Thermoforming is a popular manufacturing process for creating plastic parts, but it’s not without its challenges. From material constraints to design limitations1, understanding these hurdles is key to making informed decisions in manufacturing. This blog post delves into the limitations of thermoforming2, exploring its technical constraints3, practical implications, and how it compares to other processes. Whether you’re a designer, engineer, or manufacturer, knowing these limitations will help you choose the right process for your project.

Thermoforming shapes heated plastic sheets over molds to create parts, but it’s limited by material compatibility, design complexity, and wall thickness uniformity, making it best for simple, thin-walled components.

While thermoforming offers cost-effective solutions for many applications, its constraints can impact product quality and design flexibility. Read on to explore how these limitations affect your manufacturing choices and what alternatives might be better suited for complex needs.

Thermoforming is limited to thin-walled parts, making it unsuitable for thick or complex structures.Echt

The process stretches plastic sheets, which naturally limits part thickness and complexity, especially for deep or intricate designs.

Thermovormen kan dezelfde precisie bereiken als spuitgieten.Vals

Injection molding offers higher precision due to its closed-mold process, while thermoforming’s open-mold nature leads to less control over surface details.

- 1. What are the Key Limitations of Thermoforming?

- 2. Hoe verhoudt thermovormen zich tot andere processen?

- 3. What Materials are Compatible with Thermoforming?

- 4. How Does Thermoforming Handle Complex Designs?

- 5. What are the Wall Thickness Challenges in Thermoforming?

- 6. How Does Waste Generation Affect Thermoforming Efficiency?

- 7. Wanneer moet je thermovormen boven andere processen kiezen?

- 8. Conclusie

What are the Key Limitations of Thermoforming?

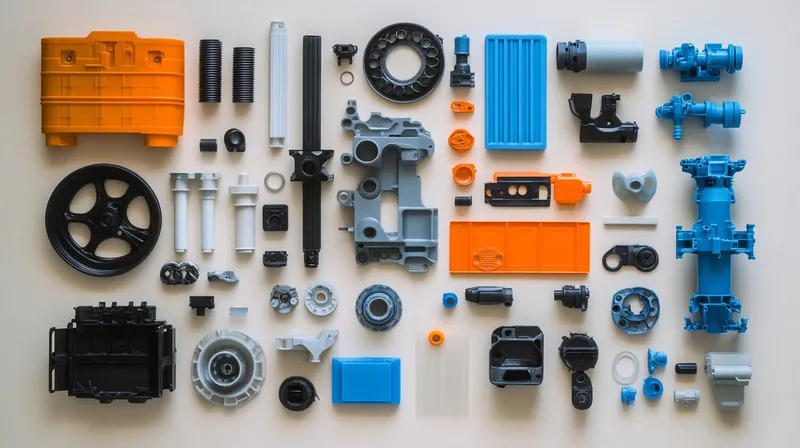

Thermoforming is widely used for its cost-effectiveness and versatility, but it comes with several limitations that can affect its suitability for certain applications. Below, we explore the primary constraints of this process.

Thermoforming’s limitations include material constraints, design complexity, wall thickness uniformity, and waste generation, making it less ideal for intricate or high-precision parts.

| Limitation | Impact on Manufacturing | Opmerkingen |

|---|---|---|

| Material Constraints4 | Limited to specific thermoplastics | Not all plastics can withstand the heat and pressure required. |

| Complex ontwerp5 | Struggles with intricate shapes and undercuts | Best for simple geometries. |

| Wall Thickness Uniformity6 | Difficult to achieve consistent thickness | Thinning occurs in deep draws, leading to weak spots. |

| Waste Generation | Significant waste from excess material | Requires trimming, adding time and cost. |

Material Constraints

Not every plastic is compatible with thermoforming. The process requires materials that can withstand high temperatures and pressure without degrading, limiting options to thermoplastics like PET, PP, or ABS. For example, EVOH, used for barrier properties in packaging, has a narrow forming window (70–90°C), making it challenging to process without compromising its integrity (Xometry Pro).

Design and Geometry Limitations

Thermoforming excels with simple shapes but falters with complex designs. Intricate geometries, undercuts, or parts requiring molded-in components (e.g., screws or fasteners) are difficult or impossible to achieve. Additionally, the depth of draw in vacuum forming is limited to about one-third to one-half of the mold’s width due to material thinning, restricting design flexibility (ScienceDirect).

Wall Thickness Issues

Achieving uniform wall thickness is a persistent challenge, especially in deeper molds where the plastic stretches unevenly. This can result in thin, weak areas that compromise the part’s strength and, in packaging, increase gas permeation (Pacific Research). For applications requiring consistent thickness, such as structural components, this limitation can be critical.

Waste and Processing

Thermoforming generates significant waste from excess sheet material, although it can be recycled. Moreover, every part requires trimming, which adds time and cost to the production process (IQS Directory). This makes thermoforming less efficient for high-volume production compared to processes like injection molding.

Thermoforming is ideal for high-volume production due to its low tooling costs.Vals

While tooling costs are lower, the per-part cost increases with volume due to slower cycle times and additional trimming steps.

Thermovormen kan onderdelen produceren met een uniforme wanddikte.Vals

The stretching of the plastic sheet inherently leads to thinning, especially in deeper sections of the mold.

Hoe verhoudt thermovormen zich tot andere processen?

Understanding how thermoforming stacks up against alternatives like injection molding or blow molding is crucial for selecting the right manufacturing method. Below, we compare these processes based on key factors.

Thermovormen biedt lagere gereedschapskosten7 and faster prototyping than injection molding but falls short in precision8, design complexity, and material efficiency.

Thermovormen vs. Spuitgieten

| Aspect | Thermovormen | Spuitgieten |

|---|---|---|

| Kosten gereedschap | Lower, especially for large parts | Higher, due to complex molds |

| Precisie | Less precise, especially on the second surface | High precision with closed molds |

| Ontwerpflexibiliteit | Limited to simple shapes and thin walls | Handles complex geometries and thick parts |

| Material Use | Generates more waste from trimming | More efficient, less waste |

| Productiesnelheid | Slower due to trimming and cooling times | Faster for high-volume runs |

While thermoforming is cost-effective for low to medium volumes and large parts, injection molding excels in precision and complexity, making it better for high-volume production of intricate components (Productieve kunststoffen).

Thermovormen vs. blazen

Blow molding is another alternative, particularly for hollow parts like bottles. Unlike thermoforming, which is limited to sheet-based materials, blow molding uses molten plastic to form hollow shapes. However, blow molding is less versatile in terms of part geometry and typically requires higher tooling costs.

Thermoforming is more versatile than blow molding for producing a wide range of part shapes.Vals

Blow molding is specialized for hollow parts, while thermoforming is better for open, thin-walled structures.

What Materials are Compatible with Thermoforming?

Material selection is critical in thermoforming, as not all plastics can withstand the process’s heat and pressure requirements. Below, we list common materials used in thermoforming and their key properties.

Thermoforming is compatible with thermoplasten9 like PET, PP, PVC, PS, and ABS, each offering unique benefits for specific applications.

| Materiaal | Eigenschappen | Toepassingen |

|---|---|---|

| PET | Clear, FDA-certifiable, recyclable | Voedselverpakking, trays |

| PP | Duurzaam, bestand tegen chemicaliën | Auto-onderdelen, containers |

| PVC | Strong, versatile | Pipes, signage, medical devices |

| PS | Lightweight, easy to form | Disposable cups, packaging |

| ABS | Impact-resistant, durable | Automotive interiors, toys |

| EVOH | Excellent barrier properties | Food packaging (barrier layer) |

Materialen zoals EVOH10, while offering superior barrier properties, have a narrow processing window (70–90°C for SPPF), making them difficult to form without specialized equipment (ScienceDirect).

All thermoplastics can be used in thermoforming.Vals

Only thermoplastics with suitable heat and pressure tolerance, like PET and PP, are compatible; others may degrade or fail to form properly.

How Does Thermoforming Handle Complex Designs?

Thermoforming is best suited for simple, thin-walled parts, but it faces significant challenges with complex designs. Below, we explore why intricate geometries are difficult to achieve.

Thermoforming struggles with complex designs due to its reliance on stretching plastic sheets, which limits undercuts, depth, and precision.

Challenges with Undercuts and Intricate Shapes

Undercuts—features that prevent the part from being easily removed from the mold—are particularly problematic in thermoforming. Since the process typically uses a single mold, parts with undercuts require additional steps like side-action molds or post-forming operations, increasing complexity and cost.

Depth of Draw Limitations

In vacuum forming, the depth of draw is limited to about one-third to one-half of the mold’s width. Exceeding this ratio leads to excessive thinning, compromising the part’s structural integrity (ScienceDirect). For deeper parts, processes like pressure forming can help, but they still can’t match the capabilities of injection molding.

Thermoforming can produce parts with deep draws and undercuts as effectively as injection molding.Vals

Injection molding’s closed-mold process allows for greater design freedom, including deep draws and complex undercuts.

What are the Wall Thickness Challenges in Thermoforming?

Achieving uniform wall thickness is one of the most significant challenges in thermoforming, especially for parts with deeper molds.

Thermoforming often results in uneven wall thickness due to the stretching of the plastic sheet, leading to thinning in deeper sections.

Thinning in Deep Draws

As the plastic sheet is stretched over the mold, the material thins, particularly at the base of deep draws. This can create weak spots that affect the part’s durability and performance. For example, in packaging applications, thinning can increase gas permeation, reducing the shelf life of products (Pacific Research).

Solutions and Workarounds

To mitigate thinning, designers can:

-

Use plug assists to pre-stretch the material.

-

Opt for pressure forming, which applies additional force to distribute the material more evenly.

-

Choose materials with higher hot strength to resist excessive stretching.

However, these solutions add complexity and cost to the process.

Thermoforming can achieve consistent wall thickness in deep-drawn parts.Vals

The inherent stretching of the plastic sheet leads to thinning, especially in deeper molds, making uniform thickness difficult.

How Does Waste Generation Affect Thermoforming Efficiency?

Waste generation is a notable drawback of thermoforming, impacting both cost and sustainability.

Thermoforming generates significant waste from excess sheet material, though it can be recycled, and requires trimming for each part, adding time and cost.

Sources of Waste

-

Excess Material: The plastic sheet extends beyond the mold, creating scrap that must be trimmed.

-

Trimming Process: Every part requires trimming, which not only generates waste but also slows down production.

Mitigating Waste

While waste is inevitable, it can be minimized by:

-

Optimizing sheet size to reduce excess material.

-

Recycling scrap material for future use.

-

Using automated trimming systems to speed up post-processing.

Despite these efforts, waste remains a challenge, particularly for high-volume production (IQS Directory).

Thermoforming is more material-efficient than injection molding.Vals

Injection molding uses precise amounts of material with minimal waste, while thermoforming generates significant scrap from trimming.

Wanneer moet je thermovormen boven andere processen kiezen?

Despite its limitations, thermoforming is the right choice for specific applications. Below, we outline scenarios where it excels.

Choose thermoforming for low to medium volume production, large parts, or when rapid prototyping is needed, but consider alternatives for high precision or complex designs.

Ideal Use Cases

-

Low to Medium Volume Production: Thermoforming’s lower tooling costs make it cost-effective for smaller runs.

-

Large Parts: For parts like automotive panels or equipment covers, thermoforming is more economical than injection molding.

-

Prototyping: Its fast turnaround time makes it ideal for testing designs before committing to expensive tooling.

Wanneer alternatieven overwegen

- Productie van grote volumes: Injection molding offers faster cycle times and lower per-part costs.

-

Complex Geometries: For parts with undercuts, thick walls, or molded-in components, injection molding or blow molding may be better suited.

-

Precision Requirements: If tight tolerances or high surface quality are needed, injection molding provides superior results.

Thermoforming is the best choice for high-volume production of complex parts.Vals

Injection molding is more efficient and precise for high-volume, complex parts due to its faster cycle times and design flexibility.

Conclusie

Thermoforming is a valuable process for producing thin-walled plastic parts, but its limitations—material constraints, design complexity, wall thickness issues, and waste generation—must be carefully considered. For applications requiring high precision, intricate geometries, or high-volume production, alternatives like injection molding may be more suitable. By understanding these constraints, manufacturers can make informed decisions to optimize their production strategies.

-

Learning about design limitations can guide you in optimizing your designs for thermoforming processes. ↩

-

Understanding the limitations of thermoforming can help you make informed decisions in your manufacturing projects. ↩

-

Exploring technical constraints will provide insights into the challenges faced during the thermoforming process. ↩

-

Understanding material constraints is crucial for selecting the right thermoplastics for thermoforming applications. ↩

-

Exploring design complexity helps in recognizing the limitations of thermoforming for intricate parts and shapes. ↩

-

Learning about wall thickness issues is essential for ensuring the strength and integrity of thermoformed parts. ↩

-

Exploring this resource will help you understand how lower tooling costs can impact manufacturing efficiency and budget. ↩

-

This link will provide insights into the significance of precision in manufacturing and its effects on product quality. ↩

-

Understanding the best thermoplastics for thermoforming can enhance your material selection process, ensuring optimal results. ↩

-

Exploring EVOH's properties can help you leverage its barrier capabilities effectively in your thermoforming projects. ↩