Screw speed in extrusion is more than just a setting—it’s a critical factor that can make or break the quality of your final product. Whether you’re crafting plastic films, pipes, or profiles, the speed at which the screw rotates in your extruder directly influences the surface finish, dimensional accuracy, and mechanical properties1 of the output. Research highlights that higher screw speed2s can ramp up production rates but often degrade the polymer, leading to rougher surfaces and weaker products. Conversely, lower speeds enhance quality by ensuring better mixing and melting, though they slow down output. Striking the right balance is key, and it hinges on your material and application. In this guide, we’ll unpack how screw speed shapes extrusion quality and equip you with insights and tools to optimize your process.

Screw speed significantly impacts extrusion quality, affecting surface finish, dimensional accuracy, and mechanical properties, with optimal settings varying by material and application.

Higher screw speeds always improve extrusion quality.False

While higher speeds boost production, they can degrade polymers, resulting in poorer surface finish and mechanical strength.

Optimizing screw speed is essential for balancing efficiency and quality.True

The right speed ensures efficient production without sacrificing the integrity of the final product.

- 1. What is Screw Speed and Why Does It Matter in Extrusion?

- 2. How Does Screw Speed Affect Extrusion Quality?

- 3. What Are the Typical Applications Affected by Screw Speed?

- 4. How Do Different Materials Respond to Screw Speed Variations?

- 5. What Are the Steps in the Extrusion Process Where Screw Speed Matters?

- 6. How to Optimize Screw Speed for Your Application ?

- 7. How Screw Speed Concepts Apply Elsewhere ?

- 8. Conclusion

What is Screw Speed and Why Does It Matter in Extrusion?

Screw speed, measured in revolutions per minute (rpm), dictates how fast the screw rotates inside the extruder, controlling the rate at which material is melted, mixed, and pushed through the die. Its importance stems from its influence on three core factors:

-

Shear Rate: Higher speeds increase shear, which can break down polymer chains if excessive.

-

Temperature: Faster rotation generates more heat, risking polymer overheating.

-

Residence Time: Slower speeds allow more time for melting and mixing, enhancing uniformity.

Screw speed governs the shear rate, temperature, and residence time in the extruder, all of which are pivotal to the quality of the extruded product.

Understanding these dynamics is vital for anyone aiming to master extrusion across industries like packaging, construction, or manufacturing.

How Does Screw Speed Affect Extrusion Quality?

Screw speed’s impact on extrusion quality3 is multi-dimensional, touching on surface finish, dimensional accuracy, and mechanical properties. Let’s break it down:

Surface Finish

-

Higher Speeds: Increased shear can lead to uneven mixing, causing rougher surfaces. For instance, in plasticized poly(lactic acid) (PLA), high speeds leave more solid particles in the melt, degrading surface quality source.

-

Lower Speeds: Promote thorough melting and mixing, yielding smoother finishes.

Dimensional Accuracy

-

Higher Speeds: May introduce flow inconsistencies, resulting in variations in thickness or shape.

-

Lower Speeds: Ensure uniform flow, enhancing precision—crucial for applications like pipe extrusion.

Mechanical Properties

-

Higher Speeds: Risk polymer degradation4, weakening tensile strength and durability.

-

Lower Speeds: Preserve polymer integrity, boosting mechanical performance.

| Quality Parameter | Higher Screw Speed | Lower Screw Speed |

|---|---|---|

| Surface Finish | Rougher due to uneven mixing | Smoother due to better mixing |

| Dimensional Accuracy | Less consistent due to flow variations | More consistent with uniform flow |

| Mechanical Properties | Weaker due to polymer degradation | Stronger with better polymer integrity |

Lower screw speeds always result in better extrusion quality.False

While quality improves with lower speeds, the trade-off is reduced production rates, which may not suit high-volume needs.

Screw speed must be tailored to specific materials and applications.True

Materials like PVC demand lower speeds to avoid degradation, while HDPE can handle higher speeds effectively.

What Are the Typical Applications Affected by Screw Speed?

Screw speed’s influence varies across extrusion applications, each with unique quality demands:

Film Production

-

Quality Focus: Thickness uniformity and surface clarity.

-

Screw Speed Impact: High speeds can cause thickness variations and haziness due to incomplete melting.

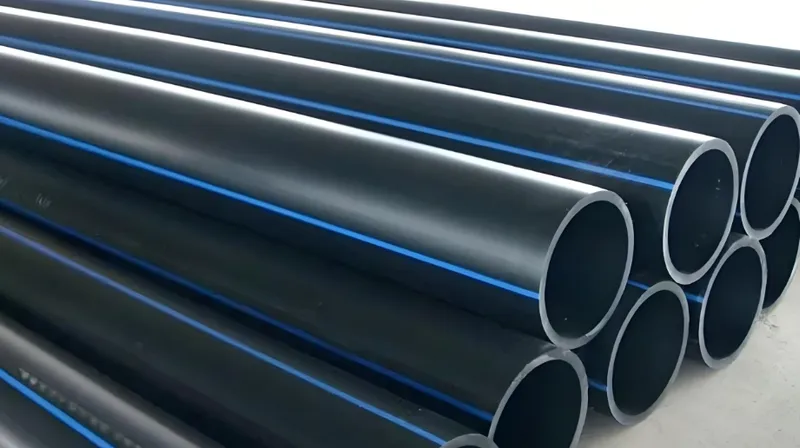

Pipe Extrusion

-

Quality Focus: Consistent wall thickness and mechanical strength.

-

Screw Speed Impact: Lower speeds ensure uniformity and durability by preventing polymer breakdown.

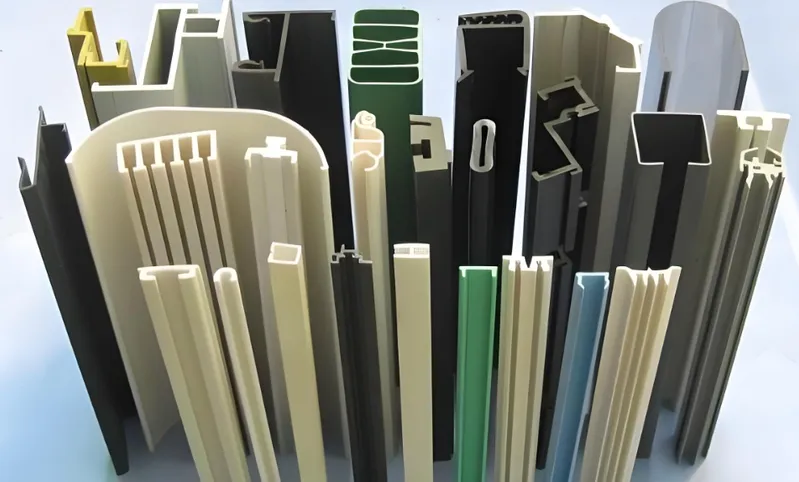

Profile Extrusion

- Quality Focus: Dimensional accuracy and surface finish5.

- Screw Speed Impact: Optimal speeds strike a balance between output and precision for complex shapes.

Screw speed is a universal factor in extrusion, shaping quality across applications from films to pipes and profiles.

Screw speed is equally critical across all extrusion applications.True

Despite differing quality priorities, screw speed consistently influences process outcomes and product performance.

How Do Different Materials Respond to Screw Speed Variations?

Material properties dictate their response to screw speed, making tailored optimization essential:

PVC (Polyvinyl Chloride)

-

Characteristics: Heat-sensitive, prone to degradation.

-

Optimal Speed: Lower speeds (e.g., 30 rpm for twin-screw) prevent overheating source.

HDPE (High-Density Polyethylene)

-

Characteristics: Thermally stable, degradation-resistant.

-

Optimal Speed: Handles higher speeds (up to 100 rpm) for high-output scenarios source.

PLA (Polylactic Acid)

-

Characteristics: Biodegradable, shear-sensitive.

-

Optimal Speed: Moderate speeds balance production and surface quality.

All materials require the same screw speed for optimal quality.False

Material-specific thermal and shear sensitivities demand customized speed settings.

What Are the Steps in the Extrusion Process Where Screw Speed Matters?

Screw speed influences multiple stages of the extrusion workflow:

-

Feeding: Material enters the extruder.

-

Conveying: Speed affects material movement to the melting zone.

-

Melting: Determines shear heat and melting efficiency.

-

Mixing: Impactshomogeneity—higher speeds may over-shear, lower speeds enhance blending.

-

Pumping: Controls flow rate through the die.

-

Shaping: Melt quality, tied to speed, defines the final form.

-

Cooling: Thermal history from speed affects surface finish.

Screw speed plays a role from conveying to cooling, shaping the entire extrusion process.

Screw speed only affects the melting stage.False

Its influence spans conveying, mixing, pumping, and beyond.

How to Optimize Screw Speed for Your Application ?

Optimizing screw speed demands a structured approach. Here’s how to get started:

Design Checklist

-

Define Quality Goals: Pinpoint key parameters (e.g., surface finish, strength).

-

Select Material: Match polymer to application needs.

-

Set Speed Range: Use material guidelines or trials to establish limits.

-

Monitor Process: Adjust speed based on real-time feedback.

Decision-Making Guide

-

High Output Needed? Lean toward higher speeds, with quality checks.

-

Quality First? Prioritize lower speeds.

-

Material Sensitivity: Start low for heat-sensitive polymers like PVC.

Optimizing screw speed is a one-time task.False

Ongoing adjustments are needed to account for material variations and conditions.

How Screw Speed Concepts Apply Elsewhere ?

Screw speed principles extend beyond extrusion to other processes:

Injection Molding

-

Similarity: Speed affects melt quality and part properties.

-

Difference: Impacts cycle time more than continuous output.

Blow Molding

-

Similarity: Influences parison quality.

-

Difference: Affects thickness uniformity in hollow parts.

3D Printing (FDM)

-

Similarity: Extrusion speed impacts layer adhesion and finish.

-

Difference: Requires dynamic speed adjustments per layer.

Screw speed optimization is unique to extrusion.False

Similar principles apply to injection molding, blow molding, and beyond, with process-specific nuances.

Conclusion

Screw speed is a linchpin in extrusion, shaping the quality of your final product. Higher speeds drive efficiency but risk degrading quality, while lower speeds enhance precision at the cost of output. The sweet spot varies by material and application—PVC thrives at lower speeds, HDPE at higher ones. Armed with an understanding of screw speed’s effects and practical tools like checklists and decision guides, you can fine-tune your process for optimal results. Apply these insights to your next project and see the difference in quality and efficiency.

-

Discover how screw speed influences mechanical properties in extrusion, which is vital for product performance. This link offers detailed explanations. ↩

-

Understanding screw speed is crucial for optimizing extrusion processes and improving product quality. Explore this link for in-depth insights. ↩

-

Learn how extrusion quality is affected by screw speed to enhance your manufacturing processes. This resource provides valuable information. ↩

-

Exploring this topic reveals critical insights into maintaining polymer integrity during processing. ↩

-

This resource can provide valuable information on achieving optimal surface quality in various applications. ↩