Durable PC Profiles for Versatile Applications

Explore durable PC profiles at UPLASTEH for versatile applications. Discover precision-engineered solutions tailored to your needs.

PC Protective Lampshade

PC LED Strip Cover

Guide to Custom PC Extrusion Profiles Manufacturing

Clear Definition: What are PC Extrusion Profiles?

PC Extrusion Profiles, technically known as Polycarbonate Extruded Profiles, are continuous linear shapes manufactured by forcing molten polycarbonate resin through a specifically designed die.

1. Prinsip-Prinsip Inti:

The process relies on the thermoplastic nature of polycarbonate, meaning it can be melted and reshaped upon cooling without significant degradation. The extrusion process involves:

① Melting: Polycarbonate pellets or granules are fed into an extruder, where they are melted and homogenized by heat and the shearing action of a rotating screw.

② Pumping & Pressurizing: The molten polymer is pumped forward by the screw and pressurized.

③ Shaping (Extrusion): The pressurized melt is forced through a custom-designed die, which imparts the desired cross-sectional shape to the material.

④ Cooling & Solidification: The extruded shape (extrudate) is then cooled, typically using air or a water bath, causing it to solidify while maintaining its form.

⑤ Pulling & Cutting: The solidified profile is pulled at a consistent speed (to maintain dimensional accuracy) and cut to the required lengths.

2. Konsep Dasar:

① Polikarbonat (PC): A group of thermoplastic polymers containing carbonate groups in their chemical structures. Known for its high impact strength, good temperature resistance, and optical clarity.

② Extrusion: A continuous manufacturing process that creates objects with a fixed cross-sectional profile.

③ Die: A specialized tool used to shape the molten plastic. The design of the die is critical to achieving the desired profile geometry and tolerances.

④ Profile: A shape with a constant cross-section along its length (e.g., L-shape, U-channel, tube, rod, custom intricate designs).

Classification and Types of PC Extrusion Profiles

PC extrusion profiles can be classified based on several criteria, allowing for a more nuanced understanding of their variations:

1. Based on Polycarbonate Resin Grade:

- General Purpose (GP) PC Profiles: Made from standard PC resins, offering a good balance of impact strength, clarity, and temperature resistance for a wide range of applications.

- UV Stabilized PC Profiles: Formulated with UV inhibitors to resist yellowing, embrittlement, and degradation when exposed to sunlight or artificial UV sources. Essential for outdoor applications or lighting fixtures.

- Flame Retardant (FR) PC Profiles: Incorporate additives to meet specific flammability ratings (e.g., UL94 V-0, V-1, V-2). Used in electronics, transportation, and construction where fire safety is critical.

- Impact Modified PC Profiles: Blended with impact modifiers to further enhance toughness, especially at low temperatures.

- Food Grade PC Profiles: Comply with regulations (e.g., FDA, EU) for direct contact with food and beverages.

- Medical Grade PC Profiles: Biocompatible grades suitable for medical devices and equipment, often sterilizable.

- Optical Grade PC Profiles: High-clarity resins with minimal haze, optimized for light transmission and diffusion in lighting and optical applications.

2. Based on Profile Complexity and Form:

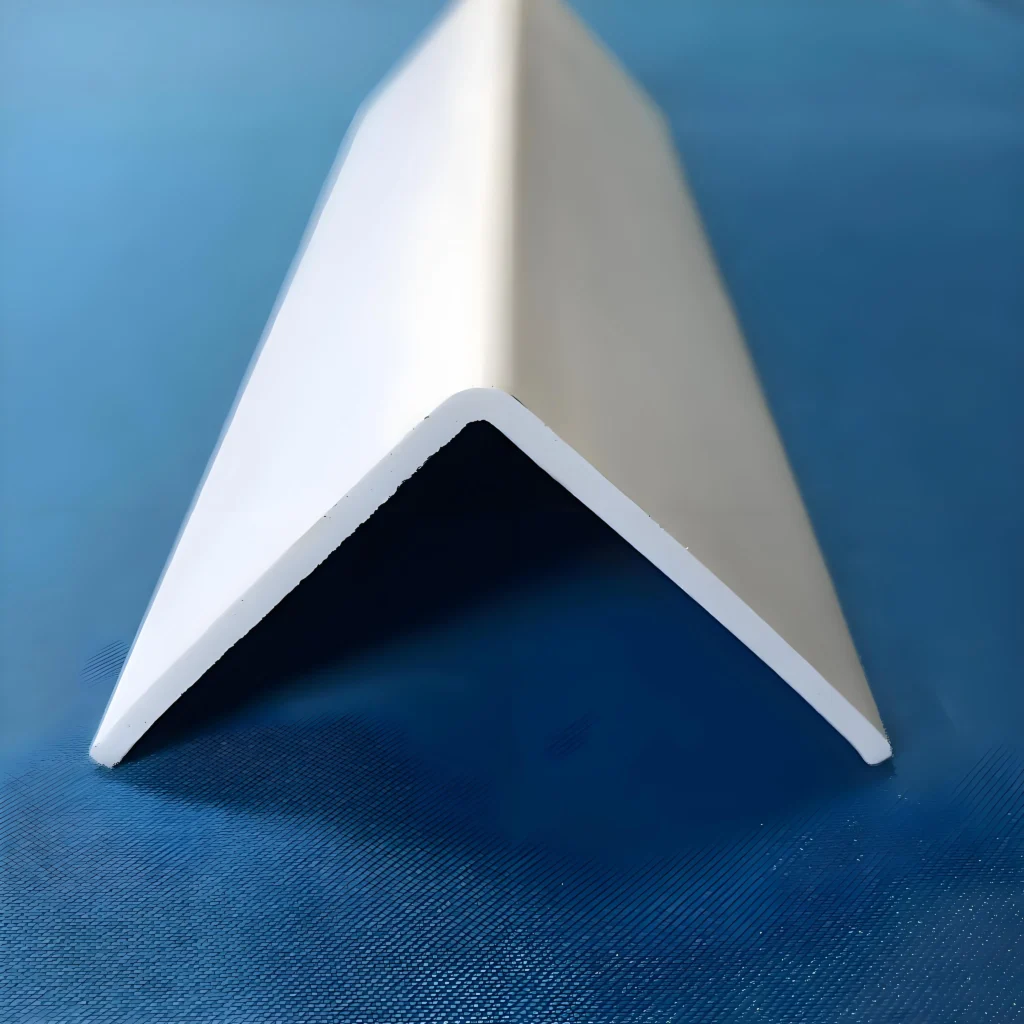

- Simple Profiles: Basic shapes like rods, tubes, square bars, flat strips, L-angles, U-channels.

- Complex Profiles: Intricate, multi-hollow, or custom-designed shapes tailored for specific functionalities (e.g., snap-fits, lens features, heat sink geometries).

- Co-extruded Profiles: Profiles made by extruding two or more different materials (or different colors/grades of the same material) simultaneously through a single die. This allows for specific properties in different parts of the profile (e.g., a rigid PC base with a flexible sealing lip, or a clear PC lens with an opaque housing).

- Tri-extruded Profiles: Similar to co-extrusion but involving three distinct material streams.

3. Based on Application Focus:

- Lighting Profiles: Diffusers, lenses, covers for LED fixtures, light guides.

- Construction Profiles: Glazing bars, window/door frame components, skylight profiles, decorative trim.

- Automotive Profiles: Interior trim, exterior decorative elements, lens covers.

- Electronic Enclosure Profiles: Housings, guides, protective covers for electronic components.

- Medical Tubing and Profiles: Catheters, diagnostic equipment components.

- Point-of-Purchase (POP) Display Profiles: Sign holders, shelf-edge strips, display components.

Typical Application Scenarios/Use Cases for PC Extrusion Profiles

Polycarbonate’s robust properties make its extruded profiles suitable for a wide array of demanding applications:

1. Lighting Industry:

- LED Diffusers and Lenses: PC’s excellent optical clarity, customizable diffusion levels (with additives), and impact resistance make it ideal for creating profiles that spread, direct, or protect LED light sources. This includes linear lighting fixtures, troffers, and task lights. UV-stabilized grades are essential here.

- Light Fixture Housings and Covers: Protective and aesthetic components for various luminaires.

- Contoh: A custom-extruded PC profile designed as a snap-on diffuser for an aluminum LED channel, providing uniform light distribution and protecting the LEDs.

2. Construction and Architecture:

- Glazing Systems: Profiles for holding glass or polycarbonate sheets in windows, curtain walls, and skylights. Its strength allows for slimmer profiles compared to PVC.

- Weather Seals and Gaskets (Co-extruded): Rigid PC parts co-extruded with flexible materials for sealing applications.

- Protective Edging and Corner Guards: High impact resistance protects walls and furniture.

- Greenhouse Glazing Bars: Durable and UV-resistant profiles for constructing greenhouses.

- Contoh: UV-stabilized PC H-profiles used to join multiwall polycarbonate sheets in a conservatory roof.

3. Automotive and Transportation:

- Interior Trim and Decorative Strips: Lightweight, durable, and can be colored or finished for aesthetic appeal.

- Window Guides and Seals: Offering smooth operation and good sealing.

- Light Covers and Lenses: For interior and some exterior lighting applications.

- Contoh: Flame-retardant PC profiles used as cable conduits or trim pieces within bus or train interiors.

4. Electronics and Electrical:

- Enclosures and Housings: Protecting sensitive electronic components due to good dielectric strength and impact resistance. FR grades are often specified.

- Cable Management Raceways and Conduits: Organizing and protecting wires and cables.

- Heat Sink Profiles (for low-power LEDs): While not as conductive as aluminum, PC can be sufficient for some thermal management.

- Contoh: A complex PC profile extruded to form part of a server rack’s cable management system, incorporating snap-fit features.

5. Retail and Point-of-Purchase (POP) Displays:

- Sign Holders and Price Tag Rails: Clear, durable, and easily fabricated.

- Shelf Edging and Dividers: Offering protection and organization.

- Contoh: Clear PC U-channels used to hold signage on retail shelving units.

6. Medical Devices:

- Tubing for Fluid Handling (Medical Grade PC): Where clarity, strength, and sterilizability are required.

- Components for Diagnostic Equipment: Housings, guides, and structural elements.

- Contoh: Extruded medical-grade PC tubing used in a diagnostic machine for sample transfer.

7. Industrial and Manufacturing Equipment:

- Machine Guards and Safety Barriers: High impact strength provides operator protection.

- Conveyor System Components: Guide rails, wear strips.

- Contoh: Yellow or clear PC profiles used as safety guards on automated assembly lines.

Advantages and Disadvantages Comparison of PC Extrusion Profiles

1. Keuntungan:

- Exceptional Impact Strength: Polycarbonate is virtually unbreakable, significantly tougher than acrylic (PMMA) and glass. This makes it ideal for applications requiring high durability and vandal resistance.

- Good Optical Clarity: Standard PC grades offer high light transmission, comparable to glass, making them suitable for lenses, diffusers, and transparent covers.

- High-Temperature Resistance: PC can withstand higher operating temperatures (typically up to 120-130°C) compared to many other thermoplastics like PVC or ABS.

- Good Dimensional Stability: Maintains its shape and size over a range of temperatures and humidity levels.

- Design Flexibility: The extrusion process allows for complex and intricate cross-sectional designs, including hollows, ribs, and snap-fit features.

- Ringan: Significantly lighter than glass and metals like aluminum, reducing structural support needs and shipping costs.

- Good Electrical Insulation Properties: Suitable for electrical and electronic enclosures.

- Flame Retardancy: Specific grades offer excellent flame-retardant properties, meeting stringent safety standards.

- Weldability and Bondability: Can be solvent welded or bonded with adhesives.

- Dapat didaur ulang: Polycarbonate is a recyclable thermoplastic.

- Cost-Effectiveness for Volume: For continuous lengths and high-volume production, extrusion is a cost-effective manufacturing method.

2. Disadvantages:

- Susceptibility to UV Degradation: Standard PC grades will yellow and become brittle with prolonged UV exposure unless UV stabilizers are added.

- Lower Chemical Resistance (to certain chemicals): Susceptible to attack by certain solvents (e.g., ketones, esters, chlorinated hydrocarbons), strong acids, and alkalis, which can cause crazing or cracking.

- Notch Sensitivity: While very tough, PC can be prone to failure if a sharp notch or crack is present.

- Higher Cost than Some Commodities: More expensive than commodity plastics like PVC, PE, or PP.

- Requires Drying Before Processing: Polycarbonate is hygroscopic (absorbs moisture). Failure to properly dry the resin before extrusion leads to splay, silver streaks, and reduced mechanical properties.

- Higher Processing Temperatures: Requires higher melt temperatures and more robust processing equipment compared to some other thermoplastics.

- Stress Cracking Potential: Can be susceptible to environmental stress cracking (ESC) when exposed to certain chemicals under stress.

- Scratch Resistance: Softer than glass, making it more prone to scratching (though coatings can improve this).

3. Brief Comparison with Alternatives:

① vs. Aluminum Extrusions:

- PC Advantages: Lighter, better thermal insulator, transparent options, dielectric, often lower tooling costs for complex profiles.

- Aluminum Advantages: Higher strength and rigidity, better thermal conductivity, superior UV resistance (anodized/powder-coated), higher temperature capability.

② vs. PVC Extrusions:

- PC Advantages: Much higher impact strength, better temperature resistance, clearer transparency.

- PVC Advantages: Lower cost, excellent chemical resistance, inherently flame retardant (for rigid PVC), easier to process.

③ vs. Acrylic (PMMA) Extrusions:

- PC Advantages: Significantly higher impact strength, better temperature resistance.

- Acrylic Advantages: Better UV resistance (inherently), higher scratch resistance, superior optical clarity/brilliance (for clear grades), lower cost.

④ vs. ABS Extrusions:

- PC Advantages: Better clarity, higher impact strength (especially at low temps), higher temperature resistance.

- ABS Advantages: Lower cost, easier processing, good chemical resistance.

Key Characteristics and Properties of PC for Extrusion Profiles

1. Sifat Mekanis:

- Tensile Strength: Typically 55-75 MPa. Indicates the material’s resistance to being pulled apart.

- Flexural Strength: Around 90-110 MPa. Resistance to bending.

- Impact Strength (Izod Notched): Very high, often >600 J/m (can be >800 J/m for some grades). This is a hallmark property of PC.

- Hardness (Rockwell): Typically R118-R120. Indicates resistance to indentation.

- Elongation at Break: Can be >100%, indicating good ductility before fracture.

2. Sifat Termal:

- Heat Deflection Temperature (HDT): Around 128-138°C (at 1.8 MPa). The temperature at which it deforms under a specified load.

- Continuous Service Temperature: Approximately 120°C.

- Coefficient of Linear Thermal Expansion (CLTE): Relatively high, around 65-70 µm/m·°C. This needs consideration in designs with large temperature variations or when combined with materials with different CLTEs.

- Glass Transition Temperature (Tg): Around 145-150°C.

3. Optical Properties (for transparent/translucent grades):

- Light Transmission: Up to 88-91% for clear, polished grades.

- Refractive Index: Around 1.586.

- Haze: Can be very low (<1%) for optical grades, or intentionally increased with diffusing additives for lighting applications.

4. Electrical Properties:

- Kekuatan Dielektrik: High, typically 15-30 kV/mm. Excellent insulator.

- Resistivitas Volume: Very high, >10^16 Ohm·cm.

5. Chemical Resistance:

- Good Resistance to: Water, dilute acids and bases (at room temp), oils, greases, aliphatic hydrocarbons.

- Poor Resistance to: Strong alkalis, strong acids, aromatic hydrocarbons (e.g., benzene, toluene), ketones (e.g., acetone), esters, chlorinated solvents. Exposure can lead to swelling, crazing, or dissolution.

- Susceptible to Environmental Stress Cracking (ESC): When under mechanical stress and exposed to certain chemicals (even vapors), PC can crack.

6. Flammability:

- Standard PC is self-extinguishing to a degree (often UL94 HB).

- Flame-retardant grades can achieve UL94 V-0, V-1, or 5VA ratings, crucial for safety-critical applications.

Core Process/Workflow/Working Principle of PC Extrusion

The extrusion of polycarbonate profiles is a precise, multi-stage process:

1. Material Preparation (Crucial Step):

- Drying: Polycarbonate is hygroscopic and must be thoroughly dried before processing. Typically dried at 120°C (250°F) for 2-4 hours (or longer depending on initial moisture content) to reduce moisture content to <0.02%. Hopper dryers with desiccant beds are commonly used.

- Blending (if applicable): Additives like colorants, UV stabilizers, or processing aids are uniformly mixed with the PC pellets.

2. Feeding:

- Dried PC pellets are fed from a hopper into the throat of the extruder.

3. Melting and Homogenizing:

- Extruder Screw: A rotating Archimedean screw within a heated barrel conveys the pellets forward.

- Barrel Zones: The barrel is divided into multiple heating zones (typically 3-5), with temperatures gradually increasing from the feed zone (rear) to the metering zone (front, near the die). For PC, temperatures range from ~240°C (feed) to ~280-300°C (die).

- Shear Heating: As the screw rotates, mechanical shear also contributes to melting and homogenizing the polymer.

- Venting (Optional): Some extruders have vented barrels to remove any residual moisture or volatiles, though proper pre-drying is still paramount.

4. Filtering (Screen Pack):

- Before entering the die, the molten PC passes through a screen pack (a series of wire meshes) supported by a breaker plate. This filters out contaminants and helps build back pressure for better mixing.

5. Extrusion (Shaping):

- Mati: The homogenized, pressurized molten PC is forced through a custom-designed die. The die’s internal geometry determines the profile’s cross-sectional shape. Die design is complex, accounting for polymer swell and drawdown. Dies are typically made from hardened tool steel and precisely machined.

- Die Heating: The die itself is heated to maintain the PC’s melt temperature and flow characteristics.

6. Sizing and Cooling (Calibration):

- Sizing Plates/Vacuum Calibrators: As the extrudate exits the die, it enters a sizing or calibration unit. This unit uses sizing plates, vacuum, or both to finalize the profile’s dimensions and surface finish while it cools.

- Cooling Trough: The profile then passes through a cooling trough, typically containing water (water bath) or cooled by air jets. Controlled cooling is vital to prevent warpage and internal stresses. The water temperature is carefully controlled.

7. Pulling:

- Puller/Haul-Off Unit: A puller (e.g., belt or cleated type) grips the solidified profile and pulls it away from the die at a constant speed. The puller speed is synchronized with the extruder output to maintain dimensional consistency.

8. Cutting or Coiling:

- Cutter: An in-line saw (e.g., flying knife, rotary cutter) or shear cuts the profile to predetermined lengths.

- Coiler (for flexible or small profiles): Some profiles might be coiled onto spools.

9. Quality Control and Post-Extrusion Operations:

- Inspection: Dimensional checks, surface finish inspection, color matching.

- Secondary Operations (Optional): Drilling, punching, milling, printing, applying adhesive tape, assembly.

Key Parameters & Influencing Factors:

- Suhu Leleh: Too low leads to high viscosity, poor surface, and unmelted particles; too high can cause degradation.

- Screw Speed: Affects output rate and shear heating.

- Desain Die: Critical for profile shape, dimensional accuracy, and surface finish.

- Cooling Rate & Method: Influences internal stresses, warpage, and crystallinity (though PC is amorphous).

- Puller Speed: Must be consistent and matched to extruder output for dimensional control.

- Resin Moisture Content: Must be extremely low (<0.02%).

Produsen Profil ABS Khusus

Temukan profil ABS khusus kami yang dirancang untuk ekstrusi plastik, yang menawarkan kekuatan luar biasa, ketahanan panas, dan daya tahan benturan.

Guide to Custom PC Extrusion Profiles Manufacturing

Key Considerations for PC Extrusion Profiles

When designing, specifying, or using PC extrusion profiles, several factors are paramount:

1. Material Grade Selection:

- Match the PC grade (GP, UV, FR, optical, etc.) to the application’s environmental conditions (UV, temperature, chemical exposure) and performance requirements (impact, flammability, clarity).

2. Kompleksitas Desain Profil:

- While extrusion allows for complex shapes, overly intricate designs can increase tooling costs and processing difficulty.

- Consider wall thickness uniformity to prevent uneven cooling and warpage.

- Incorporate radii on corners to reduce stress concentrations.

- Account for draft angles if parts of the profile are enclosed in the sizing tools.

3. Tolerances:

- Extrusion is not as precise as injection molding or machining. Define realistic dimensional tolerances. Typical commercial tolerances for PC extrusions might be ±0.5% to ±1% of the dimension, but this varies greatly with size and complexity.

4. Thermal Expansion and Contraction:

- PC has a relatively high CLTE. Design for movement, especially in long lengths or when assembled with materials with different expansion rates (e.g., aluminum).

5. Die Design and Tooling Cost:

- The extrusion die is a custom tool. Its complexity directly impacts cost and lead time. Die design requires expertise to compensate for material behavior like die swell.

6. Post-Extrusion Fabrication:

- Consider if any secondary operations (cutting, drilling, machining, printing, assembly) are needed and how the profile design facilitates them.

7. Chemical Compatibility:

- Verify compatibility with any chemicals, solvents, cleaners, or adhesives the profile will encounter during its service life.

8. UV Exposure:

- For outdoor or high UV exposure applications, always specify UV-stabilized PC grades or consider protective coatings/co-extruded layers.

9. Minimum Order Quantities (MOQs):

- Extrusion is a continuous process best suited for medium to high volumes. MOQs are common due to setup times and material consumption during startup.

10. Surface Finish:

- Standard extrusion provides a good surface finish. Special die polishing or post-extrusion treatments may be needed for very high gloss or specific textures.

Design/Implementation Guide/Best Practices for PC Extrusion Profiles

1. Keseragaman Ketebalan Dinding:

- Aim for consistent wall thicknesses throughout the profile. Uneven walls lead to differential cooling, causing warpage and internal stress.

- If varied thicknesses are unavoidable, transition gradually.

2. Corner Radii:

Incorporate generous radii on both internal and external corners. Sharp corners are stress concentrators and can be difficult to fill properly during extrusion. Minimum recommended radius is often 0.5mm to 1mm, or equal to wall thickness.

3. Hollow Sections:

For hollow sections, ensure walls are thick enough to support themselves during cooling and prevent collapse. Internal supports (webs) within the die may be needed for complex hollows.

4. Ribs and Bosses:

- Ribs can enhance stiffness. Rib thickness should generally be 50-60% of the adjoining wall thickness to avoid sink marks.

- Design bosses with proper drafts and radii.

5. Tolerancing:

- Understand standard extrusion tolerances and specify only critical dimensions with tighter tolerances. Consult with the extruder early in the design process.

- Critical tolerances are often applied to features that mate with other parts or affect functionality.

6. Material Flow:

- Design the profile to promote balanced material flow through the die. Avoid abrupt changes in mass or direction.

7. Snap-Fits and Living Hinges:

- PC is suitable for snap-fit designs due to its strength and flexibility. Design with appropriate undercut depths and lead angles.

- Living hinges are generally not recommended for PC due to its notch sensitivity and fatigue characteristics; polypropylene or polyethylene are better suited.

8. Co-extrusion Potential:

- Consider co-extrusion if different properties are needed in different areas of the profile (e.g., a UV-resistant cap layer, a soft sealing element, different colors).

9. Parting Lines and Die Lines:

- Be aware that subtle die lines (longitudinal marks) are inherent to the extrusion process. Specify surface finish requirements if they are critical.

10. Prototyping:

- For complex profiles or critical applications, consider rapid prototyping methods (e.g., 3D printing a section for form/fit check) before committing to expensive extrusion tooling, though 3D printed properties will differ. Soft tooling or single-cavity test dies can also be an interim step.

Common Problems and Solutions in PC Extrusion

| Masalah | Penyebab Potensial | Possible Solutions |

|---|---|---|

| Silver Streaks / Splay | Moisture in the resin (most common). Resin degradation (too hot, too long residence time). Volatiles. | Ensure thorough drying of PC resin (<0.02% moisture). Reduce melt temperature or residence time. Check for proper venting if using a vented extruder. |

| Pelengkungan / Distorsi | Uneven cooling. Non-uniform wall thickness. Excessive internal stresses. Puller speed mismatch. | Improve cooling uniformity (water temperature, flow, air jets). Redesign for uniform wall thickness. Optimize puller speed. Anneal parts post-extrusion if stress is an issue. |

| Rough Surface / Sharkskin | Melt fracture (flow rate too high for die geometry). Low melt temperature. Die surface imperfections. | Reduce extruder output or redesign die land length/entry angle. Increase melt temperature slightly. Polish/clean die surfaces. Use processing aids. |

| Die Lines / Streaks | Damaged or dirty die. Contamination in melt. Inconsistent material flow. | Clean or repair die. Improve melt filtration (screen pack). Check for blockages. Ensure consistent melt temperature. |

| Bubbles / Voids | Trapped air or moisture. Degradation. Too high melt temperature. | Ensure proper drying. Optimize screw design for devolatilization. Reduce melt temperature. Check for air leaks in hopper/feed throat. |

| Dimensional Instability | Inconsistent puller speed. Fluctuating melt temperature or pressure. Inadequate or inconsistent cooling/sizing. | Calibrate and stabilize puller speed. Stabilize extruder temperatures and screw speed. Optimize sizing/calibration unit (vacuum levels, contact). |

| Brittleness | Excessive moisture during processing. Degradation. Wrong PC grade. Low processing temperatures. | Verify drying. Reduce melt temperature or residence time. Confirm correct PC grade is used. Ensure melt temperature is adequate for good fusion. |

| Discoloration / Yellowing | Resin degradation (overheating). Contamination. UV degradation (if not UV stabilized and exposed). | Reduce melt temperatures or residence time. Clean extruder and hopper. Use UV-stabilized grade for UV exposure. |

| Poor Melt Strength | Resin grade with too low molecular weight. Melt temperature too high. | Use a higher molecular weight PC grade suitable for extrusion. Reduce melt temperature. |

| Surging / Pulsating Output | Inconsistent feeding of pellets. Bridging in hopper. Worn screw/barrel. Inconsistent melt temperature. | Ensure consistent material feed. Check hopper for bridging. Inspect screw and barrel for wear. Stabilize heating zones. |

Related Technologies/Concepts

1. Polymer Science:

- Termoplastik: The class of polymers to which PC belongs, characterized by their ability to be repeatedly melted and solidified. Understanding polymer rheology (flow behavior), morphology (amorphous structure of PC), and degradation mechanisms is fundamental.

- Additives: UV stabilizers, flame retardants, colorants, impact modifiers, processing aids – these significantly alter PC’s properties and processability.

2. Injection Molding:

- A complementary plastics processing technology. While extrusion creates continuous linear profiles, injection molding produces discrete, often complex three-dimensional parts by injecting molten plastic into a closed mold. Many products may use both extruded PC profiles and injection-molded PC components.

3. Co-extrusion:

- A specialized extrusion process where two or more materials are extruded simultaneously through a single die to form a multi-material profile. This is key for combining properties, e.g., a rigid PC substrate with a flexible TPE seal, or a standard PC core with a UV-protective cap layer.

4. Thermoforming (Secondary Process):

- Extruded PC sheets (not typically profiles, but related) can be thermoformed (heated and shaped over a mold) to create 3D parts like machine guards, skylight domes, or trays. Some simpler profiles might undergo secondary bending operations.

5. CNC Machining (Secondary Process):

- Extruded PC profiles can be further machined (milled, drilled, turned) to add features not possible through extrusion alone, or for high-precision requirements on specific features.

6. Material Drying Technology:

- Essential for hygroscopic materials like PC. Desiccant dryers, vacuum dryers, and hot air dryers are crucial upstream equipment to prevent processing defects.

7. Die Design and Manufacturing:

- A highly specialized field involving fluid dynamics, heat transfer, and precision machining. The quality of the die directly impacts the quality of the extruded profile. CAD/CAM and flow simulation software are often used.

8. Other Extruded Plastics:

- PVC (Polyvinyl Chloride): Widely used for pipes, window frames, siding. Lower cost, good chemical resistance.

- PE (Polyethylene): Used for pipes, films, bags. Flexible, low cost.

- PP (Polypropylene): Used for packaging, fibers, some profiles. Good chemical resistance, fatigue resistance.

- ABS (Acrylonitrile Butadiene Styrene): Used for pipes, profiles needing good toughness and finish.

- PMMA (Acrylic): Used for clear profiles, lighting, displays. Excellent clarity, UV resistance. Understanding these alternatives helps in selecting the optimal material for a given application.

9. Joining and Assembly Techniques:

- Solvent bonding, adhesive bonding, ultrasonic welding, mechanical fasteners – common methods for assembling PC profiles into larger structures or with other components.

10. Surface Treatments and Coatings:

- To enhance specific properties like scratch resistance (hard coats), anti-fog, or anti-static behavior. These can be applied post-extrusion.

Mengapa Memilih Uplastech?

Making It Easier for All Target Customers to Access High-Quality Plastic Extrusion Products

Strong Development Capabilities

We have a professional plastic extrusion technology team with extensive industry experience and expertise. Whether it’s product design or material selection, we provide expert advice and tailored solutions to meet your specific requirements.

High Processing Efficiency

Our plastic extrusion equipment and production lines are designed to handle large-scale processing quickly and efficiently. We focus on production efficiency and on-time delivery to ensure your orders are fulfilled promptly and support your project timelines.

Excellent Product Quality

We strictly adhere to a comprehensive quality management system, conducting rigorous quality control and inspection processes to ensure stable and reliable product quality. By using premium raw materials and proven manufacturing techniques, we guarantee that our products meet both industry standards and customer expectations.

Effective Communication

We value close communication with our clients to accurately understand your needs and goals. We actively participate in project discussions and feedback, ensuring a smooth development process and maintaining your involvement and satisfaction throughout.

Choose Uplastech and Your Needs Will be Perfectly Met!

FAQ UNTUK KLIEN

Memulai dengan Uplastech

Ada pertanyaan? Kami punya jawabannya.

Kami mengkhususkan diri dalam ekstrusi, pembentukan vakum, cetakan tiup, dan pembuatan cetakan presisi, menawarkan solusi yang disesuaikan untuk memenuhi beragam kebutuhan manufaktur Anda.

Kami bekerja dengan berbagai industri, termasuk otomotif, elektronik, barang konsumen, dan pengemasan, dengan fokus pada kemitraan B2B dan memberikan solusi di bidang ekstrusi, thermoforming, blow moulding, dan pembuatan cetakan presisi.

Ya, kami menyesuaikan solusi kami agar sesuai dengan kebutuhan unik Anda.

Hubungi

Jangan ragu untuk mengirim email kepada kami atau mengisi formulir di bawah ini untuk mendapatkan penawaran.

Email: uplastech@gmail.com