Extrusion is a vital manufacturing process used to create products like plastic pipes, films, and profiles for industries ranging from packaging to automotive. However, ensuring consistent quality and efficiency can be a challenge without precise oversight. Enter real-time process control1—a method that uses sensors and automation to monitor and adjust the extrusion process on the fly. But how do you implement it effectively in your operation? Let’s break it down step-by-step.

Real-time process control in extrusion leverages sensors2 and automated systems to continuously monitor and adjust parameters like temperature, pressure, and dimensions, ensuring high-quality output and operational efficiency in industries such as packaging and construction.

This blog will guide you through the essentials of implementing real-time process control, from understanding its core principles to selecting the right tools. Whether you’re aiming to reduce waste or boost production rates, this approach could be your key to staying competitive.

Real-time process control reduces defects in extrusion.True

By instantly correcting variations in key parameters, it prevents inconsistencies that lead to defects.

Real-time control is impractical for small-scale manufacturers.False

Though setup costs exist, the long-term gains in efficiency and waste reduction make it viable even for smaller operations.

- 1. What is Real-Time Process Control in Extrusion?

- 2. How to Implement Real-Time Process Control in Extrusion

- 3. What Key Parameters Should You Monitor?

- 4. How Does Material Choice Impact Real-Time Control?

- 5. What Are the Pros and Cons of Real-Time Process Control?

- 6. How to Pick the Right Control System

- 7. Conclusion

What is Real-Time Process Control in Extrusion?

Imagine a system that acts like an expert operator, constantly watching your extrusion line and making adjustments to keep everything on track. That’s real-time process control in a nutshell. It uses sensors to track critical variables—think temperature, pressure, and product dimensions—while a control system processes this data and tweaks the machinery accordingly. The result? Consistent output, whether you’re producing thin films or sturdy pipes.

Real-time process control in extrusion employs sensors and automation to monitor and adjust temperature, pressure, and dimensions, maintaining product quality and efficiency across manufacturing applications.

| Component | Role |

|---|---|

| Sensors | Measure temperature (thermocouples), pressure (gauges), and dimensions (lasers) |

| Control Systems | Analyze data and adjust settings (e.g., PLCs or software like EPIC III®) |

| Adjustments | Modify screw speed, heating zones, or feed rates |

Why It’s a Game-Changer

In extrusion, small deviations can snowball into big problems—think warped products or excessive scrap. Real-time control nips these issues in the bud by making instant corrections. It’s particularly valuable in high-stakes industries like medical device manufacturing, but even general production lines benefit from the reduced downtime and improved consistency.

Real-time control is only useful for precision industries.False

It enhances efficiency and reduces waste across all extrusion applications, not just high-precision ones.

Real-time control can cut production interruptions.True

By preventing defects early, it reduces the need for stoppages and rework.

How to Implement Real-Time Process Control in Extrusion

Getting started with real-time process control3 doesn’t have to be overwhelming. It boils down to three key elements: sensors, a control system, and operator interfaces. Here’s how to put them into action:

1. Deploy Sensors

Sensors are your frontline data collectors. You’ll need:

-

Thermocouples to track temperature along the extruder barrel.

-

Pressure gauges to monitor conditions at the die.

-

Laser or ultrasonic sensors to measure the extrudate’s dimensions in real time.

These tools provide the raw data that drives the entire system.

2. Install a Control System

The control system is the decision-maker. It takes sensor data and uses it to adjust the process. Options include:

-

PLCs (Programmable Logic Controllers4) for straightforward automation.

-

DCS (Distributed Control Systems) for complex setups.

-

Specialized solutions like Davis-Standard’s EPIC III®, which offers advanced features like recipe management.

This system ensures parameters stay within target ranges, adjusting things like screw speed or heat settings automatically.

3. Equip Operator Interfaces

Automation is great, but humans still play a role. User-friendly interfaces—think touchscreens or dashboards—let operators monitor the process and step in when necessary. Look for systems that visualize data clearly and even allow remote access for added flexibility.

Quick Tip: Start small with a pilot line to test your setup before scaling up.

Real-time control removes the need for operators.False

It automates routine tasks, but operators are still essential for oversight and handling exceptions.

Real-time control boosts energy efficiency.True

Optimized settings reduce excess energy use, lowering operational costs.

What Key Parameters Should You Monitor?

To make real-time control work, you need to focus on the right variables. Here are the big ones:

Temperature

Temperature5 controls how the material melts and flows. Too high, and you risk degradation; too low, and it won’t process properly. Sensors along the barrel and die keep it in check.

Pressure

Pressure6 at the die reflects material flow. High pressure could strain equipment, while low pressure might mean poor forming. Real-time monitoring keeps it balanced.

Dimensions

For products like pipes or sheets, size matters. Laser scanners ensure thickness or diameter stays consistent, catching deviations before they become defects.

Screw Speed

The screw’s speed affects output and material stress. Adjusting it in real time optimizes production without compromising quality.

Table: Key Parameters and Their Effects

| Parameter | Why It Matters |

|---|---|

| Temperature | Influences melt viscosity and product shape |

| Pressure | Signals flow issues or equipment stress |

| Dimensions7 | Ensures product meets specs |

| Screw Speed | Balances output rate and material properties |

Temperature is the only parameter that matters in extrusion.False

Pressure and dimensions are just as critical for a successful outcome.

Monitoring dimensions in real time cuts scrap rates.True

Early detection of size issues allows corrections before waste accumulates.

How Does Material Choice Impact Real-Time Control?

Not all materials behave the same way in an extruder, so your control system needs to adapt. Here’s how some common ones affect the process:

Polyethylene (PE)

-

Melting Range: 120–180°C

-

Control Focus: Moderate screw speed, rapid cooling

-

Uses: Packaging films, pipes

PE is forgiving but needs quick cooling to hold its shape.

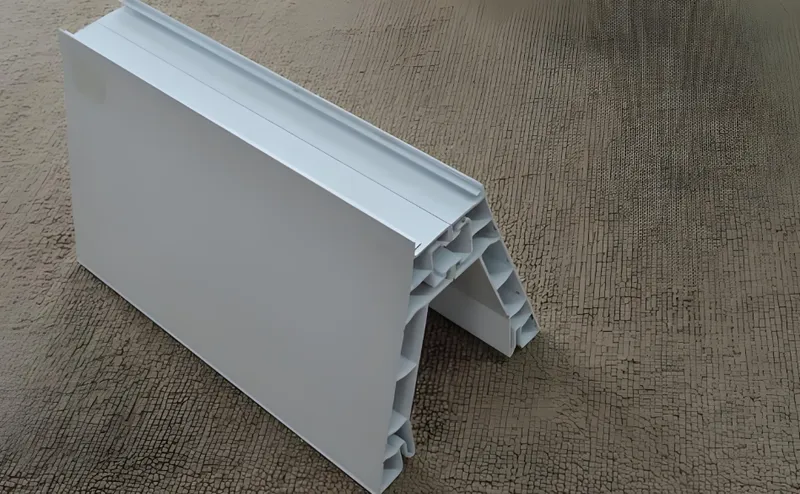

Polyvinyl Chloride (PVC)

-

Melting Range: 170–210°C

-

Control Focus: Tight temperature regulation

-

Uses: Profiles, pipes

PVC degrades if overheated, making precise control a must.

Polystyrene (PS)

-

Melting Range: 100–150°C

-

Control Focus: Low shear, careful screw settings

-

Uses: Sheets, packaging

PS requires gentle handling to avoid breaking down.

Table: Material-Specific Control Needs

| Material | Melting Range (°C) | Key Control Requirements |

|---|---|---|

| PE | 120–180 | Moderate speed, fast cooling |

| PVC | 170–210 | Precise temperature management |

| PS | 100–150 | Low shear, tailored screw design |

All materials use identical control settings.False

Each material demands unique adjustments based on its properties.

Material compatibility drives successful control.True

Tailoring the system to the material ensures optimal performance.

What Are the Pros and Cons of Real-Time Process Control?

Before diving in, weigh the benefits against the challenges:

Benefits

-

Better Quality: Fewer defects thanks to constant adjustments.

-

Less Waste: Early corrections mean less scrap.

-

Higher Efficiency: Optimized settings speed up production and save energy.

-

Safer Operations: Spotting issues early reduces risks.

Challenges

-

Upfront Costs: Sensors and systems require investment.

-

Training Needs: Staff must learn to manage the technology.

-

Material Variations: Recycled or mixed materials can complicate control.

Table: Pros vs. Cons

| Pros | Cons |

|---|---|

| Enhanced product quality | Initial setup costs |

| Reduced material waste | Requires skilled operators |

| Improved efficiency | Material inconsistency |

| Increased safety |

Real-time control solves every extrusion problem.False

It improves many aspects but doesn’t eliminate issues like equipment wear or raw material variability.

The benefits justify the investment over time.True

Savings from efficiency and waste reduction often offset initial costs.

How to Pick the Right Control System

Choosing a control system is a critical step. Here’s a quick guide:

-

Identify Priorities: Focus on what matters most—dimensional accuracy, speed, or energy use.

-

Set a Budget: Balance features with affordability.

-

Ensure Usability: Pick a system with an intuitive interface.

-

Check Integration: Confirm it works with your current setup.

-

Plan for Growth: Opt for a scalable solution.

Pro Tip: Look into systems like Conair’s TrueWeigh™ for robust monitoring options.

The priciest system is always the best.False

Fit and functionality matter more than cost alone.

Scalability future-proofs your setup.True

A flexible system can adapt to new products or higher volumes.

Conclusion

Implementing real-time process control in extrusion can revolutionize your production line, delivering consistent quality, lower waste, and greater efficiency. By focusing on key parameters, matching your system to your materials, and choosing the right tools, you’ll set yourself up for success. Yes, there’s an upfront cost, but the payoff in performance and savings is hard to ignore.

-

Explore this link to understand how real-time process control can enhance efficiency and quality in manufacturing processes. ↩

-

Discover how sensors play a crucial role in monitoring and optimizing manufacturing processes for better outcomes. ↩

-

Explore this link to understand how real-time process control enhances efficiency and quality in manufacturing processes. ↩

-

Learn about PLCs to optimize automation in your processes. This resource provides a comprehensive overview. ↩

-

Understanding temperature control is crucial for optimizing material flow and product quality in extrusion.Explore this link for detailed insights. ↩

-

Pressure management is vital for preventing equipment strain and ensuring product integrity. Discover more about its impact on extrusion processes. ↩

-

Maintaining precise dimensions is essential for product quality and compliance. Learn more about the significance of dimensional control in extrusion. ↩