Extrusion technology plays a key role in creating everyday plastic products, from household items to car parts and medical devices. Plastic extruders heat, melt, and shape plastic materials by pushing them through a screw drive and die. This article covers how extruders work, their industrial uses, and tips for improving their longevity and performance through proper maintenance.

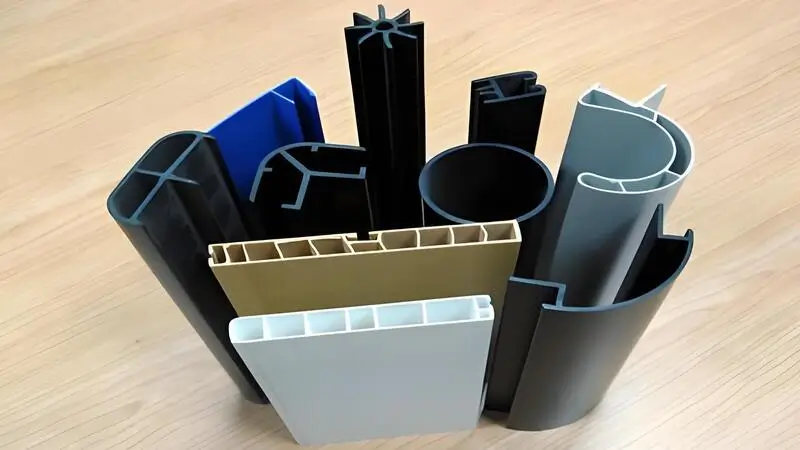

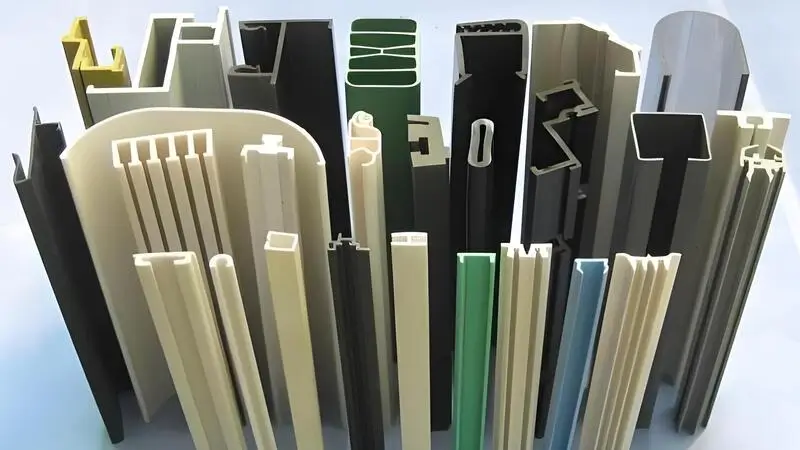

Plastic extruders are the main machines in modern plastics processing, and they’re used to make pipes, profiles, films, sheets, and other products.

Plastic extruders are primarily used to create continuous shapes like pipes, profiles, and sheets from thermoplastics.True

Plastic extruders are designed to form continuous products by pushing molten plastic through a shaped die.

Plastic extruders are only capable of processing a single type of polymer.False

Modern plastic extruders can handle a variety of polymers, including blends, depending on the machine and process setup.

- 1. What is the working principle of plastic extruder?

- 2. What are the components of a plastic extruder?

- 3. What are auxiliary equipment for plastic extruders?

- 4. What is the classification of plastic extruders?

- 5. What are the operating points of a plastic extruder?

- 6. What is the maintenance of plastic extruder?

- 7. Conclusion

What is the working principle of plastic extruder?

Plastic extruder, as an efficient plastic processing equipment, extrudes the plastic melt by heating and plasticizing the plastic material and pushing it through the screw, and finally gets continuous profiles or sheets through the mold. Next, we will specifically analyze the working principle of the extruder.

Plastic extruders heat and plasticize granules, converting them into a uniform melt. This melt is then shaped into the desired product through a die, relying on both heat and mechanical energy for the process.

Heating and Melting

In the extruder, the plastic pellets first enter the heating zone, where the heat generated by the electric heating device and friction heats the plastic to the melting temperature. During this process, the solid plastic particles gradually turn into a liquid, ensuring a smooth molding process.

Extrusion and Conveying

The heated liquid plastic is pushed into the mold by axial pressure through the rotation of the screw. In this process, the screw's speed and pressure control are very important, directly determining the quality and precision of the finished extruded product.

Cooling and Setting

After the liquid plastic passes through the mold, it needs to be quickly cooled to a solid state by a cooling device. The speed and method of cooling affects the shape and size of the product as well as the surface smoothness.

The working principle of a plastic extruder involves melting plastic and shaping it into a continuous profile.True

A plastic extruder works by feeding solid plastic pellets into a heated barrel, where they are melted and then forced through a die to form a continuous shape.

The working principle of a plastic extruder involves injection molding.False

The working principle of a plastic extruder is different from injection molding. While both processes involve melting plastic, an extruder creates continuous profiles.

What are the components of a plastic extruder?

To understand how an extruder works and what each part does, we need to understand the components of an extruder. In this section, we will take a closer look at the components of a plastic extruder and what they do.

A plastic extruder consists of the barrel, screw, heating system, and mold, each vital to the extrusion process. Proper configuration and maintenance of these components are essential for optimal production results.

Barrel

The barrel is the outer shell of the entire extruder and is responsible for housing the heating unit and screw. The interior of the barrel usually consists of multiple heating zones, each with a separate temperature control system to ensure that the temperature of the molten plastic is precisely controlled.

Screw

The screw is the core component of a plastic extruder and rotates to create thrust that propels the plastic melt forward. The screw usually consists of different segments, including a feed section, a compression section, and a metering section, each with a different function.

Heating System

The heating system heats the barrel of the machine to the proper temperature by means of an electric heater, hot air or oil circulation system to ensure the smooth plasticization of the plastic. The temperature uniformity of the heating system directly affects the melting effect of the plastic.

Mold

Molds determine the shape and size of the final product and are usually customized to meet the needs of production. Molds are designed not only to ensure molding accuracy but also to take into account cooling and venting functions.

The components of a plastic extruder include a hopper, barrel, screw, mold, and motor.True

A plastic extruder typically consists of several key components: a hopper , a barrel , a screw , a mold that shapes the material , and a motor that powers the screw.

The components of a plastic extruder are limited to just the barrel and screw.False

While the barrel and screw are essential, a complete plastic extruder also includes a hopper, die, motor, and often additional components like temperature controllers and cooling systems.

What are auxiliary equipment for plastic extruders?

Auxiliary equipment is very important in the production of plastic extrusion. They not only improve productivity, but also ensure product precision and quality. Next, we will discuss the common auxiliary equipment and their roles.

Plastic extruder's auxiliary equipment, including cooling system, metering device, extrusion tractor, and cutting machine, work with the main machine to ensure consistent product quality and high production efficiency.

Cooling System

The cooling system is used to quickly cool the plastic products after molding to ensure the stability and dimensional accuracy of the products. The cooling methods are usually water cooling or air cooling, etc., depending on the needs of different products.

Metering Device

The metering device is used to accurately control the amount of plastic raw materials to ensure the uniformity and consistency of the raw materials in each production. The metering device is usually used in conjunction with the screw speed, and the high precision can improve the consistency of the product.

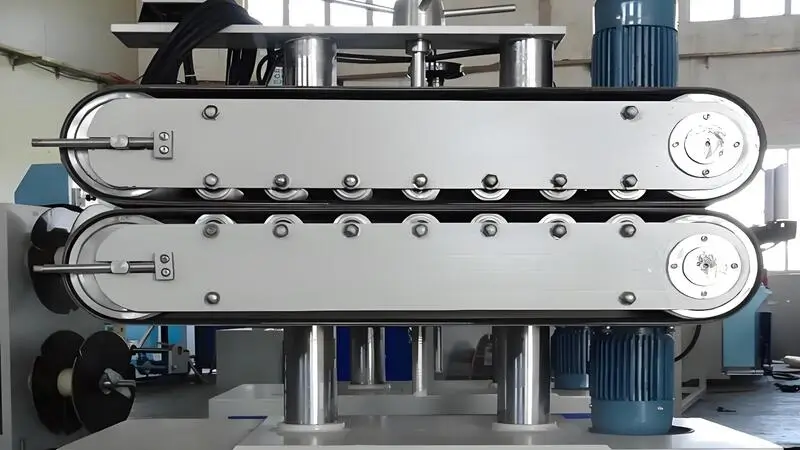

Extrusion tractor

The extrusion tractor is used to grab and pull the extruded product from the mold, ensuring that the product is stretched and shaped. The speed of the extrusion tractor must match the production speed of the extruder in order to avoid stretching or distortion of the product.

Cutting Machine

The cutting machine plays an important role in the extrusion process and is responsible for cutting the continuous profile into products of a certain length as required. There are two types of cutting methods, hot cutting and cold cutting, and the choice depends on the material being produced and the shape of the product.

Auxiliary equipment is essential for plastic extruders to optimize production.True

Auxiliary equipment such as dryers, feeders, chillers, and cutters are critical for maintaining the efficiency and quality of the extrusion process.

Auxiliary equipment is unnecessary for plastic extruders.False

While some basic extruders may function without certain accessories, auxiliary equipment is often required to ensure consistent material flow, temperature control.

What is the classification of plastic extruders?

There are different types of plastic extruders for different production needs. Understanding the characteristics and application areas of each type of extruder will help you choose the right equipment. In this section, we will introduce several common types of extruders.

Plastic extruders can be divided into single-screw extruders, twin-screw extruders, planetary extruders, etc. according to different designs, functions and applications.

Single Screw Extruder

Single-screw extruders are the most common type and are suitable for processing most plastics, especially for common materials such as polyethylene and polypropylene. It has a simple structure and high production efficiency, but is less adaptable to high viscosity and complex materials.

Twin Screw Extruder

Twin-screw extruder pushes the plastic through the interaction of two screws and is suitable for mixing, batching and other demanding production processes. Twin-screw extruders are better able to handle high-viscosity materials and are more stable in the production process.

Planetary Extruder

Planetary extruders use multiple screws rotating in coaxial rotation to provide more uniform mixing and are suitable for complex polymer processing. These extruders have advantages in producing high quality, specialized plastic products.

Plastic extruders are classified based on the type of materials they process.True

Plastic extruders are categorized by the type of materials they handle, such as thermoplastics, thermosets, and elastomers.

Plastic extruders cannot be classified based on material types.False

Plastic extruders are indeed classified based on the material types they process.

What are the operating points of a plastic extruder?

Even though plastic extruders are highly automated, the operator’s experience and skill can have a big impact on production results. Mastering key operating points will ensure efficient operation and minimize breakdowns.

When operating a plastic extruder, focus on raw material selection, equipment setup, temperature control, and proper techniques to enhance efficiency and reduce defects.

Selection and handling of raw materials

Using suitable plastic raw materials is the basis for ensuring the extrusion effect. Operators should select suitable plastics according to production requirements and ensure the dryness and uniformity of raw materials to avoid problems during extrusion.

Temperature and pressure control

Temperature and pressure control are particularly important during the extrusion process. The operator needs to monitor and adjust the temperature of each section of the barrel, as well as the screw speed and pressure in real time to ensure uniform flow and plasticization of the plastic.

Operation flow and equipment commissioning

Before starting up the machine, it is necessary to carry out debugging of each section. Confirm whether the screw speed, temperature setting, cooling system, etc. are working properly to ensure that the equipment operates in the best condition.

Operating points of a plastic extruder significantly affect product quality.True

Operating points such as temperature, pressure, and screw speed in a plastic extruder directly influence the material flow, melt quality, and the final properties of the extruded product.

Operating points of a plastic extruder are irrelevant to product quality.False

The operating points of a plastic extruder, including temperature, pressure, and screw speed, are critical factors that impact the efficiency of the extrusion process and the overall quality of the final product.

What is the maintenance of plastic extruder?

To make sure that the plastic extruder can operate stably for a long time, regular maintenance is very necessary. Proper maintenance measures can effectively prevent equipment failure and improve productivity.

Regular maintenance can extend the service life of the plastic extruder and reduce the occurrence of failures. Common maintenance items include cleaning, lubrication, checking screws and molds, etc.

Regular Cleaning

Regularly clean the barrel, screw and die of the extruder to prevent the accumulation of plastic residues that can affect product quality. Avoid using highly corrosive cleaning agents during cleaning to avoid damaging the equipment.

Lubrication and Inspection

Mechanical parts such as screws and gears need to be lubricated regularly to minimize wear and prolong equipment life. In addition, the sealing of the equipment needs to be checked to ensure that there is no leakage.

Inspection of electrical and control systems

Regularly check the stability of electrical equipment, temperature control systems and transmission systems to detect potential failures and avoid production interruptions.

Maintenance of a plastic extruder is crucial for optimal performance.True

Regular maintenance of plastic extruders ensures that they operate efficiently, prevents breakdowns, and extends the life of the equipment by addressing wear and tear, lubrication, and alignment issues.

Maintenance of a plastic extruder is unnecessary.False

Neglecting the maintenance of a plastic extruder can lead to equipment failure, reduced product quality, and increased downtime, which can be costly and inefficient for production.

Conclusion

Plastic extruders are important machines used in plastic processing. They are used in many industries to make a wide range of plastic products. By understanding how they work and how to take care of them, you can make better products and get more out of your machine.