How Do You Troubleshoot Melt Fracture in Extrusion?

Melt fracture is a common challenge in polymer extrusion that can compromise the surface quality of extruded products, impacting both their appearance and performance. This blog post offers an in-depth guide to understanding and troubleshooting melt fracture1, covering its causes, effects across industries, and practical solutions. Whether you’re involved in plastics manufacturing or seeking to […]

What are the Problems with TPE Wire Extrusion Adhesion and Surface Smoothness?

TPE wire extrusion faces challenges with adhesion and surface smoothness, impacting product quality and performance across various electrical applications. TPE wire extrusion issues like poor adhesion and surface roughness can be resolved by optimizing extrusion parameters, material selection, and cooling methods to maintain consistent quality and performance. While understanding the core challenges of TPE wire […]

What are the Common Problems Encountered in Plastic Pipe extrusion and How to Solve them?

Plastic pipe extrusion often encounters challenges that can affect product quality and efficiency. Identifying and resolving these issues ensures optimal production and performance. Optimize temperature, maintenance, and calibration to address plastic pipe extrusion issues, ensuring quality through proactive monitoring and process adjustments. Understanding these common challenges and their solutions is crucial for maintaining efficiency in […]

What are the Common Problems of Plastic Extruder Extrusion Process?

Plastic extrusion faces frequent challenges that can impair efficiency and product quality, affecting a multitude of industries. Plastic extrusion faces challenges like inconsistent material flow, overheating, die build-up, and product defects. Solving these enhances quality and efficiency, vital for packaging, automotive, and construction industries. While this summary outlines key challenges, gaining a deeper understanding of […]

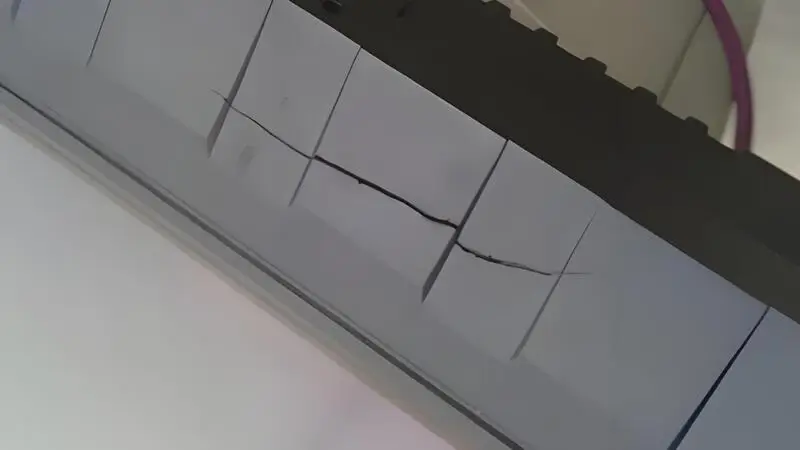

What are the Common Reasons for Cracking of Extruded PC Pipes?

Cracking in extruded polycarbonate (PC) pipes can undermine their structural integrity and performance, affecting various applications. Cracking in extruded PC pipes is caused by stress concentration, chemical exposure, and improper processing. Factors like thermal expansion, UV exposure, and material defects also contribute. Proper handling and environmental considerations can enhance durability. Knowing the causes of cracks […]

What are the Reasons and Solutions for Air Bubbles in TPE Extrusion?

Air bubbles in TPE extrusion can compromise product quality, causing weaknesses and defects. Identifying causes and solutions is essential for maintaining material integrity. Air bubbles in TPE extrusion result from moisture, incorrect temperature, or contamination. Solutions involve thorough material drying, optimizing temperatures, and maintaining clean machinery. Understanding the root causes of air bubbles is critical […]