Thermoforming is a widely used manufacturing process that shapes heated plastic sheets into functional products by forming them over molds. Central to this process are two primary mold types: positive molds1 (also called male molds) and negative molds2 (also called female molds). These molds differ fundamentally in how they shape the plastic, influencing the design, material thickness, and application of the final product.

Positive molds shape the inside of the product by stretching the plastic over their exterior, while negative molds shape the outside by drawing the plastic into a cavity, affecting both functionality and aesthetics.

This article explores the differences between positive and negative molds in thermoforming, covering their definitions, applications, workflows, and practical considerations. Whether you’re a designer, manufacturer, or simply curious about the process, this guide will equip you with the knowledge to understand and choose between these mold types effectively.

Positive molds are better for internal details, while negative molds are ideal for external aesthetics.Vero

Positive molds stretch the plastic over their surface, shaping the interior precisely, which suits internal features. Negative molds pull the plastic into a cavity, defining the exterior, making them better for outward appearance.

One mold type is always superior to the other.Falso

Neither positive nor negative molds are universally better; the choice depends on the product’s specific needs, such as internal precision versus external finish.

- 1. What are Positive and Negative Molds in Thermoforming?

- 2. How are Positive and Negative Molds Classified?

- 3. What are the Typical Applications of Positive and Negative Molds?

- 4. What are the Pros and Cons of Positive and Negative Molds?

- 5. What is the Full Workflow of the Thermoforming Process for Each Mold Type?

- 6. How Do Different Materials Affect Positive and Negative Molds?

- 7. What are the Design Considerations for Positive and Negative Molds?

- 8. How to Choose Between Positive and Negative Molds?

- 9. Quali sono le tecnologie correlate alla termoformatura?

- 10. Conclusione

What are Positive and Negative Molds in Thermoforming?

To grasp the differences, let’s define each mold type and their core principles in the processo di termoformatura3.

Positive molds (male molds)4 form the interior of the product by stretching the plastic sheet over a convex shape, while negative molds (female molds) form the exterior by drawing the sheet into a concave cavity.

Definizioni e principi fondamentali

-

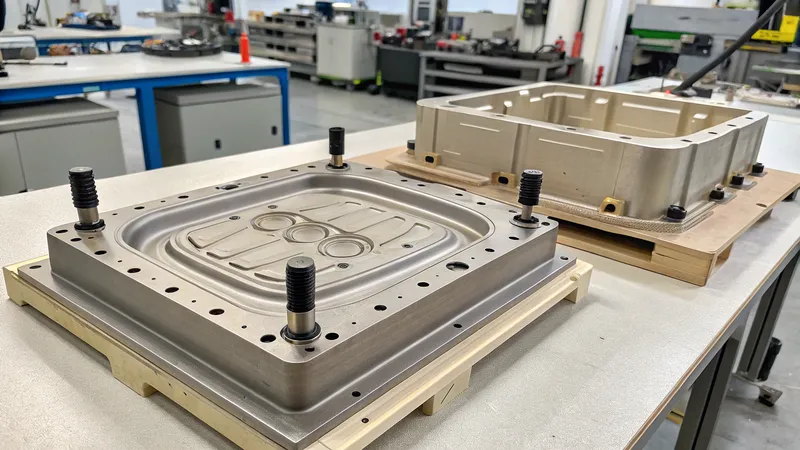

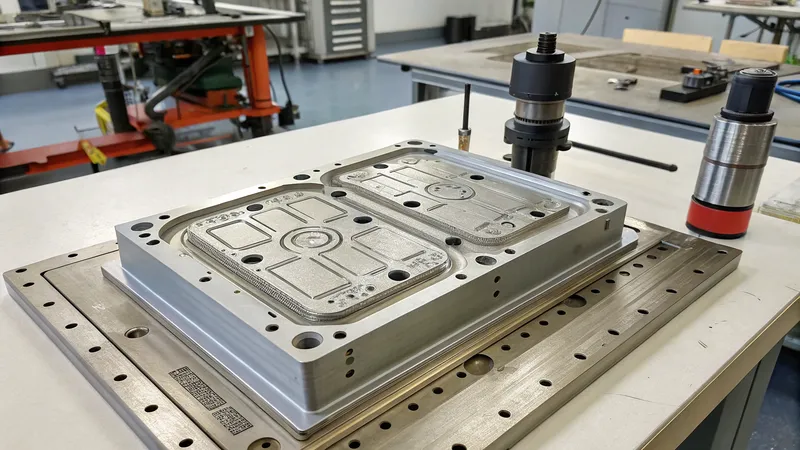

Positive Mold (Male Mold): A convex mold where the heated plastic sheet is draped over its surface. This shapes the inside of the product, making it ideal for applications where internal dimensions or finishes are critical, such as trays or containers.

-

Negative Mold (Female Mold): A concave mold with a cavity into which the heated plastic is pulled, typically using a vacuum. This shapes the outside of the product, perfect for items where external appearance matters, like automotive panels or electronic housings.

How They Work:

-

Positive Molds: The plastic stretches over the mold, transferring its shape to the product’s interior. This can lead to thinner material at edges but ensures precise internal features.

-

Negative Molds: The plastic is drawn into the mold, defining the exterior. This maintains more uniform thickness, enhancing structural integrity5 and external detail.

How are Positive and Negative Molds Classified?

Classifying these molds helps determine their best use based on process, materials, and applications.

Positive and negative molds differ in how they interact with the plastic sheet, the materials they suit, and the products they’re best for.

| Tipo di classificazione | Positive Mold (Male Mold) | Negative Mold (Female Mold)6 |

|---|---|---|

| Process Interaction | Stretches plastic over the mold | Draws plastic into the mold |

| Compatibilità dei materiali7 | Works well with HIPS, ABS | Ideal for PET, PVC |

| Applicazioni | Trays, containers, medical parts | Automotive panels, electronics |

Classification Breakdown

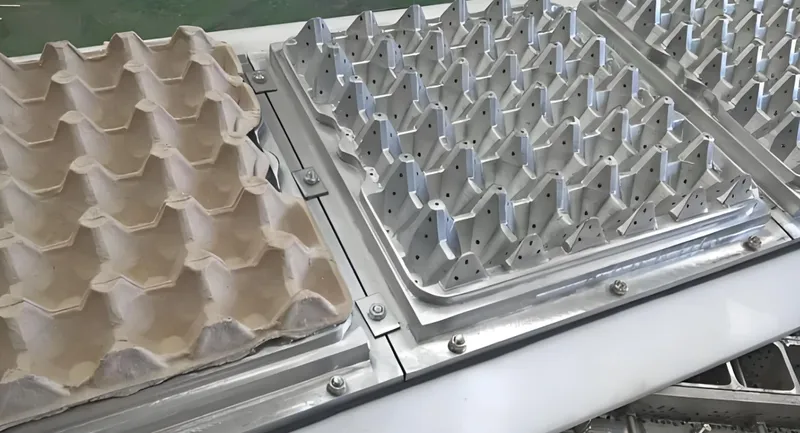

- Per processo: Positive molds stretch the plastic over a raised surface, while negative molds use suction to pull it into a recessed cavity.

-

Con i materiali: Both handle thermoplastics like PET, PVC, polystyrene (PS), high-impact polystyrene (HIPS), and acrylonitrile butadiene styrene (ABS). Positive molds may thin stretchy materials like PET, while negative molds maintain thickness with less flexible ones.

-

Per applicazioni: Positive molds suit products needing precise internal shapes (e.g., packaging trays), while negative molds excel for items requiring sleek exteriors (e.g., car dashboards).

What are the Typical Applications of Positive and Negative Molds?

The mold type you choose depends on what your product needs to do and how it should look.

Positive molds are great for products where the inside matters most, while negative molds shine when the outside takes priority.

Application Examples

-

Positive Molds:

- Imballaggio: Trays and containers where internal fit is key.

- Dispositivi medici: Parts with exact internal channels.

- Small-Scale Production: Simple shapes like displays or daily items.

-

Negative Molds:

- Automobile: Panels and dashboards with smooth exteriors.

- Elettronica di consumo: Housings with a polished look.

- Mass Production: Complex external shapes for medical or tech products.

Positive molds are limited to basic shapes.Falso

Positive molds can manage complex internal designs with proper planning, not just simple forms.

Negative molds ensure consistent thickness better than positive molds.Vero

By drawing plastic into a cavity, negative molds distribute material evenly, unlike the stretching in positive molds.

What are the Pros and Cons of Positive and Negative Molds?

Each mold type has strengths and weaknesses that impact their suitability.

Positive molds offer internal accuracy but may thin the material, while negative molds provide thickness consistency but require more complex setups.

| Tipo di stampo | Pro | Contro |

|---|---|---|

| Positive Mold | - Precise internal shapes - Faster cycles - Cheaper molds, longer lifespan |

- Thinning at edges - Less suited for complex exteriors - Wrinkles with steep angles |

| Negative Mold | - Even thickness for strength - Detailed external shapes - Good for large parts |

- Slower cycles - Higher equipment needs - More material waste |

Comparison to Other Methods

-

Vs. Injection Molding: Positive molds are less precise but more affordable for small runs; negative molds offer better detail but not the complexity of injection molding.

-

Vs. Blow Molding: Negative molds provide superior surface finish, while blow molding is better for hollow items.

What is the Full Workflow of the Thermoforming Process for Each Mold Type?

The thermoforming process varies slightly depending on the mold type, but both follow a similar sequence.

Thermoforming heats a plastic sheet, forms it over or into a mold, cools it, and trims it, with differences based on whether it’s a positive or negative mold.

Positive Mold Workflow

-

Riscaldamento: A plastic sheet is heated until pliable.

-

Formazione: The sheet is stretched over the convex mold using vacuum or pressure, shaping the interior.

-

Raffreddamento: The plastic cools on the mold, retaining its shape (edges may show cooling marks).

-

Rifinitura: Excess material is cut away, addressing uneven edges.

Key Factors:

-

Vacuum strength to avoid thinning.

-

Cooling time to prevent distortion.

-

Mold angles to reduce wrinkles.

Negative Mold Workflow

-

Riscaldamento: Same heating process.

-

Formazione: The sheet is pulled into the concave mold cavity, shaping the exterior.

-

Raffreddamento: The plastic cools in the cavity, maintaining thickness.

-

Rifinitura: Excess is trimmed, with even edges.

Key Factors:

-

Pressure for detailed shaping.

-

Draft angles for demolding.

-

Temperature to ensure cavity fill.

Positive molds always thin the material at edges.Vero

Stretching over the mold naturally thins the plastic at corners and edges.

Negative molds can’t be used for small batches.Falso

Negative molds work for small runs too, especially for detailed exteriors, though they’re more common in mass production.

How Do Different Materials Affect Positive and Negative Molds?

The plastic you use influences how each mold performs and the product’s outcome.

Material stretch and shrinkage affect how well positive and negative molds shape the plastic.

-

Positive Molds: Best with HIPS or ABS for internal precision. Stretchy materials like PET may thin too much.

-

Negative Molds: Suited for PET or PVC, maintaining thickness for external detail. Stiffer materials may thin in deep cavities.

Material Effects:

-

Stretchability: Impacts thinning in positive molds.

-

Shrinkage: Requires mold adjustments for accuracy.

-

Flessibilità: Eases demolding in negative molds.

What are the Design Considerations for Positive and Negative Molds?

Designing for thermoforming means tailoring to each mold’s strengths and limits.

Checklists ensure your design matches the mold type’s capabilities.

Positive Mold Checklist

-

Plan for edge thinning with sharp features.

-

Prioritize internal details over external ones.

-

Assess if secondary finishing is needed for exteriors.

-

Keep shapes simpler for cost-effectiveness.

Negative Mold Checklist

-

Focus on external aesthetics and finish.

-

Ensure even material flow into the cavity.

-

Add draft angles for removal.

-

Confirm equipment supports larger-scale needs.

How to Choose Between Positive and Negative Molds?

Picking the right mold involves weighing your product’s needs and production goals.

Use these prompts to decide which mold fits your project.

Decision Prompts

-

Does the inside shape matter most? → Go with a positive mold for internal accuracy.

-

Is the outside look critical? → Choose a negative mold for external appeal.

-

Are there complex features? → Test both molds for feasibility.

-

What’s your budget and volume? → Positive molds for low-cost, small runs; negative molds for high-volume complexity.

Positive molds are always less expensive.Falso

Initial costs may be lower for positive molds, but total expenses vary with volume and material use.

Quali sono le tecnologie correlate alla termoformatura?

Thermoforming connects to a network of technologies that enhance its capabilities.

Material science, mold-making tools, and finishing processes tie into positive and negative molding.

-

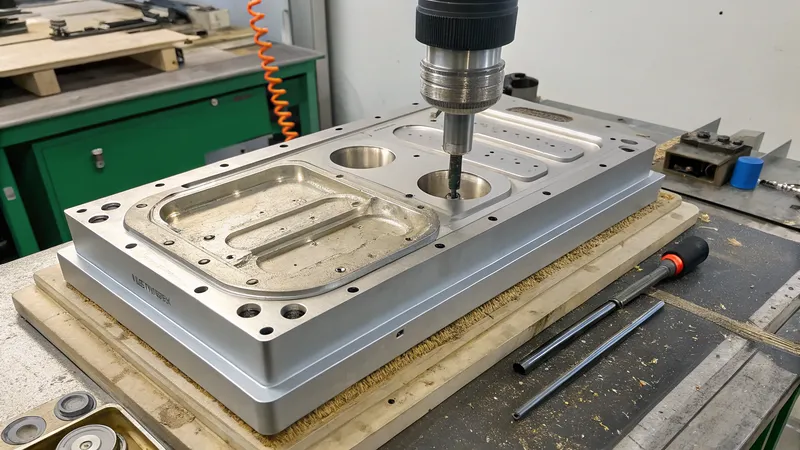

A monte: Thermoplastic development, CAD software, CNC machining for molds.

-

A valle: Trimming, painting, or assembling finished parts.

-

Alternative: Injection molding (complex parts), blow molding (hollow items), extrusion (sheets).

Conclusione

Positive and negative molds bring distinct advantages to thermoforming. Positive molds deliver precise internal shapes, while negative molds excel at uniform thickness and external detail. Your choice hinges on what your product demands—inside fit or outside finish—along with practical factors like cost and scale.

With this understanding, you can confidently navigate thermoforming to create products that meet both functional and aesthetic goals.

-

Explore this link to understand how positive molds work and their applications in the thermoforming process. ↩

-

Discover the role of negative molds in shaping products and their impact on design and functionality. ↩

-

The thermoforming process is key to various manufacturing techniques. Learn about its principles and applications to enhance your knowledge. ↩

-

Understanding positive molds is crucial for applications requiring precise internal dimensions. Explore this link to learn more about their applications and benefits. ↩

-

Learn about the importance of structural integrity in manufacturing and how it affects product durability and performance. ↩

-

Learn about the functionality and applications of Negative Molds, particularly in creating sleek exteriors for products. ↩

-

Discover the range of materials suitable for both mold types, enhancing your understanding of their applications in manufacturing. ↩