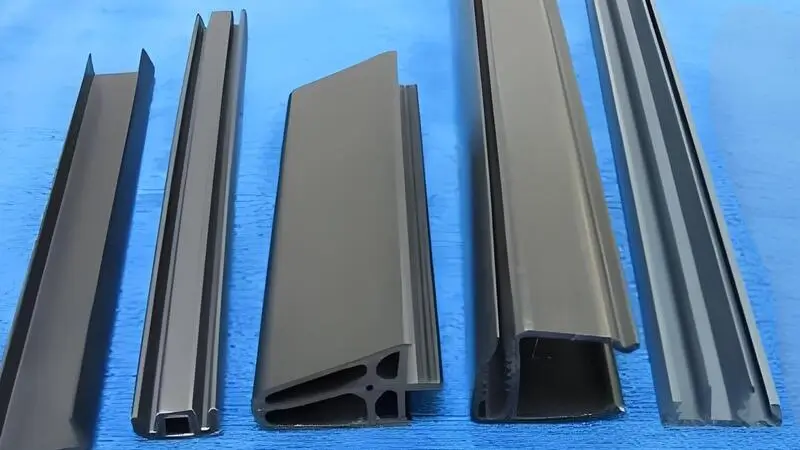

Plastic extrusion is used a lot to make pipes, profiles, films, sheets, and other stuff. But when you’re extruding, you can get defects that mess up how the product looks and works. And that makes your costs go up and slows down your production.

The plastic extrusion process faces issues like air bubbles, cracks, uneven thickness, and color differences. By identifying the causes and implementing targeted solutions, we can reduce costs and improve production efficiency.

Plastic extrusion defects are primarily caused by improper temperature control.True

Temperature fluctuations during the extrusion process can lead to various defects such as uneven material flow, incomplete shaping, or surface imperfections.

Plastic extrusion defects are always caused by poor material quality.False

While material quality can contribute to extrusion defects, factors like incorrect temperature, speed, die design, and process parameters also play significant roles in causing issues such as warping, bubbles, and color variation.

- 1. What are plastic extrusion bubble defects and solutions?

- 2. What are plastic extrusion cracking defects and solutions?

- 3. What are Plastic extrusion warping defects and solutions?

- 4. What are Plastic Extrusion Thickness Unevenness defects and Solutions?

- 5. What are Plastic Extrusion Scratching defects and Solutions?

- 6. What are plastic extrusion color difference defects and solutions?

- 7. What is plastic extrusion shrinkage defect and the solution?

- 8. Conclusion

What are plastic extrusion bubble defects and solutions?

Bubble defects are usually characterized by the presence of air bubbles on the surface or inside the product, which affects the appearance and mechanical properties of the product.

To solve the problem of air bubbles, you can control the humidity of the raw material, optimize the melt temperature, improve the efficiency of the exhaust system, and ensure equipment sealing.

High raw material humidity

Air bubbles are often caused by moisture in the raw material. When the humidity is too high, the water evaporates quickly at high temperatures and bubbles form. You must strictly control the humidity of the raw material and dry it if necessary.

Poor exhaust

Another reason for air bubbles is that the exhaust system of the extruder is poorly designed or not efficient enough. By optimizing the exhaust channel to ensure that the gas in the melt can be quickly discharged, the appearance of gas bubbles can be effectively reduced.

Melt temperature

Too high a temperature can cause thermal degradation, while too low a temperature can result in a melt that is too viscous and difficult to vent. Precise control of melt temperature can help minimize bubble defects.

Bubbles are a common defect in plastic extrusion.True

Bubbles can form in plastic extrusion due to trapped air or moisture in the material, improper temperature control, or excessive screw speed. These bubbles affect the quality and appearance of the extruded product.

Bubbles in plastic extrusion can be completely avoided.False

While it's challenging to completely eliminate bubbles, careful control of material moisture, temperature settings, and extrusion speed can significantly reduce their occurrence. In some cases, degassing techniques or better material conditioning may be necessary to minimize bubbles.

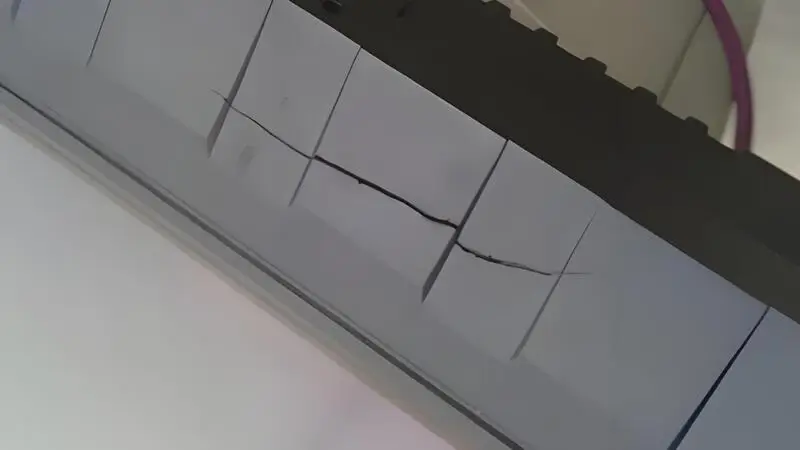

What are plastic extrusion cracking defects and solutions?

Cracking defects are usually cracks on the surface or inside of the plastic extruded product, which can reduce the strength of the product and, in severe cases, even affect the performance of the product.

To reduce cracking, we can adjust extrusion pressure, temperature, and cooling rates. Optimizing these parameters helps minimize cracking and improves product quality.

Adjustment of extrusion pressure

Excessive extrusion pressure can easily trigger pulling cracks. Appropriately lowering the extrusion pressure will reduce cracks on the surface and inside the product.

Temperature control

If the temperature is too high or too low, it will affect the fluidity of the material. Reasonable temperature control can improve the fluidity of the material and avoid cracks.

Cooling method

If you cool it too fast, you can get big thermal stresses in the material. If you cool it too slow, you can slow down the curing on the surface and get cracks. You have to cool it right and cool it evenly.

Here are the claims for "plastic extrusion crack" in the same format:

Cracks are a common defect in plastic extrusion.True

Cracks in plastic extrusion can occur due to factors such as improper cooling, incorrect temperature settings, material stress, or a high extrusion speed. These cracks can compromise the strength and integrity of the final product.

Cracks in plastic extrusion can be completely avoided.False

While it is difficult to entirely eliminate cracks, proper control of cooling rates, temperature settings, and extrusion speed can reduce the likelihood of cracks forming. In some cases, optimizing the material properties and extrusion conditions may help mitigate the issue.

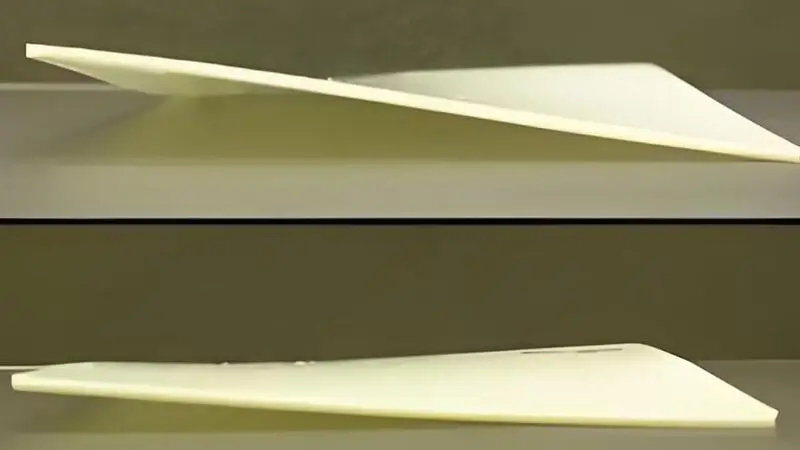

What are Plastic extrusion warping defects and solutions?

Warping is when a plastic product shrinks unevenly as it cools, causing it to get all messed up. This happens a lot with thin-walled products and complicated shapes.

To control warping defects, you need to optimize the cooling rate, optimize the mold design, and choose the right raw materials.

Optimize cooling rate

One of the main causes of warping defects is uneven cooling. By controlling the cooling rate evenly and avoiding too fast or too slow cooling, the warping phenomenon can be effectively reduced.

Optimize mold design

The mold design also has a big impact on warping defects. Reasonable mold cooling system design and runner design can reduce uneven cooling and prevent warping.

Selection of suitable raw materials

Different plastic materials shrink differently when they cool. Picking the right raw material can help you avoid warping problems, especially when you’re making thin-walled or complex-shaped products.

Warping is a common defect in plastic extrusion.True

Warping in plastic extrusion occurs when the material cools unevenly or experiences internal stresses, leading to dimensional distortions in the final product. This can affect the quality and functionality of the extruded items.

Warping in plastic extrusion can be completely avoided.False

While warping cannot always be entirely avoided, controlling cooling rates, extrusion speed, and material properties can significantly reduce the occurrence of warping. Adjusting these factors helps ensure more consistent dimensional stability.

What are Plastic Extrusion Thickness Unevenness defects and Solutions?

Tube and profile production often results in uneven product thickness. This problem can cause the product to have unstable mechanical properties and can even mess up future processing.

To solve the problem of uneven wall thickness, you can adjust the speed of the extruder, improve the design of the die, and make sure the raw material is mixed well.

Adjustment of haul-off speed

If you change the speed of the haul-off, it will change how thick the walls are on the product. By adjusting the speed of the puller on the extruder, you can control how evenly the material stretches and keep the extruded product from being thicker in some places than others.

Optimize mold design

Uneven wall thickness is often related to defects in mold design. By designing the runner and outlet shape of the die in a rational way, we can improve the distribution of wall thickness and ensure the uniformity of the product.

Raw material uniformity

The sameness of the raw material affects how thick the walls are. If you mix the raw materials well, you can avoid having the material not be evenly distributed when you squeeze it out, and that way you can avoid having walls that aren’t the same thickness.

Uneven thickness is a common issue in plastic extrusion.True

Uneven thickness in plastic extrusion occurs when the material does not flow uniformly through the die, leading to inconsistent product dimensions. This can be caused by factors such as die design, material viscosity, and temperature fluctuations.

Uneven thickness is not a significant problem in plastic extrusion.False

Uneven thickness is a significant issue in plastic extrusion that can affect the performance, appearance, and functionality of the final product. Proper control of extrusion parameters is necessary to minimize this problem.

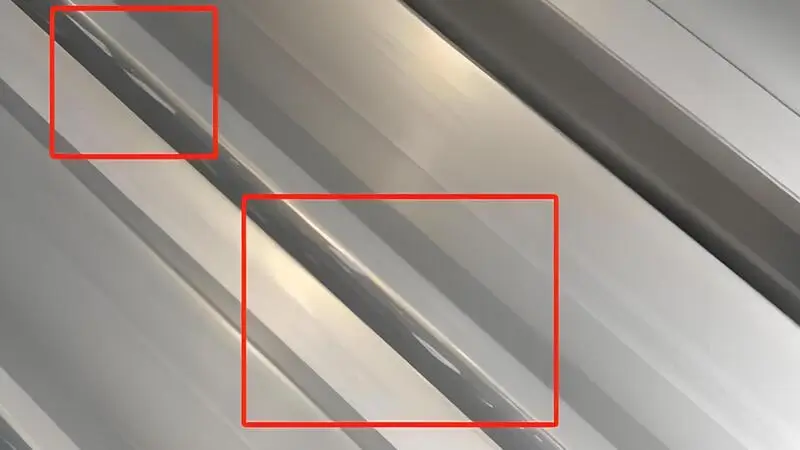

What are Plastic Extrusion Scratching defects and Solutions?

Scratches on the surface of a product not only make it look bad, but they can also mess up how it works.

To fix scratching, you can repair or replace the mold and roller, adjust the haul-off speed, and make sure the cooling system is working right.

Unsmooth, worn surfaces of molds or rollers

Check and clean the mold and roller surfaces regularly. If needed, fix or replace any worn parts.

Adjustment of haul-off speed

If you go too fast or don’t have the right touch, you can scratch the surface of the product. Make sure you have the right pressure and speed so the puller is in contact with the product.

Optimize cooling system

If the cooling water temperature is too high or too low, it can cause uneven cooling or scratches on the product surface. Make sure the cooling water system is running smoothly and keeps the right cooling temperature and flow rate.

Scratch resistance is an important property in plastic extrusion.True

Scratch resistance is a crucial characteristic for many plastic extrusions, especially in applications like automotive parts, consumer electronics, and packaging, where the durability of the surface is important to maintain aesthetics and functionality.

Scratch resistance is irrelevant for plastic extrusion.False

While not all plastic extrusions require scratch resistance, many applications benefit from materials that can withstand wear and tear, ensuring longevity and maintaining their appearance and performance over time.

What are plastic extrusion color difference defects and solutions?

Color difference defects not only affect the appearance of the product, but also affect the consumer's perception of the product and market acceptance.

To solve color difference, ensure consistent raw materials, optimize the extrusion process, and improve production environment control.

Ensure the consistency of raw materials

To avoid color difference, it is important to have consistent raw materials. Different batches of raw materials can have different colors and quality, which can cause color difference during extrusion. By strictly controlling the source of raw materials and the mixing process to ensure that the raw materials used are consistent in color, you can greatly reduce color difference defects.

Optimize the extrusion process

The color of your product can be affected by the temperature, pressure, and speed of the extrusion process. To avoid color problems caused by changes in the process, make sure the temperature and pressure stay the same while you’re making your product. Don’t run the extruder too fast or too slow. Calibrate your equipment and make sure your process is running right. That will help you make your product the same color every time.

Enhance production environment control

The color of plastic can be affected by factors like humidity and temperature in the production environment. Make sure to control the temperature and humidity in the workshop and regularly check the cleanliness of the equipment. You should also strictly control the dispersion and stability of the color masterbatches you use to reduce color differences.

Plastic extrusion can lead to color differences in the final product.True

Color differences in plastic extrusion can occur due to inconsistent material composition, temperature variations, or improper mixing of pigments, resulting in uneven coloration in the extruded product.

Plastic extrusion does not cause color differences.False

Color differences can indeed arise in plastic extrusion, often as a result of factors like material inconsistencies, temperature fluctuations, or inadequate mixing of additives or pigments.

What is plastic extrusion shrinkage defect and the solution?

Shrinkage is a common problem in extrusion, especially when making thin-walled profiles or complex shapes.

To fix shrinkage problems, you can control the temperature of the extruder, make sure the cooling system is set up right, and get the mold temperature under control.

Regulating Extrusion Temperature

The temperature of the extruder is important for how the material flows and shrinks. By controlling the temperature of the extruder, you can avoid melting the material too much or cooling it too fast. This will help keep the size and shape of the part from changing too much.

Optimize cooling system design

How fast and how you cool plastic directly affects how much it shrinks. By making sure the water that cools the plastic flows evenly and the pipes that carry the water are in the right places, you can make sure the plastic cools evenly and doesn’t shrink unevenly. That way, it won’t have any shrink marks.

Optimize mold temperature control system

The mold’s temperature control system is important for the extrusion process. By adjusting the mold’s heating and cooling temperature control parameters, it can ensure that the product maintains its shape during production and reduce shrinkage.

Plastic extrusion shrinkage is a common issue during the manufacturing process.True

Shrinkage occurs when the extruded material cools and contracts, which is a normal phenomenon in plastic extrusion. Factors like material type, extrusion speed, and cooling rates can influence the degree of shrinkage.

Plastic extrusion shrinkage can be completely eliminated.False

While shrinkage can be minimized through careful control of process parameters, it is not entirely avoidable due to the inherent properties of materials and their response to temperature changes during the extrusion process.

Conclusion

The plastic extrusion process has a lot of problems, like bubbles, pulling cracks, warping, uneven thickness, scratches, color difference, shrinkage, etc. We can improve the process from the raw materials, temperature, mold design and process, etc. Through systematic management and continuous optimization, we can effectively reduce the defects and improve the quality of products.