Thermoforming transforms plastic sheets into precise shapes using heat and molds, but additional tooling like heating systems1, vacuum or pressure devices, and trimming tools2 is essential for a complete production cycle.

Thermoforming relies on more than just molds; heating equipment, forming systems, and trimming tools work together to create parts for packaging, automotive, and medical applications, ensuring efficiency and quality.

Understanding the full scope of tooling in thermoforming is key to optimizing production and achieving high-quality results. This guide explores the process, tooling requirements, and practical considerations to help you make informed manufacturing decisions.

Thermoforming only requires a mold to produce parts.False

Beyond the mold, thermoforming necessitates heating devices, vacuum or pressure systems, and trimming tools to complete the process.

Thermoforming is limited to simple packaging applications.False

Thermoforming serves diverse industries, including automotive and medical, producing complex parts beyond basic packaging.

- 1. What is Thermoforming and Why is Tooling Important?

- 2. What are the Different Types of Thermoforming Processes?

- 3. How Does Thermoforming Compare to Other Manufacturing Processes?

- 4. What are the Key Steps in the Thermoforming Process?

- 5. How Do Different Materials Affect the Thermoforming Process?

- 6. What are the Design Considerations for Thermoforming?

- 7. When Should You Choose Thermoforming Over Other Processes?

- 8. What are the Related Technologies in Thermoforming?

- 9. Conclusion

What is Thermoforming and Why is Tooling Important?

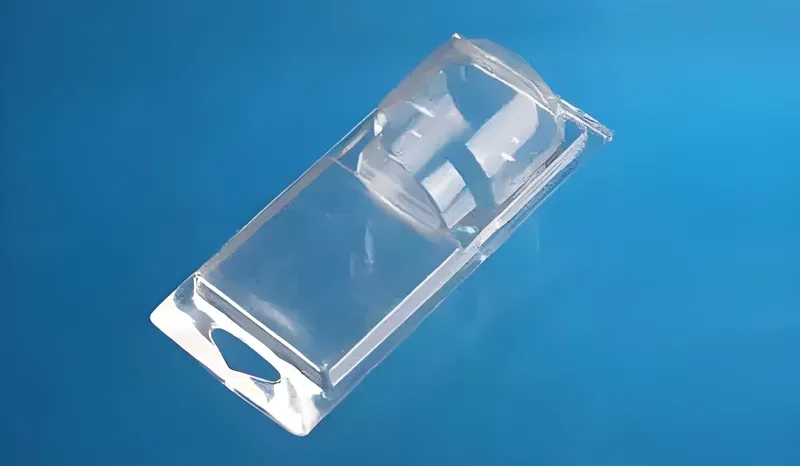

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable state, shaped over a mold, and trimmed to create a usable product. While the mold defines the part’s geometry, other tools are critical for heating, forming, and finishing.

Thermoforming combines molds, heating systems, vacuum or pressure devices3, and trimming tools to produce lightweight, durable parts across industries like packaging, automotive, and consumer goods.

| Tooling Type | Function | Importance |

|---|---|---|

| Mold | Shapes the plastic sheet | Defines part geometry |

| Heating System | Softens the plastic | Ensures uniform pliability |

| Vacuum/Pressure System | Forms the sheet to the mold | Achieves detailed shaping |

| Trimming Tools | Cuts excess material | Finishes the part |

The Role of Each Tool

The mold is the cornerstone, but heating systems ensure the plastic is pliable, vacuum or pressure systems conform it to the mold, and trimming tools refine the final shape. Each component is indispensable, and overlooking any can compromise quality or efficiency.

Heating systems are optional in thermoforming.False

Heating systems are essential to soften the plastic sheet for forming.

Trimming tools are necessary for all thermoforming applications.True

Trimming removes excess material to achieve the final part shape.

What are the Different Types of Thermoforming Processes?

Thermoforming includes several methods, each with unique tooling needs and suited to specific applications, offering flexibility for various part complexities and production scales.

Thermoforming4 processes—vacuum forming, pressure forming, mechanical forming, and drape forming—cater to diverse needs, from simple packaging to detailed automotive components.

Vacuum Forming

Vacuum forming uses a vacuum to pull the heated sheet onto the mold, ideal for simple shapes like packaging trays.

Pressure Forming

Pressure forming applies air pressure to push the sheet into the mold, enabling finer details for applications like medical housings.

Mechanical Forming

Mechanical forming employs matching male and female molds for high precision, used in aerospace or complex parts.

Drape Forming

Drape forming drapes the sheet over a male mold, suitable for large, simple shapes like signs.

| Process Type | Tooling Involved | Typical Applications |

|---|---|---|

| Vacuum Forming5 | Mold, vacuum system | Packaging trays, cups |

| Pressure Forming6 | Mold, pressure system | Automotive panels, medical |

| Mechanical Forming | Male and female molds | Aerospace components |

| Drape Forming | Male mold | Signs, light covers |

Vacuum forming is the only type of thermoforming.False

Other methods like pressure forming and mechanical forming offer different capabilities.

Pressure forming achieves more detailed parts than vacuum forming.True

Pressure forming uses air pressure for sharper details and textures.

How Does Thermoforming Compare to Other Manufacturing Processes?

Thermoforming offers unique benefits and trade-offs compared to alternatives like injection molding and blow molding, making it ideal for specific scenarios.

Thermoforming excels at producing large parts with lower tooling costs, while injection molding suits high-volume, complex parts, and blow molding targets hollow items.

Thermoforming vs. Injection Molding

Thermoforming has lower tooling costs and faster setup, perfect for low to medium volumes, whereas injection molding offers precision for high-volume production.

Thermoforming vs. Blow Molding

Blow molding creates hollow parts like bottles, while thermoforming produces open shapes like trays or panels.

| Aspect | Thermoforming | Injection Molding7 | Blow Molding8 |

|---|---|---|---|

| Tooling Cost | Low to moderate | High | Moderate |

| Setup Time | Short | Long | Moderate |

| Part Size | Large parts | Small to medium | Medium to large |

| Precision | Moderate | High | Low to moderate |

| Production Volume | Low to medium | High | Medium to high |

Thermoforming is more cost-effective than injection molding for high-volume production.False

Injection molding is more economical at scale due to lower per-part costs.

Thermoforming can produce hollow parts like blow molding.False

Thermoforming is suited for open shapes, not hollow structures.

What are the Key Steps in the Thermoforming Process?

Thermoforming involves a series of steps, each requiring specific tooling and careful control to produce consistent, high-quality parts.

The thermoforming process9 includes material selection10, heating, forming, cooling, trimming, and finishing, with each step critical to the final outcome.

Material Selection

Choosing the right thermoplastic—e.g., polystyrene or ABS—depends on the application’s needs.

Heating

The sheet is heated to its forming temperature (e.g., 120-200°C) using ovens or infrared heaters.

Forming

The heated sheet is shaped using vacuum, pressure, or mechanical molds.

Cooling

The part is cooled with fans or water-cooled molds to set its shape.

Trimming

Excess material is removed with tools like CNC routers or knives.

Finishing

Optional steps like hole punching or surface treatments refine the part.

Uniform heating is critical in thermoforming.True

Uneven heating can cause warping or incomplete forming.

Cooling is an optional step in thermoforming.False

Cooling sets the part’s shape and prevents deformation.

How Do Different Materials Affect the Thermoforming Process?

Material selection influences forming temperatures, shrinkage, and tooling, directly impacting the process and part quality.

Materials like polystyrene, polypropylene, and ABS vary in forming temperature11 and shrinkage, requiring tailored tooling and parameters.

Polystyrene (PS)

Easy to form and cost-effective, but brittle; used for packaging.

Polypropylene (PP)

High impact resistance, ideal for food containers; has higher shrinkage.

ABS

Strong and detailed, suited for automotive parts; moderate shrinkage.

| Material | Forming Temperature | Shrinkage Rate | Common Applications |

|---|---|---|---|

| Polystyrene | 120-180°C | 0.3-0.5% | Packaging, disposables |

| Polypropylene | 150-170°C | 1.5-2.2% | Food trays, automotive |

| ABS | 130-160°C | 0.5-0.8% | Consumer goods, panels |

All thermoforming materials have the same forming temperature.False

Each material requires a specific temperature range based on its properties.

Material shrinkage must be considered in mold design.True

Shrinkage affects final dimensions, requiring mold adjustments.

What are the Design Considerations for Thermoforming?

Effective design ensures parts are formable and functional, accounting for process and tooling limitations.

Key considerations include draft angles12, undercuts, shrinkage, wall thickness, and trimming to optimize thermoforming outcomes.

Draft Angles

Use 3-5° for male molds and 1-2° for female molds for easy demolding.

Undercuts

Avoid or use removable mold sections to prevent sticking.

Shrinkage

Adjust for 0.5-2% shrinkage13 based on material.

Wall Thickness

Maintain uniformity to avoid thinning.

Trimming

Design for accessible, precise trimming.

Draft angles are unnecessary in thermoforming.False

Draft angles aid demolding and prevent damage.

Uniform wall thickness is important in thermoforming.True

It prevents thinning and ensures consistent strength.

When Should You Choose Thermoforming Over Other Processes?

Thermoforming shines in specific scenarios, balancing cost, speed, and part requirements.

Opt for thermoforming for large parts, low to medium volumes, and when tooling costs and setup time are priorities.

Decision-Making Guide

-

Part Size: Large parts impractical for injection molding.

-

Volume: 100-10,000 parts annually.

-

Budget: Lower tooling costs.

-

Lead Time: Faster setup.

Thermoforming is ideal for high-volume production of small, complex parts.False

Injection molding is better for high-volume, complex parts.

Thermoforming offers faster setup times than injection molding.True

Simpler molds reduce lead times.

What are the Related Technologies in Thermoforming?

Thermoforming integrates with broader manufacturing processes, enhancing its utility.

Related technologies include sheet extrusion, trimming, finishing, and assembly, linking thermoforming to upstream and downstream operations.

Upstream Technologies

- Plastic Sheet Extrusion: Produces the raw sheets.

Downstream Technologies

-

Trimming and Finishing: Refines parts with cutting or treatments.

-

Assembly: Combines parts with other components.

Thermoforming is a standalone process without related technologies.False

It connects with extrusion, trimming, and assembly processes.

Plastic sheet extrusion is essential for thermoforming.True

Extruded sheets are the starting material.

Conclusion

Thermoforming is a versatile process that goes beyond the mold, requiring heating systems, vacuum or pressure devices, and trimming tools to produce high-quality parts. Understanding these tooling needs ensures efficient production and optimal results across industries.

Thermoforming can be performed without heating the plastic sheet.False

Heating is required to make the plastic pliable.

Material choice affects only the appearance of thermoformed parts.False

It impacts forming temperature, shrinkage, and properties.

-

Explore this link to discover the latest heating systems that enhance efficiency and quality in thermoforming processes. ↩

-

Learn about various trimming tools that ensure precision and quality in the final product of thermoforming. ↩

-

Understanding the role of these devices can significantly improve your thermoforming process and product quality. ↩

-

Explore the advantages of Thermoforming, including cost-effectiveness and flexibility in production, to enhance your understanding of this process. ↩

-

Learn about Vacuum Forming, its process, and applications in various industries, which can help you understand its practical uses. ↩

-

Discover the intricacies of Pressure Forming, its benefits, and applications, which can provide insights into advanced manufacturing techniques. ↩

-

Learn about Injection Molding's precision and efficiency compared to other methods for better decision-making. ↩

-

Discover the various applications of Blow Molding to see how it fits into different manufacturing needs. ↩

-

Understanding the thermoforming process is essential for producing high-quality parts. Explore this link for detailed insights. ↩

-

Material selection is crucial in thermoforming, impacting quality and performance. Discover more about its significance here. ↩

-

Forming temperature directly influences the quality of the final product. Learn more about its critical role in the process. ↩

-

Learn how draft angles influence the demolding process and overall part quality in thermoforming applications. ↩

-

Discover how to manage shrinkage in thermoforming to ensure precision and quality in your final products. ↩