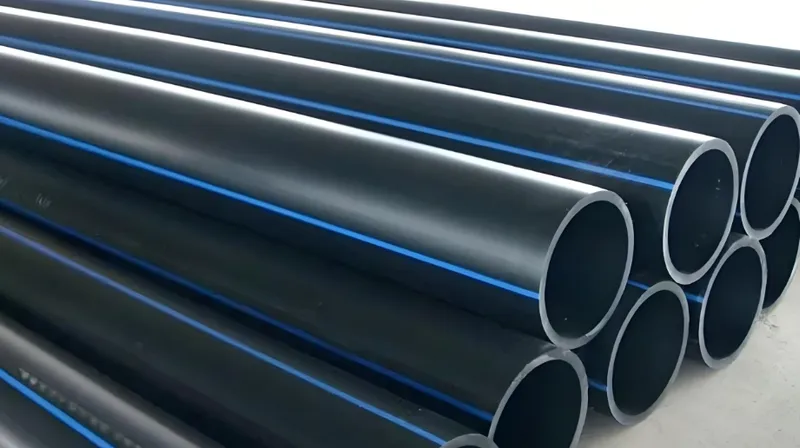

Extrusion is a manufacturing process where materials such as metals, plastics, or even ceramics are forced through a die to produce items with specific cross-sectional shapes, like pipes, window frames, or rods. One of the biggest challenges in this process is ensuring consistent product dimensions1—maintaining the same size and shape across every piece produced. This consistency is crucial for quality, functionality, and meeting industry standards in sectors like automotive, construction, and aerospace. This blog post explores the critical factors and best practices that help manufacturers achieve dimensional accuracy in extrusion.

Achieving consistent product dimensions in extrusion requires precise die design2, uniform material properties, controlled process parameters, effective cooling techniques, and rigorous quality control3 measures to ensure products meet exact specifications.

Understanding how these elements work together can help manufacturers optimize their extrusion processes. In this guide, we’ll break down the key aspects of extrusion and provide actionable insights for maintaining dimensional precision.

Consistent product dimensions in extrusion depend only on die design.False

While die design is vital, factors like material consistency, process parameters, and cooling also play significant roles in dimensional accuracy.

Extrusion is limited to plastic materials.False

Extrusion is used for a wide range of materials, including metals, plastics, and ceramics, each requiring specific techniques for dimensional control.

- 1. What are the Key Factors for Consistent Dimensions in Extrusion?

- 2. How Does Die Design Affect Product Dimensions?

- 3. Why is Material Consistency Important in Extrusion?

- 4. What Process Parameters Need to be Controlled for Dimensional Accuracy?

- 5. How Does Cooling Impact the Final Dimensions of Extruded Products?

- 6. What Quality Control Measures are Essential in Extrusion?

- 7. Conclusion

What are the Key Factors for Consistent Dimensions in Extrusion?

To produce extruded products with uniform dimensions, manufacturers must address several interconnected factors that influence the process from start to finish.

Key factors for consistent dimensions in extrusion include die design, material consistency, process parameters (temperature, pressure, speed), cooling methods, and quality control, all working together to ensure precision.

| Factor | Impact on Dimensions | Notes |

|---|---|---|

| Die Design4 | High | Must be precise and maintained |

| Material Consistency5 | High | Uniform properties required |

| Process Parameters6 | High | Needs tight control |

| Cooling Methods | Medium | Prevents warping and shrinkage |

| Quality Control | High | Ensures adherence to specs |

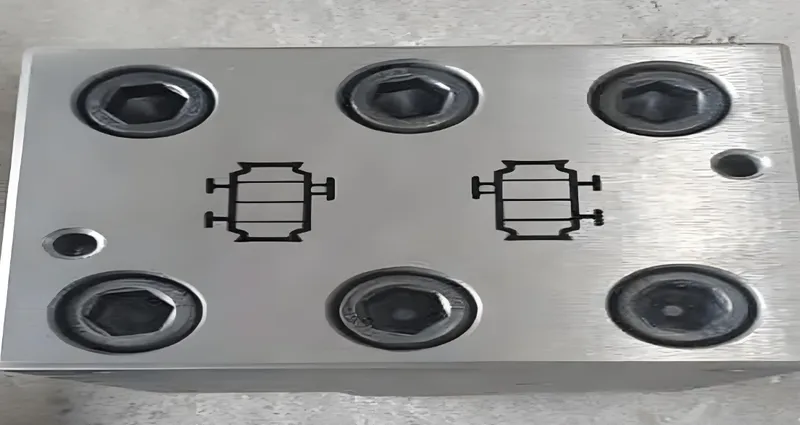

Die Design and Maintenance

The die shapes the material as it’s extruded, making its design and upkeep critical. A precisely engineered die ensures even material flow, while regular maintenance prevents wear that could alter dimensions over time. For example, in aluminum extrusion, worn dies can lead to inconsistent wall thickness.

Material Consistency

The material being extruded—whether plastic, metal, or another substance—must have uniform properties like viscosity or temperature. Variations can cause uneven flow or shrinkage, affecting the final size of the product.

Process Parameters

Temperature, pressure, and extrusion speed must be carefully controlled. For instance, in plastic extrusion, temperature fluctuations can change how much the material shrinks, while in metal extrusion, pressure variations might affect thickness.

Cooling and Post-Processing

After extrusion, uniform cooling7 prevents warping or uneven shrinkage. Techniques like water baths for plastics or controlled quenching for metals help lock in dimensions. Additional steps, such as stretching, can further stabilize the product.

Quality Control

Regular monitoring, using tools like laser gauges, ensures dimensions stay within tolerance. This allows manufacturers to catch and fix issues during production rather than after.

Proper die maintenance is crucial for consistent dimensions.True

Maintaining the die prevents wear that can lead to dimensional variations over time.

Material inconsistencies have little impact on extrusion outcomes.False

Even small variations in material properties can significantly affect the final product's dimensions.

How Does Die Design Affect Product Dimensions?

The die is the cornerstone of the extrusion process, directly shaping the material into its final form.

Die design affects product dimensions by controlling material flow, pressure distribution, and compensating for material behaviors like die swell or shrinkage, ensuring uniform output.

Flow Path and Pressure

A well-designed die promotes smooth, even material flow—known as laminar flow—reducing turbulence that could cause dimensional inconsistencies. For complex shapes, the die must balance flow across all sections to avoid uneven thickness.

Die Swell and Shrinkage

In plastic extrusion, materials expand (die swell) as they exit the die, requiring the die to be slightly smaller than the target size. For metals, thermal contraction means the die must be larger. Good design anticipates these changes EngineersEdge: Design for Extrusion Considerations.

Hollow Profiles

For products like tubes, a mandrel inside the die shapes the internal cavity. Precise mandrel alignment ensures consistent inner dimensions and wall thickness BWC Profiles: Understanding Extrusions.

Maintenance

Dies wear out from friction and pressure, so regular inspections and refurbishment are essential. Advanced materials like carbide can extend die life and maintain precision.

Die swell only occurs in plastic extrusion.False

Die swell is more common in plastics but can also happen in metals, though less noticeably due to material differences.

Regular die maintenance ensures long-term consistency.True

Preventing wear keeps the die’s shape accurate, which is critical for uniform dimensions.

Why is Material Consistency Important in Extrusion?

Uniform material properties are vital for predictable extrusion results.

Material consistency is important in extrusion because variations in composition, temperature, or viscosity can lead to uneven flow, defects, and dimensional inaccuracies.

Even Flow

Consistent material ensures steady flow through the die, preventing pressure imbalances that could alter dimensions. For example, in plastic extrusion, inconsistent viscosity can cause uneven pipe walls.

Fewer Defects

Variations in material can introduce flaws like warping or surface roughness, which affect both size and quality. In metal extrusion, inconsistent alloy composition might lead to uneven grain structure ScienceDirect: Metal Extrusion.

Predictable Behavior

Uniform materials shrink or expand predictably during cooling, allowing manufacturers to adjust the process accurately. This is key for plastics with varying shrinkage rates Resmart: Best Practices for Designing High-Quality Extruded Parts.

Material consistency is more critical for metals than plastics.False

Both require consistency, though the challenges differ based on material properties.

Recycled materials always compromise dimensional consistency.False

With proper processing, recycled materials can maintain accuracy.

What Process Parameters Need to be Controlled for Dimensional Accuracy?

Process parameters directly influence how material behaves during extrusion.

Key process parameters8 for dimensional accuracy include temperature, pressure, speed, and cooling rates, all of which must be optimized for precision.

Temperature

Temperature affects material flow—too hot, and plastics might shrink unevenly; too cold, and metals might not extrude properly. Consistent temperature control is essential Goodfish: Dimensional Stability in Plastic Extrusion9.

Pressure

Stable pressure ensures uniform material flow. Variations can lead to thickness changes or density issues.

Speed

Extrusion speed impacts how long material spends in the die and how it cools. Too fast, and it might stretch; too slow, and it could overpack.

Cooling

Controlled cooling rates prevent dimensional shifts from uneven shrinkage or warping.

Higher speeds always improve productivity without affecting dimensions.False

Faster speeds can compromise accuracy if not balanced with other parameters.

Temperature control is a top priority in extrusion.True

It directly influences flow and shrinkage, making it critical for consistency.

How Does Cooling Impact the Final Dimensions of Extruded Products?

Cooling solidifies the extruded material, locking in its shape.

Cooling impacts dimensions10 by controlling shrinkage, preventing warping, and stabilizing the material, ensuring it matches the intended design.

Shrinkage

Materials shrink as they cool, and uniform cooling ensures this happens evenly. Uneven cooling can distort plastics or metals alike.

Warping

Rapid or uneven cooling creates internal stresses that twist or bend the product. Controlled methods like water baths or air cooling prevent this Goodfish: Dimensional Stability in Plastic Extrusion.

Stabilization

For metals, techniques like annealing after cooling relieve stresses, enhancing dimensional stability.

Uniform cooling is only needed for plastics.False

Both plastics and metals require uniform cooling to avoid distortions.

Cooling affects plastics more than metals.True

Plastics have higher thermal expansion, making them more sensitive to cooling variations.

What Quality Control Measures are Essential in Extrusion?

Quality control ensures products meet dimensional standards throughout production.

Essential quality control measures include real-time measurement, statistical process control (SPC), die inspections, and feedback systems to maintain consistency.

Real-Time Measurement

Tools like laser gauges monitor dimensions during extrusion, allowing instant adjustments Alexandria Industries: Aluminum Extrusion Dimensioning.

SPC

Statistical process control tracks trends in data—like temperature or dimensions—to catch issues early.

Die Inspections

Regular checks ensure the die stays within tolerance, preventing gradual deviations.

Feedback Systems

Automated systems adjust parameters in real time based on measurement data, reducing errors.

Quality control is only needed post-production.False

Monitoring during production catches issues early, improving efficiency.

Real-time measurement reduces waste.True

It allows immediate corrections, minimizing defective output.

Conclusion

Achieving consistent product dimensions in extrusion is a balancing act of design, material management, process control, cooling, and quality assurance. By mastering these elements, manufacturers can produce high-quality extrusions that meet precise specifications every time. Whether you’re working with plastics, metals, or other materials, these principles apply universally, offering a roadmap to reliability and customer satisfaction.

-

Explore this resource to understand essential practices that ensure uniformity in product dimensions, crucial for quality and compliance. ↩

-

Learn about the critical role of die design in shaping materials and maintaining product dimensions, essential for effective manufacturing. ↩

-

Discover key quality control strategies that help maintain dimensional accuracy and product integrity in extrusion manufacturing. ↩

-

Understanding die design is crucial for achieving consistent product dimensions in extrusion. Explore this link to learn more about its impact. ↩

-

Material consistency directly affects the quality and dimensions of extruded products. Discover why it's vital for successful extrusion. ↩

-

Process parameters are key to ensuring precision in extrusion. Learn how they influence the final product dimensions. ↩

-

Uniform cooling is essential to prevent warping in extruded products. Learn about effective techniques to ensure quality. ↩

-

Optimizing process parameters is essential for precision in extrusion. Discover more about these parameters and their effects. ↩

-

Understanding dimensional stability is crucial for ensuring high-quality plastic products. Explore this link to learn more about its significance. ↩

-

Cooling plays a key role in product quality. Learn about its effects on dimensions and how to control it effectively by checking this link. ↩