Back pressure in extrusion is a critical parameter that significantly influences the quality of the final product. It refers to the resistance the molten plastic exerts on the extruder screw, ensuring the material is properly melted, mixed, and homogenized before being extruded through the die. Understanding and controlling back pressure1 is vital for achieving consistent product quality, optimizing process efficiency, and reducing production costs.

Back pressure ensures uniform melting, thorough mixing, and stable output in extrusion, enhancing product quality across industries like packaging, construction, and automotive.

In this blog post, we will explore the importance of back pressure in controlling extrusion quality2. We’ll cover its definition, classification, application scenarios, technical details, practical tools, and related technologies. By the end, you’ll understand why back pressure is a key factor in extrusion processes and how to manage it effectively.

Back pressure is essential for uniform melting and mixing in extrusion.True

It ensures the material is thoroughly prepared before extrusion, reducing defects like unmelted particles or poor color distribution.

High back pressure always improves product quality.False

Excessive back pressure can lead to material degradation and increased energy costs, negatively affecting the final product.

- 1. What is Back Pressure in Extrusion?

- 2. How Can Back Pressure Be Classified?

- 3. What are Typical Application Scenarios for Back Pressure Control?

- 4. What Does a Technical Deep Dive Reveal About Back Pressure?

- 5. What Practical Tools Help Manage Back Pressure?

- 6. What Technologies Relate to Back Pressure?

- 7. Conclusion

What is Back Pressure in Extrusion?

Back pressure in extrusion is the resistance that molten plastic exerts on the extruder screw as it pushes the material through the barrel and into the die. This resistance arises from the material’s viscosity and the design of the screw and die. Back pressure plays a crucial role in:

-

Melting the material uniformly: Ensures no unmelted particles remain.

-

Mixing additives and colorants thoroughly: Achieves consistent composition.

-

Homogenizing melt temperature and composition: Maintains uniformity.

-

Controlling output rate and process stability: Prevents fluctuations in production.

Without adequate back pressure, the material may exit the die unprepared, leading to defects like inconsistent mechanical properties or poor aesthetics. For more insights, check out Plastics Technology.

How Can Back Pressure Be Classified?

Back pressure can be viewed from multiple angles, each highlighting its role in extrusion.

Back pressure impacts melting, mixing, and output control, varying by material and application needs in extrusion processes.

Process Perspective

-

Melting and Mixing: Ensures complete melting and even additive distribution.

-

Output Rate Control: Regulates extrusion speed and throughput.

-

Quality Control3: Stabilizes conditions for consistent quality.

Material Perspective

-

High-Viscosity Materials: Require higher back pressure (e.g., HDPE).

-

Low-Viscosity Materials: Need lower levels to avoid over-mixing (e.g., LDPE).

-

Filled Compounds: Demand specific settings for uniform filler dispersion.

Application Perspective

-

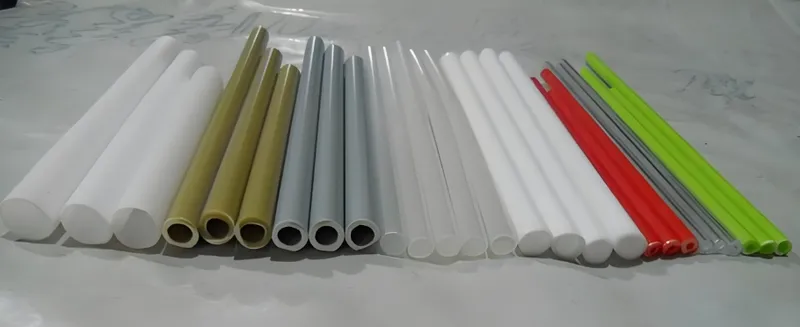

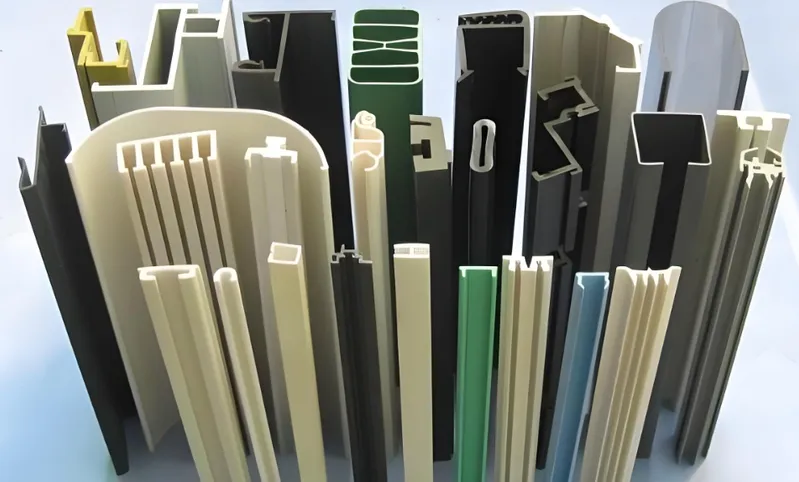

Films: Need precise control for uniform thickness and color.

-

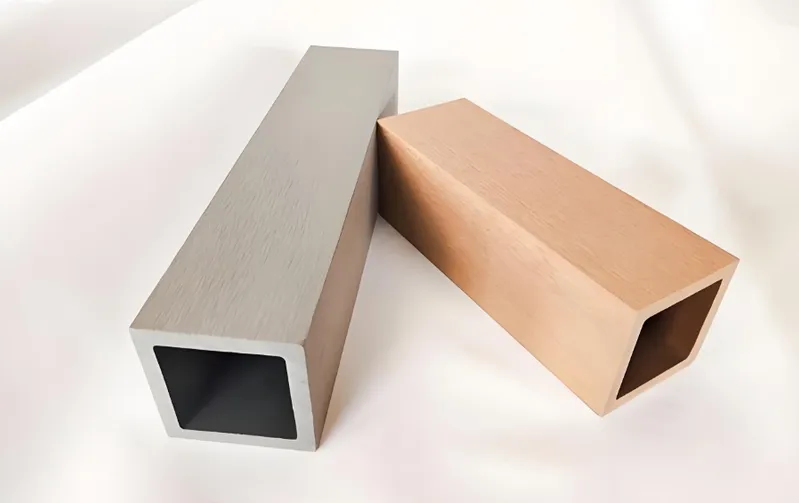

Profiles: Require consistency for mechanical strength.

- Pipes: Depend on back pressure for smooth surfaces and integrity.

This classification underscores back pressure’s versatility in extrusion.

What are Typical Application Scenarios for Back Pressure Control?

Back pressure is vital in specific extrusion scenarios, optimizing quality and performance.

Back pressure enhances quality in high-viscosity, colored, and temperature-sensitive extrusion applications.

-

High-Viscosity Materials4: Materials like HDPE or filled compounds need higher back pressure to eliminate unmelted particles.

-

Colored Plastics: Ensures uniform colorant distribution for aesthetic consistency.

-

Temperature-Sensitive Products: Manages heat generation to prevent thermal degradation.

In these cases, back pressure is a key tool for meeting product specifications.

Pros and Cons of Back Pressure Control

| Aspect | Pros of Back Pressure Control | Cons of Back Pressure Control |

|---|---|---|

| Flexibility | Allows real-time adjustments without setup changes | May not fix poor screw or die design issues |

| Quality Impact | Improves melt uniformity, reduces defects | Excessive levels can degrade material properties |

| Energy and Cost | Optimizes output rate, reduces energy if balanced | High levels increase friction and energy use |

| Comparison | More dynamic than temperature control | Less effective without screw or material tweaks |

This table shows back pressure’s strengths and limitations compared to other methods.

What Does a Technical Deep Dive Reveal About Back Pressure?

A closer look at the extrusion process reveals where back pressure exerts its influence.

Back pressure shapes melt quality during conveying and melting, affecting extrusion stability and output.

Extrusion Process Workflow

-

Feeding: Raw material enters the hopper.

-

Conveying and Melting: The screw moves material through the heated barrel, generating back pressure to homogenize the melt.

- Extrusion: Molten material exits the die, with back pressure stabilizing flow.

Key parameters influencing back pressure include:

-

Screw Design5: Length-to-diameter ratio, pitch, and depth.

-

Barrel Temperature: Affects viscosity and resistance.

-

Die Design: Impacts flow resistance.

-

Material Properties: Viscosity and thermal stability.

-

Screw Speed: Higher speeds increase back pressure.

Material Compatibility with Back Pressure

-

HDPE: High viscosity requires elevated back pressure.

-

LDPE: Lower back pressure prevents over-mixing.

-

Filled Materials: Need higher levels for filler uniformity.

-

Heat-Sensitive Materials: Require careful control to avoid degradation.

Tailoring back pressure to material properties is essential for quality outcomes. Learn more about pressure control at Equilibar.

What Practical Tools Help Manage Back Pressure?

Effective back pressure management relies on practical tools and guidelines.

Tools like checklists and decision guides ensure optimal back pressure settings for extrusion quality.

Design Checklist for Back Pressure Management

-

Verify screw design matches material needs.

-

Install pressure transducers for real-time monitoring.

-

Adjust back pressure based on material properties.

-

Check process stability indicators regularly.

-

Balance back pressure to minimize energy use.

Process Selection Decision-Making Guide

-

Assess material viscosity and thermal sensitivity.

-

Define product requirements (e.g., uniformity, strength).

-

Select equipment (single-screw vs. twin-screw) for mixing needs.

-

Implement control systems for precise regulation.

These tools empower operators to optimize back pressure effectively.

What Technologies Relate to Back Pressure?

Back pressure connects to broader extrusion technologies, enhancing process understanding.

Back pressure links to material synthesis, rheology, and downstream processes in extrusion.

-

Upstream: Material synthesis and rheological testing set back pressure needs.

-

Downstream: Cooling and sizing rely on initial melt quality.

-

Related Fields: Rheology, control systems, and die design influence back pressure management.

These connections highlight back pressure’s role in the extrusion ecosystem.

Conclusion

Back pressure is a cornerstone of extrusion quality control, ensuring proper melting, mixing, and temperature uniformity. It impacts product quality and process efficiency across applications like films, profiles, and pipes. By understanding its classification, application scenarios, technical aspects, and related technologies, professionals can harness back pressure to achieve superior results.

-

Understanding back pressure is crucial for optimizing extrusion quality and efficiency. Explore this link for in-depth insights. ↩

-

Learn how back pressure influences the quality of extruded products and the factors involved in the process. ↩

-

Quality control is essential in extrusion. Discover best practices to maintain consistency and prevent defects in your products. ↩

-

Learn how high-viscosity materials like HDPE require specific back pressure settings to ensure quality and performance in extrusion. ↩

-

Screw design is a key factor in managing back pressure. Learn more about its impact on extrusion efficiency and quality. ↩