Cycle time in thermoforming—the total duration from loading a plastic sheet into the machine to removing the finished part—is a key indicator of production efficiency and cost-effectiveness. In industries like packaging, automotive, and consumer goods, where thermoforming is prevalent, optimizing cycle time can significantly boost output and profitability.

Cycle time in thermoforming is shaped by material properties, sheet thickness, heating and cooling methods, machine design, and part complexity, with cooling often being the most time-intensive phase.

This blog post explores the critical factors that determine cycle time in thermoforming1, offering insights for both newcomers and seasoned professionals. By understanding these elements, you can enhance your thermoforming processes for better speed and efficiency.

Cycle time includes all steps from sheet loading to part removal in thermoforming.True

It covers loading, heating, forming, cooling, and removal, making it a comprehensive measure of production speed.

Cooling is always the longest step in thermoforming.False

While cooling often dominates, especially for thicker parts, heating can take longer depending on material and equipment.

- 1. What are the Key Factors Affecting Cycle Time in Thermoforming?

- 2. How Do These Factors Impact Thermoforming Applications?

- 3. What is the Full Workflow of the Thermoforming Process?

- 4. How Can You Optimize Cycle Time in Thermoforming?

- 5. How Does Thermoforming Relate to Other Manufacturing Technologies?

- 6. Conclusion

What are the Key Factors Affecting Cycle Time in Thermoforming?

Several variables influence how long it takes to complete a thermoforming cycle. Below, we break down the primary factors and their impacts.

Material type, sheet thickness, heating and cooling methods, machine design, and part geometry are the main drivers of cycle time in thermoforming.

| Factor | Impact on Cycle Time | Notes |

|---|---|---|

| Material Type2 | Varies by plastic | E.g., PP heats faster than PC |

| Sheet Thickness | Thicker = longer cycle | More time to heat and cool |

| Heating Method | Efficient heating cuts time | Double-sided heating speeds up |

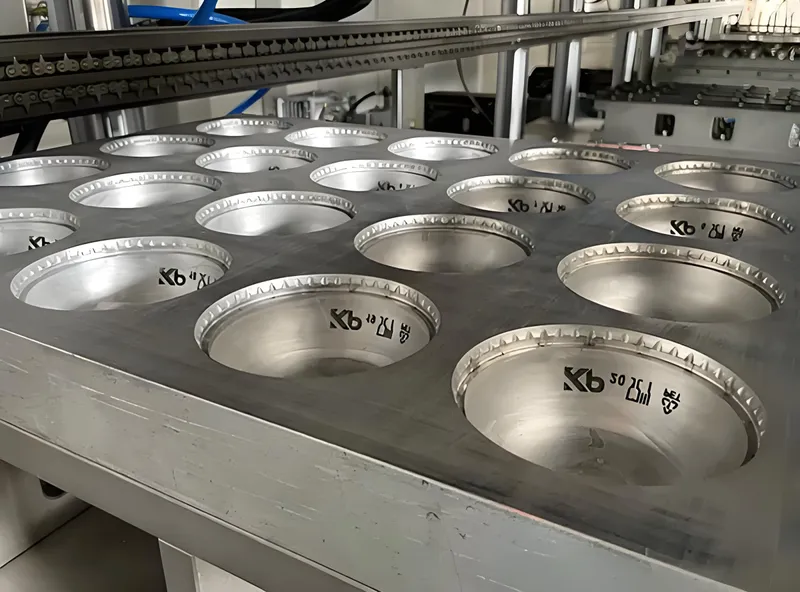

| Cooling Method | Aluminum molds cool faster | Vs. epoxy or wood molds |

| Part Geometry | Complex shapes take longer | Uniform thickness helps |

| Machine Type | Rotary machines can be faster | Overlapping steps save time |

Material Type and Thickness

The type of thermoplastic used—such as polypropylene (PP), polycarbonate (PC), or acrylonitrile butadiene styrene (ABS)—affects cycle time3 due to differing thermal properties. For instance, PP heats quickly but may cool more slowly than PC. Sheet thickness is equally critical; thicker sheets need more time to heat evenly and cool down, extending the overall cycle.

Heating Methods

Heating the plastic sheet to a pliable state is a pivotal step. Infrared heaters are standard for their speed and uniformity, but efficiency varies with factors like wavelength and heater placement. Double-sided heating, where heat is applied to both sides of the sheet, can significantly reduce heating time compared to single-sided methods.

Cooling Methods and Mold Design

Cooling often consumes the most time, especially for thick or intricate parts. Mold material plays a big role: aluminum molds, with high thermal conductivity, cool parts faster than epoxy or wood alternatives. Adding cooling channels4 within the mold can further accelerate this process, making it vital for high-speed production.

Part Geometry

The shape of the final part influences both forming and cooling durations. Complex designs with deep draws or detailed features take longer to form and cool evenly. Parts with uniform wall thickness cool more quickly, as heat dissipates consistently, reducing cycle time.

Machine Type

Thermoforming machines vary in design, impacting cycle time. Rotary machines, with multiple stations (e.g., for loading, heating, forming, and cooling), allow steps to overlap, cutting total time compared to single-station shuttle machines, which process one step at a time.

Thicker plastic sheets always increase cycle time.True

Thicker sheets require extended heating and cooling periods for uniform temperature distribution.

Aluminum molds always outperform other materials in reducing cycle time.False

While aluminum cools faster, cost or specific part needs might favor other materials like epoxy.

How Do These Factors Impact Thermoforming Applications?

These factors shape how thermoforming is applied across industries, balancing speed, cost, and quality. Let’s examine their practical implications.

In high-volume settings, fast cooling and efficient machines minimize cycle time, while prototyping prioritizes flexibility over speed.

Typical Application Scenarios

In high-volume production, like packaging or automotive parts, minimizing cycle time is crucial. Rotary machines paired with aluminum molds5 can streamline output. For prototyping or small batches, where speed is less critical, shuttle machines and varied mold materials offer greater flexibility.

Pros and Cons Compared to Other Technologies

Compared to injection molding, thermoforming often has longer cycle times per part but lower tooling costs and quicker setup, ideal for medium to low volumes. Pressure forming, a thermoforming variant, can shorten cycle times for complex parts versus vacuum forming, though it may raise equipment expenses.

Thermoforming is always slower than injection molding.False

While injection molding excels in high-volume speed, thermoforming’s cost and setup advantages suit other scenarios.

What is the Full Workflow of the Thermoforming Process?

To understand cycle time, we need to map out the thermoforming process, where each step contributes to the total duration.

Thermoforming involves sheet loading, heating, forming, cooling, and part removal, with cooling typically taking the longest.

1. Sheet Loading

The process begins with placing the plastic sheet into the machine. Automated systems in high-volume setups minimize this step’s duration.

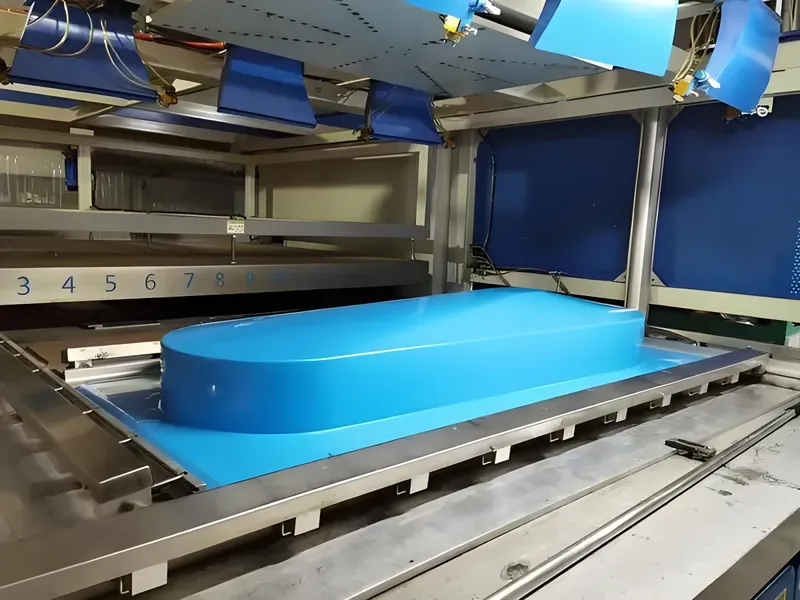

2. Heating

The sheet is heated to a formable temperature. Time varies by material and thickness—e.g., a .020-inch PVC sheet might take 20 seconds in a 4-index oven (Thermoformingdivision).

3. Forming

The pliable sheet is shaped over a mold using vacuum, pressure, or mechanical force. Complex shapes or deep draws extend this phase.

4. Cooling

The formed part cools in the mold until rigid. Aluminum molds with water cooling can cut this time significantly—up to 10 times faster than other setups (Plastic Components Inc.).

5. Part Removal

The finished part is ejected, often with trimming or post-processing. In rotary machines6, this overlaps with other steps, saving time.

Cooling is typically the longest step in thermoforming.True

Especially for thick parts, cooling dominates as the part must fully solidify before removal.

How Can You Optimize Cycle Time in Thermoforming?

Reducing cycle time requires strategic choices in materials, design, and equipment. Here are practical tools to guide optimization.

Optimize with aluminum molds, efficient heating, and uniform part designs to cut cycle time in thermoforming.

Design Checklist for Minimizing Cycle Time

-

Material Selection: Opt for plastics with fast heating/cooling profiles, like those with lower melting points.

-

Part Design: Aim for uniform wall thickness7 to ensure even cooling.

-

Mold Design: Use aluminum molds with cooling channels spaced 2–3 inches apart for rapid heat transfer (Thermoformingdivision).

-

Process Parameters: Adjust temperature and press speed to balance speed and quality.

- Machine Setup: Employ rotary machines for high-volume runs to overlap steps.

Process Selection Decision-Making

-

Vacuum vs. Pressure Forming: Pressure forming speeds up complex part production but may increase costs.

-

Machine Type: Rotary machines suit high throughput; shuttle machines offer versatility for smaller runs.

Mold design optimization is the best way to reduce cycle time.False

While important, a combined approach with material and machine optimization yields the best results.

How Does Thermoforming Relate to Other Manufacturing Technologies?

Thermoforming’s cycle time factors tie into broader manufacturing contexts, offering perspective on its role.

Thermoforming has longer per-part cycle times than injection molding but excels in cost and flexibility for medium to low volumes.

Related Technologies

-

Injection Molding: Faster for high volumes but costlier in tooling (Productive Plastics).

-

Blow Molding: Similar heating/cooling dynamics apply for hollow parts.

-

Extrusion: Supplies thermoforming sheets, influencing material properties and cycle time indirectly.

Thermoforming is always ideal for low-volume production.False

It’s cost-effective, but alternatives like 3D printing may suit very small runs or complex shapes better.

Conclusion

Cycle time in thermoforming hinges on material properties, machine efficiency, and part design. By leveraging fast-cooling molds, optimized heating, and strategic machine choices, you can slash production times and boost efficiency. Whether you’re scaling up manufacturing or refining a prototype, mastering these factors is key to success in thermoforming.

-

Understanding the factors influencing cycle time can help optimize production efficiency and reduce costs in thermoforming processes. ↩

-

Exploring the impact of different materials on cycle time can lead to better material selection and improved production outcomes. ↩

-

Understanding cycle time is crucial for optimizing production efficiency in thermoforming processes. Explore this link for in-depth insights. ↩

-

Cooling channels are essential for reducing cycle time. Discover how they enhance production speed and quality in thermoforming. ↩

-

Aluminum molds significantly enhance cooling rates, leading to faster production cycles and improved efficiency. ↩

-

Rotary machines allow for overlapping processes, drastically reducing cycle time in high-volume production settings. ↩

-

Learning about the significance of uniform wall thickness can help you achieve better cooling and quality in your products. ↩