Plastic extrusion is a common industrial processing method used to produce a wide range of plastic products such as pipes, profiles, films, seals, and more. The cost of plastic extrusion processing encompasses a variety of aspects including raw materials, equipment investment, mold costs, labor costs, energy consumption, and more. The cost of each component may affect the final product pricing and production efficiency. In this article, we will explore the components of each cost in detail and help you better understand the cost of plastic extrusion processing through specific values.

Mold costs for plastic extrusion range from $1,000 to $10,000, depending on complexity. Product pricing is based on material, shape, and precision, typically calculated by weight for large items and by meter for smaller ones.

The cost of plastic extrusion depends on various factors such as material type, complexity of the design, and production volume.True

The cost varies because different materials and production requirements influence the overall expense.

Plastic extrusion cost is always fixed regardless of production conditions.False

The cost can fluctuate based on factors like material choice, tool wear, and production scale, which influence the overall price.

- 1. How much does the raw material for plastic extrusion cost?

- 2. How much does it cost to invest in plastic extrusion equipment?

- 3. How much does plastic extrusion labor cost?

- 4. How much does plastic extrusion energy consumption cost?

- 5. How much does extrusion processing and requirements cost?

- 6. How much does plastic extrusion production cost?

- 7. How much does plastic extrusion packaging and logistics cost?

- 8. Conclusion

How much does the raw material for plastic extrusion cost?

The choice of raw materials has a direct impact on production costs. If you need high-performance plastic products, the cost of the raw material will be higher. The amount of material purchased also has a significant impact on costs. By choosing the right raw materials and controlling the quantity purchased, you can reduce overall costs.

Raw material costs typically account for 50-70% of plastic extrusion costs. The cost of different types of plastic raw materials varies greatly, and the prices of commonly used plastics such as PVC, PE, ABS, PP, etc.

Common Plastic Raw Material Prices

PVC: $1,000 - $1,600 per ton

PE : $1,600 - $2,300 per ton

ABS: $3,000 - $4,000 per ton

PP : $1,600 - $2,000 per ton

Factors Affecting the Price of Raw Materials

Raw material prices are affected by supply and demand, oil prices, transportation costs and other factors. For example, the price of PVC may rise to over $1,900 per ton during peak demand periods, while the price can fall back to less than $1,000 when there is sufficient supply.

High Performance Materials

High-performance plastics (e.g., POM, PTFE, etc.) are usually more expensive, and may reach over $5,000 per ton for high-strength, high-temperature-resistant specialty products.

Impact of Purchasing Volume

Bulk purchases usually enjoy favorable pricing, and usually the larger the volume, the lower the unit price. For example, when purchasing 100 tons of PVC raw material, the price may be 10%-15% lower than a single purchase of 10 tons.

The cost of raw materials for plastic extrusion is relatively high.True

The cost of raw materials for plastic extrusion, such as high-quality resins and polymers, can be relatively high due to factors like production processes, material properties.

The cost of raw materials for plastic extrusion is low.False

High-quality and specialized materials used for plastic extrusion often come with higher costs due to their advanced properties and manufacturing processes.

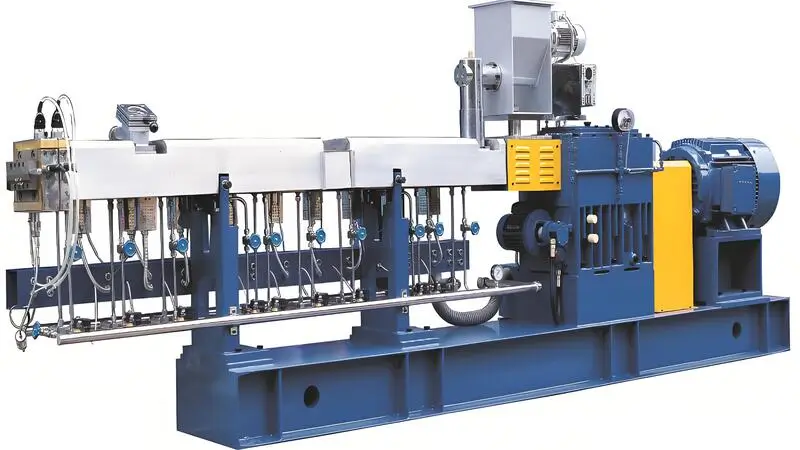

How much does it cost to invest in plastic extrusion equipment?

When you buy equipment, you don’t just pay for the equipment itself. You also have to pay for the long-term maintenance and depreciation of the equipment. Although the investment in equipment is large, once the equipment is running smoothly, it can effectively reduce the unit cost in the long run.

Equipment investment is a big upfront cost, but if you choose efficient equipment and arrange your production reasonably, you can reduce your production costs in the long run.

Extruder price

Extruders are generally priced based on their models and functions:

Small extruders: $10,000 to $30,000

Medium extruders: $40,000 to $80,000

Large extruders: $90,000 to $200,000

Mold Costs

The price of an extrusion mold can also vary depending on complexity and material selection. Extrusion molds usually cost between $1,000 and $10,000. Higher precision or complex shapes may cost more.

Equipment Depreciation

The depreciation period for an extruder is usually 5 to 10 years. Assuming you buy an extruder for $100,000, the depreciation expense would be around $10,000 to $20,000 per year, spread out over the life of the equipment.

Equipment Maintenance

Equipment maintenance costs are usually 5% to 10% of the cost of the equipment per year, so about $5,000 to $10,000 per year. Maintenance costs for larger lines can be higher.

Investing in plastic extrusion equipment is a high-cost endeavor.True

The cost to invest in plastic extrusion equipment can be significant, depending on the scale, complexity, and automation of the equipment.

Investing in plastic extrusion equipment is affordable for small businesses.False

Plastic extrusion equipment typically involves substantial upfront costs, which may be challenging for small businesses without sufficient capital.

How much does plastic extrusion labor cost?

The cost of labor is one of the important costs in plastic extrusion processing, especially in low automation lines. The cost of labor varies according to different production modes and regions.

Labor cost is influenced by production scale, worker skill requirements, and working hours. Automated production lines can significantly reduce labor costs.

Salary of operators

The salary of an ordinary operator is usually between $1,000 and $1,500 per month. In the case of a small production line, five operators may be needed, with a total wage of $60,000 to $90,000 per year.

Salary of technicians and managers

The salary of technicians is typically $1,500 to $2,400 per month, while the salary of managers is usually $2,000 to $3,000 per month. If a business has 10 technicians and managers, the annual payroll expense may be $180,000 to $360,000 per year.

Balancing automation and labor

The introduction of automated equipment can reduce labor costs. For example, labor costs can be reduced by about 30% to 50% by automating cutting and packaging equipment.

Training costs

The cost of employee training typically ranges from $1,000 to $4,000 per year, depending on the number of employees and the content of the training.

Labor costs in plastic extrusion are a significant factor in overall production expenses.True

Labor costs are an important aspect of plastic extrusion, as they contribute to machine setup, operation, and maintenance.

Labor costs in plastic extrusion are negligible.False

Skilled operators and technicians are essential for managing the extrusion process, ensuring product quality, all of which contribute significantly to production expenses.

How much does plastic extrusion energy consumption cost?

Plastic extrusion is a power-hungry process. It takes a lot of electricity, heat, and water to make plastic, and energy costs can account for 10-20% of the cost of making plastic. If you can use less energy, you can save money.

Energy costs are a big part of the cost of making plastic, and if you use energy-efficient equipment and optimize your process, you can use less energy and save money.

Electricity

Extruders use a lot of electricity. It can cost $400 to $1,000 a month to run one extruder. Big extruders can cost more than $10,000 a month.

Heat energy

Heating and cooling systems use 30-40% of the energy in a plant. It can cost $10,000 to $40,000 a year to heat and cool a plant, depending on how much you run it and how efficient your equipment is.

Saving Energy

You can use less energy by using energy-efficient equipment and optimizing your process. It might cost 10-20% more to buy energy-efficient equipment, but it can save you 30-40% on your energy bill in the long run.

Energy Prices

Energy prices go up and down. If electricity or natural gas prices go up, your energy costs could go up 10-20%.

Plastic extrusion has high energy consumption and cost.True

Plastic extrusion processes typically require significant energy due to the need for heating, cooling, and high pressure to shape the material.

Plastic extrusion has low energy consumption and cost.False

While plastic extrusion can be optimized for efficiency, the process still generally involves substantial energy use.

How much does extrusion processing and requirements cost?

Plastic extrusion costs vary based on product complexity and performance requirements. Higher precision, special needs, and additional process steps increase technical demands, leading to higher production costs.

The complexity of the process directly affects the cost of plastic extrusion. Customized products that require a high level of technical expertise will generally cost more.

Difficulty of the process affects the cost

Complex extrusion processes, such as multi-layer co-extrusion or high-precision molding, typically increase the cost of production by about 20-30%.

Special requirements and costs

Plastic products that require special colors, UV resistance, high temperature resistance, etc. will increase the cost of production by about 30%-50%.

Automated processes

By implementing an automated control system, you can reduce the amount of manual intervention, increase production efficiency, reduce losses due to improper operation, and therefore reduce costs.

Quality control

Quality control costs account for about 5-10% of the total production cost. High-quality products require strict testing and management, which increases costs.

Plastic extrusion technology requires constant investment in maintenance and upgrades.True

Plastic extrusion technology demands ongoing investment in maintenance and periodic upgrades to keep machines operating efficiently and meet evolving product standards.

Plastic extrusion technology requires minimal maintenance and upgrades.False

Plastic extrusion technology involves regular maintenance and occasional upgrades to ensure optimal performance and adapt to new material requirements or production needs.

How much does plastic extrusion production cost?

Mass production reduces the unit price by diluting fixed costs, while small batch production is suitable for flexible response to market demand, but has a higher unit cost.

Mass production helps to reduce the cost per unit of product. Small batch production usually leads to higher unit costs.

Advantages of mass production

Mass production usually leads to more efficient raw material procurement and equipment use, reducing unit costs by about 20%-40%.

Challenges of small batch production

Small batch production can be 50-100% more expensive per unit of product than batch production due to longer line adjustments and equipment downtime.

Optimization of production planning

Proper production planning can balance the demands of mass production and small lot production, reducing waste and lowering costs.

Supply Chain Management

Optimized supply chain management, through centralized purchasing and efficient logistics, can reduce costs in small batch production, reducing purchasing costs by about 10-15%.

Plastic extrusion production cost is high due to expensive materials and equipment.True

Plastic extrusion production costs can be high because of the cost of raw materials, energy consumption, and the need for specialized machinery to ensure high-quality output.

Plastic extrusion production cost is low due to the simplicity of the process.False

While the extrusion process is relatively straightforward, the cost of materials, equipment maintenance, and energy consumption can still contribute to a higher overall production cost.

How much does plastic extrusion packaging and logistics cost?

Packaging and shipping costs are a big part of the cost of plastic extrusion and they directly affect the final cost of the product to the customer. Proper packaging design and logistics can reduce unnecessary expenses.

Even though packaging and shipping costs are small, optimizing packaging and shipping methods can still be effective in reducing total costs.

Packaging Material Costs

The cost of packaging materials varies depending on the size, weight, and protection needs of the product and typically ranges from $100 to $500 per ton.

Shipping Costs

Shipping costs are affected by weight and distance and typically range from $100 to $400 per ton, with higher costs for long-distance or international shipments.

Optimizing Packaging and Shipping

Simple packaging and optimizing shipping routes can save about 10-30% of shipping costs.

Plastic extrusion packaging and logistics cost is low.True

The lightweight and durable nature of extruded materials can help reduce transportation costs, while streamlined manufacturing processes can also lower overall expenses.

Plastic extrusion packaging and logistics cost is high.False

The cost of plastic extrusion packaging and logistics depends on factors like production volume, transportation distance, and packaging materials.

Conclusion

The cost of plastic extrusion processing is mainly raw materials, equipment, molds, labor, energy, packaging and transportation. Customers can know how to quote the cost of plastic extrusion by understanding the composition of the cost. Manufacturers can help improve production efficiency and save costs by choosing raw materials wisely, optimizing equipment utilization, optimizing mold design, improving labor efficiency, saving energy, and optimizing packaging and transportation links