Extrusion machinery is a vital part of modern manufacturing, shaping materials into continuous profiles for products ranging from plastic pipes to metal beams and even snack foods. Recent advancements in this technology are enhancing efficiency, precision, and sustainability, transforming industries such as automotive, aerospace, construction, and food processing. These innovations allow manufacturers to create complex shapes, reduce waste, and improve product quality, keeping extrusion at the forefront of industrial progress.

Recent advancements in extrusion machinery focus on efficiency, precision, and sustainability, with innovations like Differential Velocity Sideways Extrusion (DVSE)1 for metals and supercritical fluid extrusion2 for food processing leading the way.

Whether you’re an industry professional or simply interested in manufacturing trends, this blog post explores the latest developments in extrusion machinery3, their applications, and their impact. Let’s dive into how these breakthroughs are reshaping the manufacturing landscape.

Extrusion machinery is only used in the plastics industry.False

Extrusion is widely applied across multiple sectors, including metals, food processing, rubber, and construction, not just plastics.

Recent advancements have made extrusion more energy-efficient.True

Innovations like energy-efficient extruder designs and renewable energy integration are reducing the environmental footprint of extrusion processes.

- 1. What is Extrusion Machinery?

- 2. What are the Typical Applications of Extrusion Machinery?

- 3. What are the Key Steps in the Extrusion Process?

- 4. What are the Recent Advancements in Extrusion Machinery?

- 5. How Do You Choose the Right Extrusion Process?

- 6. What are the Related Technologies in Extrusion?

- 7. Conclusion

What is Extrusion Machinery?

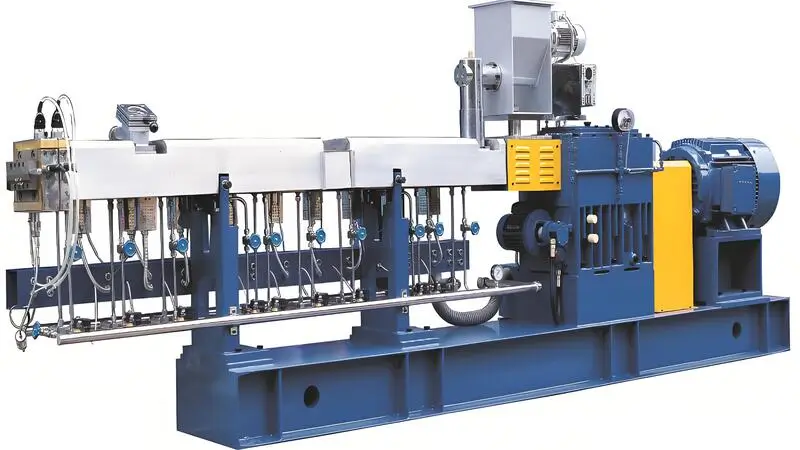

Extrusion machinery refers to equipment that forces materials through a die to produce objects with a consistent cross-sectional profile. This process is fundamental for creating long, continuous products like pipes, rods, and sheets, and it’s used across industries such as plastics, metals, food, and rubber.

Extrusion machinery pushes materials through a die to create continuous profiles, enabling efficient, high-volume production in industries like plastics, metals, and food.

The process begins with heating or melting the material, then shaping it by pushing it through a die under pressure. Parameters like temperature, pressure, and die design are adjusted based on the material, making extrusion highly adaptable.

Extrusion is only suitable for producing simple shapes.False

Advanced techniques like Differential Velocity Sideways Extrusion (DVSE) enable the creation of complex, curved profiles, especially in metals.

Classification of Extrusion Machinery

Extrusion machinery4 can be categorized by several criteria:

-

By Process:

-

Hot Extrusion: For metals and thermoplastics at elevated temperatures.

-

Cold Extrusion: For rubber and some metals at room temperature.

-

Direct Extrusion: Material moves through a stationary die.

-

Indirect Extrusion: Die moves relative to the material.

-

-

By Material:

-

Metal Extrusion5: Aluminum, steel, etc.

-

Polymer Extrusion6: Thermoplastics like polyethylene and polypropylene.

-

Food Extrusion: Cereals, snacks, and pet food.

-

Rubber Extrusion: Tires, seals, and hoses.

-

-

By Application:

-

Structural Components: Construction and aerospace.

-

Pipes and Tubes: Plumbing and automotive.

-

Wires and Cables: Electronics.

-

Food Products: Snacks and pet food.

-

Rubber Products: Seals and medical tubing.

-

This classification helps match the machinery to specific production needs.

What are the Typical Applications of Extrusion Machinery?

Extrusion machinery’s versatility makes it indispensable across industries. Here are some key applications:

-

Metal Extrusion: Produces lightweight structures for aerospace, chassis components for automotive, and beams for construction. Aluminum extrusions, for instance, are critical in aircraft due to their strength-to-weight ratio.

-

Polymer Extrusion: Creates packaging films, window frames for construction, and automotive interiors. Polyethylene pipes are a staple in water supply systems.

-

Food Extrusion: Manufactures snacks like cheese puffs, cereals, and pet food, leveraging high-volume production.

-

Rubber Extrusion: Used for automotive seals, construction weatherstripping, and medical tubing, enhancing durability.

Extrusion machinery supports metals for structural components, polymers for packaging, food for snacks, and rubber for seals, offering efficiency and versatility across industries.

Extrusion is the most energy-efficient manufacturing process.False

While efficient for continuous production, processes like additive manufacturing may be more energy-efficient for small batches or complex designs.

Extrusion can handle both thermoplastics and thermosets.False

Extrusion is mainly suited for thermoplastics, as thermosets cannot be remelted once cured.

Pros and Cons of Extrusion Compared to Other Technologies

Extrusion has distinct advantages and limitations compared to other methods:

-

Advantages:

-

Continuous Production: Ideal for high volumes, unlike injection molding’s batch process.

-

Material Efficiency: Generates less waste than machining.

-

Complex Cross-Sections: Produces intricate profiles difficult for casting or forging.

-

-

Limitations:

-

Uniform Cross-Section: Limited to consistent profiles along the length.

-

Setup Costs: High initial costs for dies and machinery, especially for custom shapes.

-

Compared to injection molding, extrusion excels at long parts but struggles with discrete, complex shapes. Against casting, it offers better material properties but is less flexible for intricate geometries.

What are the Key Steps in the Extrusion Process?

The extrusion process consists of several stages, each critical to the final product’s quality:

-

Material Preparation: Raw materials (pellets, powders, billets) are prepared for uniformity.

-

Feeding: Material enters the extruder via a hopper.

-

Melting/Plasticizing: Material is heated and melted (e.g., 400°C for metals, 200°C for thermoplastics).

-

Extrusion: Molten material is forced through a die to form the profile.

-

Cooling and Shaping: The extrudate is cooled to solidify its shape.

-

Cutting or Coiling: The product is cut to length or coiled.

Key Parameters:

-

Temperature: Ensures proper flow (e.g., 500°C for aluminum, 180°C for polyethylene).

-

Pressure: Affects rate and integrity (500–2000 psi for polymers).

-

Die Design: Shapes the product and requires precision.

-

Flow Rate: Controls speed and uniformity.

Temperature control is the most important factor in extrusion.False

Temperature is vital, but pressure, die design, and material properties are equally critical.

Material Compatibility in Extrusion

Materials demand specific conditions:

-

Metals: High temperatures and pressures (e.g., aluminum at 500°C).

-

Thermoplastics: Precise temperature and moisture control (e.g., ABS needs <0.1% moisture).

-

Food Products: Lower temperatures (e.g., 100°C) with additives like supercritical CO2.

-

Rubber: Often cold extruded for energy efficiency and elasticity.

Material behavior dictates process optimization.

What are the Recent Advancements in Extrusion Machinery?

Recent innovations are revolutionizing extrusion machinery. Here are the highlights:

1. Differential Velocity Sideways Extrusion (DVSE)

DVSE enables curved metal profiles with fine grains and high strength by using two punches at different velocities. It’s a game-changer for aerospace and automotive applications.

DVSE creates curved metal profiles with enhanced strength and reduced waste, ideal for aerospace and automotive industries.

2. Supercritical Fluid Extrusion (SCFX)

SCFX uses supercritical CO27 in food processing to foam at lower temperatures (~100°C), preserving nutrients and creating unique textures for snacks and biodegradable materials.

SCFX enables low-temperature food extrusion, enhancing nutrient retention and texture innovation.

3. 3D Printing Integration

Combining 3D printing with extrusion allows for customized, complex shapes in polymers and metals, boosting prototyping and small-scale production.

3D printing integration8 enhances customization and rapid prototyping in extrusion.

4. Energy Efficiency and Sustainability

New extruders reduce energy use, incorporate renewables, and improve recycling, especially in metals and polymers, supporting sustainable manufacturing.

Energy-efficient designs and recycling make extrusion more sustainable.

5. Precision Extrusion Technology

Advanced controls improve temperature, pressure, and speed management, delivering tighter tolerances for industries like medical devices and electronics.

Precision extrusion enhances quality and consistency for high-precision applications.

Table: Summary of Recent Advancements

| Advancement | Sector | Key Benefit | Example Application |

|---|---|---|---|

| DVSE | Metals | Curved profiles, fine grains | Aerospace aluminum profiles |

| SCFX | Food | Low-temperature, unique textures | Nutrient-fortified snacks |

| 3D Printing Integration | Polymers, Metals | Customization, prototyping | Aerospace prototyping |

| Energy Efficiency & Sustainability | All | Reduced energy, waste | Metal recycling, pet food |

| Precision Extrusion | Polymers, Metals | Tight tolerances | Medical device components |

3D printing integration is only for prototyping.False

It’s also used for small-scale production and customized manufacturing.

SCFX is exclusive to food.False

It’s also applied in biodegradable materials and pharmaceuticals.

How Do You Choose the Right Extrusion Process?

Selecting an extrusion process involves:

-

Material Type: Metal, polymer, food, or rubber?

-

Product Shape: Simple profiles or complex curves?

-

Production Volume: High-volume continuous or small batches?

-

Cost: Balance setup costs, energy, and waste.

A decision tree starts with material type, then considers shape, volume, and cost.

Design Checklist for Extrusion Projects

-

Define cross-section and tolerances.

-

Select material (e.g., aluminum for lightweight needs).

-

Design die for shrinkage and flow.

-

Choose extruder type (e.g., twin-screw for polymers).

-

Monitor temperature, pressure, and speed.

What are the Related Technologies in Extrusion?

Extrusion connects to:

-

Upstream: Material production (e.g., polymer synthesis), handling (e.g., pellet dryers).

-

Downstream: Finishing (e.g., painting, cutting).

-

Related Processes: Injection molding, blow molding, forging.

Conclusion

Extrusion machinery is advancing rapidly, with innovations like DVSE, SCFX, and 3D printing integration enhancing its capabilities. These developments improve efficiency, precision, and sustainability, impacting industries worldwide. Staying informed about these trends is key to leveraging extrusion’s full potential.

-

Explore this link to understand how DVSE is revolutionizing metal extrusion with enhanced efficiency and precision. ↩

-

Discover the innovative uses of supercritical fluid extrusion in food processing, enhancingproduct quality and sustainability. ↩

-

Learn about the cutting-edge advancements in extrusion machinery that are transforming manufacturing across various industries. ↩

-

Explore this link to understand the fundamentals of extrusion machinery and its applications across various industries. ↩

-

Discover the advantages of metal extrusion in manufacturing lightweight and strong structures, crucial for aerospace and automotive industries. ↩

-

Learn about the role of polymer extrusion in creating essential products like packaging films and window frames, enhancing efficiency in production. ↩

-

Learn about the advantages of using supercritical CO2 in food processing for better nutrient retention and texture. ↩

-

Discover how 3D printing integration is revolutionizing customization and rapid prototyping in extrusion applications. ↩