a more efficient and environmentally friendly production model.

-

Exploring this link can provide innovative strategies and practical tips for effectively recycling and reusing waste materials, significantly reducing material waste and production costs. ↩

-

Exploring this link provides actionable strategies to reduce waste in plastic extrusion, enhancing both environmental sustainability and production efficiency. ↩

-

This resource offers in-depth guidance on optimizing extruder settings, crucial for minimizing material waste and improving product quality. ↩

-

Discover how innovative mold design can significantly reduce material waste, leading to more sustainable and cost-effective production processes. ↩