Thermoforming machines are essential in modern manufacturing, enabling the production of precise, durable plastic products by heating and shaping thermoplastic sheets, commonly used in industries like packaging, automotive, and medical.

Understanding the thermoforming process and its applications is crucial for leveraging its benefits in various industries. This guide explores thermoforming machines, their materials, processes, influencing factors, applications, and how they compare to injection molding.

Thermoforming is a versatile manufacturing process.Verdadero

It can produce both lightweight packaging and robust structural components, making it suitable for diverse applications.

Thermoforming is only used for small-scale production.Falso

Thermoforming is efficient for both small and large production runs, depending on the machine and setup.

- 1. What is a Thermoforming Machine?

- 2. ¿Cuáles son los materiales más utilizados en el termoformado?

- 3. ¿Cuáles son las etapas del proceso de termoformado?

- 4. What are the Key Factors in the Thermoforming Process?

- 5. ¿Cuáles son las aplicaciones del termoformado?

- 6. What are the Differences Between Thermoforming and Injection Molding?

- 7. Conclusión

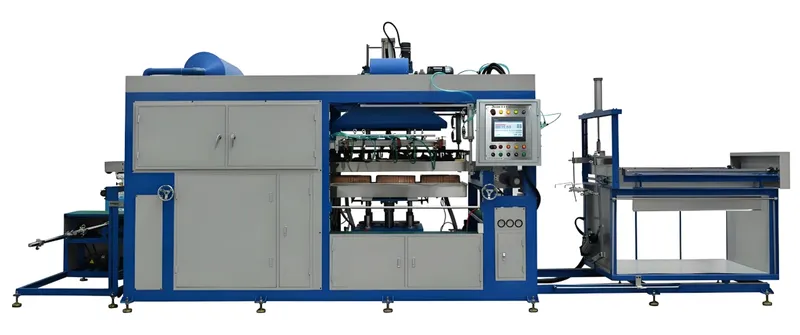

What is a Thermoforming Machine?

Thermoforming machines are pivotal in industries requiring precise, durable plastic products, enhancing efficiency and reducing costs.

A thermoforming machine heats a thermoplastic sheet until it becomes pliable, shapes it using a mold with vacuum, pressure, or mechanical force, and cools it to retain the form. Different types include vacuum forming, pressure forming, and twin-sheet forming, each tailored to specific needs.

| Thermoforming Type | Descripción | Aplicaciones |

|---|---|---|

| Moldeo por vacío | Uses vacuum to shape the sheet | Envases, bandejas |

| Moldeo a presión | Applies additional pressure for detailed parts | Complex shapes, enclosures |

| Conformado de doble chapa | Forma dos chapas simultáneamente para piezas huecas | Containers, panels |

Moldeo por vacío

Vacuum forming uses a vacuum to pull a heated plastic sheet over a mold, ideal for simple, large parts like trays. Learn more about the proceso de formación al vacío1.

Moldeo a presión

Pressure forming adds air pressure for finer details, suitable for complex parts like medical housings, offering enhanced surface quality.

Conformado de doble chapa

Twin-sheet forming creates hollow parts by forming two sheets simultaneously, used for items like containers and panels.

Thermoforming machines can handle both thin and thick gauge materials.Verdadero

Thermoforming is versatile, allowing for the production of both lightweight packaging and robust structural components.

¿Cuáles son los materiales más utilizados en el termoformado?

Thermoforming materials are essential for creating products that are lightweight, durable, and cost-effective, enhancing performance across industries.

Common materials include polystyrene (PS), polyethylene terephthalate (PET), polypropylene (PP), and acrylonitrile butadiene styrene (ABS), each chosen for specific properties.

| Material | Propiedades | Aplicaciones |

|---|---|---|

| Poliestireno (PS) | Rigid, brittle, clear | Disposable cups, food containers |

| Tereftalato de polietileno (PET) | Strong, lightweight, recyclable | Blister packs, trays |

| Polipropileno (PP) | Flexible, resistente a productos químicos | Piezas de automóvil, envases |

| Acrilonitrilo butadieno estireno (ABS) | Resistente a los golpes | Automotive components, housings |

Poliestireno (PS)

PS is valued for its clarity and rigidity, perfect for disposable items, though it’s less impact-resistant.

Tereftalato de polietileno (PET)

PET’s strength and recyclability make it a top choice for packaging like blister packs. Explore PET properties2.

Polipropileno (PP)

PP’s flexibility and chemical resistance suit it for automotive parts and reusable containers.

Acrilonitrilo butadieno estireno (ABS)

ABS offers toughness, ideal for structural components in automotive and electronics.

PET is a popular choice for thermoforming due to its recyclability.Verdadero

PET’s strength, clarity, and recyclability make it ideal for sustainable packaging solutions.

¿Cuáles son las etapas del proceso de termoformado?

The thermoforming process is critical for producing precise, durable products by shaping heated plastic sheets over molds.

The process includes heating, forming, cooling, and trimming, with variations depending on the method used.

Calefacción

The plastic sheet is heated to a pliable state using infrared heaters or ovens, a key step for quality forming.

Formando

The heated sheet is shaped over a mold using vacuum, pressure, or mechanical force, determining part detail.

Refrigeración

The part is cooled with air or water to maintain its shape, preventing warping.

Recorte

Excess material is removed, finalizing the product, often automated for efficiency.

Proper heating is critical for successful thermoforming.Verdadero

Achieving the right temperature ensures the plastic is pliable without degrading, affecting the quality of the final product.

What are the Key Factors in the Thermoforming Process?

The thermoforming process relies on several factors that determine the quality and performance of the final product.

Key factors include temperature, mold design, vacuum/pressure levels, material properties, and cooling rate.

Heating Temperature and Time

Precise heating ensures pliability without degradation, critical for part quality.

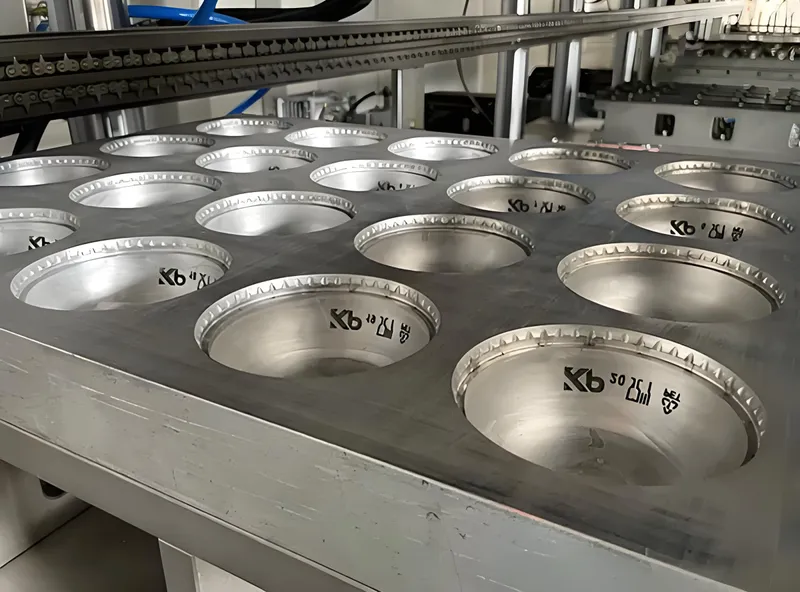

Diseño de moldes

Mold shape and finish impact detail and removal ease. See mold design tips3.

Vacuum or Pressure Level

These levels affect how well the plastic conforms to the mold, influencing thickness and detail.

Propiedades de los materiales

Thickness and thermal properties dictate forming behavior and part characteristics.

Tasa de enfriamiento

Controlled cooling prevents defects like shrinkage, balancing speed and quality.

Mold design significantly impacts part quality.Verdadero

The mold’s shape, draft angles, and surface finish determine the detail and ease of part removal.

¿Cuáles son las aplicaciones del termoformado?

Thermoforming offers versatile solutions in manufacturing, contributing to lightweight, durable products across several sectors.

It’s used in packaging, automotive, medical, and more for its efficiency and cost-effectiveness.

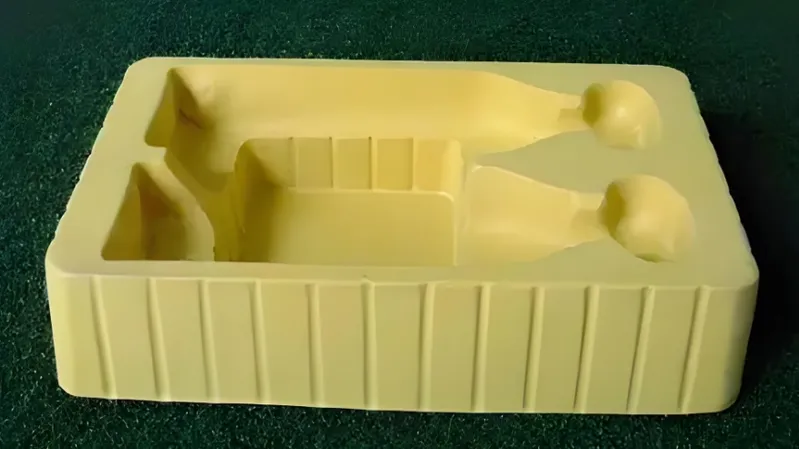

Embalaje

Produces items like cups, trays, and blister packs, leveraging thin-gauge materials.

Automoción

Creates dashboards and panels, benefiting from thick-gauge durability. See automotive applications4.

Médico

Makes sterile trays and housings, meeting precision standards.

Aeroespacial

Forms lightweight panels, reducing aircraft weight.

Thermoforming is widely used in the automotive industry.Verdadero

Its ability to produce large, lightweight parts makes it ideal for automotive interior components.

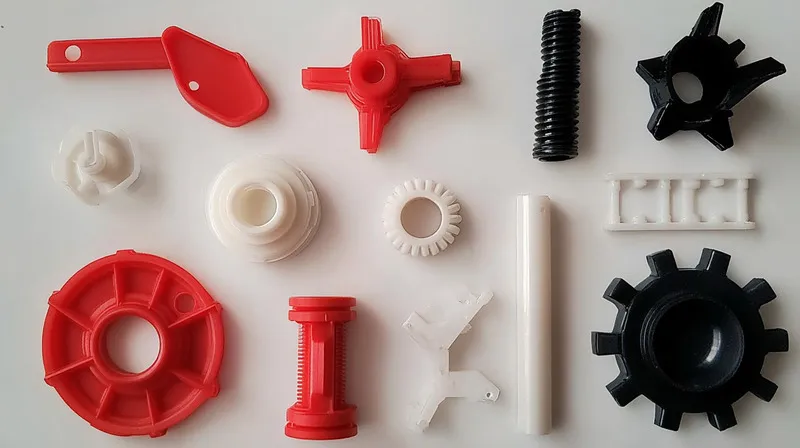

What are the Differences Between Thermoforming and Injection Molding?

Termoformado5 y moldeo por inyección6 differ in process, cost, and application suitability.

Flujo de procesos

Thermoforming shapes a heated sheet over a mold; injection molding injects molten plastic into a cavity.

Principio

Thermoforming stretches a sheet, while injection molding fills a mold, affecting part complexity.

Características del moldeo

Thermoforming suits large, shallow parts; injection molding excels with detailed, 3D shapes.

Escenarios de aplicación

Thermoforming is cost-effective for low to medium runs; injection molding fits high-volume, complex parts.

Ventajas y desventajas

Thermoforming has lower tooling costs; injection molding offers precision for mass production.

Thermoforming has lower tooling costs than injection molding.Verdadero

This makes thermoforming more economical for small to medium production runs.

Conclusión

Thermoforming machines7 are vital for producing diverse plastic products efficiently. By mastering materials, processes, and factors, manufacturers can optimize outcomes for packaging, automotive8, and beyond, offering a cost-effective alternative9 to methods like injection molding.

-

Learn more about vacuum forming techniques and applications. ↩

-

Explore PET’s role in thermoforming and its benefits. ↩

-

Understand how mold design enhances thermoforming quality. ↩

-

Discover thermoforming’s impact in the automotive sector. ↩

-

Explore the benefits of Thermoforming to understand its cost-effectiveness and suitability for various applications. ↩

-

Learn about injection molding to see how it excels in producing complex parts with precision and efficiency. ↩

-

Explore how Thermoforming machines enhance production efficiency and reduce costs in various industries. ↩

-

Discover the applications of Thermoforming in key industries and its impact on product design and functionality. ↩

-

Learn about the advantages of Thermoforming over injection molding and how it can save costs in production. ↩