A matte finish in extrusion1 refers to a non-glossy, dull surface that enhances both the aesthetic appeal and functional properties of products, making it a popular choice in industries such as automotive and home decor. Achieving this finish requires a blend of specific techniques tailored to the material and application. This blog post delves into the common methods, material choices, process adjustments, applications, and comparisons with glossy finishes to provide a comprehensive guide on mastering matte finishes in extrusion.

Achieving a matte finish in extrusion involves using material additives like silica or talc, selecting specific resins such as higher K-value PVC2, and adjusting process parameters like lowering die temperature, widely applied in automotive and home decor for non-glossy aesthetics.

Understanding these techniques empowers manufacturers to customize their extruded products effectively. Read on to explore how materials and processes interplay to create the perfect matte finish.

Matte finishes are only achievable with specific resins.False

While certain resins like higher K-value PVC can naturally provide a matte finish, additives and process adjustments can also achieve similar results with other materials.

Lowering the die temperature always results in a matte finish.False

Lowering the die temperature can help, but it’s not the sole factor; material composition and other process parameters are equally critical.

- 1. What are the Common Methods to Achieve a Matte Finish in Extrusion?

- 2. How Do Material Choices Affect the Matte Finish?

- 3. What Process Adjustments are Necessary for a Matte Finish?

- 4. Where is Matte Finish Commonly Applied in Extrusion Products?

- 5. How Does Matte Finish Compare to Glossy Finish in Extrusion?

- 6. Conclusion

What are the Common Methods to Achieve a Matte Finish in Extrusion?

Several proven methods exist to achieve a matte finish in extrusion, each adaptable to specific materials and desired outcomes.

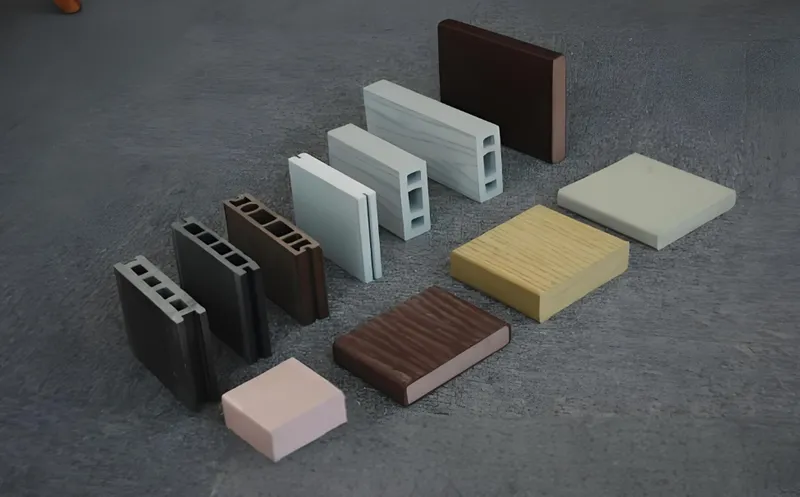

Common methods include incorporating matting agents like silica or talc3, choosing resins with inherent matte properties, and tweaking process parameters such as die temperature and extrusion speed.

| Method | Description | Common Materials |

|---|---|---|

| Matting Agents | Additives like silica or talc to reduce gloss | PVC, PE |

| Resin Selection | Using resins with natural matte properties | Higher K-value PVC, Borstar LLDPE |

| Process Adjustments | Lowering die temperature, adjusting extrusion speed | Various |

Matting Agents

Matting agents, such as silica or talc, are blended into the material prior to extrusion to diminish gloss. For instance, acrylic-based agents like PARALOID™ KF-710 can reduce gloss in PVC from 42% to 10% at 5 parts per hundred (phr), offering a reliable matte effect .

Resin Selection

Choosing resins with inherent matte characteristics simplifies the process. Higher K-value PVC (K 70-72) or Borstar LLDPEfrom Borealis/Borouge naturally yield matte surfaces without extensive modification .

Process Adjustments

Adjusting parameters like die temperature and extrusion speed can refine surface texture. Lowering the die temperature, for example, minimizes reflectivity by altering how the material cools and sets post-extrusion .

Matting agents are the only way to achieve a matte finish.False

While matting agents are effective, resin selection and process adjustments offer alternative paths to a matte finish.

How Do Material Choices Affect the Matte Finish?

Material selection plays a pivotal role in determining the success of a matte finish, with each polymer requiring a tailored approach.

Materials like PET, rPET, PVC, and PE demand specific additives or resin choices to achieve a matte finish, each contributing unique properties suited to various applications.

PET and rPET

For PET and rPET, Modern Matte masterbatches4 enable a matte finish in mono and multilayer extrusion without additional steps, ideal for personal care and automotive uses.

PVC

In PVC, higher K-value resins or the addition of ethylene-vinyl acetate (EVA)5 with 8-28% VA content disrupts gloss, creating a matte surface. EVA serves as an effective dulling agent in flexible PVC formulations .

PE

Polyethylene (PE) benefits from resins like Borstar LLDPE for a natural matte look, enhanced further by additives such as oxidized HDPE waxes to reduce gloss .

All materials can achieve a matte finish with the same additives.False

Different materials necessitate specific additives and adjustments to attain the desired matte finish.

What Process Adjustments are Necessary for a Matte Finish?

Process tweaks are essential to fine-tune the matte finish, complementing material choices.

Key adjustments include lowering die temperature, modifying extrusion speed6, and controlling cooling rates to shape surface texture.

Die Temperature

Reducing die temperature decreases gloss by slowing the material’s cooling rate, a technique particularly effective in PVC extrusion.

Extrusion Speed

Adjusting extrusion speed influences texture; slower speeds allow precise control, while faster speeds may require compensatory measures to maintain matte quality.

Cooling Methods

Cooling techniques, such as air knives or water baths, stabilize the matte effect by controlling solidification speed post-extrusion.

Process adjustments alone can guarantee a matte finish.False

While crucial, process adjustments must pair with suitable material selection and additives for optimal results.

Where is Matte Finish Commonly Applied in Extrusion Products?

Matte finishes serve both aesthetic and practical purposes across multiple industries.

Matte finishes are prevalent in automotive interiors, home decor, and luxury packaging, valued for their non-glossy appearance and functional benefits like glare reduction.

| Industry | Typical Products |

|---|---|

| Automotive | Dashboard panels, interior trims |

| Home Decor | Wall panels, decorative profiles |

| Packaging | Luxury product packaging, bottles |

Automotive

In automotive applications, matte finishes7 on dashboard panels and trims reduce glare, enhancing safety and aesthetics.

Home Decor

Wall panels and decorative profiles in home decor leverage matte finishes for a modern look that conceals minor imperfections.

Packaging

Luxury packaging, such as bottles, uses matte finishes to project a premium, sophisticated image.

Matte finishes are only used for aesthetic purposes.False

Beyond aesthetics, matte finishes enhance functionality, such as reducing glare in automotive settings.

How Does Matte Finish Compare to Glossy Finish in Extrusion?

Matte and glossy finishes cater to different needs, each with distinct production and application profiles.

Matte finishes are dull and non-reflective, excelling at hiding imperfections and reducing glare, while glossy finishes are shiny, easy to clean, but prone to showing flaws.

| Aspect | Matte Finish | Glossy Finish |

|---|---|---|

| Appearance | Dull, non-reflective | Shiny, reflective |

| Functionality | Reduces glare, hides imperfections | Smooth, easy to clean |

| Production | May require additives or process tweaks | Often standard process |

Appearance and Functionality

Matte finishes excel in concealing imperfections and minimizing glare, though they may highlight dirt. Glossy finishes offer a polished look and ease of cleaning but expose surface flaws more readily.

Production Considerations

Matte finishes may involve extra steps like additives or resin selection, whereas glossy finishes typically emerge from standard extrusion processes. Costs vary by method; resin choice can sometimes offset additional expenses.

Matte finishes are always more expensive to produce than glossy finishes.False

Costs depend on the approach; selecting the right resin can achieve a matte finish economically.

Conclusion

Achieving a matte finish in extrusion blends material selection, additives, and process adjustments into a versatile toolkit. From automotive interiors to luxury packaging, these techniques allow manufacturers to meet diverse aesthetic and functional demands. Experimentation with these methods is key to finding the perfect balance for specific applications. Dive into the referenced resources for deeper insights.

-

Explore this resource to understand the techniques and materials used to achieve a matte finish in extrusion, enhancing product aesthetics and functionality. ↩

-

Discover the significance of higher K-value PVC in creating matte finishes, essential for industries like automotive and home decor. ↩

-

Learn about the role of matting agents in achieving non-glossy finishes in extrusion, crucial for various applications. ↩

-

Explore this link to understand how Modern Matte masterbatches can enhance matte finishes in various applications, especially in personal care and automotive industries. ↩

-

Explore how EVA enhances matte finishes in PVC, making it a crucial component for achieving desired aesthetics and functionality. ↩

-

Understanding the impact of extrusion speed can help optimize production processes and improve product quality. ↩

-

Explore the diverse applications and advantages of matte finishes across industries, enhancing both aesthetics and functionality. ↩