Manufacturers widely use plastic extrusion technology for mass production due to its efficiency and cost-effectiveness. Compared to other molding methods, plastic extrusion boosts productivity and customizability, significantly reducing the cost of each product, especially in large-scale production.

Plastic extrusion is ideal for mass production, offering low per-piece costs and excellent material efficiency. While mold setup requires upfront investment, mass production spreads this cost, reducing individual product costs and enhancing economic benefits.

Plastic extrusion is a process where material is forced through a mold to create specific shapes.True

This process is commonly used to produce profiles, tubes, and sheets with consistent dimensions.

Plastic extrusion requires high temperatures for all materials.False

The temperature varies based on the type of material being extruded, with some materials requiring lower temperatures for processing.

- 1. Why is plastic extrusion mass production efficient?

- 2. Why are plastic extrusion mass production costs low?

- 3. Why is the quality of plastic extrusion mass production stable?

- 4. Why is plastic extrusion adaptable?

- 5. Why improved automation ensures stability in mass production of plastics extrusion?

- 6. Conclusion

Why is plastic extrusion mass production efficient?

Plastic extrusion is a mass production process. It is faster than other methods of making plastic products. It also costs less.

Through advanced equipment and technology, plastic extrusion not only increases production speed, but also reduces production costs per product.

Continuous production line

Extrusion lines are able to run continuously without interruption, making mass production possible. There are few interruptions in the production process, saving time and increasing output.

High speed production

With modern technology, plastics extrusion enables rapid production, especially in mass production, with significantly shorter cycle times per product.

Change fast

With the optimization of the equipment, the switching of production modes has become more flexible. The production parameters can be quickly adjusted to the requirements, ensuring efficient production.

Plastic extrusion mass production is highly efficient.True

Plastic extrusion is considered highly efficient for mass production due to its ability to produce large quantities of products with consistent quality.

Plastic extrusion mass production is inefficient.False

Plastic extrusion is a highly efficient manufacturing process for mass production. It allows for fast production speeds, and able to create complex profiles .

Why are plastic extrusion mass production costs low?

When it comes to mass production, plastic extrusion can significantly reduce the cost of producing each individual product. Compared to small-batch production, mass production can quickly pay off the upfront investment costs of things like molds through efficient processes and equipment inputs, resulting in much lower manufacturing costs per product.

While plastic extrusion technology does require an investment in mold costs upfront, once it gets into the mass production phase, the cost per unit of the product goes down. That’s why plastic extrusion is perfect for mass production.

High mold costs

If you’re not mass producing the product, you have to make a separate mold, and molds are usually expensive, which can lead to higher production costs when you’re making small batches.

Minimizing material waste

The extrusion process further reduces the cost per product by precisely controlling the amount of material used and minimizing waste.

Automation reduces labor costs

The high level of automation in extrusion equipment reduces the amount of manual intervention and labor costs, which can be effective in reducing production costs over the long term.

High production efficiency

Because the production line can run continuously without stopping, you reduce the extra cost of downtime, so you can reduce the overall production cost.

Plastic extrusion is a cost-effective method for mass production.True

Plastic extrusion is highly efficient and cost-effective for mass production due to its ability to continuously produce large quantities of uniform products.

Plastic extrusion results in high costs for mass production.False

Plastic extrusion is generally considered a cost-effective process for mass production, especially when producing large volumes of standardized parts.

Why is the quality of plastic extrusion mass production stable?

Consistency is key when it comes to mass production. Plastic extrusion technology ensures consistent quality from product to product through advanced control systems and production processes. This consistency is especially important in mass production because it makes the product much more reliable.

Plastic extrusion ensures a high level of consistency in dimensions, appearance, and physical properties through precise process control, which is important in markets that require mass production.

Precise control of process parameters

Extruders can precisely control key process parameters like temperature, pressure, and speed, making sure that every aspect of the production process is running at optimal levels.

Uniform product thickness

Plastic extrusion allows for a high level of consistency in the thickness and shape of the product, avoiding potential quality fluctuations during the production process.

Highly consistent physical properties

Extruded products have very uniform physical properties like density, strength, etc., making sure that there is no variation in product quality during mass production.

Real-time quality monitoring

Modern extrusion lines are equipped with real-time monitoring systems that can check the quality of each batch in real time and adjust the production parameters in time to make sure that each product meets the quality standard.

The quality of plastic extrusion mass production is stable.True

With the right conditions, such as controlled temperature, pressure, and consistent material quality, plastic extrusion can achieve stable.

The quality of plastic extrusion mass production is unstable.False

When managed properly, plastic extrusion can produce stable, high-quality results in mass production.

Why is plastic extrusion adaptable?

Plastic extrusion technology not only suits mass production but also adapts flexibly to various types, shapes, and sizes of plastic products. By flexibly adjusting process parameters and changing dies, plastic extrusion can respond to a wide range of customized requirements.

Plastic extrusion not only produces standardized products but also offers flexible customization to meet customer needs, enabling quick responses to market demands and providing an edge in high-volume production.

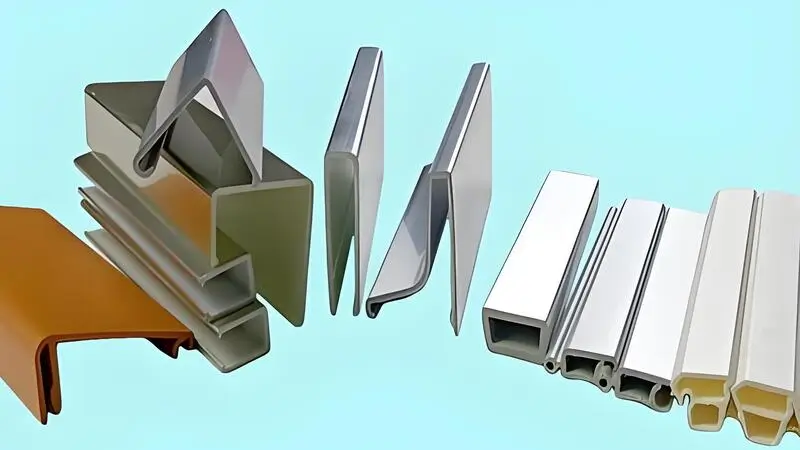

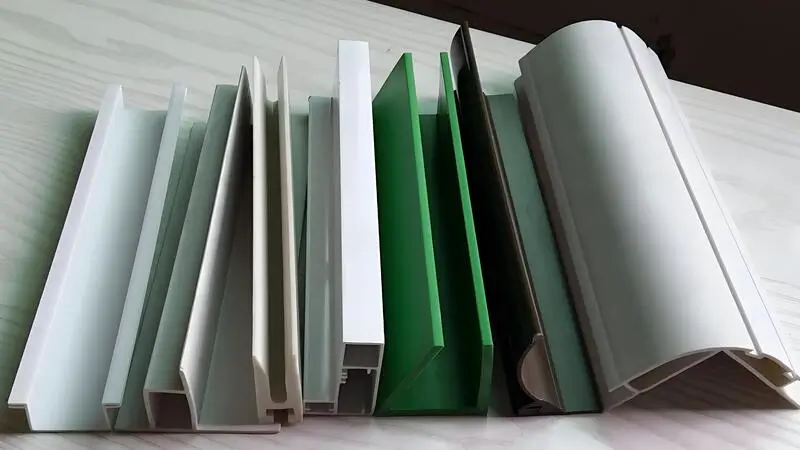

Multiple Product Forms

Through different mold designs, plastic extrusion can produce various forms of products such as pipes, profiles, sheets, plates, films, etc., adapting to the needs of different industries.

Adjustable size and specification

The extrusion line can adjust the size and specification of the product according to the demand, which improves the production flexibility while ensuring the quality.

Fast switching production

Modern plastic extrusion equipment supports rapid die change and production mode adjustment, ensuring switching to different production tasks in a short period of time.

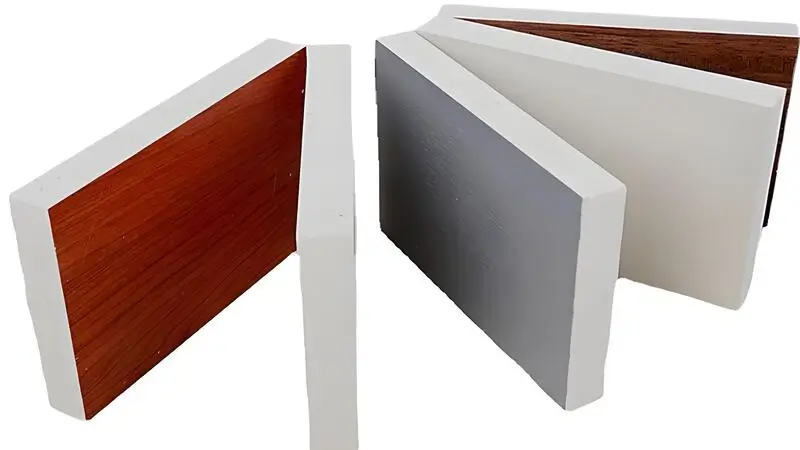

Customized production

Plastic extrusion can also be personalized to meet specific market needs, such as adjusting color, shape, strength, etc., to meet diverse customer demands.

Plastic extrusion is adaptable to a wide range of materials.True

Plastic extrusion is highly versatile and can accommodate a variety of thermoplastics, including PVC, ABS, PET, and HDPE,etc.

Plastic extrusion is not adaptable to different materials.False

Plastic extrusion enables the production of diverse products across industries, from packaging to construction and automotive.

Why improved automation ensures stability in mass production of plastics extrusion?

The advent of automation has brought about a high degree of stability in the production of plastic extrusion. Automation not only reduces human error, but also improves productivity and consistency, ensuring high quality standards for mass production.

Automated production lines allow for long continuous production times, reducing human intervention, ensuring consistent product quality and greatly increasing production efficiency.

Automated Monitoring Systems

Automated monitoring systems adjust and optimize production parameters in real time to ensure consistency and efficiency in the production process.

Precise Adjustment of Production Processes

Through intelligent control systems, automated production lines are able to accurately adjust each step of the production process to ensure the highest standards of product quality.

Reduced human intervention

Automation technology significantly reduces the need for human intervention, minimizing the possibility of human error and ensuring product consistency.

Improve production continuity

Automation equipment enables continuous production 24 hours a day, ensuring stable production line operation and maximizing productivity.

Improved automation ensures stability in mass production of plastic extrusion.True

Automation in plastic extrusion significantly enhances the consistency, quality, and efficiency of mass production.

Improved automation does not ensure stability in mass production of plastic extrusion.False

Increased automation in plastic extrusion plays a crucial role in ensuring stability by streamlining production processes, minimizing defects.

Conclusion

Plastic extrusion technology is the most desirable production method for mass production due to its high efficiency, flexibility, low cost, and environmental friendliness. While the initial investment (e.g., mold, etc.) may be high, mass production can quickly dilute these upfront costs and reduce the cost of producing individual products. Plastic extrusion helps manufacturers achieve higher productivity and lower costs while meeting market demands.