Extrusion, a manufacturing process where materials like metals or plastics are forced through a die to create continuous profiles, is a cornerstone of industries such as automotive, aerospace, and packaging. As demands for complexity and efficiency rise, traditional extrusion methods are evolving with the help of digital design tools1—software solutions that streamline design, enhance precision, and reduce costs. These tools are transforming how we approach extrusion, making it more innovative and adaptable to modern needs.

In this post, we’ll dive into the digital design tools revolutionizing extrusion, exploring their applications, benefits, and how they’re reshaping manufacturing. From die design to process simulation, these tools are driving efficiency and opening new possibilities.

Digital design tools like QForm Extrusion Die Designer2 and Altair Inspire Extrude Metal3 are transforming extrusion by automating die creation and simulating material flow, reducing costs and improving product quality.

| Tool Name | Primary Function | Key Benefit |

|---|---|---|

| QForm Extrusion Die Designer | Die design for aluminum | Automates die creation |

| Altair Inspire Extrude Metal | Process simulation | Predicts material behavior |

| Ansys Polyflow | Polymer extrusion simulation | Handles complex polymer flows |

These tools offer a glimpse into the future of extrusion. Let’s explore what they are, how they’re applied, and why they matter.

Digital design tools reduce the need for physical prototypes.True

By simulating the extrusion process, these tools allow engineers to test and optimize designs virtually, minimizing the need for costly physical trials.

All digital design tools are equally effective for all materials.False

Tools are often specialized for specific materials, like metals or polymers, and may not perform optimally outside their intended use.

- 1. What Are Digital Design Tools in Extrusion?

- 2. How Are Digital Design Tools Applied in Extrusion?

- 3. What Is the Workflow for Using Digital Design Tools in Extrusion?

- 4. What Practical Considerations Should Be Made When Using These Tools?

- 5. How Do Digital Design Tools Fit Into the Broader Manufacturing Ecosystem?

- 6. Conclusion

What Are Digital Design Tools in Extrusion?

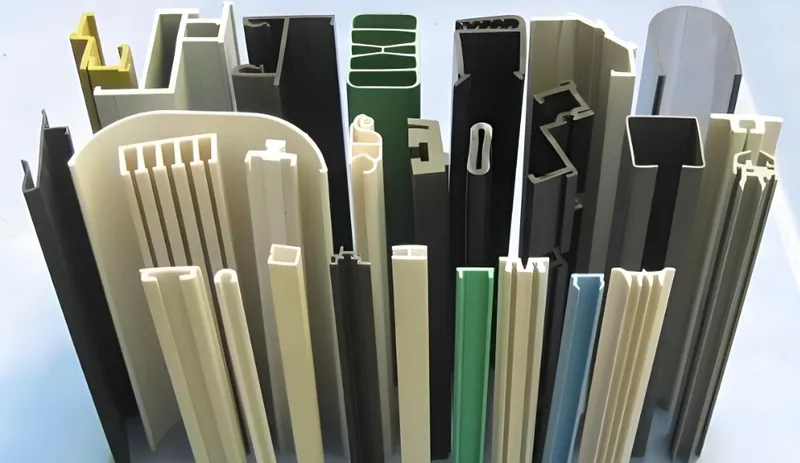

Digital design tools for extrusion are software applications that assist in designing dies, simulating the extrusion process4, and optimizing parameters. They fall into two main categories:

-

Die Design Tools5: These focus on creating the die geometry that shapes the extruded material. For example, QForm Extrusion Die Designer automates die creation for aluminum extrusion, ensuring precision and efficiency.

-

Process Simulation Tools6: These model the extrusion process, predicting material flow, cooling, and potential defects. Tools like Altair Inspire Extrude Metal handle metals, while Ansys Polyflowexcels with polymer extrusion.

You can also classify these tools by the materials they’re designed for—metals (e.g., aluminum, steel) or polymers (e.g., plastics)—since each material has unique flow and processing needs.

Digital design tools can be classified by their function or by the materials they handle.True

Tools are often categorized as die design or process simulation tools, and further distinguished by whether they are optimized for metals or polymers.

All extrusion design tools are equally suitable for both metals and polymers.False

Most tools are specialized for specific materials due to differences in flow behavior and processing conditions.

How Are Digital Design Tools Applied in Extrusion?

These tools address real-world challenges in extrusion, offering practical solutions across industries.

Typical Application Scenarios

-

New Product Development: Need a custom aluminum profile7 for an automotive part? Die design tools quickly generate the die geometry, speeding up the design phase.

-

Process Optimization: Manufacturers can use simulation tools8 to tweak parameters like temperature or speed, reducing defects and boosting efficiency in existing extrusion lines.

-

Troubleshooting: When defects like warping occur, simulation tools pinpoint whether the issue lies in the die design or process conditions, saving time and resources.

These scenarios shine in precision-driven fields like aerospace (metal extrusions) and packaging (polymer profiles).

Pros and Cons Comparison

How do digital tools stack up against traditional methods? Here’s a breakdown:

| Aspect | Pros | Cons |

|---|---|---|

| Speed | Faster design and testing cycles | Initial learning curve for new users |

| Cost Efficiency | Fewer physical prototypes, lower development costs | High upfront software and training costs |

| Quality | Predicts and prevents defects | Relies on accurate material data |

| Flexibility | Handles complex designs effectively | May over-rely on simulation over real-world testing |

Digital tools can significantly reduce development costs in extrusion.True

By minimizing physical prototypes and optimizing designs virtually, these tools lower overall expenses.

Digital design tools always eliminate the need for physical testing.False

While they reduce prototyping, some physical testing is often still needed to validate simulations.

What Is the Workflow for Using Digital Design Tools in Extrusion?

Here’s how these tools come to life in a typical extrusion project:

Process Full Workflow Breakdown

-

Define Product Requirements: Specify the shape, dimensions, and material properties of the extruded product.

-

Material Selection: Choose a material (e.g., aluminum or polymer) based on its flow and extrusion behavior.

-

Die Design: Use tools like QForm to craft the die, setting parameters like die land length for optimal flow.

-

Process Simulation: Simulate the process with tools like Altair or Ansys, tweaking variables like temperature to avoid defects.

-

Analysis and Optimization: Adjust the design or parameters based on simulation results (e.g., fixing uneven flow).

-

Manufacturing: Build the die and run the extrusion process using the optimized settings.

Material Compatibility Explanation

Materials matter. Metals like aluminum need tools that account for strength and heat sensitivity, while polymers require focus on viscosity and cooling rates. Many tools include material libraries, but custom materials may need extra data input for accuracy.

Material properties must be accurately represented for reliable simulations.True

Inaccurate data can skew results, impacting the final product’s quality.

All materials behave similarly during extrusion.False

Metals and polymers have distinct flow characteristics, requiring tailored simulation approaches.

What Practical Considerations Should Be Made When Using These Tools?

To get the most out of these tools, here are some hands-on tips:

Design Checklist

-

Shape Feasibility: Avoid shapes with undercuts or excessive complexity that extrusion can’t handle.

-

Material Properties: Double-check that the software reflects your material’s real-world behavior.

-

Process Parameters: Monitor temperature, pressure, and speed—they’re make-or-break factors.

-

Simulation Accuracy: Treat simulations as a guide, not gospel; real-world variables can differ.

Process Selection Decision-Making

Choosing the right tool? Follow these steps:

-

Identify Needs: Die design, simulation, or both?

-

Match Material: Pick a tool suited for metals or polymers.

-

Check Features: Prioritize usability and material support.

-

Budget: Weigh software costs and training needs.

A design checklist can help prevent common mistakes in extrusion design.True

By addressing key factors like shape and material properties, designers avoid costly errors.

All digital design tools are equally user-friendly.False

Some tools require more training due to their complexity.

How Do Digital Design Tools Fit Into the Broader Manufacturing Ecosystem?

These tools don’t work alone—they’re part of a bigger picture:

-

CAD Software: Tools like SolidWorks handle initial designs before extrusion tools step in.

-

Other Simulations: Pair extrusion tools with Moldflow (injection molding) or Deform (forging) for multi-process workflows.

-

Additive Manufacturing: Use 3D printing for prototyping alongside extrusion design.

This integration streamlines manufacturing from start to finish.

Digital design tools for extrusion can be integrated with other manufacturing software.True

Linking with CAD and other tools creates a seamless design-to-production process.

Extrusion design tools are standalone and do not require other software.False

They work best when paired with CAD and related technologies.

Conclusion

Digital design tools are reshaping extrusion, making it faster, more precise, and cost-effective. Whether you’re crafting dies with QForm, simulating metal flow with Altair, or tackling polymers with Ansys, these tools are vital for staying competitive. Looking ahead, advancements like AI and machine learning promise even smarter extrusion solutions.

By mastering these tools—their applications, strengths, and limits—you can unlock new levels of innovation and efficiency in your extrusion projects.

Digital design tools are essential for modern extrusion processes.True

They streamline design, cut costs, and boost quality, making them indispensable today.

The use of digital design tools eliminates all challenges in extrusion.False

While transformative, they can’t fully address issues like material variability or equipment quirks.

-

Explore this link to discover the latest digital design tools that are revolutionizing the extrusion process and enhancing manufacturing efficiency. ↩

-

Learn how QForm Extrusion Die Designer automates die creation, ensuring precision and efficiency in aluminum extrusion. ↩

-

Find out how Altair Inspire Extrude Metal predicts material behavior, improving product quality and reducing costs in extrusion. ↩

-

Understanding the extrusion process is crucial for optimizing production; this link provides valuable insights into its mechanics and applications. ↩

-

Explore this link to discover top Die Design Tools that enhance precision and efficiency in extrusion processes. ↩

-

Check out this resource to learn about leading Process Simulation Tools that optimize extrusion processes and reduce defects. ↩

-

Explore how custom aluminum profiles can enhance automotive design and performance, offering tailored solutions for specific needs. ↩

-

Learn how simulation tools can optimize manufacturing processes, reduce defects, and enhance efficiency in extrusion applications. ↩