High-Quality PE Profiles for Versatile Applications

Discover high-quality PE profiles at UPlastech, designed for durability and versatility in various applications. Explore our range today!

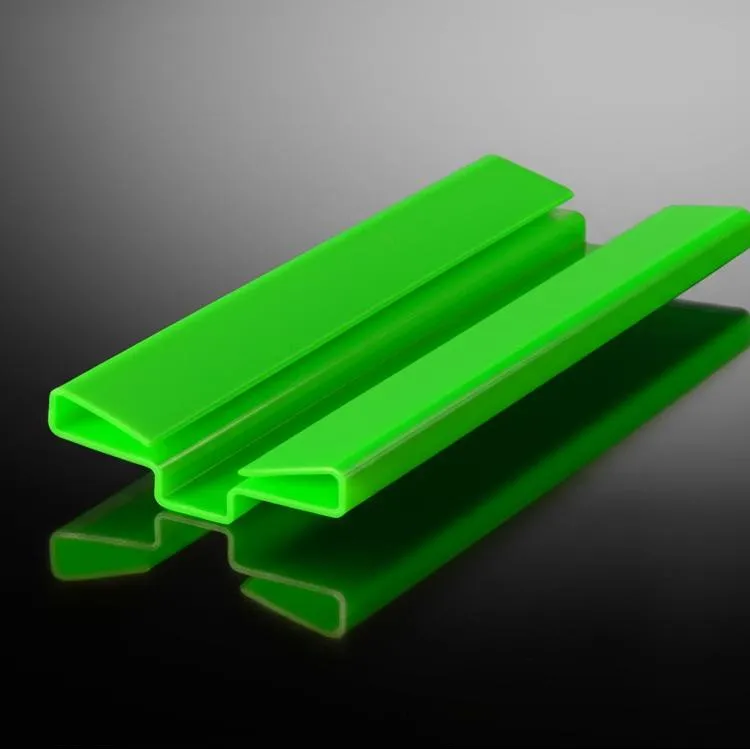

PE Guide Rail Wear Strip

HDPE Guide Rail Profile (Wear Strip)

PE Square Tube

Guide to Custom PE Extrusion Profiles Manufacturing

What Are Custom PE Profiles?

Custom PE Profiles refer to specialized, continuous shapes manufactured from polyethylene (PE) plastic through the extrusion process, tailored to meet specific design and functional requirements of a particular application.

Full Technical Name: Polyethylene Extruded Profiles.

Common Aliases: PE extruded shapes, custom polyethylene extrusions, PE sections.

Core Principles: The fundamental principle involves thermoplastic extrusion. Polyethylene, a thermoplastic polymer, is heated to a molten state and then forced (extruded) through a specifically shaped die. As the molten plastic exits the die, it takes on the die’s cross-sectional shape. This continuous shape is then cooled, solidified, and cut to the desired lengths, resulting in a “profile.”

Basic Concepts:

- Polyethylene (PE): A versatile and widely used thermoplastic polymer known for its chemical resistance, electrical insulation properties, low cost, and ease of processing. It exists in various densities, each offering different properties.

- Profile: A product of extrusion with a constant cross-section along its length. Examples include L-shapes, U-channels, T-sections, tubes, rods, or highly complex and unique geometries.

- Extrusion: A manufacturing process where a material is pushed through a die of a desired cross-section.

- Die: A specialized tool, typically made of hardened steel, with an opening machined to the negative of the desired profile shape. It’s the heart of the profile extrusion process.

- Extruder: The machine that melts the plastic resin and forces it through the die. It typically consists of a hopper (for raw material input), a heated barrel, a rotating screw (or screws), and a drive system.

- Calibration/Sizing: Post-extrusion processes that ensure the profile meets precise dimensional specifications as it cools and solidifies.

- Thermoplastic: A type of polymer that becomes moldable at a certain elevated temperature and solidifies upon cooling. Thermoplastics can be repeatedly melted and reshaped.

Classification and Type: Understanding the Varieties of PE Profiles

Custom PE profiles can be classified based on several factors, including the type of polyethylene resin used, the complexity of the profile shape, and its intended application area.

1. Classification Based on Polyethylene (PE) Material Type:

Different grades of polyethylene offer a spectrum of properties, making them suitable for diverse applications:

① Low-Density Polyethylene (LDPE) Profiles:

- Characteristics: Soft, flexible, good toughness, excellent chemical resistance, low melting point, good processability.

- Common Uses: Flexible tubing, packaging films and components, gaskets, squeeze bottles, wire and cable insulation.

② Linear Low-Density Polyethylene (LLDPE) Profiles:

- Characteristics: Higher tensile strength, impact strength, and puncture resistance compared to LDPE. Offers good flexibility and stress crack resistance.

- Common Uses: Geomembranes, liners, flexible tubing demanding higher strength, agricultural films.

③ Medium-Density Polyethylene (MDPE) Profiles:

- Characteristics: Properties intermediate between LDPE and HDPE. Good shock and drop resistance, better stress cracking resistance than HDPE.

- Common Uses: Gas pipes and fittings, sacks, shrink film.

④ High-Density Polyethylene (HDPE) Profiles:

- Characteristics: Stiffer, stronger, and more abrasion-resistant than LDPE. Excellent chemical resistance, good impact strength even at low temperatures, low moisture absorption.

- Common Uses: Pipes (water, drainage, industrial), chemical containers, cutting boards, wear strips, automotive components, boat components.

⑤ Ultra-High Molecular Weight Polyethylene (UHMWPE) Profiles:

- Characteristics: Extremely high abrasion resistance, very low coefficient of friction, high impact strength, good chemical resistance. More challenging to extrude than other PE types.

- Common Uses: Guide rails, wear strips for conveyors, bearings, medical implants (specific grades), chute liners.

⑥ Cross-linked Polyethylene (XLPE/PEX) Profiles:

- Characteristics: Enhanced properties like improved high-temperature performance, strength, and chemical resistance due to cross-linking of polymer chains. Extrusion is often followed by a post-extrusion cross-linking process.

- Common Uses: Hot water pipes (PEX tubing), chemical resistant tubing, electrical cable insulation.

2. Classification Based on Profile Complexity/Shape:

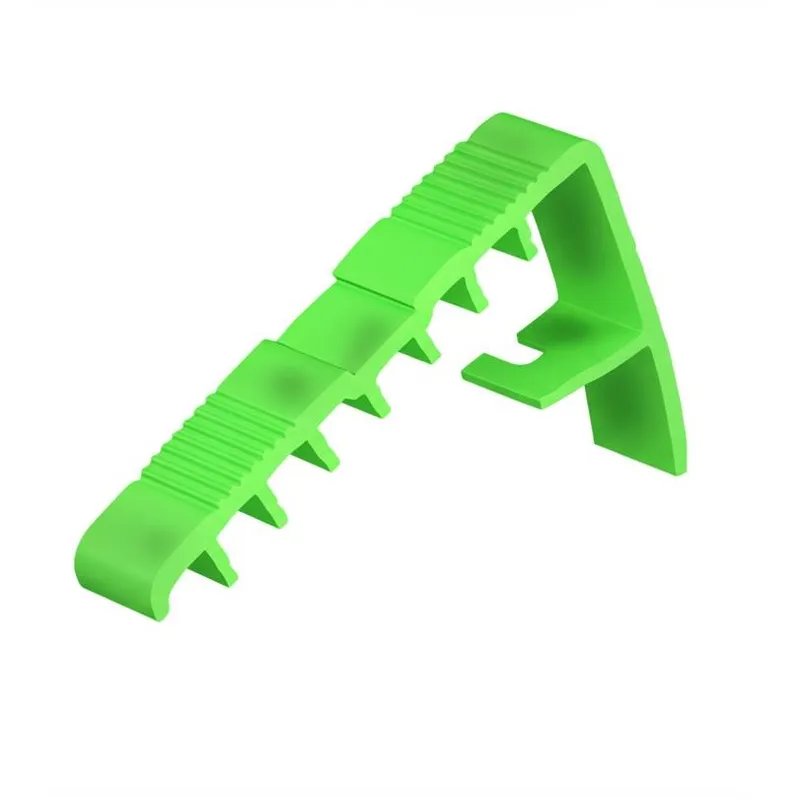

① Simple Profiles: These have basic geometric cross-sections.

- Examples: Solid rods, hollow tubes, flat strips, square bars, L-angles, C-channels.

② Complex Profiles: These involve intricate geometries, multiple hollows, varying wall thicknesses, or features requiring advanced die design.

- Examples: Multi-lumen tubing, window glazing beads, custom gaskets with detailed features, profiles with integrated hinges.

③ Co-extruded Profiles: These are made by extruding two or more different materials (or colors of the same material) simultaneously through a single die.

- Examples: Rigid PE profile with a flexible PE sealing lip, a profile with a colored cap layer over a base material, multi-layer tubing.

3. Classification Based on General Application Area:

While detailed applications are discussed later, a broad classification includes:

- Construction Profiles: Used in building and infrastructure.

- Packaging Profiles: Used for product protection and presentation.

- Automotive Profiles: Components for vehicles.

- Industrial Profiles: Parts for machinery, equipment, and plant infrastructure.

- Consumer Goods Profiles: Components for everyday products.

- Electrical Profiles: For insulation, conduit, and cable management.

Typical Application Scenarios/Use Cases for Custom PE Profiles

The versatility of polyethylene, combined with the adaptability of the extrusion process, allows custom PE profiles to serve a vast range of industries and applications.

1. Construction Industry:

① Window and Door Components: Glazing beads, weather stripping, seals, frame components, spacers. (Often LDPE for flexibility, HDPE for more rigid parts).

② Piping and Conduit: Corrugated pipes for drainage, smooth pipes for water and gas (HDPE, MDPE), electrical conduit.

③ Edge Protectors and Trim: Protecting corners of walls, furniture, or equipment during construction or in finished products.

④ Expansion Joints and Waterstops: Sealing gaps in concrete structures.

⑤ Decking and Railing Components: Some composite decking incorporates PE, and pure PE profiles can be used for railings or infill.

2. Packaging Solutions:

① Sealing Strips and Closures: For bags and containers, providing airtight or tamper-evident seals. (LDPE, LLDPE).

② Protective Edging and Dunnage: Cushioning and protecting goods during transit.

③ Display Components: Point-of-purchase display frames, channels for signage.

④ Tubes for Packaging: For cosmetics, industrial adhesives, or food products.

3. Automotive Sector:

① Seals and Gaskets: Window seals, door seals, weather stripping. (Often TPE co-extruded with PE, or specialized PE grades).

② Trim and Moldings: Interior and exterior decorative or functional trim pieces.

③ Tubing: For fluid transfer (windshield washer fluid, HVAC drainage), wire harnesses. (HDPE, MDPE).

④ Impact Protectors and Bumper Components: Minor impact absorption components.

⑤ Cable Conduits and Wire Management: Protecting electrical wiring.

4. Industrial and Manufacturing:

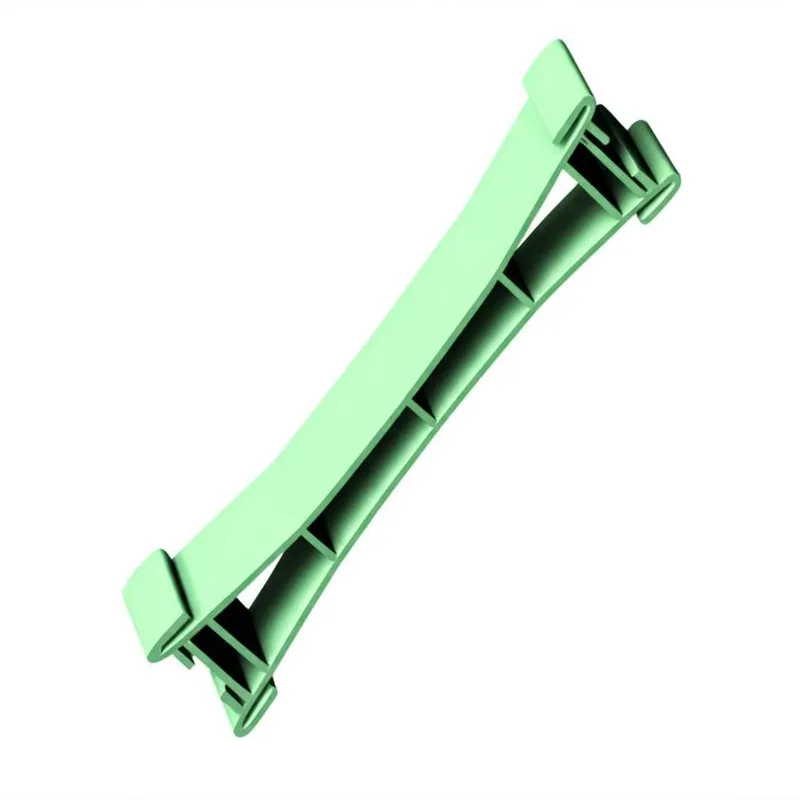

① Conveyor Components: Wear strips, guide rails (especially UHMWPE for its low friction and high wear resistance), chain guides.

② Tank Liners and Chute Liners: Protecting tanks from corrosive chemicals or providing smooth flow in material handling chutes (HDPE, UHMWPE).

③ Machine Guards and Safety Barriers: Lightweight and impact-resistant guards.

④ Cable Management Systems: Ducts, channels, and conduits for organizing and protecting cables.

⑤ Rollers and Bearings: (UHMWPE) for low-load applications.

5. Consumer Goods:

① Furniture Edging and Trim: Decorative and protective edges for tables, shelves.

② Toy Components: Safe, durable, and colorful parts for toys.

③ Sporting Goods: Components for skis, snowboards (base layers), protective gear.

④ Horticultural Products: Plant stakes, trellises, edging for garden beds.

6. Electrical and Electronics:

① Cable Jacketing and Insulation: Primary insulation or outer protective sheath for electrical wires and cables. (LDPE, HDPE, XLPE).

② Electrical Conduit: Protecting electrical wiring in buildings and industrial settings.

③ Busbar Insulation: Insulating profiles for electrical distribution systems.

7. Medical and Healthcare (using specific medical-grade PE):

① Tubing: For fluid transfer, catheters (though often more specialized polymers or silicone are used for indwelling devices). PE is common for non-critical tubing.

② Connectors and Fittings: Simple extruded components.

8. Agriculture and Aquaculture:

① Irrigation Tubing and Driplines: (LDPE, LLDPE) for efficient water distribution.

② Greenhouse Profiles: Components for greenhouse structures, film attachment profiles.

③ Netting and Cage Components: For fish farming or crop protection.

Advantages and Disadvantages Comparison of Custom PE Profiles

Like any material and process combination, custom PE profiles offer a distinct set of benefits and limitations.

1. Advantages of Custom PE Profiles:

- Cost-Effectiveness: Polyethylene resins are generally among the lowest-cost commodity plastics, making PE profiles an economical choice for many applications. The extrusion process itself is also efficient for high-volume production of continuous lengths.

- Versatility: The availability of different PE grades (LDPE, HDPE, UHMWPE, etc.) allows for a wide range of properties (flexibility, rigidity, wear resistance) to be achieved.

- Excellent Chemical Resistance: PE is highly resistant to a broad spectrum of acids, bases, solvents, and other chemicals, making it suitable for harsh environments.

- Good Electrical Insulation: PE possesses high dielectric strength and volume resistivity, making it an ideal material for electrical insulation and cable jacketing.

- Low Coefficient of Friction: HDPE and especially UHMWPE exhibit very low friction, making them excellent for sliding applications like wear strips and guide rails.

- Moisture Resistance: PE has very low water absorption, ensuring dimensional stability and property retention in humid or wet conditions.

- Ease of Processing: PE generally has good melt flow characteristics, making it relatively easy to extrude into complex shapes.

- Lightweight: PE profiles are lightweight, reducing material consumption, transportation costs, and easing handling and installation.

- Recyclability: Polyethylene is a thermoplastic and is widely recycled (Codes #2 for HDPE, #4 for LDPE/LLDPE), contributing to sustainability efforts.

- Customization: The “custom” aspect means profiles can be precisely tailored to specific shapes, sizes, colors, and can incorporate additives (UV stabilizers, flame retardants, anti-static agents) to meet application demands.

- Good Impact Strength: Particularly HDPE, offers good resistance to impact, even at lower temperatures.

2. Disadvantages of Custom PE Profiles:

- Lower Strength and Rigidity (compared to engineering plastics or metals): PE profiles are not typically suited for high structural load-bearing applications where materials like steel, aluminum, or engineering plastics (e.g., polycarbonate, nylon) would be preferred.

- Limited Temperature Resistance: Standard PE grades have relatively low melting points and service temperatures (typically up to 60-80°C for continuous use, though some grades like XLPE or UHMWPE can tolerate slightly higher). They are not suitable for high-temperature environments.

- Susceptibility to UV Degradation: Unstabilized PE can degrade when exposed to prolonged sunlight (UV radiation), leading to brittleness and discoloration. UV stabilizers must be added for outdoor applications.

- Potential for Environmental Stress Cracking (ESC): Certain PE grades can be susceptible to cracking when exposed to specific chemicals (e.g., detergents, alcohols) while under stress. Material selection is key to mitigate this.

- Poor Adhesion and Printability: The non-polar, waxy surface of PE makes it difficult to bond with adhesives or print on without specialized surface treatments (e.g., corona, flame, plasma treatment).

- Flammability: PE is combustible and will burn unless flame retardant additives are incorporated, which can affect other properties and cost.

- Tooling Costs: The initial cost of designing and manufacturing a custom extrusion die can be significant, especially for complex profiles. This cost is usually amortized over the production volume.

- Thermal Expansion: PE has a relatively high coefficient of thermal expansion, meaning it will expand and contract significantly with temperature changes. This must be considered in design, especially for long profiles or assemblies.

3. Brief Comparison with Other Related Technologies/Methods:

① vs. PVC (Polyvinyl Chloride) Profiles:

- PE: Generally more flexible (LDPE), better chemical resistance to certain substances, better low-temperature impact.

- PVC: Can be more rigid (uPVC), inherently flame retardant, good weatherability, often easier to bond.

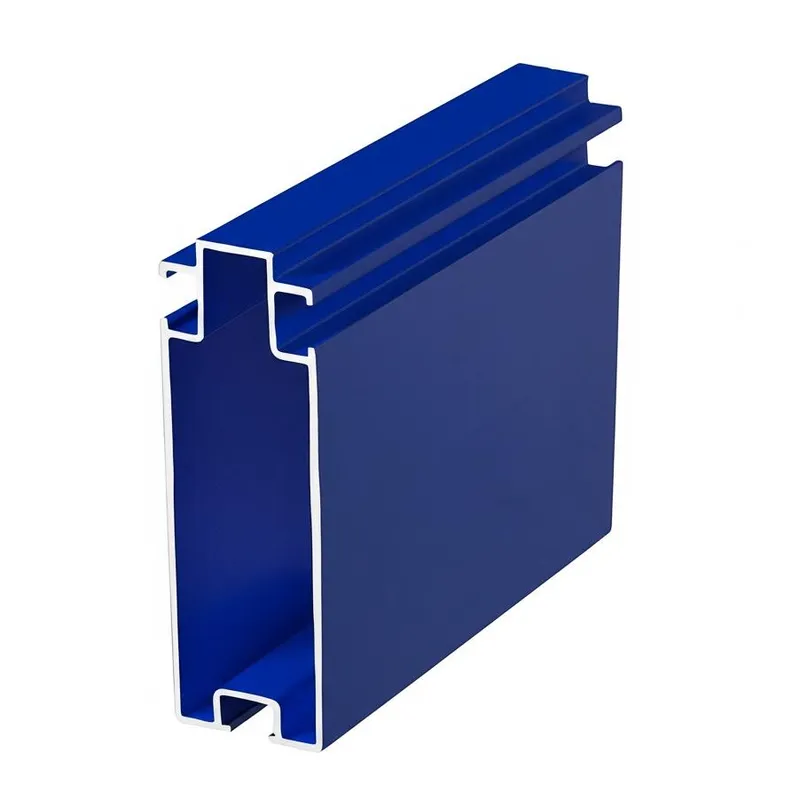

② vs. Aluminum Extrusion:

- PE: Lower cost, lighter weight, electrical insulator, corrosion-resistant without finishing.

- Aluminum: Much higher strength and stiffness, higher temperature resistance, better dimensional stability, conductive.

③ vs. Injection Molding:

- PE Extrusion: Ideal for continuous lengths of constant cross-section, lower tooling cost for simple profiles, high production rates for linear parts.

- Injection Molding: Suitable for producing discrete, often complex three-dimensional parts. Higher tooling costs, but can produce intricate features not possible with extrusion. If short, discrete PE parts are needed with complex 3D geometry, injection molding would be chosen over cutting extruded profiles.

④ vs. Silicone Extrusion:

- PE: Lower cost, different chemical resistance profile, lower temperature range.

- Silicone: Much wider temperature range (both high and low), excellent flexibility and elasticity, biocompatibility for medical grades, higher cost. Silicone extrusion is common for seals and tubing requiring these properties.

Key Characteristics of PE (relevant to extrusion & profiles)

The properties of polyethylene are fundamental to its performance both during extrusion and in the final application.

1. Melt Flow Index (MFI) / Melt Flow Rate (MFR):

- Description: A measure of the ease of flow of molten plastic. It is expressed as the weight of polymer (in grams) flowing in 10 minutes through a capillary of a specific diameter and length by a pressure applied via prescribed alternative gravimetric weights for alternative prescribed temperatures.

- Significance: Crucial for extrudability. Higher MFI generally means easier flow but potentially lower strength in the final part. Extrusion grades typically have lower MFI than injection molding grades for better melt strength.

2. Density:

- Description: Mass per unit volume. PE is classified by its density (LDPE, MDPE, HDPE).

- Significance: Directly influences stiffness, hardness, tensile strength, chemical resistance, and melting point. Higher density generally means higher stiffness and strength.

3. Molecular Weight (MW) and Molecular Weight Distribution (MWD):

- Description: MW refers to the average mass of a polymer chain. MWD describes the range of molecular weights within the polymer.

- Significance: Higher MW generally improves toughness, impact strength, and stress crack resistance but makes processing more difficult (higher viscosity). A narrow MWD can lead to more uniform properties and processing behavior. UHMWPE has exceptionally high molecular weight.

4. Crystallinity:

- Description: The degree of structural order in a polymer. PE is a semi-crystalline polymer.

- Significance: Affects density, stiffness, tensile strength, opacity (higher crystallinity = more opaque), and shrinkage. Cooling rate during extrusion influences the degree of crystallinity.

5. Tensile Strength & Elongation at Break:

- Description: Tensile strength is the maximum stress a material can withstand while being stretched or pulled before necking. Elongation is the measure of how much it can stretch before breaking.

- Significance: Key mechanical properties indicating the profile’s ability to resist pulling forces.

6. Impact Strength (e.g., Izod or Charpy):

- Description: The material’s ability to withstand a sudden applied load or shock.

- Significance: Important for applications where the profile might experience impacts. HDPE and UHMWPE have excellent impact strength.

7. Hardness (e.g., Shore D):

- Description: Resistance of the material to permanent indentation or scratching.

- Significance: Indicates surface durability. HDPE is harder than LDPE.

8. Thermal Properties:

- Melting Point (Tm): Temperature at which the crystalline regions of PE melt.

- Vicat Softening Point / Heat Deflection Temperature (HDT): Indicates the temperature at which the material begins to soften significantly under a load.

- Coefficient of Thermal Expansion (CTE): Measures the change in size per degree change in temperature. PE has a relatively high CTE.

9. Electrical Properties:

- Dielectric Strength: The maximum electric field strength that PE can withstand without breaking down.

- Volume Resistivity: A measure of its resistance to leakage current through its body.

10. Chemical Resistance:

- Description: Ability to resist degradation when exposed to various chemicals.

- Significance: PE is generally excellent but specific resistance varies with PE type and the chemical. HDPE is often more resistant than LDPE.

Core Process/Workflow/Working Principle: PE Profiles

The plastic extrusion process for PE profiles is a continuous operation involving several key stages:

1. Material Handling and Preparation:

① Resin Selection: Choosing the appropriate PE grade (LDPE, HDPE, etc.) based on application requirements. Additives like colorants, UV stabilizers, flame retardants, processing aids, or fillers are often pre-compounded into the resin or added as a masterbatch.

② Drying (if necessary): While PE is not highly hygroscopic (absorbs little moisture), excessive surface moisture can cause defects like voids or splay in the extrudate. Drying may be needed in humid conditions or for specific grades, though it’s less critical than for plastics like nylon or PET.

③ Blending: If using masterbatches or multiple components, they are thoroughly blended before being fed into the extruder to ensure homogeneity.

2. Extrusion:

① Feeding: PE pellets (or powder) are gravity-fed from a hopper into the extruder’s barrel.

② Melting, Mixing, and Pumping: This occurs within the extruder barrel, primarily by a rotating screw (typically single-screw for PE profiles).

- Feed Zone: The screw picks up the pellets from the hopper and conveys them forward into the heated barrel.

- Transition Zone (Compression Zone): The depth of the screw channel decreases, compressing the material. Frictional heat from the screw’s rotation (shear heating) and external heaters on the barrel melt the PE.

- Metering Zone: The shallowest part of the screw, designed to homogenize the molten polymer, ensure consistent temperature, and build up sufficient pressure to force the melt through the die.

③ Temperature Profile: The barrel is equipped with multiple heating/cooling zones, allowing precise control of the temperature profile along its length, crucial for proper melting and melt quality.

④ Screw Design: Key parameters include Length-to-Diameter ratio (L/D, typically 24:1 to 32:1 for PE), compression ratio, and specific screw geometry (e.g., mixing elements).

⑤ Screen Pack and Breaker Plate: Located between the screw tip and the die. The screen pack (multiple layers of wire mesh) filters out contaminants and unmelted particles. The breaker plate supports the screen pack and helps convert the spiral flow of melt from the screw into a more linear flow. Both contribute to building back pressure, improving melt homogeneity.

3. Die Shaping:

① Forcing Through the Die: The homogenized, pressurized molten PE is forced through the custom-designed extrusion die. The die’s orifice has the negative shape of the desired profile.

② Die Design: This is a critical and complex aspect. Designers must account for:

- Material Flow Characteristics: Ensuring even flow to all parts of the profile to prevent distortion.

- Land Length: The length of the parallel section at the die exit, which influences surface finish and dimensional stability.

- Drawdown: The stretching of the extrudate as it is pulled away from the die. The die opening is typically made slightly larger than the final profile dimensions to account for this.

- Die Swell: The tendency of the extrudate to expand in cross-section as it exits the die due to the relaxation of molecular stresses. This must also be compensated for in die design.

③ Dies can be made from various steels, often hardened and polished for longevity and smooth profile surfaces.

- Land Length: The length of the parallel section at the die exit, which influences surface finish and dimensional stability.

- Drawdown: The stretching of the extrudate as it is pulled away from the die. The die opening is typically made slightly larger than the final profile dimensions to account for this.

- Die Swell: The tendency of the extrudate to expand in cross-section as it exits the die due to the relaxation of molecular stresses. This must also be compensated for in die design.

③ Dies can be made from various steels, often hardened and polished for longevity and smooth profile surfaces.

4. Sizing and Calibration:

① Purpose: To cool the extrudate and solidify it into the precise desired shape and dimensions. The profile is still hot and malleable as it exits the die.

② Methods:

- Water Baths: The profile passes through one or more tanks filled with chilled or ambient temperature water.

- Air Cooling: For some profiles or in conjunction with water cooling, streams of air may be used.

- Chilled Rollers: Used for sheet or film, less common for complex profiles.

③ Controlled cooling rate is important to manage crystallinity, minimize internal stresses, and prevent warping.

5. Cooling:

① Purpose: To fully solidify the profile and reduce its temperature for handling.

② Methods:

- Water Baths: The profile passes through one or more tanks filled with chilled or ambient temperature water.

- Air Cooling: For some profiles or in conjunction with water cooling, streams of air may be used.

- Chilled Rollers: Used for sheet or film, less common for complex profiles.

③ Controlled cooling rate is important to manage crystallinity, minimize internal stresses, and prevent warping.

6. Pulling (Haul-Off):

① Purpose: To draw the profile away from the die and through the sizing and cooling equipment at a constant speed.

② Equipment: Caterpillar pullers (using two or more moving belts) or cleated belt pullers are common.

③ The puller speed must be precisely synchronized with the extruder output rate to maintain consistent profile dimensions and avoid excessive drawdown or material buildup.

7. In-line Finishing (Optional):

Depending on requirements, various operations can be performed in-line with the extrusion process:

- Cutting to Length: Saws (fly-knife, traveling saw) or cutters to produce discrete lengths.

- Printing/Marking: For branding, part numbers, or specifications.

- Embossing: Creating textured surfaces.

- Applying Adhesive Tape: For profiles that need to be self-adhesive.

- Punching/Drilling: Creating holes or slots.

- Coiling/Winding: For flexible profiles like tubing or small seals.

8. Quality Control and Inspection:

Throughout the process, and on finished parts, quality checks are performed:

- Dimensional measurements (using calipers, optical comparators, laser gauges).

- Surface finish inspection (for defects like die lines, smoothness).

- Color consistency checks.

- Testing of mechanical properties (if required, on sample pieces).

Custom PE Profiles: The Ultimate Guide to Plastic Extrusion

Unlock custom PE profiles with our comprehensive guide to plastic extrusion. Learn about PE types, applications, design, technical details & best practices.

Guide to Custom PE Extrusion Profiles Manufacturing

- Key Considerations in Custom PE Profile Extrusion

- Design/Implementation Guide/Best Practices for Custom PE Profiles

- Common Problems and Solutions in PE Profile Extrusion

- Advanced PE Formulations and Specialty Profiles

- Quality Control Methods and Relevant Standards for PE Profiles

- Sustainability in Custom PE Profile Production

Key Considerations in Custom PE Profile Extrusion

Several factors are critical for the successful design, production, and use of custom PE profiles:

1. Material Selection:

- Matching the specific PE grade (LDPE, LLDPE, MDPE, HDPE, UHMWPE) and any necessary additives (UV stabilizers, colorants, flame retardants, processing aids) to the application’s mechanical, chemical, thermal, electrical, and environmental requirements.

- Considering melt flow characteristics for extrudability of the desired profile complexity.

2. Profile Design Complexity:

- Highly intricate designs, very thin walls, sharp internal corners, or large variations in wall thickness can be challenging to extrude consistently.

- Simpler, more uniform designs generally lead to better process stability and lower tooling costs.

3. Die Design and Manufacturing:

- This is arguably the most critical element. Proper die design ensures balanced material flow, correct profile shape, good surface finish, and accounts for die swell and drawdown.

- Experienced die designers and manufacturers are essential for complex profiles.

- Material choice for the die (e.g., D2 tool steel, stainless steel) and surface finish (e.g., polishing, coatings) impact die life and profile quality.

3. Processing Parameters:

- Precise control of extruder barrel temperatures, screw speed, melt temperature, die temperature, puller speed, and cooling conditions is vital.

- These parameters are interdependent and must be optimized for each specific PE grade and profile design.

4. Cooling and Sizing Techniques:

- The efficiency and uniformity of cooling significantly impact dimensional stability, internal stresses, crystallinity, and potential for warping.

- Proper sizing tool design and vacuum levels (if used) are crucial for achieving tight tolerances.

5. Tolerances:

- Understand the achievable dimensional tolerances for PE extrusion. These depend on material, profile size and complexity, and process control. Industry standards (e.g., from the Plastic Pipe Institute or custom extrusion associations) can provide guidance.

- Overly tight, non-functional tolerances increase cost and difficulty.

6. Shrinkage:

- Polyethylene, especially HDPE, has a relatively high and non-uniform shrinkage rate as it cools from melt to solid state. This must be accurately predicted and compensated for in the die design.

7. Cost Factors:

- Resin Cost: Varies by PE grade and additives.

- Tooling Cost: Die design and fabrication, plus sizing tools. Can be substantial but is a one-time cost amortized over part volume.

- Production Volume: Higher volumes generally lead to lower per-unit costs.

- Complexity: More complex profiles require more sophisticated tooling and slower production rates, increasing cost.

- Secondary Operations: Any post-extrusion finishing steps add to the cost.

8. Secondary Operations Requirements:

- If the profile requires cutting, drilling, punching, printing, assembly, or other downstream operations, these should be considered during the initial design phase to ensure compatibility.

9. Environmental Considerations:

- PE is recyclable, but collection and reprocessing infrastructure must be available.

- Energy consumption of the extrusion process.

- Use of additives and their environmental impact.

Design/Implementation Guide/Best Practices for Custom PE Profiles

Following these guidelines can lead to more successful and cost-effective custom PE profile projects:

1. Early Supplier Involvement (ESI):

Collaborate with an experienced custom PE extruder early in the design phase. Their expertise in material selection, DFM (Design for Manufacturability for extrusion), and tooling can prevent costly redesigns and ensure feasibility.

2. Simplify Profile Design Where Possible:

Avoid unnecessarily complex features, sharp internal corners (use radii), and extreme or abrupt variations in wall thickness. Simpler designs are easier to tool, run more consistently, and are generally less expensive.

3. Aim for Consistent Wall Thickness:

Uniform wall thickness promotes even material flow, uniform cooling, reduces internal stresses, and minimizes warping or distortion. If varying thicknesses are necessary, make transitions gradual.

4. Incorporate Generous Radii:

Use radii on all internal and external corners instead of sharp edges. This improves material flow in the die, reduces stress concentrations in the final part, and can improve die life.

5. Consider Material Flow Dynamics:

Design features that promote balanced flow of the molten plastic through the die. Avoid isolated thick sections fed by thin sections.

6. Specify Realistic and Functional Tolerances:

Understand the limitations of the PE extrusion process for the chosen material and profile complexity. Only specify tight tolerances on truly critical functional dimensions. Over-tolerancing significantly increases costs.

7. Clearly Define All Functional Requirements:

Provide the extruder with comprehensive information about the profile’s end-use, including:

- Critical functional dimensions and features.

- Required mechanical properties (stiffness, flexibility, impact resistance).

- Operating environment (temperature range, chemical exposure, UV exposure).

- Aesthetic requirements (color, surface finish, transparency).

- Assembly or mating part details.

8. Material Selection Based on End-Use, Not Just Cost:

While PE is cost-effective, select the grade (LDPE, HDPE, etc.) and any additives based on the performance demands of the application. Under-specifying can lead to premature failure.

9. Be Aware of Shrinkage and Die Swell:

While primarily the extruder's responsibility to compensate for these in die design, designers should understand that the die opening will not be identical to the final part dimensions.

10. Design for Assembly and Secondary Operations:

If the profile needs to be assembled, welded, or have other operations performed, incorporate features that facilitate these processes (e.g., channels for fasteners, flat surfaces for bonding).

11. Invest in Prototyping for Complex Profiles:

For new or complex designs, creating prototype tooling (often simpler, less expensive "soft" tooling) can validate the design, material choice, and processability before committing to expensive production tooling.

12. Communicate Quantity and Lifespan Expectations:

Knowing the expected annual volume and product lifecycle helps the extruder optimize tooling and production planning.

Common Problems and Solutions in PE Profile Extrusion

Even with careful planning, issues can arise during PE profile extrusion. Here are common problems and their potential solutions:

1. Dimensional Instability (Warping, Bowing, Twisting):

- Problem: Uneven cooling rates, internal stresses due to non-uniform wall thickness, inconsistent puller speed, insufficient support after exiting the die.

- Solution: Optimize cooling (adjust water temperature, flow, or spray patterns), ensure uniform wall thickness in design, verify consistent puller speed and tension, provide adequate support for the hot extrudate, adjust melt or die temperatures, consider annealing post-extrusion for stress relief.

2. Surface Defects:

① Die Lines (Streaks along extrusion direction):

- Problem: Scratches or imperfections on the die land surfaces, contaminated material, die buildup.

- Solution: Polish or repair die lands, improve melt filtration, clean die regularly.

② Sharkskin (Rough, matte surface with ridges perpendicular to flow):

- Problem: Excessive stress at the die exit, often at higher output rates. Melt too cold.

- Solution: Increase die/melt temperature, use processing aids (e.g., fluoropolymers), reduce output rate, redesign die exit geometry (e.g., increase land length, chamfer die lip).

③ Melt Fracture (Grossly irregular or helical distortion):

- Problem: Excessive shear stress in the die, melt too cold, or flow rate too high for the die geometry.

- Solution: Reduce output rate, increase melt/die temperature, redesign die for smoother flow (e.g., tapered entry), use lower viscosity PE grade if feasible.

3. Inconsistent Wall Thickness:

- Problem: Unbalanced flow in the die (poor die design or damage), extruder surging, inconsistent puller speed, die not centered (for tubing).

- Solution: Adjust die (e.g., centering bolts for tubing dies, restrictors for flat dies), investigate and correct cause of surging (see below), ensure consistent puller operation, inspect die for wear or damage.

4. Bubbles, Voids, or Porosity in Profile:

- Problem: Moisture in resin (less common for PE but possible), trapped air, degradation of polymer releasing volatiles, contaminants.

- Solution: Ensure resin is dry if required, optimize screw design for devolatilization (if applicable), check for air leaks in hopper/feed throat, reduce melt temperature if degradation is suspected, improve melt filtration.

5. Brittleness or Low Impact Strength:

- Problem: Polymer degradation (excessive heat or shear), wrong material grade, insufficient cooling before handling/stressing, too much regrind.

- Solution: Optimize temperature profile and screw speed to reduce shear, verify correct PE grade is used, ensure adequate cooling, limit regrind percentage.

6. Color Streaks or Inconsistent Color:

- Problem: Poor dispersion of color masterbatch, incompatible masterbatch carrier, insufficient mixing in the extruder.

- Solution: Use high-quality masterbatch with good compatibility, increase back pressure for better mixing, use a screw with better mixing elements, ensure proper let-down ratio of masterbatch.

7. Surging (Pulsating or Unsteady Extruder Output):

- Problem: Inconsistent feeding of pellets (bridging in hopper, poor solids conveying in feed zone), improper temperature profile (e.g., feed zone too hot), screw design issues, worn screw/barrel.

- Solution: Check hopper for flow issues, adjust feed zone temperature (often cooler helps), optimize overall temperature profile, check screw and barrel for wear, ensure consistent material properties.

8. Excessive Die Swell or Shrinkage:

- Problem: Inherent material property, incorrect processing conditions.

- Solution: Primarily addressed in die design, but optimizing melt temperature and cooling rates can have some influence. Ensure consistency for predictable results.

Advanced PE Formulations and Specialty Profiles

While standard PE grades cover many applications, specific performance demands necessitate advanced formulations or specialized profile types:

1. Foamed PE Profiles:

① Description: These profiles incorporate a cellular or foamed core, either through chemical blowing agents mixed with the resin or physical foaming (injecting gas like CO2 or N2 into the melt). This results in a profile that is lighter than a solid counterpart of the same dimensions.

② Properties: Reduced material consumption (cost savings), lighter weight, improved thermal and acoustic insulation, good cushioning properties. Mechanical strength is typically lower than solid profiles.

③ Applications: Protective packaging (edge protectors, cushioning), thermal insulation strips, lightweight structural components (where high strength isn’t paramount), buoyancy aids, decorative trim with a softer feel.

2. Conductive/Anti-static PE Profiles:

① Description: Standard PE is an excellent insulator. For applications requiring dissipation of static electricity (e.g., in electronics handling or explosive environments), conductive fillers like carbon black, carbon fibers, or inherent conductive polymers (ICPs) are compounded into the PE resin.

② Properties: Provide a controlled path for static charge to dissipate, preventing electrostatic discharge (ESD) damage or dust attraction. Surface resistivity or volume resistivity values define their effectiveness (e.g., anti-static: 10^9-10^12 ohms/sq; conductive: <10^6 ohms/sq).

③ Applications: Trays and channels for handling sensitive electronic components, profiles for cleanroom environments, components for equipment used in explosive atmospheres, conveyor parts in electronics assembly.

3. Filled PE Profiles:

① Description: Incorporating inorganic fillers (e.g., calcium carbonate, talc, mica, glass fibers, wood flour) into the PE matrix to modify its properties.

② Properties:

- Calcium Carbonate/Talc: Can increase stiffness, improve dimensional stability, reduce cost, and enhance printability. May reduce impact strength.

- Glass Fibers (Short or Long): Significantly increase tensile strength, stiffness, and heat deflection temperature. Can make the material more abrasive to processing equipment.

- Wood Flour/Natural Fibers (Wood-Plastic Composites – WPC): Offer a wood-like appearance and feel, increased stiffness. Commonly used with PE for decking, fencing, and outdoor profiles. Requires careful formulation to ensure good bonding and moisture resistance.

③ Applications: Automotive components requiring higher stiffness, WPC decking and railings, industrial components needing enhanced mechanical properties, cost-reduction in non-critical applications.

4. High-Strength/High-Modulus PE Profiles (e.g., oriented PE):

① Description: Through specialized processing techniques like die drawing or rolling post-extrusion, PE molecular chains can be highly oriented in the extrusion direction, leading to significantly enhanced mechanical properties along that axis.

② Properties: Dramatically increased tensile strength and modulus, sometimes approaching that of some engineering plastics.

③ Applications: Strapping, reinforcing tapes, specialized fibers, high-performance ropes, potentially lightweight structural elements where uni-directional strength is key. UHMWPE fibers are an extreme example.

5. Flame Retardant PE Profiles:

① Description: Standard PE is flammable. Flame retardant (FR) additives (e.g., halogenated compounds often with antimony trioxide, or halogen-free systems like phosphorus-based or mineral hydrates like ATH or MDH) are incorporated to meet specific flammability ratings (e.g., UL 94 V-0, V-1, V-2).

② Properties: Reduced flammability, self-extinguishing characteristics. FR additives can affect mechanical properties, processing, and cost. Halogen-free options are increasingly preferred due to environmental concerns with some halogenated FRs.

③ Applications: Electrical conduit, wire and cable jacketing in building and construction, components for appliances and electronics, transportation applications requiring fire safety.

Quality Control Methods and Relevant Standards for PE Profiles

Ensuring that custom PE profiles meet specifications requires a robust quality control (QC) program, often guided by industry standards.

1. Dimensional Inspection:

Methods: Crucial for verifying that the profile meets the drawing tolerances.

- Hand Tools: Calipers, micrometers, pin gauges, radius gauges, protractors for basic measurements.

- Optical Comparators/Profile Projectors: Magnify the profile’s cross-section and project it onto a screen with an overlay of the nominal dimensions and tolerances for quick go/no-go checks or detailed measurement.

- Non-Contact Vision Systems: Automated systems using cameras and software to measure multiple dimensions rapidly.

- Laser Scanners/Gauges: Can provide continuous in-line or off-line measurement of profile dimensions.

- Coordinate Measuring Machines (CMMs): For highly precise 3D measurement of complex profiles or sample sections.

2. Material Property Testing (often performed on raw material batches or test plaques/specimens extruded under similar conditions):

Melt Flow Index (MFI) Verification (ASTM D1238): Confirms the resin’s flow characteristics are within specification, crucial for consistent processing and final properties.

- Density (ASTM D792, ASTM D1505): Verifies the correct PE grade is being used and can indicate issues with crystallinity or void content.

- Tensile Properties (ASTM D638): Measures tensile strength, elongation, and modulus of elasticity. Provides insight into the material’s strength and ductility.

- Impact Strength (Izod ASTM D256, Charpy ASTM D6110): Assesses the profile’s ability to withstand sudden impact, important for many applications.

- Hardness (Shore D – ASTM D2240): Measures resistance to indentation.

- Differential Scanning Calorimetry (DSC) (ASTM D3418): Can determine melting points, crystallization temperatures, and degree of crystallinity, useful for verifying material grade and consistency of processing.

- Heat Deflection Temperature (HDT) (ASTM D648) / Vicat Softening Point (ASTM D1525): Indicates the temperature at which the material softens under load.

3. Surface Finish and Appearance Checks:

- Visual Inspection: Checking for defects like die lines, sharkskin, melt fracture, discoloration, voids, surface contamination, or inconsistencies. Often compared against approved visual standards or limit samples.

- Color Matching: Using spectrophotometers or visual comparison under standardized lighting conditions (e.g., light booth) against color plaques or master standards (e.g., Pantone, RAL).

- Gloss Measurement (ASTM D523): Quantifies the surface gloss level if specified.

4. Specific Application Tests:

- Environmental Stress Cracking Resistance (ESCR) (ASTM D1693): Important for PE grades exposed to certain chemicals under stress.

- Pipe Testing Standards (e.g., ASTM D3350 for PE pipe materials, ISO 4427 for PE pipes for water supply): Involve pressure testing, burst strength, long-term hydrostatic strength.

- Flammability Testing (e.g., UL 94): For profiles requiring flame retardant properties.

5. Relevant Industry Standards (General Categories):

- ASTM International: Publishes numerous standards for plastics testing, material specifications, and product performance.

- ISO (International Organization for Standardization): Global standards covering similar areas to ASTM, often harmonized.

- Industry-Specific Standards: Such as those from the Plastics Pipe Institute (PPI), National Electrical Manufacturers Association (NEMA), or automotive standards (SAE).

- Customer-specific standards and specifications are also common.

Sustainability in Custom PE Profile Production

The environmental impact of plastics is a significant global concern, and the PE profile industry is actively engaging with sustainability initiatives.

1. Inherent Recyclability of Polyethylene:

- PE is a thermoplastic, meaning it can be melted and reprocessed multiple times. HDPE (resin ID code #2) and LDPE/LLDPE (resin ID code #4) are widely recycled.

- Post-Consumer Recycled (PCR) Content: Incorporating PE recovered from household or commercial waste streams into new profiles. Quality and consistency of PCR can be challenging but are improving.

- Post-Industrial Recycled (PIR) Content / Regrind: Utilizing scrap and off-spec material generated within the extrusion plant or from other industrial sources. This is common practice and helps minimize waste.

2. Use of Recycled Content in PE Profiles:

- Many non-critical applications can readily use PE profiles with high percentages of recycled content.

- Challenges include potential variations in color, slight reduction in mechanical properties, and ensuring consistent supply of quality recycled feedstock.

- Advances in sorting and cleaning technologies are improving the quality of recycled PE.

3. Bio-based and Renewable Polyethylene Options:

- Bio-PE: Chemically identical to fossil-fuel-based PE but derived from renewable resources like sugarcane (ethanol converted to ethylene). It is a “drop-in” replacement, processable on existing extrusion equipment.

- Benefit: Reduces reliance on fossil fuels and can have a lower carbon footprint (depending on agricultural practices and land use).

- Consideration: Cost is typically higher, and availability can be limited compared to conventional PE. Not inherently biodegradable unless specifically designed to be (most bio-PE is durable).

4. Design for Environment (DfE) / Design for Recycling Principles:

- Material Selection: Choosing PE grades that are easily recyclable. Avoiding complex multi-material profiles where materials cannot be easily separated if recycling is a primary goal (unless the combination is also recyclable as a composite).

- Minimizing Additives: Using only necessary additives and avoiding those that can contaminate recycling streams (e.g., certain fillers or problematic pigments).

- Ease of Disassembly: If the profile is part of a larger product, designing for easy removal and separation.

- Lightweighting: Optimizing profile design to use less material without compromising function (e.g., foamed profiles, optimized wall thicknesses).

5. Energy Efficiency in the Extrusion Process:

- Modern extruders with energy-efficient motors (e.g., AC vector drives), improved barrel insulation, and optimized screw designs consume less energy.

- Process optimization to reduce startup times and scrap rates also contributes to overall energy savings.

6. Waste Reduction:

- Minimizing scrap during startup, shutdown, and product changeovers.

- Efficiently recycling in-house scrap (regrind).

- Optimizing packaging for finished profiles to reduce waste.

7. Challenges and Opportunities:

- Contamination: Ensuring recycled streams are free from contaminants that affect profile quality.

- Consumer Perception: Building confidence in the performance of profiles made with recycled content.

- Infrastructure: Expanding collection and reprocessing infrastructure for PE globally.

- Opportunity: Growing demand for sustainable products is driving innovation in recycled materials and bio-based alternatives.

FAQs FOR CLIENT

Getting Started with Uplastech

Have questions? We have answers.

We specialize in extrusion, vacuum forming, blow molding, and precision mold-making, offering customized solutions to meet your diverse manufacturing needs.

We work with various industries, including automotive, electronics, consumer goods, and packaging, focusing on B2B partnerships and delivering solutions across extrusion, thermoforming, blow molding, and precision mold-making.

Yes, we tailor our solutions to fit your unique requirements.

Get In Touch

Feel free to email us or fill out the form below to get a quote.

Email: uplastech@gmail.com