Environmental policies are increasingly shaping the industrial landscape, and the extrusion industry is no exception. Extrusion, a manufacturing process where materials like plastics and metals are melted and forced through a die to create continuous shapes such as pipes, sheets, and films, is being reshaped by regulations aimed at reducing environmental harm. These policies influence material choices, energy consumption, and waste management, driving the industry towards sustainability. This blog post explores how environmental policies impact the extrusion industry, offering insights for professionals, policymakers, and sustainability enthusiasts.

Environmental policies are significantly influencing the extrusion industry by encouraging the adoption of sustainable materials1 and energy-efficient processes, reducing its environmental footprint.

Understanding this dynamic is essential for navigating the evolving extrusion landscape. Read on to discover how these policies affect processes, applications, and technologies in the industry.

Environmental policies are driving the extrusion industry towards more sustainable practices.True

Policies promote reduced emissions, waste minimization, and eco-friendly materials, leading to greener manufacturing processes.

Environmental policies have no impact on the extrusion industry.False

Policies directly affect material choices, energy use, and waste management, significantly altering operations.

- 1. What is Extrusion and How Do Environmental Policies Affect It?

- 2. How Are Extrusion Processes Classified and Influenced by Environmental Policies?

- 3. What Are the Typical Applications of Extrusion and How Do Policies Impact Them?

- 4. How Do Environmental Policies Influence the Extrusion Process Workflow?

- 5. What Practical Tools Can Help Navigate Environmental Policies in Extrusion?

- 6. How Do Environmental Policies Connect Extrusion to Related Technologies?

- 7. Conclusion

What is Extrusion and How Do Environmental Policies Affect It?

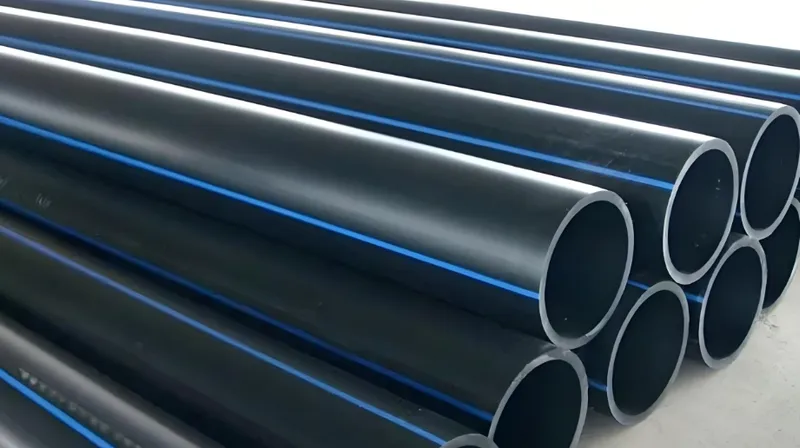

Extrusion is a versatile manufacturing process where materials—typically plastics like polyethylene or metals like aluminum—are melted and pushed through a die to form continuous shapes. Environmental policies, comprising regulations and guidelines, aim to protect the environment by controlling emissions, waste, and resource use. These policies are transforming the extrusion industry by promoting sustainable practices, such as using recycled materials and adopting energy-efficient technologies.

Environmental policies are reshaping the extrusion industry by pushing for sustainable materials and energy-efficient processes, aligning production with global sustainability goals.

For example, policies like the EU's Circular Economy Action Plan encourage the use of recycled plastics2, while energy efficiency standards reduce the carbon footprint of extrusion processes. This shift is critical for industry professionals aiming to stay compliant and competitive.

How Are Extrusion Processes Classified and Influenced by Environmental Policies?

Extrusion processes vary by type, material, and application, each influenced uniquely by environmental policies:

-

Process Type: Hot extrusion (used for metals like aluminum) and cold extrusion (common for plastics) differ in energy demands, with policies favoring lower-energy cold processes.

-

Materials: Thermoplastics (e.g., polyethylene), thermosets, and metals (e.g., aluminum) are common, with policies promoting recycled or bio-based options.

- Applications: Construction (pipes, window frames), packaging (films), and automotive (trim) see policy-driven shifts towards sustainability.

Environmental policies are reshaping extrusion classifications by promoting sustainable materials and energy-efficient processes3, especially in construction and packaging.

| Classification Type | Examples | Policy Influence |

|---|---|---|

| Process Type | Hot extrusion, cold extrusion | Energy efficiency standards favor cold extrusion for lower energy use. |

| Materials | Thermoplastics, metals | Policies encourage recycled or bio-based materials over virgin plastics. |

| Applications | Construction, packaging | Regulations push for eco-friendly products like recyclable packaging. |

Policies such as the EU's Energy Efficiency Directive drive these changes, encouraging innovations that align with environmental goals.

What Are the Typical Applications of Extrusion and How Do Policies Impact Them?

Extrusion serves diverse industries, with environmental policies influencing each application:

-

Packaging: Plastic films face pressure from policies like the EU's Single-Use Plastics Directive, pushing for biodegradable or recyclable alternatives.

-

Automotive: Lightweight extruded parts reduce vehicle emissions, supporting global emission reduction targets.

-

Construction: Extruded window frames and insulation materials support energy-efficient buildings, aligning with policies like the EU's Energy Efficiency Directive.

While extrusion offers high production rates and versatility, its energy intensity and reliance on non-renewable materials are challenges policies aim to mitigate.

Environmental policies4 are driving innovation in extrusion applications by promoting sustainable materials and energy-efficient designs, notably in construction and automotive sectors.

Extrusion is essential for creating energy-efficient building materials.True

Extruded insulation and window frames enhance energy savings in buildings, supporting sustainability goals.

Extrusion has no role in reducing plastic waste.False

Policies encourage recycled plastics in extrusion, aiding waste reduction efforts.

How Do Environmental Policies Influence the Extrusion Process Workflow?

The extrusion process includes material feeding, melting, extrusion through a die, cooling, and cutting. Environmental policies impact each step:

-

Material Feeding: Regulations promote recycled or bio-based materials5 over virgin plastics.

-

Melting: Energy efficiency standards encourage renewable energy sources and efficient equipment.

-

Extrusion and Cooling: Waste reduction policies advocate recycling production scrap.

-

Cutting and Finishing: Sustainability policies influence designs for end-of-life recyclability.

Material compatibility also shifts, with policies favoring recyclable options like aluminum over petroleum-based plastics.

Environmental policies are transforming the extrusion process by promoting sustainable materials, energy efficiency, and waste reduction at every stage.

| Process Step | Policy Impact |

|---|---|

| Material Feeding | Shift to recycled/bio-based materials |

| Melting | Use of energy-efficient equipment |

| Extrusion and Cooling | Recycling of production waste |

| Cutting and Finishing | Design for recyclability |

What Practical Tools Can Help Navigate Environmental Policies in Extrusion?

To comply with environmental policies, professionals can use these tools:

Design Checklist

-

Use energy-efficient equipment6 (e.g., modern extruders).

-

Select low-impact materials (e.g., recycled plastics).

-

Implement waste reduction strategies (e.g., scrap recycling).

-

Design products for end-of-life recyclability.

Process Selection Decision-Making Guide

-

Material Choice: Prioritize recycled or bio-based materials.

-

Energy Use: Opt for processes with minimal energy consumption (e.g., cold extrusion).

-

Waste Management: Use closed-loop systems to recycle waste.

Practical tools like design checklists and decision-making guides are essential for helping extrusion professionals balance efficiency with environmental compliance.

How Do Environmental Policies Connect Extrusion to Related Technologies?

Environmental policies influence not only extrusion but also related technologies:

-

Injection Molding: Policies promote energy-efficient machines and recycled materials.

-

Additive Manufacturing: Sustainability drives adoption of waste-reducing 3D printing.

These interconnections foster a broader ecosystem of sustainable manufacturing practices.

Environmental policies are fostering a network of sustainable manufacturing technologies, linking extrusion with innovations in injection molding and additive manufacturing.

Conclusion

Environmental policies are revolutionizing the extrusion industry, pushing it towards sustainability through material innovation, energy efficiency, and waste reduction. From construction to packaging, these regulations are driving changes that benefit both the environment and industry stakeholders. By leveraging practical tools and understanding these impacts, professionals can thrive in this evolving landscape.

-

Exploring this resource will provide insights into how sustainable materials can enhance the extrusion process and reduce environmental impact. ↩

-

Discover how recycled plastics are transforming the extrusion industry and contributing to sustainability efforts. ↩

-

This link will help you understand the significance of energy-efficient processes in reducing costs and environmental footprints in extrusion. ↩

-

Explore how environmental policies are reshaping the extrusion industry, promoting sustainability and innovation across various sectors. ↩

-

Discover the significance of using recycled or bio-based materials in extrusion for sustainability and compliance with environmental policies. ↩

-

Learn about the advantages of energy-efficient equipment in extrusion, including cost savings and reduced environmental impact. ↩