How Can You Manage the Gloss Level in Extruded Products?

Managing the gloss level in extruded products is a critical aspect of manufacturing that balances aesthetic appeal with functional performance. From glossy automotive trim to matte packaging materials, gloss control influences how products are perceived and how they perform in real-world applications. This guide explores the essentials of gloss management in extrusion, covering definitions, influencing […]

What Are the Causes and Solutions for Surface Roughness?

Surface roughness, a critical aspect of manufacturing, significantly influences product performance, durability, and aesthetics. This article explores the causes of surface roughness, offers practical solutions for managing it, and highlights its applications across various industries, providing insights into optimizing surface finishes for enhanced product quality. Surface roughness, the microscopic irregularities on a surface, is shaped […]

What Techniques Help Achieve a Matte Finish in Extrusion?

A matte finish in extrusion1 refers to a non-glossy, dull surface that enhances both the aesthetic appeal and functional properties of products, making it a popular choice in industries such as automotive and home decor. Achieving this finish requires a blend of specific techniques tailored to the material and application. This blog post delves into […]

Which Markets for Plastic Extruded Products Are Growing the Fastest?

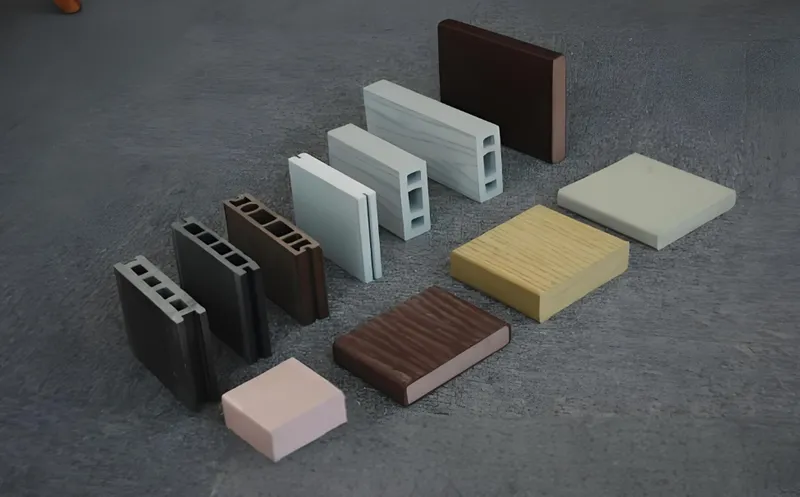

What Types of Plastics Are Commonly Used in Extrusion? The type of plastic used in extrusion shapes the product’s properties and its fit for specific markets. Here’s a breakdown of the most common plastics and their key applications. Colored Plastics Polyvinyl Chloride (PVC) Market Applications: Construction (pipes, window frames), healthcare (medical tubing), packaging (films). Growth Insight: […]

How Can You Ensure Color Consistency in Extruded Products?

Ensuring color consistency1 in extruded products is vital for maintaining product quality, meeting customer expectations, and reinforcing brand identity. Color consistency refers to achieving a uniform color across an entire extruded product and maintaining that uniformity across multiple production batches. This is especially critical in industries where appearance is tied to quality perception, such as […]

How Do Additives Improve the Properties of Extruded Products?

Additives are vital components in the extrusion process, enhancing the properties of extruded products to meet specific industry demands. By modifying characteristics such as strength, flexibility, appearance, and safety, additives ensure that extruded products perform optimally in applications ranging from construction to packaging. This blog explores how additives improve extruded products, providing insights into their […]