Imagine a material that combines the clarity of glass with the lightweight durability of plastic. That’s acrylic, or polymethyl methacrylate1 (PMMA), a thermoplastic that’s revolutionizing industries through thermoforming. In this post, we’ll explore how acrylic is used in thermoforming, its advantages and limitations, and how you can leverage this technology for your projects.

Thermoforming with acrylic2 creates durable, transparent products by heating and shaping plastic sheets, ideal for signs, medical devices, and automotive parts, offering cost-effective, flexible design solutions.

Understanding the nuances of acrylic in 열성형3 can help you make informed decisions for your manufacturing needs. Dive deeper to explore how acrylic compares to other materials and the key factors that influence its application.

Acrylic is the best material for all thermoforming applications.False

While acrylic offers excellent clarity and UV resistance, other materials like polycarbonate provide higher impact strength, making them better for certain applications.

Thermoforming with acrylic is more cost-effective than injection molding for small to medium production runs.True

Thermoforming typically involves lower tooling costs and faster production times, making it ideal for runs of 50-5,000 units.

- 1. What is Thermoforming and How Does Acrylic Fit In?

- 2. Where is Acrylic Thermoforming Commonly Used?

- 3. How Does the Thermoforming Process Work with Acrylic?

- 4. What are the Key Design Considerations for Acrylic Thermoforming?

- 5. How Does Acrylic Compare to Other Thermoforming Materials?

- 6. 열성형 관련 기술에는 어떤 것이 있나요?

- 7. 결론

What is Thermoforming and How Does Acrylic Fit In?

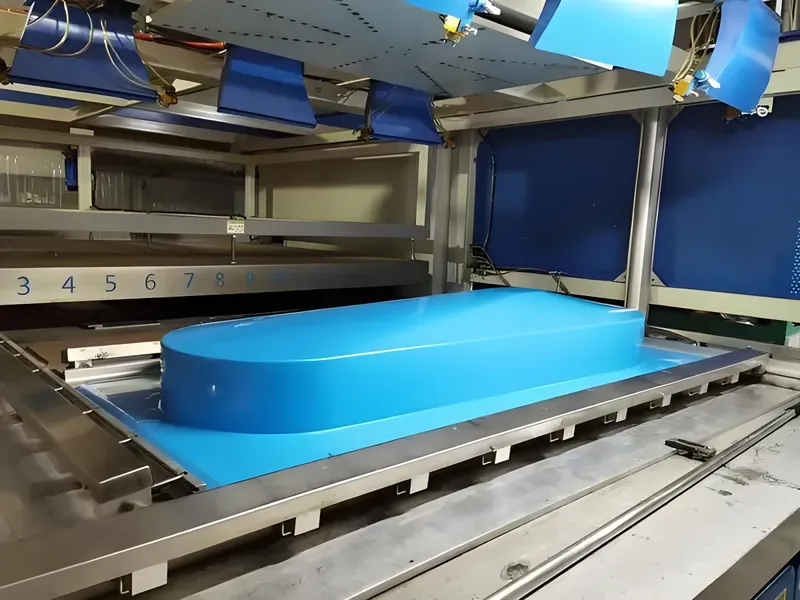

Thermoforming is a manufacturing process where a plastic sheet is heated until it’s soft and pliable, then formed into a specific shape using a mold. The process can be broken down into several techniques, including 진공 성형4, pressure forming, and mechanical forming.

Acrylic, specifically polymethyl methacrylate (PMMA)5, is a transparent thermoplastic known for its excellent optical clarity, high surface hardness, and resistance to UV light and weathering. It’s often used as a substitute for glass due to its lightweight and shatter-resistant properties.

Classification of Thermoforming and Acrylic Materials

-

Thermoforming Processes:

-

Acrylic Types:

- Cast Acrylic7: Produced by pouring liquid monomer into molds, offering superior optical clarity and higher molecular weight for better crazing resistance.

- Extruded Acrylic: Made by pushing plastic through a form, providing uniform thickness and lower cost but slightly reduced optical quality.

Where is Acrylic Thermoforming Commonly Used?

Acrylic thermoforming shines in industries requiring transparency, durability, and cost-efficiency. Here’s a look at typical applications and how acrylic stacks up.

Acrylic thermoforming8 is widely used in signage, medical devices, automotive components, and architecture for its clarity, lightweight nature, and cost-effectiveness in small to medium production runs.

| 애플리케이션 | Industry Example | Why Acrylic? |

|---|---|---|

| Signage & Displays | Illuminated signs | High clarity and light transmission |

| 의료 기기 | Equipment housings | Biocompatibility and visibility |

| 자동차 부품 | Light covers, dashboards | Durability and aesthetic appeal |

| Architecture | Skylights, canopies | Weather resistance and light transmission |

Pros and Cons of Acrylic in Thermoforming

-

장점:

- Cost-effective for small to medium runs (50-5,000 units)

Vacuum Forming products - Fast tooling production (typically 2-3 weeks)

- 우수 UV resistance and optical clarity9

- Lightweight and shatter-resistant compared to glass

- Cost-effective for small to medium runs (50-5,000 units)

-

단점:

- Limited ability to form complex shapes with undercuts

- Non-uniform wall thickness due to sheet forming

- Requires secondary operations like trimming

Acrylic thermoforming is ideal for applications requiring transparency and UV resistance.True

Acrylic’s clarity and weatherability make it perfect for outdoor signs and architectural features.

Acrylic is unsuitable for high-impact applications.True

For applications needing high impact strength, materials like polycarbonate are preferred.

How Does the Thermoforming Process Work with Acrylic?

The thermoforming process with acrylic is a carefully controlled sequence that transforms flat sheets into functional shapes. Here’s how it works and what makes acrylic unique.

Thermoforming with acrylic involves heating the sheet to 290-320°F, forming it using vacuum or pressure, cooling, and trimming, with careful control to avoid defects like warping.

프로세스 워크플로 분석

-

난방: Acrylic sheets are heated to their forming temperature—290-320°F for extruded acrylic, 340-380°F for cast acrylic—making them pliable.

-

형성: The sheet is shaped over or into a mold using vacuum, pressure, or mechanical methods.

-

냉각: The part is cooled uniformly to set its shape, preventing stress or warping.

-

트리밍: Excess material is removed, and finishing touches like polishing are applied.

재료 호환성

- Cast Acrylic: Its higher molecular weight resists stretching, ideal for thermal stability but less formable.

-

Extruded Acrylic: Easier to form with more detail, though it may shrink more during cooling.

-

첨가제: Acrylic can be colored or textured, but it’s sensitive to certain chemicals, often requiring protective coatings.

Uniform cooling is critical in thermoforming to prevent warping.True

Uneven cooling can cause internal stresses, leading to part deformation.

What are the Key Design Considerations for Acrylic Thermoforming?

Designing for acrylic thermoforming requires balancing aesthetics with manufacturability. Here are practical tools to guide your process.

Key design considerations include draft angles, radii, draw ratios, and managing wall thickness to avoid defects and ensure part strength.

디자인 체크리스트

-

초안 각도: Use 1.5°-2° for female molds, 4°-6° for male molds to ease part removal.

-

반지름: Avoid sharp corners to reduce stress concentrations.

-

그리기 비율: Calculate surface area to footprint ratio to determine starting sheet thickness.

-

벽 두께: Account for thinning in deep draw areas.

프로세스 선택 의사 결정

- 진공 성형: Best for simple, shallow parts with large radii.

- 압력 형성: Ideal for detailed parts with sharp features.

- 기계 성형: Suited for high-precision, complex geometries.

Pressure forming is necessary for parts with fine details.True

Pressure forming applies additional air pressure to achieve sharper corners and intricate designs.

How Does Acrylic Compare to Other Thermoforming Materials?

Choosing the right material is critical. Here’s how acrylic compares to alternatives like polycarbonate, ABS, and PETG.

Acrylic offers superior clarity and UV resistance but lower impact strength compared to materials like polycarbonate, making it ideal for specific applications.

| 재료 | 투명성 | 충격 강도 | Temperature Resistance | 비용 | 일반적인 애플리케이션 |

|---|---|---|---|---|---|

| Acrylic | 높음 | 낮음 | Up to 160°F | 보통 | 간판, 디스플레이, 채광창 |

| 폴리카보네이트 | 높음 | 매우 높음 | Up to 240°F | 높음 | Safety shields, machine guards |

| ABS | 낮음 | 높음 | Up to 180°F | 낮음 | 자동차 부품, 인클로저 |

| PETG | 높음 | Medium | Up to 150°F | 보통 | Medical devices, food packaging |

Polycarbonate is a better choice than acrylic for high-impact applications.True

Polycarbonate’s impact strength makes it suitable for safety and protective equipment.

열성형 관련 기술에는 어떤 것이 있나요?

Understanding acrylic thermoforming means looking at the bigger picture—upstream and downstream processes, plus alternatives.

Related technologies include acrylic sheet production (upstream), trimming and finishing (downstream), and alternative processes like injection molding for high-volume production.

-

업스트림: Acrylic sheets are made via casting or extrusion.

-

다운스트림: Parts undergo trimming, CNC machining, or assembly.

-

대안:

- 사출 성형: Better for high-volume, precise parts.

-

블로우 성형: Suited for hollow components.

Thermoforming is more flexible than injection molding for design changes.True

Thermoforming allows for quicker and cheaper tooling modifications, ideal for iterative design.

결론

Acrylic thermoforming offers a unique blend of clarity, durability, and cost-effectiveness for applications ranging from signage to medical devices. By mastering its process, weighing its pros and cons, and applying smart design principles, you can unlock its potential for your projects.

-

Discover the properties and applications of polymethyl methacrylate to see why it's a popular choice in many industries. ↩

-

Explore the advantages of acrylic in manufacturing to understand its unique properties and applications in various industries. ↩

-

Learn about the thermoforming process with acrylic to see how it can enhance product design and functionality. ↩

-

Learning about vacuum forming will provide insights into one of the key techniques in thermoforming and its practical applications. ↩

-

Exploring PMMA's properties will reveal its advantages in various applications, especially as a glass substitute. ↩

-

Discover how Pressure Forming enhances detail and precision in molded parts, crucial for high-quality manufacturing. ↩

-

Learn about the superior optical clarity and resistance properties of Cast Acrylic, making it a preferred choice for many applications. ↩

-

Explore the advantages of Acrylic thermoforming to understand its impact on industries like signage and automotive. ↩

-

Discover why acrylic's UV resistance and clarity make it ideal for applications in signage and medical devices. ↩