Thermoforming is a versatile manufacturing process used to create a wide range of plastic products, from packaging to automotive components. However, one common defect that can occur during thermoforming is webbing, which appears as unwanted wrinkles or folds in the plastic sheet. Webbing can compromise both the aesthetic and functional qualities of the final product, leading to issues such as poor fit, added friction, or structural weaknesses. Preventing webbing is therefore crucial for ensuring high-quality thermoformed parts.

Key strategies for preventing webbing include optimizing mold design, ensuring uniform heating, selecting appropriate materials, and choosing the right forming technique.

Understanding the causes of webbing and how to mitigate them is essential for manufacturers aiming to produce defect-free parts. This guide explores the materials, processes, and design considerations that can help you avoid webbing in thermoforming.

Proper mold design is the most important factor in preventing webbing.True

Mold designs with rounded corners, appropriate draft angles, and avoidance of sharp transitions can significantly reduce the risk of webbing by promoting even material distribution.

Webbing can be completely eliminated by using thicker plastic sheets.False

While thicker sheets are less prone to webbing, other factors such as mold design and process parameters must also be optimized to prevent webbing effectively.

- 1. What are the Common Materials Used in Thermoforming to Minimize Webbing?

- 2. What are the Steps in the Thermoforming Process Where Webbing Can Occur?

- 3. What are the Key Factors in Preventing Webbing in Thermoforming?

- 4. What are the Applications Where Preventing Webbing is Critical?

- 5. What are the Differences Between Thermoforming and Injection Molding Regarding Webbing?

- 6. Conclusion

What are the Common Materials Used in Thermoforming to Minimize Webbing?

Selecting the right material is critical for minimizing webbing in thermoforming. Different plastics exhibit varying behaviors during the forming process, with some being more susceptible to webbing than others. Below are the most common materials used in thermoforming, along with their tendencies regarding webbing.

-

PET (Polyethylene Terephthalate): Known for its rigidity and clarity, PET is less prone to webbing, making it ideal for applications like packaging where smooth surfaces are essential.

-

ABS (Acrylonitrile Butadiene Styrene): A versatile plastic that can be prone to webbing if overheated or overstretched, but it performs well with proper process control.

-

PP (Polypropylene): Valued for its chemical resistance, PP can be prone to webbing in thin gauges but is manageable with careful heating and forming techniques.

Table: Thermoforming Plastics and Webbing Tendencies

| Plastic Type | Typical Thickness Range | Notes on Webbing |

|---|---|---|

| PET | 0.010" - 0.060" | Less prone to webbing due to rigidity |

| ABS | 0.030" - 0.250" | Can web if overheated or stretched too much |

| PP | 0.020" - 0.125" | Prone to webbing in thin gauges |

PET is the best material for preventing webbing in thermoforming.False

While PET is less prone to webbing, the best material depends on the specific application and process conditions.

For more insights on material selection, check out Advanced Plastiform: How to Avoid Webbing in Thermoformed Plastics1.

What are the Steps in the Thermoforming Process Where Webbing Can Occur?

The thermoforming process involves several stages, and webbing can emerge at various points if not properly managed. Understanding these steps helps pinpoint where to apply prevention strategies.

-

Heating: The plastic sheet is heated to its softening point. Uneven heating can cause certain areas to stretch more than others, increasing the risk of webbing.

-

Forming: The heated sheet is stretched over the mold using vacuum, pressure, or mechanical force. This is the primary stage where webbing occurs if the material does not distribute evenly.

-

Cooling: The formed part is cooled to set its shape. Improper cooling can worsen existing webbing or introduce additional distortions.

-

Trimming: Excess material is trimmed away. While webbing is usually set by this stage, trimming can highlight or aggravate existing defects.

Webbing only occurs during the forming stage.False

While webbing is most common during forming, issues in heating or cooling can also contribute to its formation.

For a deeper dive into the thermoforming process, visit Wikipedia: Thermoforming2.

What are the Key Factors in Preventing Webbing in Thermoforming?

Several factors influence the occurrence of webbing, and addressing them is key to achieving defect-free production. Here are the most critical elements to consider.

-

Mold Design:

-

Use draft angles (1.5°–2° for female features, 4°–6° for male) to facilitate material flow and part release.

-

Incorporate rounded corners (minimum 0.015"–0.125" radius) to avoid sharp transitions that can trap material and cause webbing.

-

-

Sheet Thickness:

- Thicker sheets (>1/16") are less susceptible to webbing but require precise heating to prevent other defects.

-

Heating Uniformity:

- Even heating prevents overly stretchy areas that can lead to webbing.

-

Forming Technique:

- Pressure forming applies positive pressure to distribute material more evenly, reducing webbing compared to vacuum forming.

Using pressure forming instead of vacuum forming can reduce the risk of webbing.True

Pressure forming applies positive pressure to the sheet, helping distribute the material more evenly and reducing webbing compared to vacuum forming.

For detailed guidelines, refer to Ray Products: Designing: From the Design Guide Chapter 23.

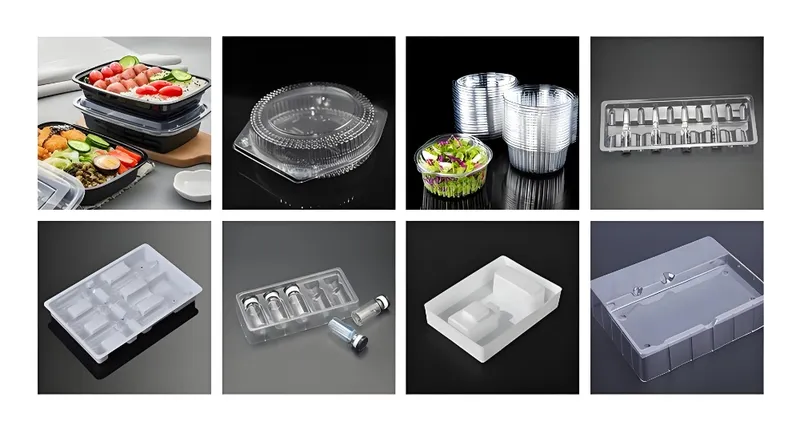

What are the Applications Where Preventing Webbing is Critical?

Webbing can be especially detrimental in industries where precision and aesthetics are vital. Below are key applications where avoiding webbing is a priority.

-

Packaging:

- Webbing can compromise seal integrity in blister packs or food containers, risking contamination or reduced shelf life.

-

Automotive:

- Interior panels and trim require smooth surfaces for aesthetics and functionality, such as proper fit and minimal friction.

-

Medical Devices:

- Trays and packaging must be defect-free to ensure sterility and proper fit, as webbing can harbor bacteria or disrupt device placement.

In these sectors, preventing webbing is essential for both product quality and performance.

Webbing is only a cosmetic issue in thermoformed parts.False

Webbing affects both appearance and functionality, potentially causing fit issues, added friction, or structural weaknesses.

What are the Differences Between Thermoforming and Injection Molding Regarding Webbing?

Thermoforming4 and injection molding are both used to produce plastic parts, but they differ significantly in terms of webbing.

-

Thermoforming:

-

Free of webbing issues, as molten plastic is injected into a closed mold under high pressure, ensuring uniform distribution.

-

However, it’s often costlier for large parts or low-to-medium volumes.

Thermoforming excels for larger parts, lower production runs, and faster prototyping, despite the webbing risk, while injection molding suits high-volume, intricate components.

Injection molding is always a better choice than thermoforming to avoid webbing.False

While injection molding avoids webbing, thermoforming is more cost-effective for certain applications, and webbing can be managed with proper design and process control.

For a detailed comparison, see Productive Plastics: Injection Molding vs. Thermoforming7.

Conclusion

Preventing webbing in thermoforming demands a comprehensive approach, encompassing optimized mold design8, careful material selection9, and precise process control10. By addressing factors such as mold geometry, sheet thickness, and heating uniformity, manufacturers can produce high-quality parts that meet the rigorous demands of industries like packaging, automotive, and medical devices. Mastering these techniques ensures defect-free production and enhances both the functionality and appearance of thermoformed products.

-

Advanced Plastiform: How to Avoid Webbing in Thermoformed Plastics ↩

-

Discover the benefits of thermoforming for larger parts and prototyping, which can enhance your production strategy. ↩

-

Understanding webbing is crucial for optimizing plastic production processes. Explore this link to learn more about its impact and solutions. ↩

-

Learn how injection molding can improve efficiency and quality in high-volume production, making it a valuable resource for manufacturers. ↩

-

Exploring this resource will provide insights into effective mold design techniques that enhance product quality and efficiency. ↩

-

Understanding material selection is crucial for achieving optimal results in thermoforming, ensuring durability and performance of the final product. ↩

-

Learning about process control can help manufacturers minimize defects and improve the overall quality of thermoformed products. ↩