Plastic vacuum forming, a subset of termoformowanie1, is a manufacturing process where a heated plastic sheet is molded into precise shapes using vacuum pressure. This technique is prized for its cost-effectiveness and versatility, making it a cornerstone in industries like packaging, automotive, medical, and consumer goods. In Argentina, the vacuum forming sector is experiencing growth, fueled by rising demand for custom plastic components2. Although pinpointing the definitive "top 5" factories is challenging due to limited public data, several key players and industry trends highlight the capabilities within the country.

Argentina's formowanie próżniowe3 industry thrives on advanced factories delivering tailored solutions for packaging, automotive, and medical applications, utilizing cutting-edge machinery and a broad range of materials.

This blog post dives into the vacuum forming landscape in Argentina, spotlighting notable companies and the qualities that define top-tier factories.

Vacuum forming is limited to small-scale production.Fałsz

Vacuum forming supports both small and large-scale production, with advanced factories capable of handling high volumes and large parts.

Argentina lacks a significant vacuum forming industry.Fałsz

Market reports suggest a growing thermoforming plastic sector in Argentina, indicating a robust presence of capable factories.

- 1. Jakie materiały są powszechnie stosowane w formowaniu próżniowym?

- 2. Jakie są etapy procesu formowania próżniowego?

- 3. What are the Key Factors in Selecting a Top Vacuum Forming Factory?

- 4. What are the Applications of Vacuum Forming in Argentina?

- 5. Who are the Top 5 Vacuum Forming Factories in Argentina?

- 6. Wnioski

Jakie materiały są powszechnie stosowane w formowaniu próżniowym?

The choice of material in vacuum forming is critical, as it dictates the final product's properties and suitability for specific applications.

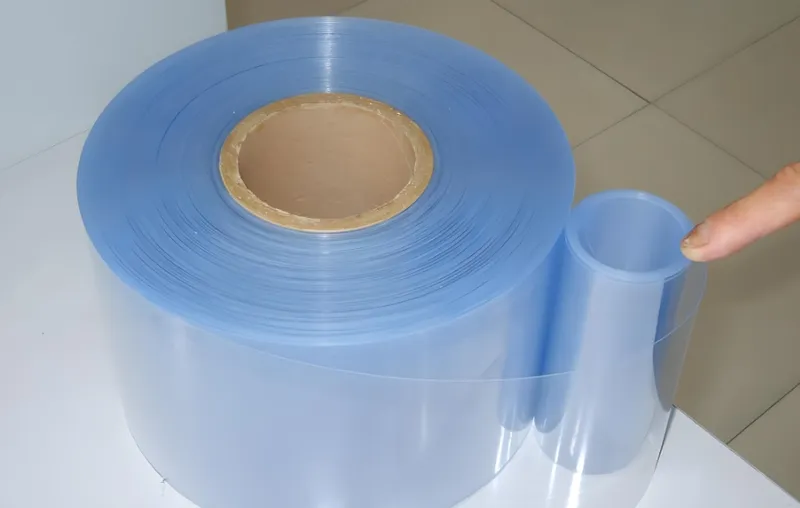

Wspólny vacuum forming materials4 include ABS, polystyrene, polycarbonate, PVC, and PETG, prized for their strength, clarity, and formability across diverse industries.

| Materiał | Kluczowe właściwości | Typowe zastosowania |

|---|---|---|

| ABS | Impact-resistant, easy to form | Części samochodowe, obudowy |

| Polistyren | Low cost, lightweight | Opakowania, tacki jednorazowe |

| Poliwęglan | High strength, heat-resistant | Electronics, automotive components |

| PVC | Cost-effective, good clarity | Blister packs, signage |

| PETG | Klarowność, wytrzymałość | Tacki medyczne, opakowania do żywności |

Akrylonitryl-butadien-styren (ABS)

ABS stands out for its durability and ease of forming, making it a go-to for automotive components like dashboards and consumer goods enclosures.

Polistyren (PS)

Polystyrene’s affordability and lightweight nature make it ideal for disposable packaging, such as food containers and trays.

Poliwęglan (PC)

With its superior strength and heat resistance, polycarbonate is perfect for demanding applications like electronic housings and automotive parts.

Polichlorek winylu (PVC)

PVC’s clarity and low cost make it a staple in blister packaging and signage, offering versatility at an economical price point.

Glikol politereftalanu etylenu (PETG)

PETG excels in medical and food applications due to its clarity, toughness, and chemical resistance, ensuring safety and visibility.

PVC is the most versatile material for vacuum forming.Fałsz

While PVC is widely used, materials like ABS and PETG offer greater versatility depending on strength, clarity, or industry-specific needs.

Material selection impacts vacuum forming quality.Prawda

The right material ensures optimal forming, durability, and functionality for the intended application.

Jakie są etapy procesu formowania próżniowego?

Vacuum forming is a streamlined process that transforms plastic sheets into functional products with precision and efficiency.

The vacuum forming process heats a plastic sheet, shapes it over a mold with vacuum pressure, cools it, and trims it into a finished product.

Projektowanie i tworzenie form

It starts with designing the part and crafting a mold—often from aluminum or resin—whose precision shapes the final product.

Wybór materiału

Selecting the appropriate arkusz termoplastyczny5 (0.5mm to 6mm thick) considers factors like color, thickness, and material properties.

Ogrzewanie

The sheet is heated to its pliable state (e.g., 120-180°C for ABS), ensuring even temperature distribution for consistent forming.

Formowanie

A vacuum pulls the heated sheet onto the mold, creating the desired shape with tight conformity to the mold’s contours.

Chłodzenie

Cooling with air or water solidifies the shape, preventing distortion and maintaining dimensional accuracy.

Przycinanie i wykańczanie

Excess material is trimmed—often with Maszyny CNC6—and finishing touches like painting or assembly complete the product.

Vacuum forming requires expensive molds.Fałsz

Molds can be made from cost-effective materials like wood or resin for prototyping, though aluminum is used for high-volume runs.

Cooling is a critical step in vacuum forming.Prawda

Proper cooling prevents warping and ensures the part retains its intended shape and strength.

What are the Key Factors in Selecting a Top Vacuum Forming Factory?

Identifying a top factory hinges on evaluating specific attributes that guarantee quality and capability.

Top vacuum forming factories excel with advanced machinery7, material versatility, design expertise, quality certifications8, and broad industry experience9.

Advanced Machinery

Leading factories use machines that handle large sheets (up to 1500x2000mm) and thick materials (up to 8mm), enabling complex, large-scale production.

Kompatybilność materiałowa

The ability to process a wide array of thermoplastics—ABS, polystyrene, PVC, etc.—meets diverse industry demands.

Design and Prototyping

In-house design and prototyping ensure products are refined before production, enhancing quality and fit.

Quality Certifications

Certifications like ISO 9001 signal adherence to rigorous quality standards, vital for industries like medical and automotive.

Industry Experience

Experience across sectors like packaging, automotive, and medical equips factories to tackle varied, complex projects.

Advanced machinery defines a top vacuum forming factory.Prawda

State-of-the-art equipment enables larger parts, precision, and higher output, distinguishing elite factories.

All factories offer the same level of design support.Fałsz

Top factories provide in-house design and prototyping, setting them apart from basic service providers.

What are the Applications of Vacuum Forming in Argentina?

In Argentina, vacuum forming serves a range of industries, showcasing its adaptability and economic benefits.

Vacuum forming in Argentina supports opakowanie10, motoryzacja11, medical, and consumer goods with lightweight, durable, custom plastic parts.

Opakowanie

Blister packs, clamshells, and trays protect and display products, leveraging materials like PVC and PETG.

Motoryzacja

Interior trim, dashboards, and panels benefit from vacuum forming’s ability to produce large, sturdy components.

Medyczny

Device housings and trays, often made from PETG, meet stringent safety and clarity requirements.

Towary konsumpcyjne

Enclosures for electronics and signage highlight vacuum forming’s design flexibility and affordability.

Vacuum forming is more cost-effective than injection molding for small runs.Prawda

Lower tooling costs make vacuum forming ideal for prototyping and limited production.

Vacuum forming lacks precision for medical applications.Fałsz

With advanced molds and machinery, it achieves the accuracy needed for medical components.

Who are the Top 5 Vacuum Forming Factories in Argentina?

While specific rankings are elusive due to limited data, several companies and trends point to Argentina’s leading vacuum forming factories.

Argentina’s top vacuum forming factories likely include key players like ITA and I.T.F.A., alongside those tied to advanced machinery suppliers11.

-

Industrias Termoplásticas Argentinas S.A. (ITA)

Known for its thermoplastic expertise, ITA likely offers vacuum forming, given its thermoforming focus and industry presence.

-

Industria de Termoformado Argentina (I.T.F.A.)

Specializing in thermoforming, I.T.F.A. is a prominent player, potentially excelling in vacuum forming applications.

-

Factories Linked to Lakatos

Lakatos, a Brazilian manufacturer with a commercial footprint in Argentina, may supply or partner with top local factories.

-

Factories Using WM Thermoforming Machines

Represented by Sixmar Representaciones S.R.L., factories employing WM’s advanced machines are likely leaders in capability.

-

Other Industry Leaders

Additional top factories are those investing in cutting-edge technology, large-scale production, and certifications like ISO 9001.

These factories stand out for their advanced equipment, material versatility, and market adaptability, aligning with Argentina’s growing thermoforming sector.

ITA and I.T.F.A. are definitively the top two factories in Argentina.Fałsz

While prominent, their exact ranking is unconfirmed due to limited data; they are key players among others.

Access to advanced machinery elevates a factory’s status.Prawda

Equipment from suppliers like WM and Lakatos enhances production quality and capacity, a hallmark of top factories.

Wnioski

Argentina’s vacuum forming industry12 is on an upward trajectory, driven by factories that combine advanced technology, material expertise, and industry versatility. Companies like Industrias Termoplásticas Argentinas S.A.13 (ITA) and Industria de Termoformado Argentina (I.T.F.A.14), along with those leveraging machinery from Lakatos and WM Thermoforming Machines, exemplify the sector’s potential. Top factories distinguish themselves with large-scale capabilities, quality certifications, and service across packaging, automotive, and medical fields. For businesses seeking vacuum forming partners in Argentina, these traits—paired with local industry resources—point to the cream of the crop.

-

This resource will clarify the distinctions between vacuum forming and thermoforming, helping you grasp their unique advantages in manufacturing. ↩

-

Discover how custom plastic components are produced and their significance across different sectors, enriching your understanding of their market demand. ↩

-

Zapoznaj się z tym linkiem, aby zrozumieć proces formowania próżniowego i jego zastosowania w różnych branżach, poszerzając swoją wiedzę na temat technik produkcji. ↩

-

Explore this link to understand the various materials used in vacuum forming and their specific applications, enhancing your knowledge in manufacturing. ↩

-

Learn about various thermoplastic sheets and their properties to make informed choices for your projects. ↩

-

Discover how CNC machines enhance precision in trimming and finishing vacuum formed products, ensuring high-quality results. ↩

-

Explore how advanced machinery enhances production efficiency and quality in vacuum forming, crucial for industry success. ↩

-

Understanding the role of quality certifications can help ensure product reliability and compliance in various industries. ↩

-

Discover innovative packaging solutions that utilize vacuum forming for better product protection and display. ↩

-

Learn how vacuum forming contributes to the production of lightweight and durable automotive components, improving vehicle performance. ↩

-

Learn about the key suppliers of advanced machinery that support the vacuum forming industry in Argentina. ↩ ↩

-

Explore this link to gain insights into the growth and innovations shaping Argentina's vacuum forming industry. ↩

-

Discover the offerings of ITA, a key player in Argentina's vacuum forming sector, and how they can meet your business needs. ↩

-

Learn about I.T.F.A.'s specialization and contributions to the vacuum forming industry in Argentina, enhancing your understanding of local options. ↩