Twin-screw extruders have surged in popularity across industries like plastics, food processing, and pharmaceuticals, thanks to their unmatched versatility and efficiency. But how do they stack up against single-screw extruders? This blog post dives into the advantages of twin-screw extruders, offering a detailed comparison with single-screw extruders1 and spotlighting their unique benefits.

Twin-screw extruders excel over single-screw extruders in mixing, material versatility, and processing complex or heat-sensitive materials, making them a top choice for industries requiring precision and flexibility.

Whether you’re aiming to enhance product quality, handle diverse materials, or optimize production, understanding these differences is key to choosing the right extruder for your needs. Let’s explore the specifics.

Twin-screw extruders offer superior mixing capabilities compared to single-screw extruders.True

The intermeshing screws in twin-screw extruders provide intensive mixing, ideal for complex materials and blends.

Single-screw extruders are always more cost-effective than twin-screw extruders.False

While single-screw extruders have lower initial costs, twin-screw extruders can be more cost-effective for complex materials due to their efficiency and adaptability.

- 1. What Are Twin-Screw and Single-Screw Extruders?

- 2. What Are the Typical Applications of Twin-Screw Extruders?

- 3. What Are the Pros and Cons of Twin-Screw vs. Single-Screw Extruders?

- 4. What Is the Process Workflow of a Twin-Screw Extruder?

- 5. Why Are Twin-Screw Extruders Better for Certain Materials?

- 6. How Do You Choose Between Twin-Screw and Single-Screw Extruders?

- 7. What Are the Related Technologies to Twin-Screw Extrusion?

- 8. Conclusion

What Are Twin-Screw and Single-Screw Extruders?

Extruders are machines that process materials by forcing them through a die to create continuous shapes. The two primary types—single-screw and twin-screw extruders2—differ significantly in design and functionality.

A single-screw extruder uses one rotating screw in a barrel to convey, melt, and mix materials, best for homogeneous substances. A twin-screw extruder features two intermeshing screws, enhancing mixing and handling of complex or heat-sensitive materials3.

| Extruder Type | Description | Common Applications |

|---|---|---|

| Single-Screw | One screw rotates in a barrel, suited for simple materials. | Plastics, rubber, basic food processing |

| Twin-Screw | Two intermeshing screws for superior mixing and versatility. | Compounding, pharmaceuticals, food |

Single-Screw Extruder

A single-screw extruder has a single screw rotating inside a heated barrel. It’s designed for:

-

Conveying materials

-

Melting polymers

-

Basic mixing of uniform materials

It shines in cost-sensitive applications with straightforward material requirements.

Twin-Screw Extruder

A twin-screw extruder, with its two screws (often intermeshing), offers:

-

Enhanced mixing

-

Precise control over material residence time

-

Ability to process complex or high-viscosity materials

It’s the go-to choice for applications needing precision and flexibility.

Twin-screw extruders are more versatile than single-screw extruders.True

Their design allows them to process a wider range of materials and applications with better control.

Single-screw extruders are limited to basic tasks.False

They’re widely used in industries like plastics for cost-effective production of homogeneous materials.

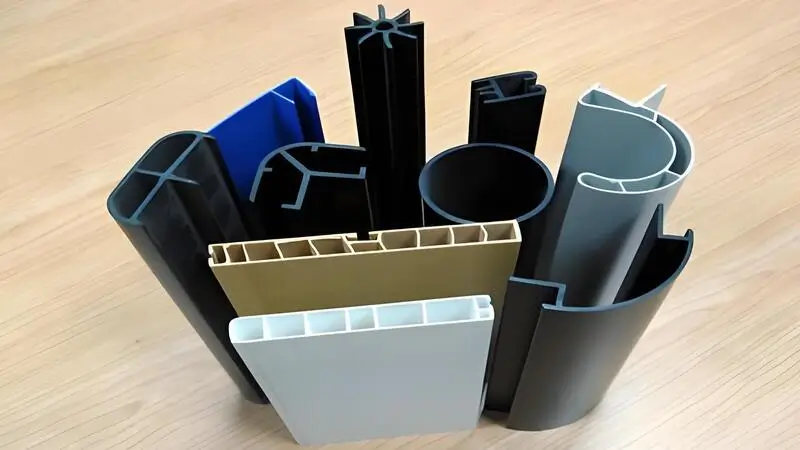

What Are the Typical Applications of Twin-Screw Extruders?

Twin-screw extruders shine in scenarios demanding intensive mixing, flexibility, and precision. Their ability to handle diverse materials makes them indispensable across multiple sectors.

Twin-screw extruders are widely used in plastics compounding, food processing, and pharmaceuticals4 for their excellent mixing, adaptability, and ability to process heat-sensitive materials.

Plastics Industry

In plastics, twin-screw extruders are key for:

-

Compounding polymers with additives

-

Creating custom blends with precise filler dispersion

-

Processing heat-sensitive materials like PVC

Companies like Bausano rely on them for high-quality compounds.

Food Processing

In food production, they’re used for:

-

Simultaneous mixing and cooking

-

Producing textured products like snacks

-

Ensuring uniform ingredient distribution

Their versatility suits sticky or viscous materials.

Pharmaceutical Industry

For pharmaceuticals, twin-screw extruders enable:

-

Uniform blending of active ingredients

-

Precise processing of heat-sensitive compounds

-

Consistent product quality

This precision is critical for drug efficacy.

Twin-screw extruders are vital for heat-sensitive materials.True

Shorter residence times and precise temperature control prevent material degradation.

Single-screw extruders can match twin-screw performance in all applications.False

They lack the mixing and control needed for complex or sensitive materials.

What Are the Pros and Cons of Twin-Screw vs. Single-Screw Extruders?

Choosing between these extruders requires understanding their strengths and weaknesses. Here’s a side-by-side comparison:

Twin-screw extruders provide better mixing, material range, and efficiency for complex tasks, while single-screw extruders offer cost savings and simplicity for basic applications.

| Aspect | Twin-Screw Extruder | Single-Screw Extruder |

|---|---|---|

| Mixing Capability | Excellent, thanks to intermeshing screws. | Limited, best for uniform materials. |

| Material Range | Broad, including complex and heat-sensitive types. | Narrow, suited to simple materials. |

| Output Rates | High for complex materials. | High for simple materials. |

| Energy Efficiency | Often better for complex tasks. | May lag for complex materials. |

| Cost | Higher upfront and maintenance costs. | Lower initial cost, easier upkeep. |

| Flexibility | High, adaptable to various needs. | Lower, less versatile. |

Key Insights

-

Mixing: Twin-screw extruders dominate in blending and compounding.

-

Versatility: They handle a wider material spectrum.

-

Cost: Single-screw extruders are budget-friendly but less adaptable.

Twin-screw extruders are more energy-efficient for all tasks.False

They excel for complex materials, but single-screw may be more efficient for simple ones.

Single-screw extruders suffice for most needs.False

They fall short in industries needing advanced mixing or material variety.

What Is the Process Workflow of a Twin-Screw Extruder?

The workflow of a twin-screw extruder is a multi-step process that ensures high-quality output. Each stage is optimized for performance.

The twin-screw extrusion process includes feeding, conveying, melting, mixing, pressurizing, and shaping, with parameters like screw speed and temperature driving results.

1. Feeding

Materials enter via a hopper or feeder, with feed rate setting the pace.

2. Conveying

Screws move the material through the barrel, controlled by speed and temperature.

3. Melting

Heat and friction melt the material, requiring precise temperature management.

4. Mixing

Intermeshing screws ensure thorough blending, adjustable via screw design.

5. Pressurizing

Material is pressurized before the die, ensuring consistent flow.

6. Shaping

The melt exits through a die, forming the final shape.

Screw design is critical in twin-screw extrusion.True

Custom configurations optimize mixing and conveying for specific tasks.

Temperature control is optional in twin-screw extruders.False

It’s essential, especially for heat-sensitive materials.

Why Are Twin-Screw Extruders Better for Certain Materials?

Material compatibility often dictates extruder choice. Twin-screw extruders have distinct advantages for specific material types.

Twin-screw extruders excel with blends, composites, and heat-sensitive materials due to superior mixing and shorter residence times.

Complex Blends

Intermeshing screws ensure uniform additive dispersion in polymer blends.

Heat-Sensitive Materials

Shorter processing times and better temperature control protect materials like PVC.

High-Viscosity Materials

Enhanced mixing handles thicker substances effectively.

Twin-screw extruders outperform single-screw for all materials.False

Single-screw may be better for simple, uniform materials.

Residence time benefits heat-sensitive processing.True

Faster processing reduces thermal exposure.

How Do You Choose Between Twin-Screw and Single-Screw Extruders?

The right extruder depends on your material, production goals, and budget. Here are practical tools to guide you.

Evaluate material complexity, scale, and cost with a checklist or decision tree to select between twin-screw and single-screw extruders.

Design Checklist for Twin-Screw Systems

-

Screw Type: Co-rotating or counter-rotating?

-

Configuration: Mixing or conveying elements?

-

Temperature: Multi-zone control?

-

Die: Matches product shape?

-

Feeding: Consistent and monitored?

Decision-Making Guide

-

Simple, uniform material?

-

Yes: Single-screw (cost-effective).

-

No: Next question.

-

-

Needs intensive mixing?

-

Yes: Twin-screw.

-

No: Single-screw possible.

-

-

Heat-sensitive?

-

Yes: Twin-screw (shorter residence).

-

No: Assess scale and cost.

-

-

Scale and budget?

-

Large, cost-driven: Single-screw.

-

Flexible, small-medium: Twin-screw.

-

Twin-screw is always the best choice.False

Single-screw suits simple, large-scale tasks.

A decision tree aids extruder selection.True

It simplifies choices based on key factors.

What Are the Related Technologies to Twin-Screw Extrusion?

Twin-screw extrusion fits into a larger manufacturing ecosystem, enhanced by related processes.

Upstream preparation, downstream finishing, alternative molding, and reactive extrusion complement twin-screw technology.

Upstream

-

Pelletizing: Uniform material prep.

-

Compounding: Pre-blending materials.

Downstream

-

Cutting/Cooling: Final shaping.

-

Packaging: Ready for distribution.

Alternatives

-

Injection Molding: Complex shapes.

-

Blow Molding: Hollow products.

Complementary

- Reactive Extrusion: In-process material enhancement.

Reactive extrusion enhances twin-screw capabilities.True

It modifies properties during processing.

Twin-screw is the only option for complex materials.False

Other methods like batch mixing exist, though less efficient.

Conclusion

Twin-screw extruders stand out for their mixing prowess5, material versatility, and efficiency, particularly for complex or heat-sensitive applications. While single-screw extruders offer cost advantages for simpler tasks, twin-screw technology is the superior choice where precision and flexibility matter most.

-

Learn about the functionality and applications of single-screw extruders to understand their role in manufacturing processes. ↩

-

Explore the unique benefits of twin-screw extruders and how they outperform single-screw models in various applications. ↩

-

Learn about the challenges and techniques for processing heat-sensitive materials effectively in manufacturing. ↩

-

Discover the critical functions of twin-screw extruders in pharmaceuticals, especially in ensuring drug efficacy and quality. ↩

-

Discover why mixing prowess is crucial in twin-screw extrusion and how it enhances product quality and efficiency. ↩