The integration of robotics into modern plastic extrusion1 is reshaping manufacturing by boosting efficiency, precision, and safety. From material handling2 to quality inspection, robots are automating key tasks in this process, reducing costs and enhancing product quality across industries like automotive, packaging, and construction.

Robotics in modern plastic extrusion automate material handling, quality inspection, and post-processing tasks, increasing efficiency and safety while reducing labor costs and human error.

Understanding how robotics enhance plastic extrusion can empower manufacturers to optimize their production lines. Dive into this article to explore the definitions, applications, technical details, and more about this transformative technology.

Robotics reduce labor costs in plastic extrusion.True

By automating repetitive tasks, robotics minimize the need for manual labor, leading to significant cost savings.

Robotics are only used in large-scale plastic extrusion operations.False

While beneficial for high-volume production, robotics can also be scaled for smaller operations, though cost-effectiveness may vary.

- 1. What is Plastic Extrusion and How Do Robotics Fit In?

- 2. How Are Robotics Classified in Plastic Extrusion?

- 3. What Are the Typical Applications of Robotics in Plastic Extrusion?

- 4. What Are the Pros and Cons of Using Robotics in Plastic Extrusion?

- 5. How Does the Plastic Extrusion Process Work with Robotics?

- 6. What Are the Key Considerations for Implementing Robotics in Plastic Extrusion?

- 7. What Technologies Are Related to Robotics in Plastic Extrusion?

- 8. Conclusion

What is Plastic Extrusion and How Do Robotics Fit In?

Plastic extrusion is a manufacturing process where raw plastic is melted and shaped into a continuous profile—like pipes, sheets, or films—through a die. Robotics enhance this process by automating tasks that are repetitive, hazardous, or demand precision, such as feeding materials, handling products, and inspecting quality.

Plastic extrusion involves melting and shaping plastic into continuous profiles, with robotics enhancing automation in material handling, inspection, and post-processing for improved efficiency and safety.

| Process Type | Automation Level | Notes |

|---|---|---|

| Material Feeding | High | Robots ensure consistent supply |

| Product Handling | Medium to High | Reduces manual labor and risk |

| Quality Inspection | High | Machine vision for precision |

Definition of Plastic Extrusion

Plastic extrusion melts plastic pellets and forces them through a die to form continuous shapes. Known as a high-volume process, it’s ideal for producing uniform products efficiently. Learn more at Plastic Extrusion Explained.

Role of Robotics in Extrusion

Robots play critical roles in:

-

Material Feeding: Delivering plastic pellets to the extruder consistently.

-

Product Handling: Moving hot extruded products safely to cooling or cutting stations.

-

Quality Inspection: Using machine vision to detect defects in real-time.

-

Post-Processing: Cutting and packaging finished products.

These contributions reduce human error and improve workplace safety, especially in handling high-temperature materials.

Robotics improve safety in plastic extrusion.True

By handling hot or heavy materials, robots reduce the risk of workplace injuries.

Robotics are essential for all plastic extrusion processes.False

While beneficial, robotics are not mandatory and may not be cost-effective for all operations, especially smaller ones.

How Are Robotics Classified in Plastic Extrusion?

Robotics in plastic extrusion3 can be categorized by their function, type, or application, offering a clear framework to understand their roles.

Robotics in plastic extrusion are classified by function (e.g., material handling, inspection), robot type (e.g., articulated arms, gantry robots), and application (e.g., automotive, packaging).

Functional Classification

-

Material Handling Robots4: Load raw materials and transport extruded products.

-

Inspection Robots: Monitor quality with advanced sensors.

-

Post-Processing Robots5: Perform cutting, trimming, or packaging.

Robot Type Classification

- Articulated Arm Robots: Versatile for tasks like handling and assembly.

-

Gantry Robots: Suited for linear tasks such as material feeding.

-

Collaborative Robots (Cobots): Work alongside humans for flexible operations.

Application-Based Classification

-

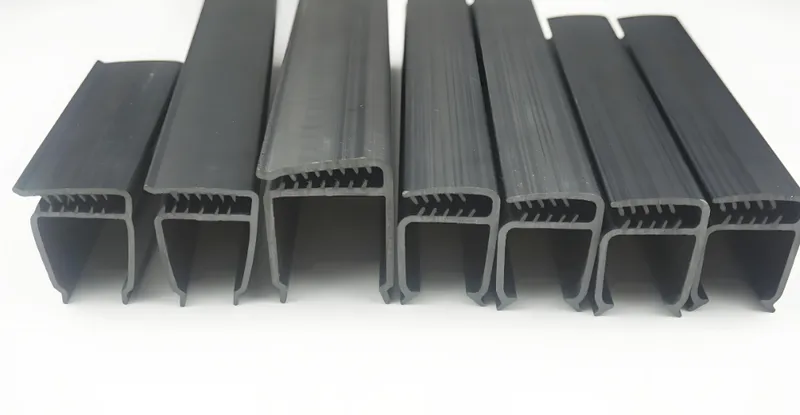

Automotive: Robots manage extruded seals and trims.

-

Packaging: Handle films and sheets for packaging.

-

Construction: Assist in producing profiles for building materials.

Articulated arm robots are the most common in plastic extrusion.True

Their flexibility makes them suitable for various tasks in the extrusion process.

All robots in plastic extrusion are fully autonomous.False

Some robots, like cobots, are designed to work alongside humans and may require human oversight.

What Are the Typical Applications of Robotics in Plastic Extrusion?

Robotics are deployed across multiple stages of plastic extrusion, tailoring solutions to industry needs.

Typical applications include material feeding, product handling, quality inspection, and post-processing in industries like automotive, packaging, and construction.

| Application | Industry | Benefits |

|---|---|---|

| Material Feeding | Packaging, Automotive | Consistent supply, reduced downtime |

| Product Handling | Construction, Automotive | Safe handling of hot materials |

| Quality Inspection6 | All industries | High precision, reduced defects |

| Post-Processing | Packaging, Consumer Goods | Streamlined cutting and packaging |

Material Feeding

Robots deliver plastic pellets to the extruder, ensuring a steady flow and minimizing interruptions. This is vital for high-volume production, as detailed in Robotics in Plastics Industry7.

Product Handling

Post-extrusion, robots move hot products to cooling zones, enhancing safety and reducing damage risks, as seen in KUKA Extrusion Solutions8.

Quality Inspection

Equipped with machine vision, robots inspect products for defects, ensuring high standards, a practice common across industries per Material Handling Robots.

Post-Processing

Robots cut, trim, and package products, streamlining workflows and cutting labor costs, as noted in Plastics Industry Automation.

Robotics increase production speed in plastic extrusion.True

Automation reduces downtime and enhances workflow efficiency.

Robotics eliminate the need for human workers in plastic extrusion.False

While they reduce manual labor, human oversight is still necessary for programming, maintenance, and quality control.

What Are the Pros and Cons of Using Robotics in Plastic Extrusion?

Robotics bring significant advantages to plastic extrusion but come with trade-offs that manufacturers must weigh.

Robotics enhance efficiency, safety, and quality but require high initial investment and skilled maintenance.

| Aspect | Pros | Cons |

|---|---|---|

| Efficiency | Increases output with continuous operation | High initial investment |

| Quality | Ensures consistent, high-quality products | Requires skilled personnel for programming |

| Labor Costs | Reduces need for manual labor | Maintenance can be costly |

| Safety | Handles hazardous tasks | May not be cost-effective for small operations |

| Flexibility | Can be reprogrammed for different tasks | Integration with existing systems can be challenging |

This analysis aligns with findings from 5 Proven Ways the Plastics Industry Can Use Robots, emphasizing the balance between benefits and challenges.

Robotics reduce operational costs in the long term.True

Despite high initial costs, robotics lower labor and maintenance expenses over time.

Robotics are always more efficient than manual labor.False

In small-scale or custom production, manual labor may be more flexible and cost-effective.

How Does the Plastic Extrusion Process Work with Robotics?

The plastic extrusion process is a multi-step workflow where robotics enhance automation at critical points.

The process includes material feeding, melting, extrusion, cooling, and post-processing, with robotics handling feeding, product movement, inspection, and packaging.

Process Workflow

-

Material Feeding: Robots supply plastic pellets to the extruder.

-

Melting and Extrusion: Plastic is melted and shaped, with robots aiding in die adjustments if needed.

-

Cooling: Robots transfer hot products to cooling stations.

-

Post-Processing: Robots cut, inspect, and package the output.

Explore the full process at Plastic Extrusion Process.

Material Compatibility

Robotics adapt to various plastics:

-

Temperature-Sensitive Plastics (e.g., polyethylene): Require precise handling to avoid deformation, per All About Plastic Extrusion.

-

Flexible Plastics (e.g., PVC): May need specialized grippers, as noted in Robot Platform Knowledge on Plastics.

Robotics can handle all types of plastics in extrusion.False

Some plastics may require specialized tooling or handling techniques, which can limit robotic applications.

Robotics improve the consistency of extruded products.True

Automation ensures uniform handling and processing, leading to consistent product quality.

What Are the Key Considerations for Implementing Robotics in Plastic Extrusion?

Successful robotic integration in plastic extrusion hinges on strategic planning and execution.

Key considerations include task definition, robot selection, end-of-arm tooling, payload capacity, integration with existing systems, and safety measures.

| Consideration | Details |

|---|---|

| Task Definition | Clearly define tasks (e.g., feeding, handling) |

| Robot Type | Choose based on task (e.g., articulated arm for flexibility) |

| End-of-Arm Tooling | Select grippers or suction tools for the material |

| Payload and Reach | Ensure the robot can handle the weight and reach required areas |

| Integration | Ensure compatibility with control systems |

| Safety | Implement protocols to protect workers and equipment |

For robot selection tips, see Material Handling Robots by Kawasaki.

Decision-Making for Robotics Adoption

Consider robotics when:

-

Production volume is high.

-

Tasks are repetitive or hazardous.

-

Quality consistency is critical.

Guidance is available at How the Plastic Industry Can Benefit From Robots.

Robotics are suitable for all plastic extrusion operations.False

They are most beneficial in high-volume, repetitive tasks but may not be cost-effective for small or custom operations.

Proper planning is crucial for successful robotics integration.True

Careful consideration of tasks, robot types, and integration ensures optimal performance and ROI.

What Technologies Are Related to Robotics in Plastic Extrusion?

Robotics in plastic extrusion connect to a wider network of manufacturing technologies, amplifying their impact.

Related technologies include 3D printing, machine vision, and automated guided vehicles (AGVs), which complement robotic applications in manufacturing.

3D Printing

Robotics guide extruder heads in additive manufacturing, a related extrusion process, as explored in Robotic AM System for Plastic Materials.

Machine Vision

Paired with robots, machine vision ensures real-time quality control, per Industry Insights on Plastics Robotics.

Automated Guided Vehicles (AGVs)

AGVs transport materials, enhancing robotic workflows, as detailed in Material Handling Robots.

Robotics are the only automation technology used in plastic extrusion.False

Other technologies like AGVs and machine vision also play crucial roles in enhancing automation.

Integrating related technologies can further optimize plastic extrusion processes.True

Combining robotics with machine vision or AGVs creates a more efficient and automated production line.

Conclusion

Robotics are revolutionizing plastic extrusion by automating key tasks, enhancing safety, and ensuring consistent quality. While the upfront costs are notable, the long-term gains in efficiency and reduced labor make them a game-changer for high-volume manufacturers. This exploration of their roles, benefits, and implementation considerations offers a roadmap for leveraging robotics in your production line.

-

Explore this link to gain a deeper understanding of plastic extrusion, its processes, and its significance in manufacturing. ↩

-

Learn about effective material handling techniques that can optimize production and reduce costs in manufacturing environments. ↩

-

Discover how robotics are revolutionizing plastic extrusion, enhancing efficiency and safety in manufacturing. ↩

-

Explore how Material Handling Robots optimize efficiency and safety in the plastics industry, enhancing production processes. ↩

-

Learn how Post-Processing Robots streamline workflows and reduce labor costs in the plastics sector. ↩

-

Discover the impact of robotic Quality Inspection on reducing defects and ensuring high standards in manufacturing. ↩

-

Explore this resource to understand how robotics revolutionize efficiency and safety in plastic manufacturing. ↩

-

Discover KUKA's innovative solutions that enhance safety and efficiency in the extrusion process. ↩