Plastic vacuum forming, also known as vacuum Thermoformung1, is a versatile manufacturing process that shapes heated plastic sheets into precise forms using vacuum pressure. This technique is widely used across industries for its cost-effectiveness, flexibility, and ability to produce detailed, lightweight components. In Israel, a country renowned for its innovation and advanced manufacturing capabilities2, several factories excel in plastic vacuum forming3, catering to diverse sectors such as packaging, automotive, medical, and consumer goods.

Israel's top plastic vacuum forming factories—Vacopak Industries Ltd., MCP Performance Plastic Ltd., Plasto-Vack, RION INDUSTRIES Ltd., and Polycad Plastic Products ACS—lead the industry with their specialization in thermoforming, packaging, and sustainable solutions.

Understanding the capabilities and specialties of these factories is crucial for businesses seeking reliable partners in plastic manufacturing. This blog delves into the top five plastic vacuum forming factories in Israel, exploring their processes, materials, applications, and contributions to the industry.

Vacopak Industries Ltd. is a pioneer in disposable plastic packaging in Israel.Wahr

With over five decades of experience, Vacopak has developed over 8,000 types of high-quality packaging for food, medicine, and technology.

MCP Performance Plastic Ltd. focuses exclusively on packaging for the food industry.Falsch

While MCP specializes in food packaging, it also serves other industries with its advanced thermoplastic solutions.

- 1. What is Plastic Vacuum Forming?

- 2. What are the Common Materials Used in Plastic Vacuum Forming?

- 3. What are the Steps in the Plastic Vacuum Forming Process?

- 4. Was sind die Schlüsselfaktoren im Vakuumformungsprozess?

- 5. What are the Applications of Plastic Vacuum Forming?

- 6. What are the Differences Between Vacuum Forming and Other Plastic Forming Processes?

- 7. Schlussfolgerung

What is Plastic Vacuum Forming?

Plastic vacuum forming is a manufacturing process where a plastic sheet is heated until pliable, stretched over a mold, and shaped using vacuum pressure. This method is ideal for producing lightweight, durable parts with complex geometries, making it a popular choice for industries requiring cost-effective, medium-volume production.

Vacuum forming is used to create products like packaging trays, automotive components, and medical device housings, offering a balance between cost, speed, and design flexibility.

| Factory Name | Location | Founded | Employees | Specialties |

|---|---|---|---|---|

| Vacopak Industries Ltd. | Yehud, Israel | 1972 | 50-100 | Thermoforming, Vacuum Forming, Packaging |

| MCP Performance Plastic Ltd. | HaMa’apil, Israel | 1976 | 51-200 | Thermoplastic Packaging, Vacuum Forming |

| Plasto-Vack | Rishon Lezion, Israel | 1971 | 50-200 | Thermoforming, Plastic Packaging |

| RION INDUSTRIES Ltd. | Kibbutz Cabri, Israel | 1995 | 50-100 | Packaging, Thermoforming, Injection Molding |

| Polycad Plastic Products ACS | Shefayim, Israel | 1974 | 100-200 | Thermoforming, Blow Forming, Injection Molding |

Vacopak Industries Ltd.

Founded in 1972, Vacopak Industries Ltd. is a leader in disposable plastic packaging, specializing in thermoforming and vacuum forming. With over 8,000 packaging solutions developed, Vacopak serves industries like food, medicine, and technology. Their expertise in blister packs and bubble welding makes them a go-to for high-quality, cost-effective packaging (Vacopak Industries Ltd.).

MCP Performance Plastic Ltd.

Established in 1976, MCP Performance Plastic Ltd. focuses on advanced custom co-extruded thermoplastics, particularly for food packaging. Their CPET and APET trays are widely used in the food industry, and their recent acquisition by the MPP group has enhanced their technological capabilities (MCP Performance Plastic Ltd.).

Plasto-Vack

Plasto-Vack, founded in 1971, is Israel’s largest thermoforming PET packaging company. They emphasize sustainability, with 97% of their packaging made from recycled materials. Certified under BRC-IOP standards, Plasto-Vack is a leader in eco-friendly packaging solutions for food and confectionery (Plasto-Vack).

RION INDUSTRIES Ltd.

Part of the PLASSON Group, RION INDUSTRIES Ltd. was founded in 1995 and specializes in complex plastic products for industries like medical equipment and food and beverage. With over 80 injection machines, they offer a wide range of thermoforming and injection molding solutions (RION INDUSTRIES Ltd.).

Polycad Plastic Products ACS

Since 1974, Polycad has been a key player in packaging for detergents and food. Their 12,000 sqm factory houses over 50 advanced machines, enabling them to serve global markets with a focus on Nachhaltigkeit4 and innovation (Polycad Plastic Products ACS).

Plasto-Vack is Israel’s largest thermoforming PET packaging company.Wahr

Plasto-Vack leads the market with its extensive use of recycled materials and innovative designs for food packaging.

All top vacuum forming factories in Israel focus solely on packaging.Falsch

While packaging is a major focus, factories like RION INDUSTRIES Ltd. also serve medical and automotive sectors.

What are the Common Materials Used in Plastic Vacuum Forming?

The choice of materials in vacuum forming is critical, as it affects the product's durability, flexibility, and cost. Factories in Israel use a variety of thermoplastics to meet the needs of different industries.

Common materials in vacuum forming include ABS, HIPS, PVC, PET, and PC, each offering unique properties for applications in packaging, automotive, and medical industries.

| Material Typ | Eigenschaften | Gemeinsame Anwendungen |

|---|---|---|

| ABS | High impact resistance, durable | Autoteile, Konsumgüter |

| HIPS | Kostengünstig, leicht zu formen | Verpackung, Beschilderung |

| PVC | Chemical resistance, versatile | Blisterverpackungen, Medizinprodukte |

| PET | Clarity, barrier properties | Food packaging |

| PC | Hohe Festigkeit, Hitzebeständigkeit | Safety shields, automotive parts |

Acrylnitril-Butadien-Styrol (ABS)

ABS is widely used in vacuum forming for its high impact resistance and durability. It is commonly employed in automotive components like dashboards and interior trims, as well as in consumer goods such as appliance housings (Vacuum Forming Guide).

Hochschlagfestes Polystyrol (HIPS)

HIPS is a cost-effective material ideal for packaging and signage. Its ease of forming and affordability make it a popular choice for disposable trays and display stands.

Polyvinylchlorid (PVC)

PVC offers excellent chemical resistance and is often used in blister packs and medical device housings. Its versatility allows for a wide range of applications, from packaging to industrial components.

Polyethylenterephthalat (PET)

PET is known for its clarity and barrier properties, making it perfect for food packaging. Factories like Plasto-Vack specialize in PET packaging, leveraging its recyclability and sustainability.

Polycarbonat (PC)

PC is valued for its high strength and heat resistance, used in safety shields, automotive parts, and other applications requiring durability and transparency.

ABS is a key material used in vacuum forming for automotive applications.Wahr

ABS's high impact resistance and durability make it ideal for automotive components like dashboards and trim.

Vacuum forming materials are unsuitable for all industries despite their benefits.Wahr

While versatile, some industries may require materials with higher precision or different physical properties, such as aerospace or electronics.

What are the Steps in the Plastic Vacuum Forming Process?

The vacuum forming process is a multi-step procedure that transforms plastic sheets into finished products. Each step is crucial for ensuring the quality and precision of the final part.

The vacuum forming process involves Materialauswahl5, Formgestaltung6, heating, forming, cooling, trimming, and finishing, used across industries for its efficiency and cost-effectiveness.

Auswahl des Materials

Choosing the right plastic sheet is the first step, based on the product's requirements. Common materials include ABS, HIPS, PVC, PET, and PC, each offering specific properties like durability, flexibility, or clarity.

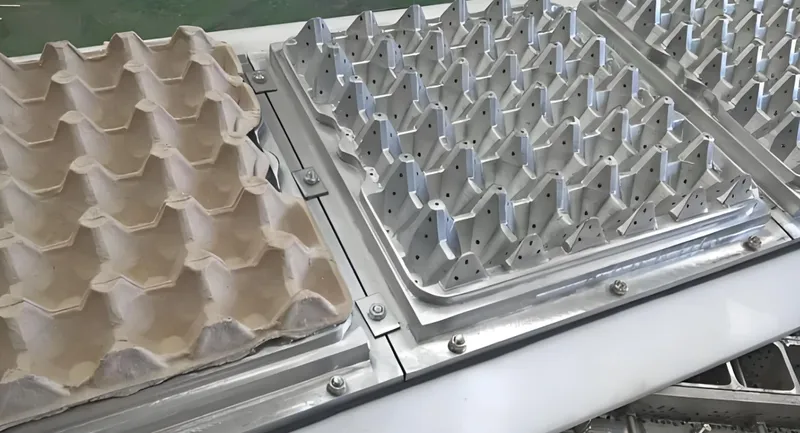

Mold Design and Creation

Molds are typically made from aluminum or wood, with draft angles (minimum 3°) to facilitate part removal. The mold design must account for the part's geometry, including undercuts and deep draws.

Heating the Plastic Sheet

The plastic sheet is clamped and heated uniformly in an oven until it reaches a pliable state. The heating time and temperature depend on the material and thickness.

Bildung von

The heated sheet is lowered onto the mold, and vacuum pressure is applied to pull the plastic tightly against the mold surface, forming the desired shape.

Kühlung

The formed part is cooled on the mold to set the shape, using air, water, or other cooling methods. Proper cooling ensures dimensional stability.

Beschneiden und Endbearbeitung

Excess plastic is trimmed, and secondary operations like drilling, cutting, or assembly are performed to complete the part.

Vacuum forming always results in precise, high-detail parts.Falsch

While vacuum forming is cost-effective, it may not achieve the same level of detail as injection molding, especially for complex geometries.

Vacuum forming reduces tooling costs compared to injection molding.Wahr

Vacuum forming molds are simpler and less expensive to produce, making it ideal for low to medium-volume production.

Was sind die Schlüsselfaktoren im Vakuumformungsprozess?

Several factors influence the success of the vacuum forming process, from material choice to process parameters. Understanding these factors is essential for achieving optimal results.

Key factors in vacuum forming include material selection, mold design, Heiztemperatur7, vacuum pressure, and cooling rate, all of which affect the part's quality and performance.

Auswahl des Materials

The choice of material impacts the part's strength, flexibility, and cost. For example, ABS is used for durable automotive parts, while PET is preferred for food packaging due to its clarity and recyclability.

Formenbau

Mold design must account for draft angles, undercuts, and the part's complexity. Aluminum molds are durable and suitable for high-volume production, while wood molds are cost-effective for prototypes.

Heizung Temperatur

The heating temperature must be carefully controlled to ensure the plastic sheet is uniformly pliable. Overheating can cause the material to degrade, while underheating may result in incomplete forming.

Unterdruck

Sufficient vacuum pressure is necessary to pull the plastic sheet tightly against the mold. Inadequate pressure can lead to poor detail or incomplete forming.

Abkühlungsrate

The cooling rate affects the part's dimensional stability. Rapid cooling can cause warping, while slow cooling ensures the part retains its shape.

Material selection is crucial for determining the final product's properties.Wahr

Different materials offer unique benefits, such as durability, clarity, or cost-effectiveness, directly influencing the product's performance.

All vacuum forming processes use the same mold material.Falsch

Molds can be made from various materials, including aluminum, wood, or epoxy, depending on the production volume and part complexity.

What are the Applications of Plastic Vacuum Forming?

Vacuum forming is used across a wide range of industries due to its versatility and cost-effectiveness. The top factories in Israel cater to these diverse applications with their specialized capabilities.

Vacuum forming is used in packaging, automotive, medical, consumer goods, and signage for its ability to produce lightweight, durable, and cost-effective parts.

Verpackung

Vacuum forming is ideal for producing blisters, trays, and clamshells for food, medicine, and cosmetics. Factories like Vacopak and Plasto-Vack specialize in high-quality packaging solutions8.

Automobilindustrie

In der automotive industry9, vacuum forming is used to create interior trim, dashboards, and console components. The process's ability to handle large, complex shapes makes it a preferred choice.

Medizinische

Medical device housings, trays, and covers are often produced using vacuum forming due to the process's ability to meet hygiene standards and material compatibility requirements.

Konsumgüter

Appliance parts, toy components, and furniture are commonly made with vacuum forming, balancing aesthetics and functionality.

Beschilderung

Vacuum forming is used to create large, visually appealing displays and point-of-purchase signage, leveraging its capability for large-format production.

Vacuum forming reduces production costs for medium-volume runs.Wahr

By using simpler molds and faster production times, vacuum forming is more cost-effective than injection molding for medium-volume production.

Vacuum forming is only used in the packaging industry.Falsch

While packaging is a major application, vacuum forming is also used in automotive, medical, and consumer goods industries.

What are the Differences Between Vacuum Forming and Other Plastic Forming Processes?

Understanding the differences between vacuum forming and other plastic forming methods helps businesses choose the right process for their needs.

Das Vakuumformen unterscheidet sich von Spritzgießen10 in cost, production speed, and part complexity, making it ideal for medium-volume, large-format production.

Vakuumformung vs. Spritzgießen

-

Kosten: Vacuum forming has lower tooling costs due to simpler molds, while injection molding requires expensive, complex molds.

-

Production Speed: Vacuum forming is faster for medium-volume runs, whereas injection molding is better for high-volume production.

-

Part Complexity: Injection molding can achieve higher detail and precision, making it suitable for complex parts with tight tolerances.

Vakuumtiefziehen vs. Blasformen

-

Prozess: Vacuum forming uses a single mold and vacuum pressure, while blow molding uses air pressure to inflate a parison inside a mold.

-

Anwendungen: Blow molding is ideal for hollow objects like bottles, whereas vacuum forming is better for solid, single-sided parts.

Vacuum Forming vs. Thermoforming

-

Scope: Vacuum forming is a subset of thermoforming, which also includes pressure forming and mechanical forming.

-

Druck: Vacuum forming uses negative pressure (vacuum), while pressure forming uses positive pressure for more detailed parts.

Schlussfolgerung

Israel's top plastic vacuum forming factories—Vacopak Industries Ltd., MCP Performance Plastic Ltd., Plasto-Vack, RION INDUSTRIES Ltd., and Polycad Plastic Products ACS—are at the forefront of innovation in thermoforming and packaging. Their expertise in materials, processes, and applications makes them invaluable partners for businesses across industries. Whether you're looking for sustainable packaging solutions or durable automotive components, these factories offer the capabilities and experience to meet your needs.

-

Learn about the advantages of thermoforming, a key technique in plastic manufacturing, and its impact on production efficiency. ↩

-

Discover how advanced manufacturing capabilities enhance production processes and innovation in various sectors. ↩

-

Explore this link to understand the process and applications of plastic vacuum forming in various industries. ↩

-

Discover innovative practices in sustainable plastic packaging, which are crucial for environmentally friendly manufacturing solutions. ↩

-

This resource will provide insights into the critical factors influencing material selection for optimal vacuum forming results. ↩

-

Understanding mold design is essential for achieving precision in vacuum forming; this link will enhance your knowledge on the topic. ↩

-

This resource will help you learn about the critical heating temperature needed for successful vacuum forming, ensuring quality outcomes. ↩

-

Discover innovative packaging solutions that utilize vacuum forming, showcasing its effectiveness in various industries, especially in packaging. ↩

-

Learn about the specific applications of vacuum forming in the automotive sector, highlighting its advantages in producing complex parts. ↩

-

Learn about injection molding's precision and complexity to see if it's the right choice for your project needs. ↩