- 1. I. Basic Cognitive Level: Establishing Conceptual Framework

- 2. II. Application Analysis Level: Solving User Decision-Making Problems

- 3. III. Technical Deep Dive Level: Meeting Professional Reader Needs

- 4. IV. Practical Tools Level: Enhancing Content Operability

- 5. V. Extension Level: Building a Knowledge Network

I. Basic Cognitive Level: Establishing Conceptual Framework

Clear Definitions

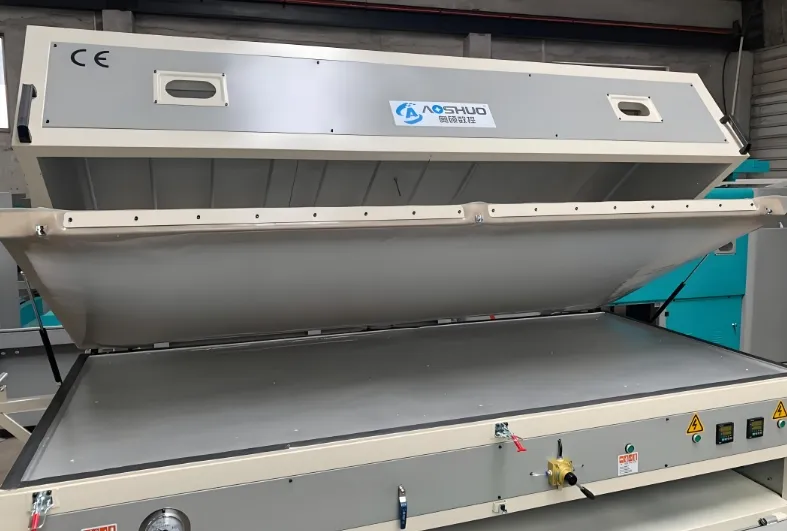

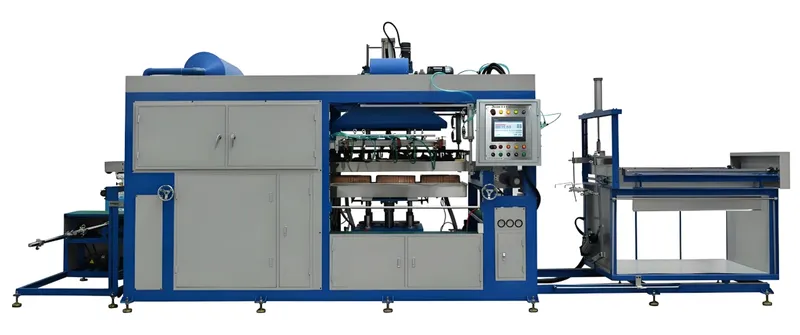

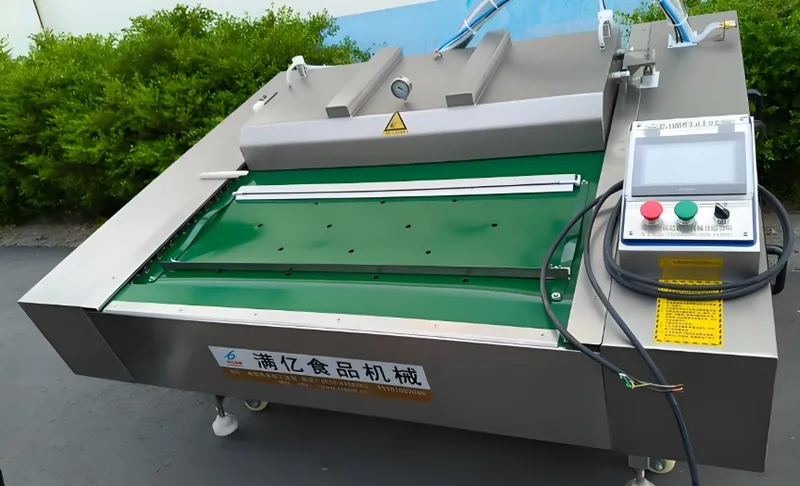

- Vacuum Forming Machine (Thermoforming Machine):

- Full Technical Name: Thermoforming Machine (Vacuum Forming is a specific type of thermoforming).

- Common Aliases: Vac Former, Thermoformer.

- Core Principle: A manufacturing process where a plastic sheet is heated to a pliable forming temperature, stretched onto or into a single-surface mold, and held against the mold by applying a vacuum between the mold surface and the sheet.

- Key Components Requiring Maintenance: Heaters (ceramic, quartz, halogen), vacuum pump, seals, clamping frame, mold platen, cooling system, control panel.

Classification (of Maintenance Approaches)

Understanding different maintenance types helps in planning:

-

Preventive Maintenance (PM)1: Scheduled inspections and servicing to prevent breakdowns. This is the most crucial type for vacuum formers.

- Process: Regular checks, cleaning, lubrication, replacement of wear parts before they fail.

- Materials: Lubricants, cleaning agents, spare seals, filters.

- Application: Daily, weekly, monthly, and annual checklists.

-

Corrective Maintenance (CM)2: Repairing the machine after a breakdown or malfunction has occurred.

- Process: Troubleshooting, diagnosing, repairing/replacing faulty components.

- Materials: Specific spare parts needed for the repair.

- Application: Unplanned, reactive. Aims to restore functionality ASAP.

- Predictive Maintenance (PdM)3: Using condition-monitoring tools to predict when maintenance should be performed.

- Process: Monitoring vibration, temperature, vacuum levels with sensors to detect anomalies.

- Materials: Sensors, diagnostic software.

- Application: More advanced; can reduce unnecessary PM and prevent unexpected CM.

II. Application Analysis Level: Solving User Decision-Making Problems

Why Prioritize Vacuum Former Maintenance?

For industries relying on vacuum forming (e.g., packaging, automotive interiors, medical device housings, point-of-sale displays), consistent machine performance is non-negotiable.

-

Ensures Consistent Part Quality4: Well-maintained heaters provide even heating, strong vacuum systems ensure proper material draw, and clean molds prevent surface defects.

-

Maximizes Uptime5: Prevents unexpected breakdowns that halt production, crucial for meeting export deadlines.

-

Extends Machine Lifespan: Reduces wear and tear on critical components, delaying costly replacements or new machine purchases.

-

Enhances Safety: Prevents electrical faults, air leaks, or mechanical failures that could injure operators.

-

Reduces Operational Costs6: Minimizes waste from rejected parts and reduces the likelihood of expensive emergency repairs.

Pros of Good Maintenance vs. Cons of Neglect

| Aspect | Good Maintenance (Pro) | Neglect (Con) |

|---|---|---|

| Output Quality | Consistent, high-quality parts | Inconsistent quality, high defect rates |

| Machine Uptime | High reliability, planned downtime only | Frequent unexpected breakdowns, lost production |

| Operational Cost | Lower long-term costs, efficient energy use | High repair costs, wasted material & energy |

| Machine Lifespan | Extended operational life | Premature failure, costly replacement |

| Safety | Safer working environment | Increased risk of accidents and injuries |

III. Technical Deep Dive Level: Meeting Professional Reader Needs

Process Full Workflow Breakdown for Maintenance (General Schedule)

This is a general guideline. Always refer to your specific machine's manual for detailed instructions and frequencies.

-

Daily Checks (Before & During Operation):

- Visual Inspection: Check for loose wires, damaged hoses, debris around heaters or moving parts.

- Heaters: Ensure all heating elements are functioning (visually check for even glow when appropriate).

- Clamping Frame: Check for smooth operation and secure material holding.

- Work Area: Keep clean and free of plastic trimmings and dust.

- Emergency Stops: Verify functionality.

-

Weekly Checks:

- Vacuum Seals: Inspect door/platen seals for wear, cracks, or compression. Clean them.

- Vacuum Pump7: Check oil level (if oil-lubricated pump). Listen for unusual noises.

- Air Filters: Inspect and clean/replace primary air filters for the vacuum pump and cooling fans.

- Heater Reflectors: Clean any dust or residue buildup for optimal heat reflection.

- Moving Parts: Lightly lubricate guides, bearings, and linkages as per manual.

-

Monthly Checks:

- Vacuum System Test: Measure maximum vacuum level; compare to machine specifications. Check for leaks in hoses and connections.

- Electrical Connections8: (Requires qualified personnel) Inspect terminals in the control cabinet for tightness and signs of overheating.

- Cooling System: Clean fan blades and shrouds. If water-cooled, check for leaks and flow.

- Heater Elements: Thoroughly inspect for signs of sagging, burnout, or damage. Check connections.

- Pneumatic System (if applicable): Check for air leaks in cylinders and valves. Drain water from air line filters.

-

Annual/Semi-Annual Checks (Often requires professional service):

- Vacuum Pump Service: Oil change, vane inspection/replacement (for rotary vane pumps), thorough filter replacement.

- Comprehensive Electrical Inspection: Check wiring integrity, contactor wear, safety circuit functionality.

- Calibration: Temperature controller calibration, platen parallelism.

- Structural Integrity: Inspect frame welds and fasteners.

Material Compatibility Explanation (Impact on Maintenance)

The type of plastic being formed can influence maintenance needs:

-

PVC (Polyvinyl Chloride): Can release corrosive gases (HCl) when overheated. Requires good ventilation and more frequent cleaning of metal parts, especially reflectors and heater elements, to prevent corrosion.

-

ABS (Acrylonitrile Butadiene Styrene) & HIPS (High Impact Polystyrene): Generally clean to run. Standard maintenance applies.

-

PETG (Polyethylene Terephthalate Glycol): Can be more prone to stringing or "angel hair." Requires diligent cleaning around the mold and clamp frame.

-

Polycarbonate (PC): Requires higher forming temperatures. This can put more stress on heaters and surrounding components over time. Ensure heater elements are rated for these temperatures.

-

Filled Materials (e.g., talc-filled PP, glass-filled plastics): Abrasive fillers can accelerate wear on mold surfaces (though less of an issue for the machine itself compared to injection molding). Dust from these materials can be more pervasive, requiring more frequent filter cleaning.

IV. Practical Tools Level: Enhancing Content Operability

Design Checklist for Maintenance Procedures (Reminders)

-

Safety First: Is the machine powered off and locked out/tagged out (LOTO) before starting any maintenance?

-

Refer to Manual: Is the machine-specific maintenance manual readily available and consulted?

-

Correct Tools & PPE: Are you using the appropriate tools and Personal Protective Equipment (gloves, safety glasses, etc.)9?

-

Cleanliness: Is the machine cleaned before, during, and after maintenance?

-

Lubrication: Are the correct lubricants being used as specified by the manufacturer?

-

Inspection Detail: Are you looking for wear, damage, loose parts, leaks, and unusual noises/smells?

-

Part Replacement: Are replacement parts OEM or equivalent quality?

-

Test After Maintenance: After maintenance, is the machine tested under supervision before returning to full production?

-

Log Keeping: Is all maintenance work, including dates, tasks performed, and parts replaced, recorded in a maintenance log10?

-

Operator Training: Are operators trained to perform daily checks and report issues?

Process Selection Decision-Making (Basic Maintenance Troubleshooting Flow)

This is a simplified decision prompt for common issues:

- Problem: Poor Vacuum / Slow Draw

- Check seals (platen, door): Worn, dirty, or misaligned? -> Clean/Replace.

- Check hoses & fittings: Leaks, kinks, loose? -> Tighten/Replace.

- Check vacuum pump oil (if applicable): Low, dirty? -> Top up/Change.

- Check vacuum pump filter: Clogged? -> Clean/Replace.

- Still an issue? -> Consider pump internal wear or valve malfunction (Professional Service11).

-

Problem: Uneven Heating / Cold Spots

- Check heater elements: Any visibly burnt out or not glowing? -> Replace faulty element(s).

- Check heater wiring & connections: Loose, corroded, or burnt? -> Tighten/Clean/Replace (Qualified Personnel).

- Check heater reflectors: Dirty, dull? -> Clean.

- Check temperature controller settings: Correct for material? -> Adjust.

- Still an issue? -> Suspect faulty temperature controller or power supply issue (Professional Service).

-

Problem: Marks or Imperfections on Formed Part

- Check mold surface: Dirty, damaged, or debris? -> Clean/Repair mold.

- Check plastic sheet: Contamination, moisture, scratches? -> Use clean, dry material.

- Check heating: Overheating (webbing, thinning) or underheating (poor definition)? -> Adjust temperature/time.

- Check vacuum: Insufficient for full draw? -> See "Poor Vacuum" troubleshooting.

V. Extension Level: Building a Knowledge Network

Related Technology Navigation

Understanding the context of your vacuum forming machine helps in holistic maintenance:

-

Upstream Technologies:

- Material Storage & Handling: Proper storage (e.g., drying hygroscopic plastics like PETG or PC before forming) impacts material behavior and final part quality. Dust control in storage also reduces machine contamination.

- Sheet Extrusion (if producing own sheet): Maintenance of extruders, dies, and calendars is crucial for consistent sheet quality, which directly affects forming.

- Pre-heating Ovens (Separate): If used, these also require heater and control system maintenance.

-

Downstream Technologies:

- Trimming Equipment (CNC Routers, Die Cutters, Clicker Presses): These have their own maintenance needs (blades, bits, hydraulics, pneumatics, controls) that are vital for finishing formed parts.

- Assembly/Fabrication Stations: Tools and jigs used post-forming also require upkeep.

-

Related Maintenance Concepts:

- Total Productive Maintenance (TPM): A holistic approach involving all employees in maintenance.

- Root Cause Analysis (RCA): Investigating failures to find the underlying cause, not just treating symptoms.

- Spare Parts Management: Maintaining an inventory of critical spare parts to minimize downtime.

By implementing a robust maintenance schedule and fostering a proactive maintenance culture, you can significantly enhance the performance and longevity of your vacuum forming machines. This commitment to operational excellence is something we value deeply at ZetarMold, as it directly translates to the quality and reliability of the products we deliver to our international clients.

-

Explore this link to learn effective strategies for Preventive Maintenance that can enhance the longevity and performance of your vacuum former. ↩

-

Discover insights on implementing Corrective Maintenance to quickly restore functionality and minimize downtime for your equipment. ↩

-

Learn about advanced tools and techniques for Predictive Maintenance that can help you anticipate issues before they arise, ensuring smooth operations. ↩

-

Understanding the importance of consistent part quality can help improve production processes and reduce defects. ↩

-

Exploring uptime maximization strategies can lead to more efficient operations and better meeting of deadlines. ↩

-

Learning about cost-reduction strategies can significantly enhance profitability and operational efficiency. ↩

-

Understanding vacuum pump maintenance is crucial for optimal performance and longevity. Explore this resource for expert insights. ↩

-

Proper inspection of electrical connections ensures safety and efficiency. This resource provides essential guidelines for safe practices. ↩

-

Understanding the best practices for PPE can enhance safety and compliance during maintenance tasks. ↩

-

An effective maintenance log is crucial for tracking machine performance and ensuring compliance with safety standards. ↩

-

Knowing when to seek professional help can prevent costly repairs and ensure machinery operates safely and efficiently. ↩