Plastic extrusion and injection molding are two common manufacturing processes used in plastics processing. They use different technologies and equipment in their production processes, so there are significant differences in their applications and cost efficiencies. This article compares the two processes to help you better understand their differences and application scenarios.

Plastic extrusion is ideal for continuous products, while injection molding suits complex parts. Understanding these processes helps companies balance efficiency and cost in production, making informed choices for optimal results.

Plastic extrusion and injection molding are both widely used manufacturing processes for plastic products.True

Plastic extrusion and injection molding are two of the most common plastic processing methods. Extrusion is typically used for creating continuous profiles, while injection molding is used to create complex shapes and components. Both processes offer high efficiency and versatility in producing a wide range of plastic products.

Plastic extrusion and injection molding are interchangeable processes.False

Although both processes are used in plastic manufacturing, extrusion and injection molding serve different purposes. Extrusion is ideal for producing long, continuous shapes, while injection molding is better suited for creating intricate and detailed parts with complex geometries.

- 1. What is the difference between plastic extrusion and injection molding processes?

- 2. What is the difference between plastic extrusion and injection molding efficiency and cost?

- 3. What is the difference between plastic extrusion and injection molding molds?

- 4. What is the difference between plastic extrusion and injection molding applications?

- 5. What are the advantages and disadvantages of plastic extrusion and injection molding?

- 6. Conclusion

What is the difference between plastic extrusion and injection molding processes?

When it comes to plastics processing, the molding process is a big deal. It’s what decides how your product is going to look and work. There are two main ways to mold plastic: extrusion and injection molding. Each one has a different way of molding, which changes how your final product is going to look and work.

Extrusion molding: You melt plastic and push it through a mold to make a long, continuous product.

Injection molding: You melt plastic and shoot it into a closed mold. Then you cool it down and take it out. This makes complicated parts.

Working Principle of Extrusion Molding

Extrusion molding heats and melts plastic through a screw. The screw squeezes the molten plastic into the mouth of a mold. Depending on the shape of the mold, the plastic flows out and cures into the desired product.

Working Principle of Injection Molding

Injection molding is the process of injecting molten plastic into a mold cavity using an injection molding machine. Once the plastic has cooled and solidified, it is ejected from the mold and takes on the desired shape.

Differences between the two processes

Extrusion molding is good for making things that can be as long as you want them to be. Injection molding is good for making things that have a lot of sh s and need to be the right size.

Extrusion molding and injection molding differ in the process and application.True

Extrusion molding is used for creating long, continuous profiles like pipes and sheets, whereas injection molding is ideal for producing intricate, high-volume parts with detailed designs.

Extrusion molding and injection molding are the same process.False

Extrusion molding involves continuously forcing material through a die to create long shapes, while injection molding involves injecting material into a mold to create specific, often complex shapes.

What is the difference between plastic extrusion and injection molding efficiency and cost?

When you’re making stuff, how fast and how cheap you can make it directly affects how much money you make. Understanding how fast and how cheap different processes are will help you pick the best way to make your stuff.

Extrusion: Good for making a lot of stuff, cheap per piece, good for making a lot of stuff for a long time.

Injection molding: Expensive to make the molds and the machines, but good for making a few things that are really complicated and have to be perfect.

Production efficiency of extrusion molding

Extrusion molding is great for making a lot of stuff because it’s easy and you can make a lot of it really fast.

Production efficiency of injection molding

Although injection molding takes longer to prepare the mold at first, it makes each product more precise and is suitable for making complex parts.

Cost Comparison

Extrusion molding is cheaper at the beginning, but it’s good for making a lot of stuff. Injection molding is expensive at the beginning, but it’s good for making a few things that are really complicated.

Extrusion molding is generally more cost-effective than injection molding.True

Extrusion molding typically involves lower tooling costs and faster production times for continuous products, making it more cost-effective for high-volume, long-length manufacturing.

Injection molding is more cost-effective than extrusion molding.False

Injection molding tends to have higher initial tooling costs, but it is more suitable for producing complex shapes and high-precision parts, which can justify the higher cost in certain applications.

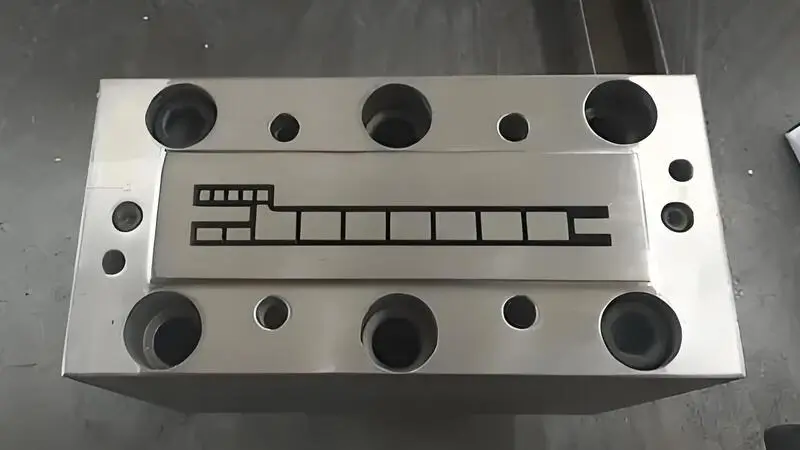

What is the difference between plastic extrusion and injection molding molds?

When choosing a molding process, you have to consider how much it costs to make the mold and how complicated it is. The kind of mold you use also depends on whether you’re extruding or injecting the plastic.

Extrusion: You can use a simpler mold and make a lot of parts quickly.

Injection: You need a more expensive mold, but you can make more complicated parts with it.

Extrusion Molding Mold Characteristics

Extrusion molding molds are generally simpler and flexible in design, allowing for the rapid production of a variety of profiles and suitable for mass production.

Injection Molding Mold Characteristics

Injection molding molds are usually more complex, have longer production cycles, and are more expensive, but are capable of producing very precise and complex parts.

Mold Life and Maintenance

Extrusion molds last longer and are easier to maintain, while injection molds last longer and cost more to maintain because they have to be more precise.

Mold life and maintenance requirements are generally longer for extrusion molds compared to injection molds.True

Extrusion molds tend to have a longer mold life and require less frequent maintenance due to the continuous nature of the extrusion process, which often leads to less wear and tear compared to the cyclical nature of injection molding.

Mold life and maintenance requirements are the same for extrusion molds and injection molds.False

Mold life and maintenance differ between extrusion and injection molds. Injection molds usually experience more stress due to the high-pressure injection of material, leading to more frequent maintenance and potentially shorter mold life compared to extrusion molds, which experience a more uniform stress distribution during continuous operation.

What is the difference between plastic extrusion and injection molding applications?

Different molding processes are good for different things. Knowing what they’re good for will help you pick the right one.

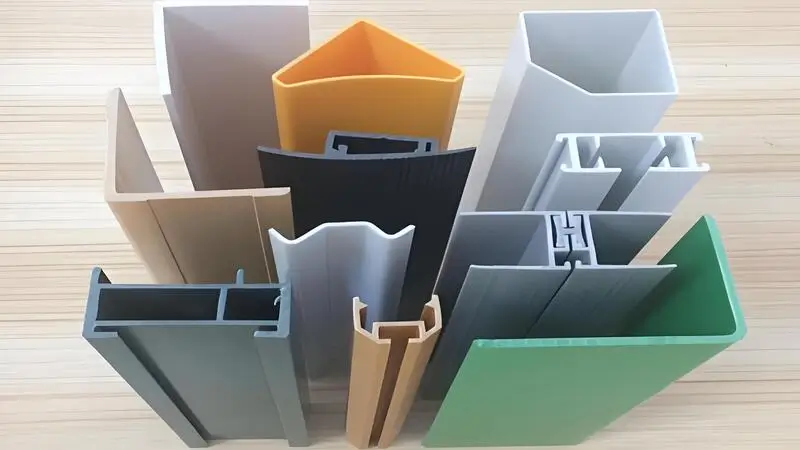

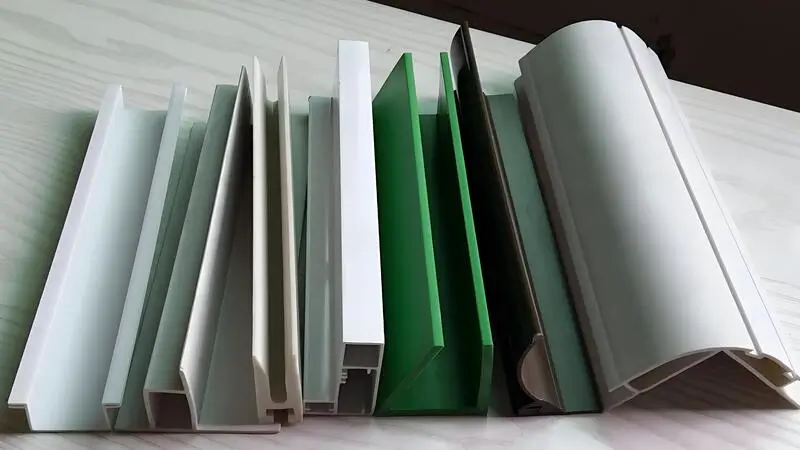

Extrusion molding: Makes long things like pipes, profiles, rods, and films.

Injection molding: Makes all kinds of complicated parts.

Common applications of Extrusion Molding

Extrusion molding is used a lot for making long things like pipes, profiles, films,tubes and sheets.

Common Applications of Injection Molding

Injection molding is a popular method for making precise plastic parts, like electronic product cases and car parts.

Industry Suitability

Extrusion molding is widely used in construction, packaging, automotive, electronics, agriculture, and other industries. It is especially good for making long products like pipes, profiles, rods, window frames, and plastic films.

Injection molding is mainly used in automotive, home appliances, consumer electronics, medical devices, toys, and other industries. It is good for making complex small parts and housings.

Plastic extrusion and injection molding are both used for creating plastic products, but they serve different applications.True

Plastic extrusion is typically used for continuous shapes like pipes, sheets, and profiles, whereas injection molding is ideal for creating complex, detailed parts with precise dimensions, such as consumer products and automotive components.

Plastic extrusion and injection molding are interchangeable processes for all applications.False

Plastic extrusion and injection molding have distinct advantages. Extrusion is better suited for continuous shapes and large volumes, while injection molding is preferred for high-precision, complex parts that require detailed molding.

What are the advantages and disadvantages of plastic extrusion and injection molding?

Knowing the pros and cons of each process can help us make better choices when we have different production needs.

Extrusion molding: It’s efficient, cheap, and good for making lots of stuff, but you can’t make anything too complicated.

Injection molding: It’s good for making complicated, precise parts, but it’s more expensive to buy the machines and molds, and it takes longer to make stuff.

Advantages of extrusion molding

Extrusion molding is good for making a lot of stuff, it’s cheap to make each thing, and you can make a lot of things before the mold wears out.

Advantages of Injection Molding

Injection molding can produce high-precision parts with complex shapes and is suitable for small-lot, high-precision requirements.

Plastic extrusion is more cost-effective and suitable for producing continuous profiles, while injection molding offers high precision and complex shapes.True

Plastic extrusion is ideal for producing long, continuous shapes like pipes, profiles, and sheets, and is generally more cost-effective for high-volume production. Injection molding, on the other hand, is perfect for creating detailed, complex, and high-precision parts, making it ideal for intricate designs and tight tolerances.

Plastic extrusion is not suitable for creating highly detailed or complex shapes, while injection molding can produce such parts.False

While plastic extrusion excels at producing long, simple shapes, injection molding is specifically designed for high-precision, complex, and detailed parts, making it ideal for intricate designs that extrusion cannot achieve.

Conclusion

When comparing the molding process, efficiency and cost, mold design, application areas, as well as advantages and disadvantages of plastic extrusion molding and injection molding, we can see that each of them has its own specific advantages and application scenarios. Enterprises need to consider the complexity of the product, production scale, cost-effectiveness and other factors when choosing production methods. For high-volume, simple shaped products, extrusion molding is the ideal choice; while for products that require high precision and complex shapes, injection molding is more advantageous.