Introduction to Custom Extrusions

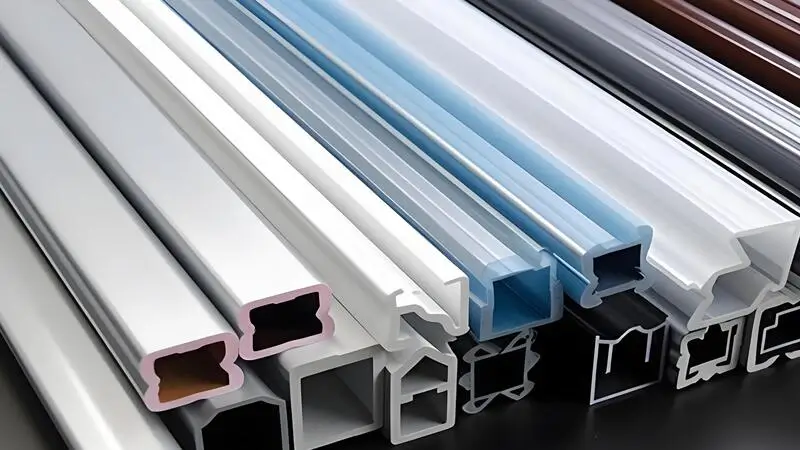

Custom extrusions are revolutionizing manufacturing by offering a versatile and cost-effective way to create products with specific shapes and properties.

This process involves pushing materials like aluminum or plastic through a die to produce tailored solutions for industries such as construction, automotive, and agriculture. Unlike traditional manufacturing methods, custom extrusions1 reduce material waste and enable the creation of complex designs that meet precise specifications.

Custom extrusions are a cost-effective solution for many industries.True

By reducing material waste and enabling efficient production processes, custom extrusions help companies cut costs and improve their bottom line.

For deeper insights into market trends, check out the IMARC Group's aluminum extrusion market2 report.

How Custom Extrusions are Used Across Industries

Custom extrusions are increasingly vital across diverse sectors, addressing unique challenges with tailored applications.

In construction, custom aluminum extrusions are used for window frames, siding, and railings, prized for their corrosion resistance, durability, and design flexibility. The automotive industry leverages custom plastic extrusions for interior trim, seals, and structural components, reducing vehicle weight and boosting fuel efficiency. In agriculture, custom extrusions form tubing and crop protection systems, supporting sustainable practices and enhancing yields.

| Industry | Applications | Benefits |

|---|---|---|

| Construction | Window frames, siding, railings | Lightweight, durable, customizable, corrosion-resistant |

| Automotive | Interior trim, seals, structural components | Reduces weight, improves fuel efficiency, design flexibility |

| Agriculture | Tubing, crop protection | Enhances yield, supports sustainability, cost-effective |

The Growing Demand for Custom Extrusions

The demand for custom extrusions is surging, propelled by their adaptability and efficiency. The IMARC Group projects the global aluminum extrusion market to grow at a compound annual growth rate (CAGR) of 7.6% from 2024 to 2033. Meanwhile, the plastic extrusion market3 is anticipated to expand at a CAGR of 3.7% from 2022 to 2030, according to Inplex LLC's trends. This growth is fueled by trends like the adoption of Industry 4.0 practices—such as real-time monitoring and predictive maintenance—which enhance production efficiency and accessibility.

The demand for custom extrusions is expected to grow significantly in the coming years.True

Market projections indicate strong growth, driven by cost efficiency, sustainability, and technological advancements.

Factors Driving the Demand

Several key factors are behind the rising popularity of custom extrusions:

-

Cost Savings4: By producing parts with precise shapes and minimizing waste, custom extrusions reduce the need for additional machining or assembly, lowering overall costs.

-

Design Flexibility5: The process allows for complex shapes and the integration of multiple functions into a single component, streamlining production and enhancing product performance.

-

Regulatory and Performance Benefits6: Custom extrusions help meet industry standards, such as fuel efficiency mandates in automotive or durability requirements in construction.

These advantages make custom extrusions a go-to solution for companies aiming to stay competitive and innovative.

Challenges and Opportunities

Despite their growth, custom extrusions face hurdles. Supply chain disruptions—like those seen during the COVID-19 pandemic—have impacted raw material availability and transportation costs. Economic uncertainty and the need for specialized equipment also pose challenges. Yet, these obstacles open doors for progress:

-

Innovation: Companies are turning to local sourcing and automation to overcome supply chain issues.

-

New Materials: Advances in high-strength plastics and alloys are expanding applications into fields like aerospace and medical devices.

-

Emerging Markets: Growth opportunities abound in regions like South America, Africa, and Southeast Asia.

Technological advancements are making custom extrusions more accessible and versatile.True

Innovations in materials and manufacturing processes are expanding the applications and efficiency of custom extrusions.

Conclusion

Custom extrusions are reshaping manufacturing with their cost-effectiveness, versatility, and ability to meet industry-specific needs. As demand climbs—driven by savings, flexibility, and technological progress—the industry is poised for innovation and expansion. By embracing new materials and advanced technologies, companies can capitalize on this trend, positioning themselves for success in a dynamic market. The future of custom extrusions promises continued growth as industries prioritize efficient, sustainable solutions.

-

Explore this link to understand how custom extrusions can enhance manufacturing efficiency and product design. ↩

-

This resource provides valuable insights into market trends and growth projections for aluminum extrusions. ↩

-

Discover the latest trends and forecasts in the plastic extrusion market to stay informed about industry developments. ↩

-

Explore how cost savings in custom extrusions can enhance your manufacturing efficiency and reduce expenses. ↩

-

Learn about the importance of design flexibility in custom extrusions and how it can improve product performance. ↩

-

Discover how custom extrusions can help meet industry standards and enhance product durability and efficiency. ↩