Surface roughness, a critical aspect of manufacturing, significantly influences product performance, durability, and aesthetics. This article explores the causes of surface roughness, offers practical solutions for managing it, and highlights its applications across various industries, providing insights into optimizing surface finishes for enhanced product quality.

Surface roughness, the microscopic irregularities on a surface, is shaped by manufacturing processes, tool wear, material properties, and environmental factors, with solutions like optimized machining and post-processing enhancing product quality.

Understanding surface roughness is essential for industries where precision and performance are paramount. Dive into this guide to discover how different factors influence surface finishes and how to select the right processes for your applications.

Surface roughness directly impacts product performance.True

Rough surfaces can increase friction, wear, and corrosion, while smooth surfaces enhance durability and aesthetics.

Surface roughness is only a concern in high-precision industries.False

While critical in precision fields like optics, surface roughness also affects everyday products in automotive, packaging, and construction.

What Are the Common Causes of Surface Roughness?

Surface roughness arises from multiple factors during manufacturing, each affecting the final product's quality and functionality.

Surface roughness is commonly caused by machining processes1, tool wear, material hardness2, and environmental conditions, impacting industries from automotive to optics.

| Cause | Impact on Roughness | Notes |

|---|---|---|

| Machining Processes | Varies by process | Turning, milling, grinding |

| Tool Wear | Increases roughness | Regular maintenance needed |

| Material Properties | Hardness affects finish | Softer materials may deform |

| Environmental Factors | Corrosion, temperature | Affects surface integrity |

Machining Processes

The type of machining process used significantly influences surface roughness. For example, turning typically produces a roughness average (Ra) of 1.6–6.3 μm, while grinding can achieve an Ra as low as 0.1–1.6 μm. Selecting the appropriate process is key to achieving the desired surface texture Surface Finish Chart: A Guide to Understanding Surface Finishing Chart - AT-Machining.

Tool Wear

As tools wear, they leave irregular marks on the workpiece, increasing surface roughness. This effect is more pronounced at lower cutting speeds, where built-up edge formation occurs. Regular tool maintenance and timely replacement are essential to maintain consistent surface quality A Review of the Factors Influencing Surface Roughness in Machining and Their Impact on Sustainability - MDPI.

Material Properties

Material hardness and ductility play a significant role in surface roughness. Softer materials like aluminum often achieve smoother finishes more easily than harder materials like hardened steel, which may require specialized techniques such as grinding Surface Roughness Value - an overview | ScienceDirect Topics.

Environmental Factors

Conditions like temperature and humidity can alter surface roughness. High humidity, for instance, may cause corrosion, leading to increased surface irregularities. Controlling the manufacturing environment is vital for precision applications Surface Roughness – About Tribology.

Tool wear is a leading cause of increased surface roughness.True

Worn tools create irregular surfaces, especially in processes like turning and milling.

Surface roughness cannot be controlled in manufacturing.False

By optimizing processes, tools, and materials, manufacturers can achieve desired surface finishes.

What Are the Solutions to Manage Surface Roughness?

Managing surface roughness effectively is crucial for meeting performance and quality standards in manufacturing.

Solutions for managing surface roughness include optimizing machining parameters, using appropriate tools, and applying post-processing techniques like polishing or grinding.

Optimizing Machining Parameters

Adjusting variables such as cutting speed, feed rate, and depth of cut can minimize surface roughness3. For instance, lower feed rates paired with higher cutting speeds often result in smoother surfaces during turning Surface Finish: A Complete Guide to Surface Roughness - WayKen.

Tool Selection and Maintenance

Sharp, high-quality tools, such as those coated with carbide or diamond, reduce surface roughness. Regular maintenance ensures consistent performance and prevents degradation of surface quality Surface Roughness in Manufacturing - Inovatec Machinery.

Post-Processing Techniques

Methods like grinding, polishing, and lapping refine surfaces after initial machining. These techniques are critical for applications requiring ultra-smooth finishes, such as optics and precision engineering Surface Finishing: Types, Methods, and Technologies - Kemet USA.

Material Considerations

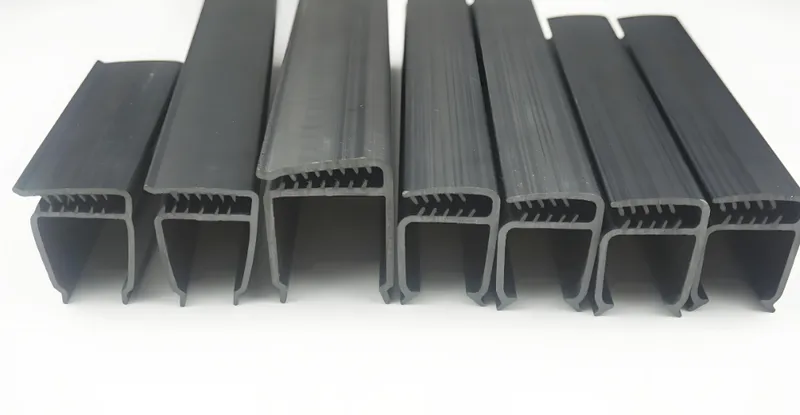

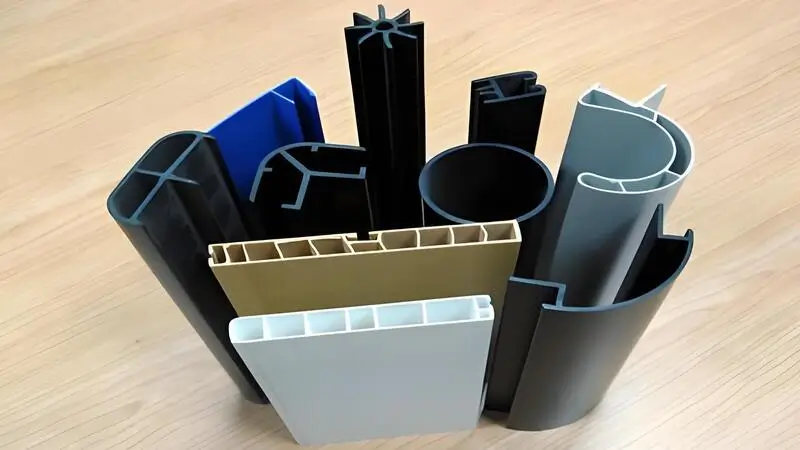

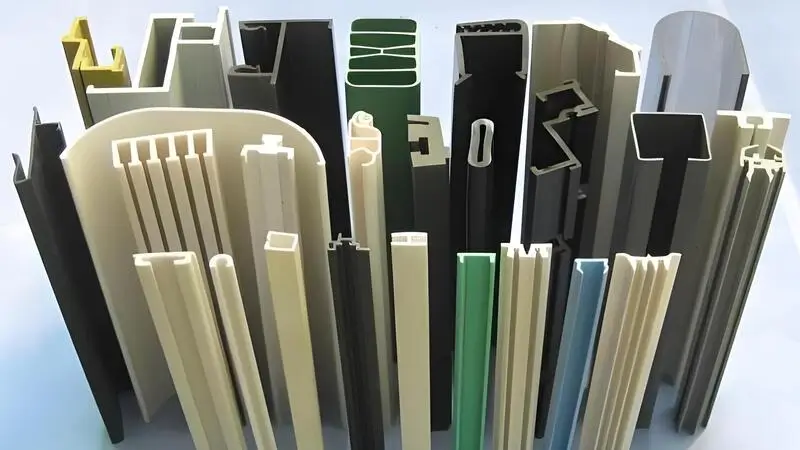

Choosing materials with inherent smoothness or ease of machining can reduce roughness. Plastics like PVC, with a natural smoothness of about 0.0015 mm, are ideal for fine-finish applications Roughness & Surface Coefficients - Engineering ToolBox.

Post-processing is always necessary to achieve smooth surfaces.False

While post-processing can enhance smoothness, optimized machining can achieve acceptable finishes without additional steps.

Optimizing machining parameters can reduce surface roughness.True

Adjusting speed, feed, and depth of cut directly impacts the final surface texture.

What Are the Applications of Surface Roughness?

Surface roughness plays a vital role across multiple industries, affecting both functionality and performance.

Surface roughness is crucial in automotive, medical devices, optics, and consumer products, influencing friction, wear, and aesthetics.

Automotive Industry

In automotive applications, surface roughness impacts engine components like pistons and cylinders, where smooth surfaces reduce friction and boost fuel efficiency. Conversely, rougher surfaces in brake systems enhance grip Surface Roughness In Manufacturing - ISO Finishing LLC.

Medical Devices

For medical implants and devices, surface roughness is tailored to promote biocompatibility and reduce infection risks. Dental implants, for example, often feature controlled roughness to support osseointegration Surface Roughness - an overview | ScienceDirect Topics.

Optics

In optics, extremely smooth surfaces (Ra < 0.1 μm) are essential for lenses and mirrors to minimize light scattering and ensure clarity Understanding Surface Roughness | Edmund Optics.

Consumer Products

Surface roughness affects both the functionality and aesthetics of consumer goods. Smooth finishes on electronics improve user experience, while textured surfaces on packaging enhance grip and visual appeal Surface Finish: Standards, Techniques, Applications, and More.

Surface roughness is only important for aesthetic purposes.False

While aesthetics are important, surface roughness also critically affects functional aspects like friction and wear.

In optics, smoother surfaces are always better.True

Smoother surfaces reduce light scattering, enhancing optical performance.

What Are the Differences Between Surface Roughness and Surface Finish?

Clarifying the distinction between surface roughness and surface finish is key to effective manufacturing communication.

Surface roughness refers to the microscopic irregularities on a surface, while surface finish encompasses the overall texture, including roughness, waviness, and lay.

Surface Roughness

Surface roughness measures fine irregularities, typically quantified by parameters like Ra (average roughness) or Rz (mean roughness depth), focusing on the smallest scale of texture Surface Roughness - Wikipedia.

Surface Finish

Surface finish is a broader concept, incorporating roughness, waviness (larger-scale undulations), and lay (surface pattern direction). It describes the complete texture and appearance of a surface Surface Finish - Roughness - Symbols, Charts, Callouts & Costs.

Measurement and Specification

Surface roughness is assessed using tools like profilometers, while surface finish4 may involve additional visual or tactile evaluations. Specifications often combine roughness parameters with finish descriptors Measuring Surface Roughness: A Comprehensive Guide.

Surface roughness and surface finish are interchangeable terms.False

Surface roughness is a component of surface finish, which includes additional texture characteristics.

Surface finish specifications often include roughness parameters.True

Roughness is a key aspect of surface finish, commonly specified in engineering drawings.

Comparative Tables

Manufacturing Processes and Surface Roughness

| Process | Typical Ra (μm) | Notes |

|---|---|---|

| Turning | 1.6–6.3 | Depends on feed rate |

| Milling | 0.8–3.2 | Varies with tool condition |

| Grinding | 0.1–1.6 | High precision achievable |

| Polishing | <0.1 | Ultra-smooth finishes |

Material Compatibility with Finishing Techniques

| Material | Grinding | Polishing | Notes |

|---|---|---|---|

| Aluminum | Excellent | Good | Soft, easy to finish |

| Hardened Steel | Good | Challenging | Requires precision |

| Plastics (PVC) | Good | Excellent | Naturally smooth |

| Titanium | Moderate | Good | Resists wear |

Conclusion

Surface roughness is a multifaceted element of manufacturing that influences product performance across industries. Its causes—machining processes5, tool wear, material properties, and environmental factors—can be managed through solutions like optimized parameters, tool maintenance, and post-processing6. Applications in automotive, medical devices, optics, and consumer products underscore its importance for functionality and aesthetics. Understanding the distinction between surface roughness and surface finish enhances precision in manufacturing specifications.

-

Explore how various machining techniques influence surface quality and learn to choose the right one for your needs. ↩

-

Discover how material properties impact surface finishes and the techniques needed for different materials. ↩

-

Understanding surface roughness is vital for improving product quality and performance in manufacturing processes. ↩

-

Exploring surface finish can reveal its impact on functionality and aesthetics, crucial for product design and engineering. ↩

-

This resource will provide insights into how different machining processes can impact surface roughness and product quality. ↩

-

Learn about the advantages of post-processing techniques in enhancing surface roughness and overall product performance. ↩